Scratch protection coating - an individually sprayed paint protection layer made of 2.5 mm MetaLine 785 protects the radiator grille during production work in the engine compartment. Elastic and anti-static to counteract dust collection

Paint protection overlay - MetaLine 785 can be used for the professional production of scratch protection mats in any conceivable geometry. Virtually indestructible, low weight, dimensionally stable yet supple. Stackable and can be coded with laser print

Vehicle protection - elastic, rubber-like individual mounting protection pad. Can be produced as a single part or small series within a short time - without mold making. Cost-optimized, fast and absolutely safe in its protective effect!

Scratch protection panel - MetaLine 785 with integrated magnets for paint protection in the door lock area. An elastic cushion (pad) that absorbs all impacts. Where it is needed - and only where it is needed, because anything unnecessary interferes with installation!

Scratch protection covering – This car assembly protective cover made out of 2 mm MetaLine 785/795 was created without moldmaking just by use of the MetaLine spray technology. It protects the bootom frame part as well as the A- and B-coloumns. Delivery time is just 3-4 days

Car protector manufacturing – MetaLine enables car manufacturers to create individual protectors within one working day and without investment into moldmaking. The Know-How, training as well as the product is offered by MetaLine – the pressure to do so is derived from your assembly and quality control department . . .

Scratch protection overlay - these protectors are a sprayed-on and removable rubber-like protective mat that precisely covers all desired areas in a shock- and impact-resistant manner. The special feature?

The absolute protection!

Scratch protection coating - it's often the little things that annoy you. A small tool that used to cause damage before the coating. A coating with MetaLine 785 gives the part rubber-like properties and saves you trouble in the future!

Glass protection coating - an assembly jig for fixing windshield wipers. The part that touches the glass has a soft and gentle MetaLine coating. It also has high static friction and does not slip easily. In addition to protection, a functional improvement also comes into play!

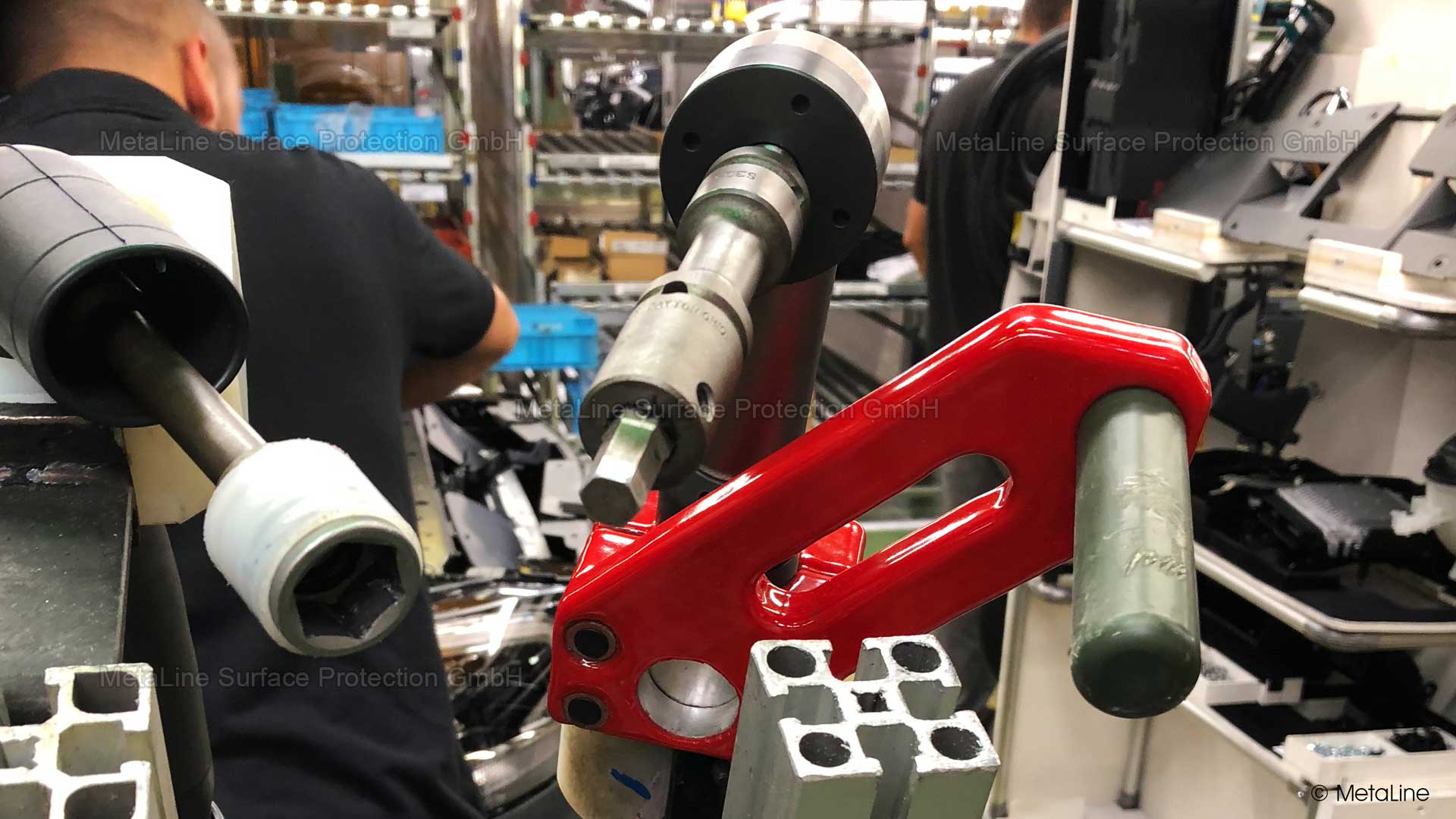

Rim protection coating - an elastic assembly jig for fixing vehicle rims. High-quality rims are protected from scratches and damage to the paintwork during transportation and/or fitting. A simple concept for sensitive components . . .

Impact protection coating - tool socket coated with 3 mm (120 mil) MetaLine 785 for interior protection during car interior assembly

Tool coating - Small tools elastomer coated with 1 mm (40 mil) MetaLine 590 for use in car production. Different colors stand for different series. Supple with good grip for a secure hold

Handle coating - Rotary handle of a pneumatic tool coated with 2 mm (80 mil) MetaLine 560 velvet to prevent the hand from cooling down during use. Thermal and electrical insulation are the domain of MetaLine ...

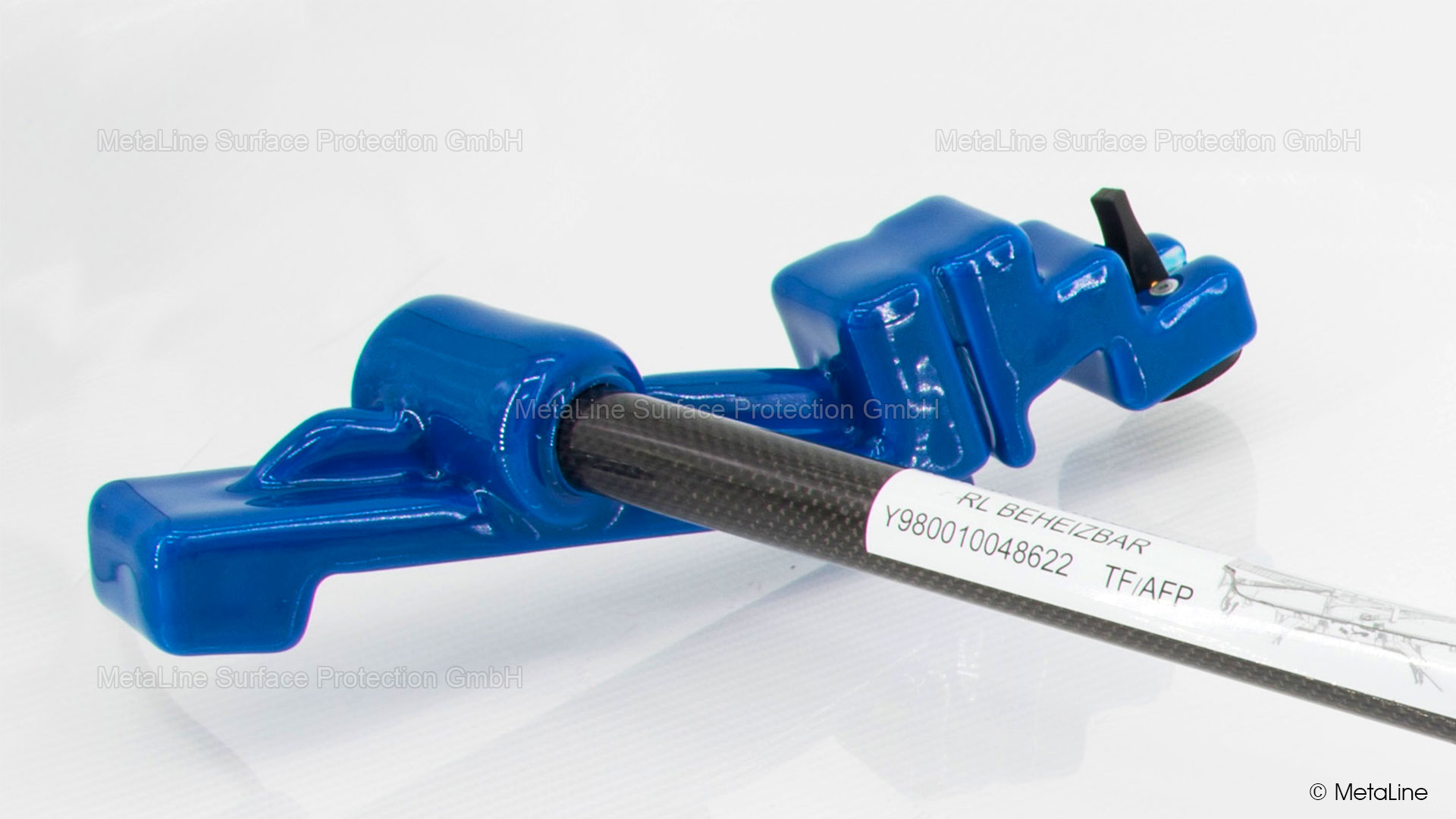

Vehicle test plug coated with MetaLine Series 500 to offer varnish protection

Wrench coating – MetaLine coatings are not only functional but decorative as well. These torque spanners can be used in scratch sensitive areas due to their rubberlike protective MetaLine covering

Assembly protective coating - bracket coated with 2 mm (80 mil) MetaLine 785 for the assembly of the fuselage segment of an Airbus 350, preventing direct contact with the aircraft hull and the tool

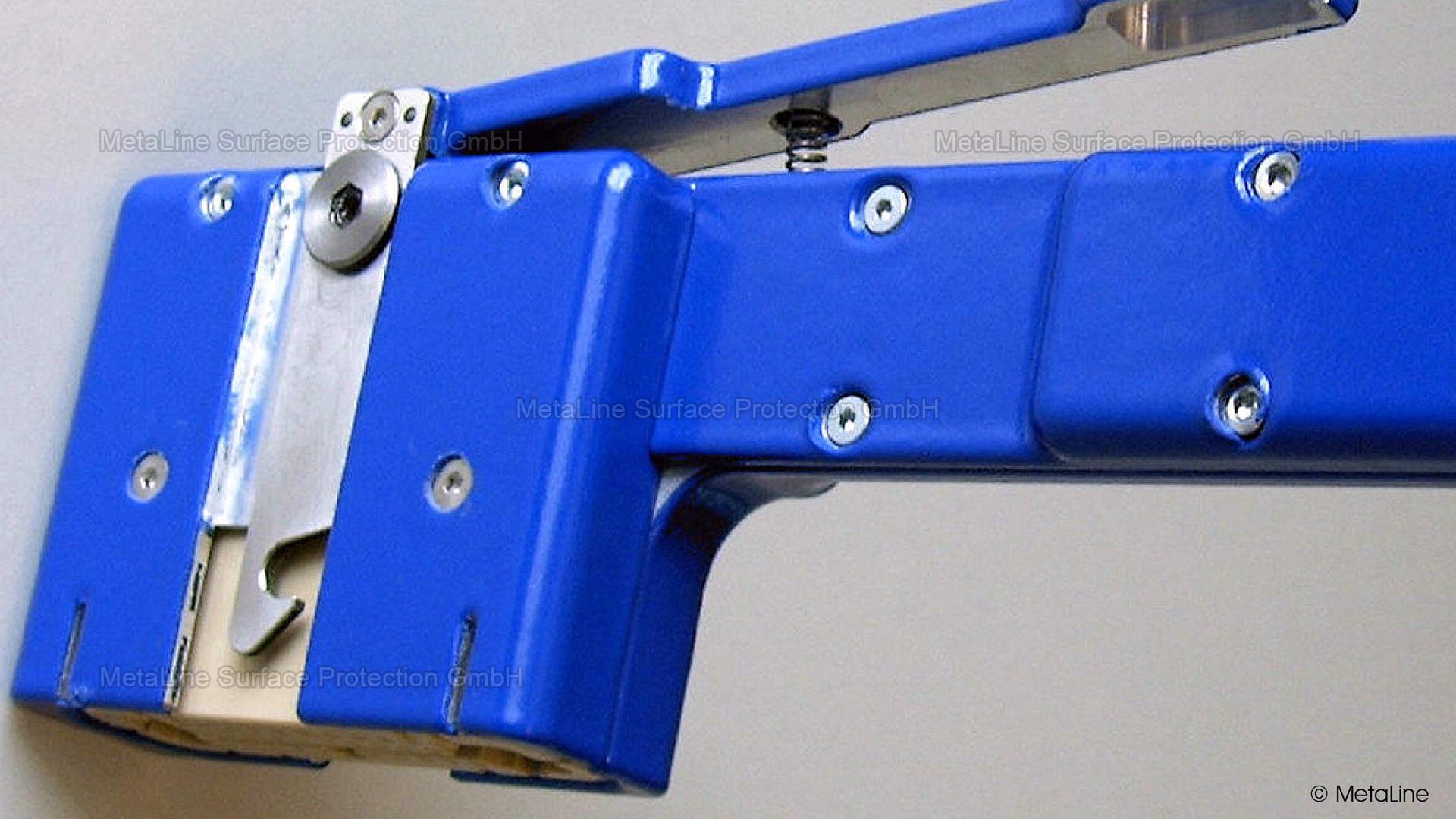

Tool holder coating - MetaLine 785 is used for the gentle storage of sensitive special tools. The coating is applied by casting using a plastic blank

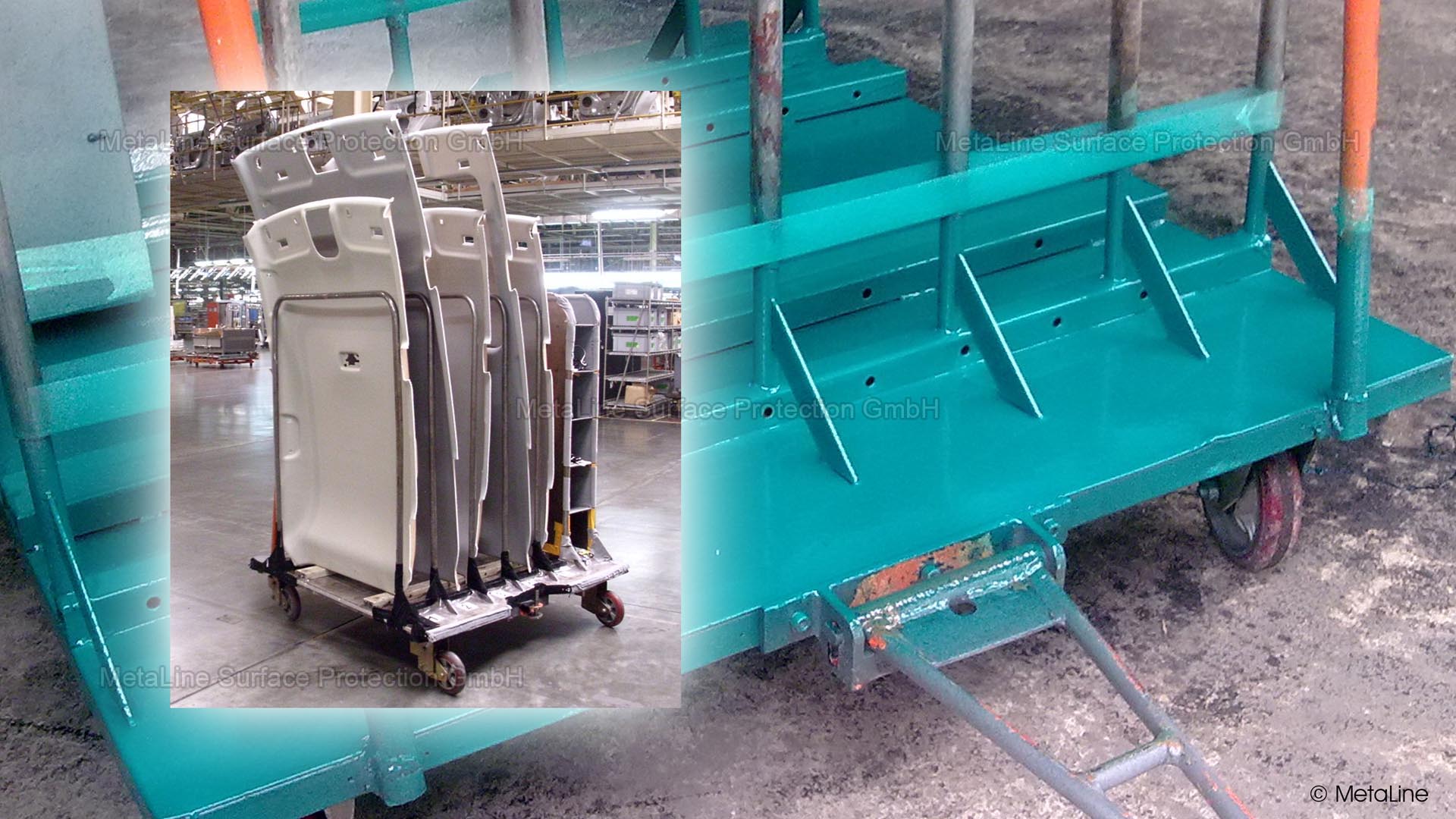

Assembly trolley coating - The purpose of MetaLine elastomer coatings on assembly trolleys is to deliver assembly components cleanly, gently and without defects. The crucial points are softly padded and the workpieces arrive in exactly the condition they should be in

Transportation coatings - any support on which a painted component is placed can cause damage! MetaLine coatings are a reliable way of permanently removing the danger posed by such holders . . .

Insulating coating - handle coatings in series production. Non-slip, non-allergenic, electrically and thermally insulating, smooth or haptically structured, self-applicable! Any questions? You can find the answers at +49703431000 . . .

Gear coating - here a special tool for drive technology in a gear-like shape. Cast with the MetaLine 795 with a casting volume of approx. 3 liters (0,8 gallon). It not only looks good, but is also extremely durable!

Lifting device coating – MetaLine sprayable elastomeric coatings combine an unachieved scratch protection with high static friction values – a must in lifting technology

Snap hook coating - MetaLine 785 is an unbeatable solution when the hook needs to sit securely, but at the same time must not cause any damage when securing. The optimum thickness depends on the maximum load weight . . .

Load hook coating - special tools, hooks, load equipment - coated with MetaLine Series 700. What makes it special? The variable static friction of the coating, the variable thickness of the coating, the variable electrical conductivity of the coating and, of course, the variable coloring of the coating . . .