Paint protection coating - a transparent, rubber-like - removable - coating with MetaLine 785 protects this Caterpillar from premature visual ageing and thus increases the resale value. A sensible consideration, especially for new leasing machines!

After 4 years in the salt mine – the coating has optically aged! But NO corrosion and the original paint is intact. After removal of the peelable MetaLine protective skin, the vehicle can be returned to the used market with maximum resale value

Tire repair - The MetaLine process is suitable for repairing partial damage. But not to fundamentally reinforce the strength of overloaded tires. Every technology has its limits . . .

Dozer blade coating - MetaLine 795 protects this dozer blade against stone chipping, corrosion and minimizes adhesion. More resistant than any paint and at the same time has a remarkable anti-adhesive effect. More safety + more function!

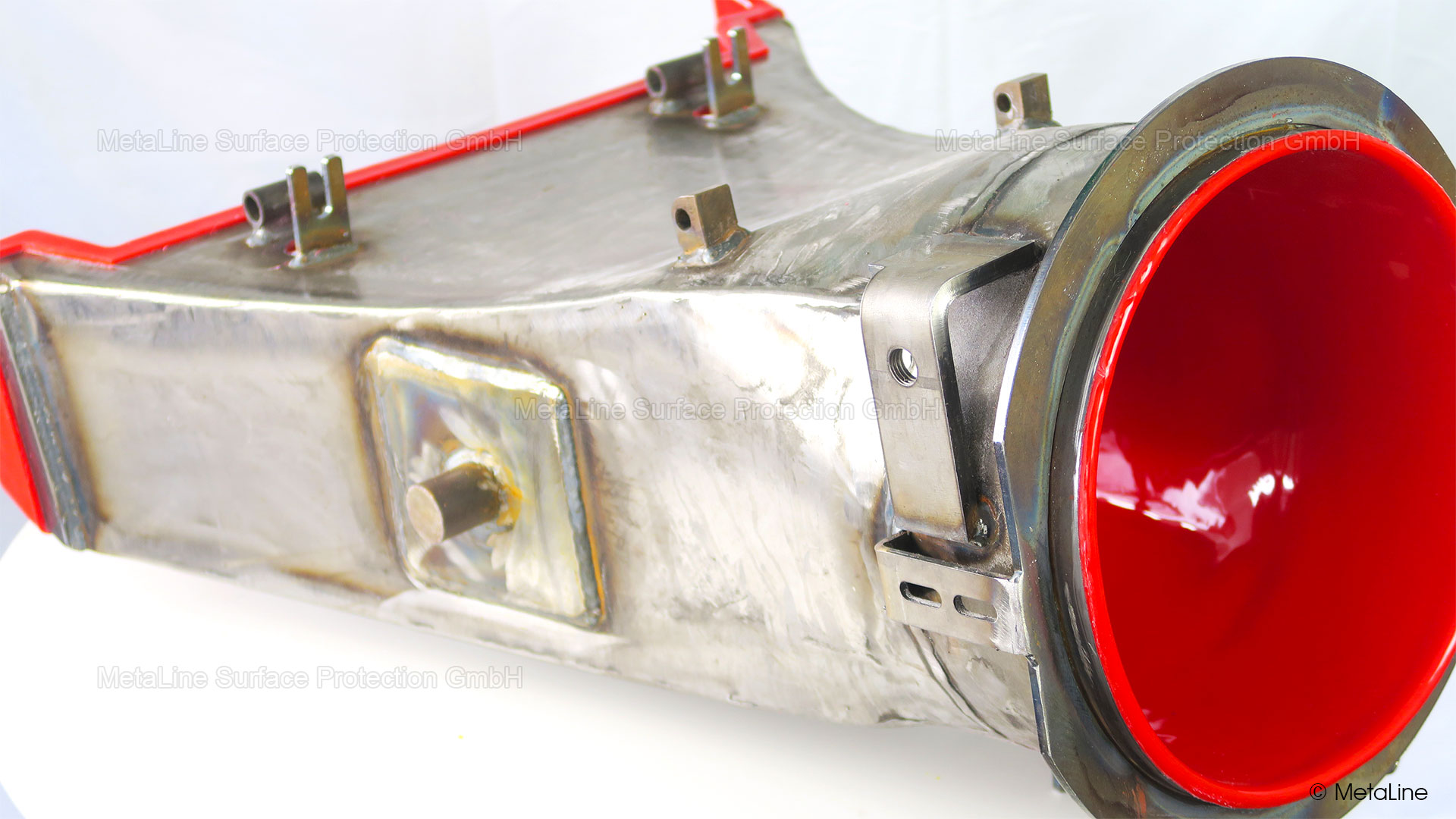

Suction excavator wear protection - MetaLine 785 with a coating thickness of 10 mm (400 mils) protects this suction pipe of a street cleaning vehicle. The geometry is a prime example of a MetaLine spray coating due to the transition from rectangular to round

Concrete mixer coating - MetaLine 785 protects against wear and especially against sticking during concrete production, transportation and processing! Less cleaning means more time for more important things . . .

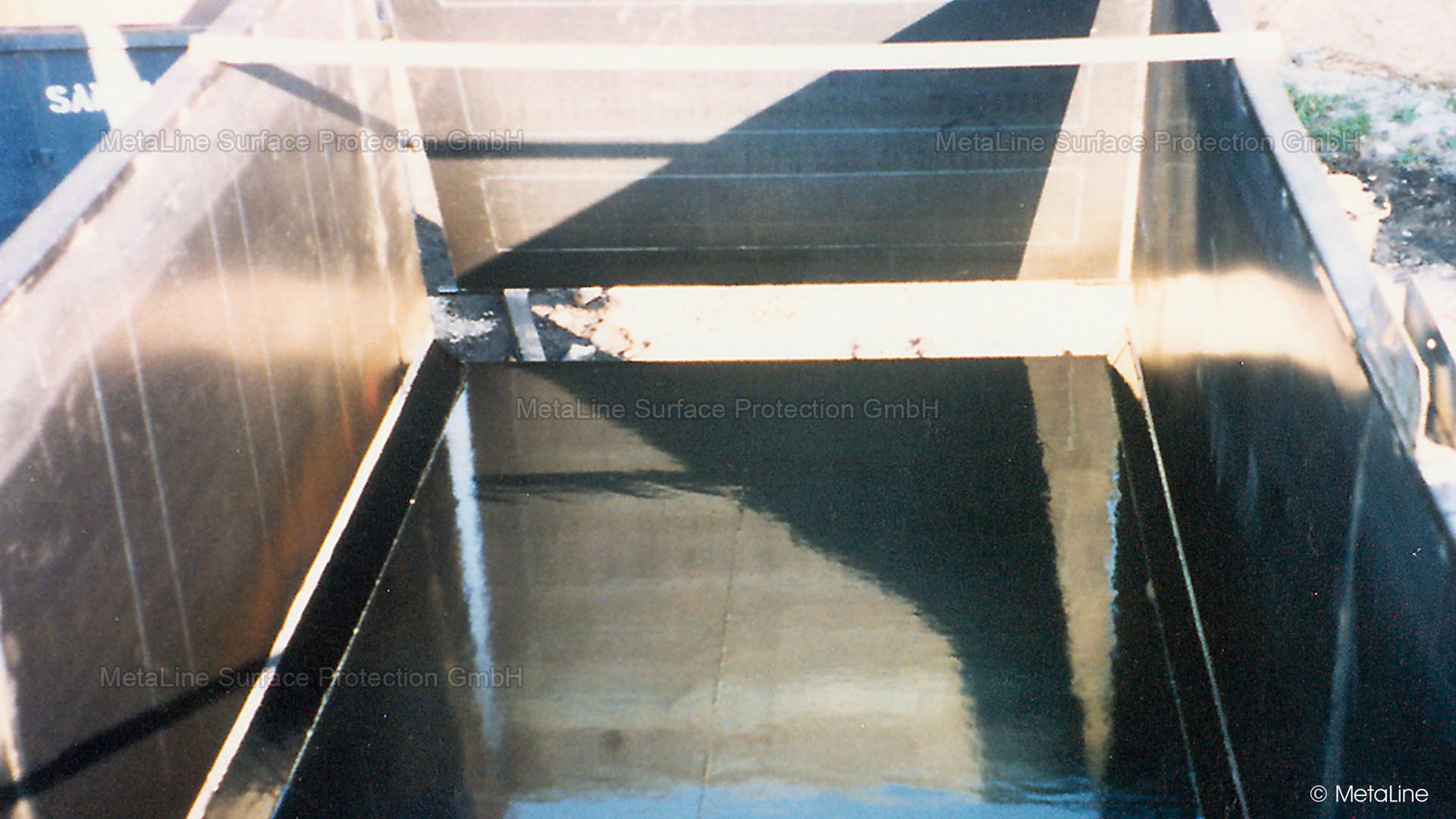

Dump truck coating - non-stick coating for clay, sand, salt or biomass. Works well - but you have to be aware that a non-stick skip should not be used for “everything” afterwards . . .

Dump truck coating - MetaLine 795 is a “mobile” coating. This means that non-stick properties can be applied directly on site - here in a salt plant. However, this has nothing to do with “do-it-yourself” - preparation and know-how must be right . . .

Excavator blade coating - certainly not a standard solution, but interesting for extremely adhesive clay soils. MetaLine 795 in 5 mm layer thickness on this dozer blade

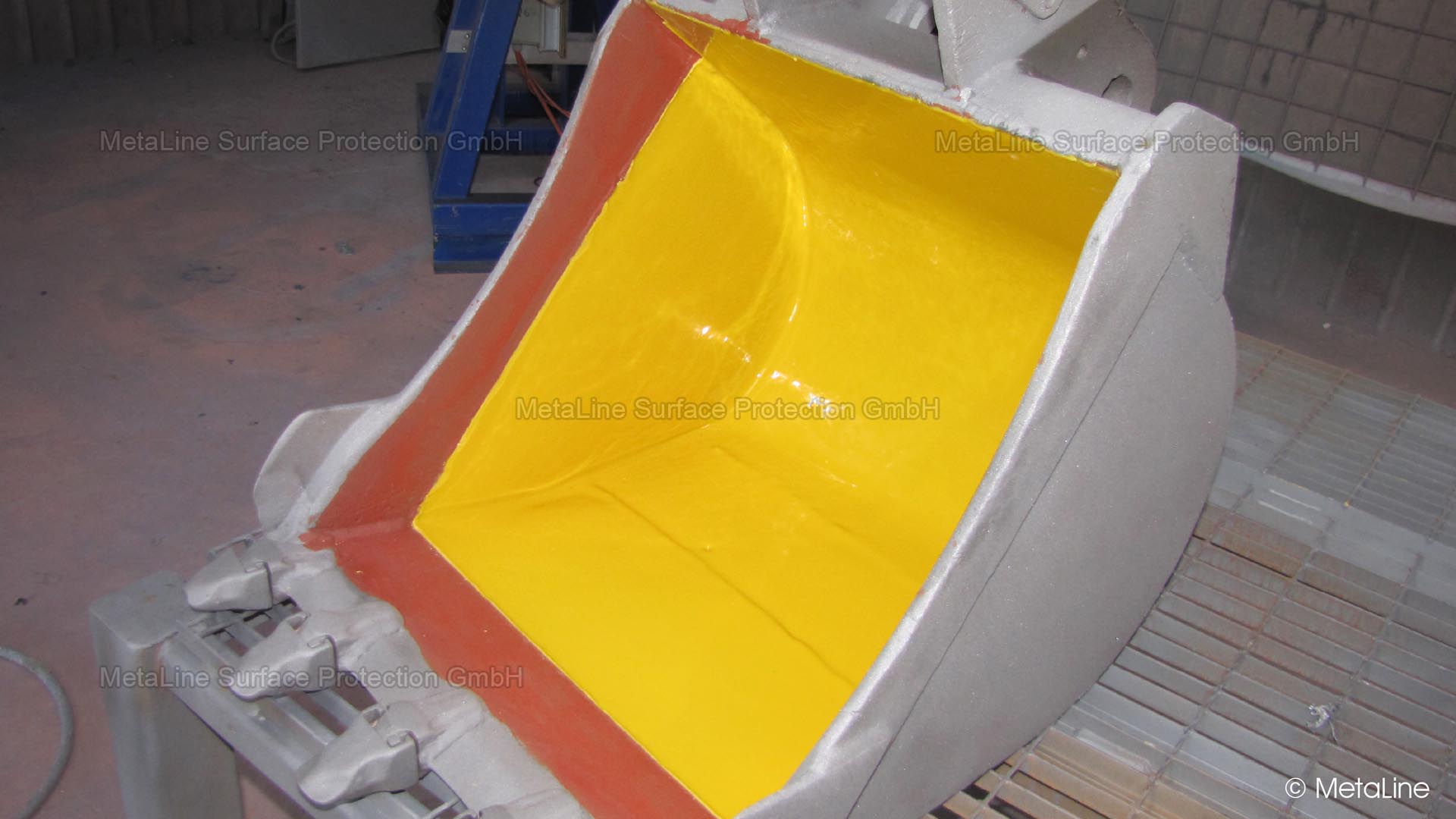

Excavator bucket coating - for particularly sticky material. MetaLine 795 with a coating thickness of 5 mm (200 mils) optimizes sliding on this bucket and thus increases the working speed. But that's all! A coated excavator bucket is no longer an all-purpose tool!

Excavator bucket coating - an important solution to the problem of caking. Coated shovels can no longer be used for conventional excavation or demolition work, but are special tools that are used when necessary

Excavator bucket lining - MetaLine supports you with its entire application know-how in the correct preparation of the components and the professional substrate pre-treatment. It's the edges that count . . . .

Excavator bucket coating - MetaLine 795 can be repaired and recoated at any time. But this should not happen if a non-stick coated excavator bucket is used correctly

Non-Stick-Coating – wear resistant nonstickcoatings are a domain of MetaLine. However this massive drilling tool coated with 5 mm (200 mils) of MetaLine 795 is even a challenge for us

Conveyor roller coating - mobile conveyor belt system for concrete conveying. The rollers were coated with 2 mm MetaLine 795 to improve friction and protect against deposits