Features

MetaLine Series 500 consists out of the following 4 elastomeric coating types:

- MetaLine 560, soft, 60 Shore A

- MetaLine 580, semi-soft, 80 Shore A

- MetaLine 590, semi-hard 90 Shore A

- MetaLine 598, hard, 98 Shore A

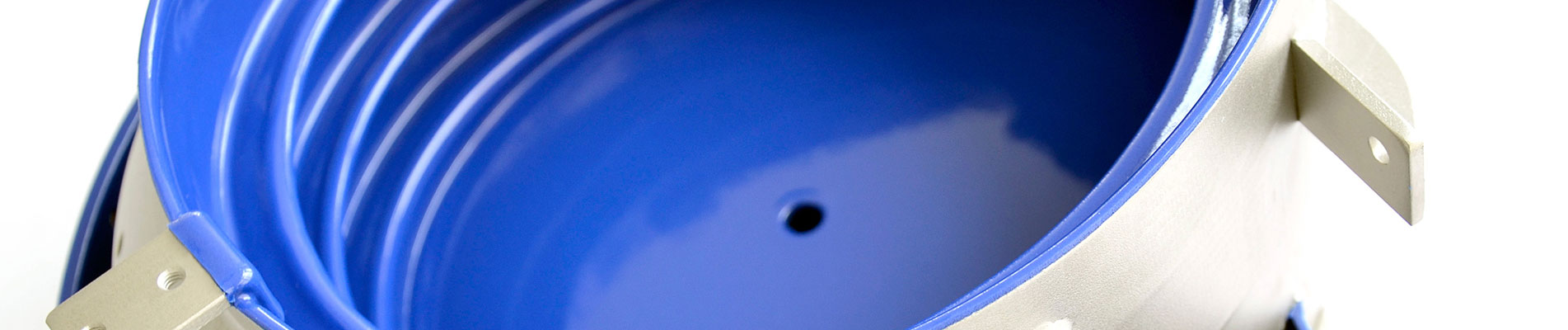

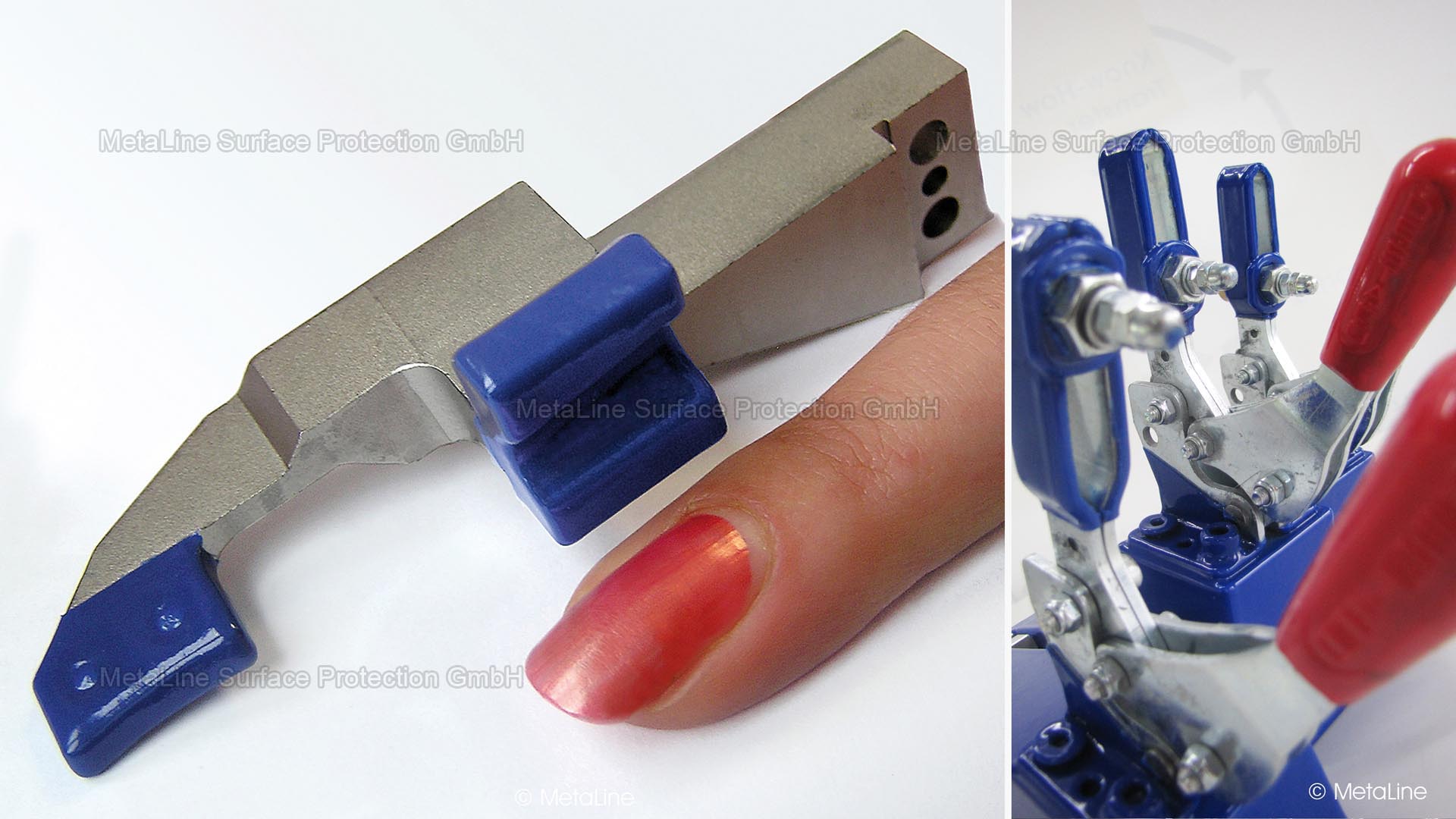

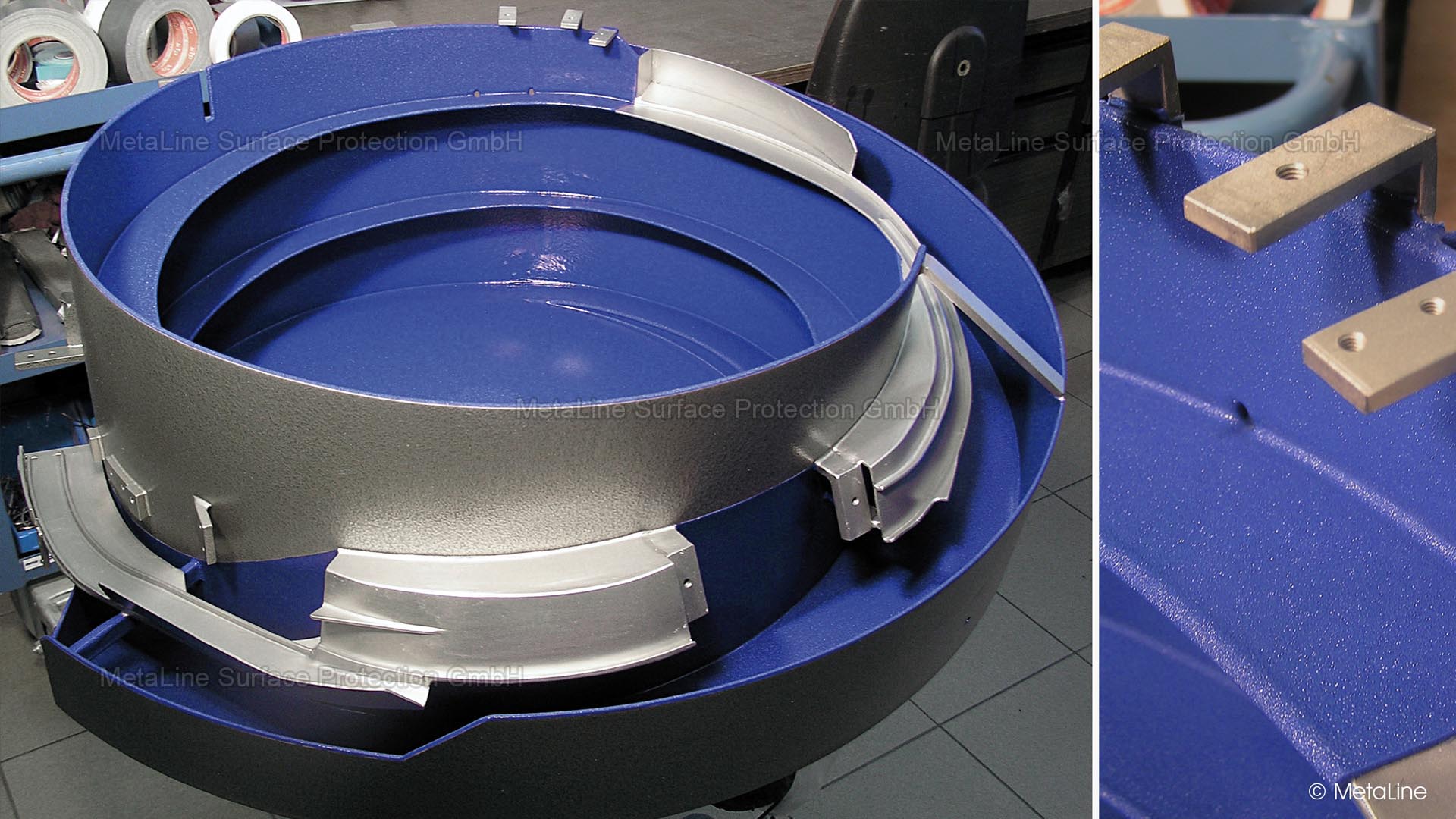

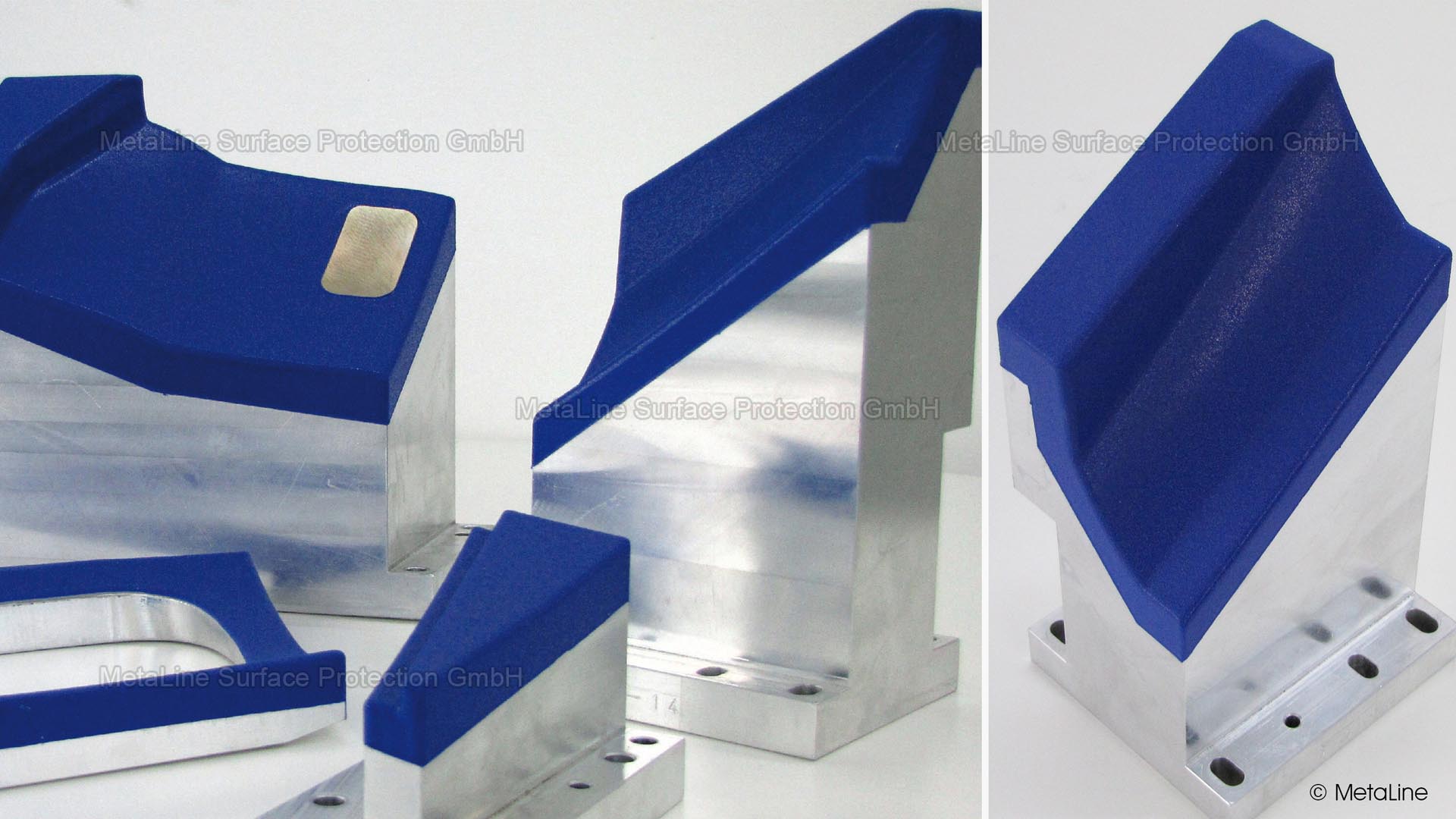

The main field of application is the surface optimization of vibratory feeding devices like feederbowls in all technical designs as stepped, conical or cylindrical shape. In addition, the coatings are suitable for the repair and surface protection purposes against dynamic effects caused by impact, shock and wear.

Approvals have been received from almost all leading European automation, bowlfeeder and robotic gripper manufacturers.

Process

Processing of MetaLine Series 500 is based on tools usually used for high end paint spraying. After mixing, an airless spray system is used to apply the material in thin layers each 500 my (20 mils) at the most. The required spray pressure amounts to approximately 120 bar (1,750 psi). For ultra-small applications a mastic gun might be used as well but is not recommended. The high dilution ratio and low gun output limit the application efficiency significantly, while the air-dispersion leads to a certain porosity of the caoting system.

The rubber-like surface reacts thermally and electrically insulating and can be machined by most processes. Temperature resistance amounts to max. 100°C (212 °F) (dry load). Drug and food safety according to FDA and EU approval is available.

MetaLine Series 500 offers very intensive additivation possibilities. Different MetaLine additives might be added to individually adapt the coating characteristics as:

- Hardness (durometer)

- Surface stiction

- Smoothness / surface texture

- Electrical conductivity / anti-static properties

- Color

- Film thickness

Technical data

| Material basis | solvent-containing elastomers on a modified PUR basis |

| Properties | elastic, impact-damping, grip improving |

| Characteristics | resistant against wear, erosion, corrosion, cavitation |

| Coating thickness | 0.8 mm (30 mils) up to a few millimeters |

| Static surface friction my(0) | variable from 0.1 to 0.7 |

| Electrical conductivity | Insulating or anti-static (upon special request) |

| Chemical resistance | usually ph 3-11 |

| Thermal resistance | up to max. 100 °C (212 °F) dry |

| Mechanical processablility | machinable with most processes |

| Surface finish | smooth, velvet like, structured (depending on the technical requirement) |

| Area weight | 1.05 kg per m²/mm (0.22 lb per 40 mils/sqft) film thickness |

| Color | white, light grey, dark grey, red, green, blue, black |

| Special colors | special colors on request |

| Pharma compatibility | according to FDA 177.1680 (title 21) (except MetaLine 560) |

| Food compatibility | according to EU 1935/2004 (MetaLine 580 / MetaLine 590) |

| Type of processing | high pressure airless spaying (in certain limited instances low pressure air spraying) |

| Thermal treatment | no heat treatment required |

| Number of layers | in coats of 500 my (20 mils) wet (with an flash off time of at least 20 minutes in between coats) |

| Surface preparation | mechanical roughing or gritblasting / degreasing / priming |

| Ready for use | minimum 24 hours |