Casting porosity repair - there is the need for “invisible” casting defect removal and the need for pure “sealing”. Here is an example of the latter, namely the full-surface coating of a larger casting with the brushable MetaLine repair ceramic KXL

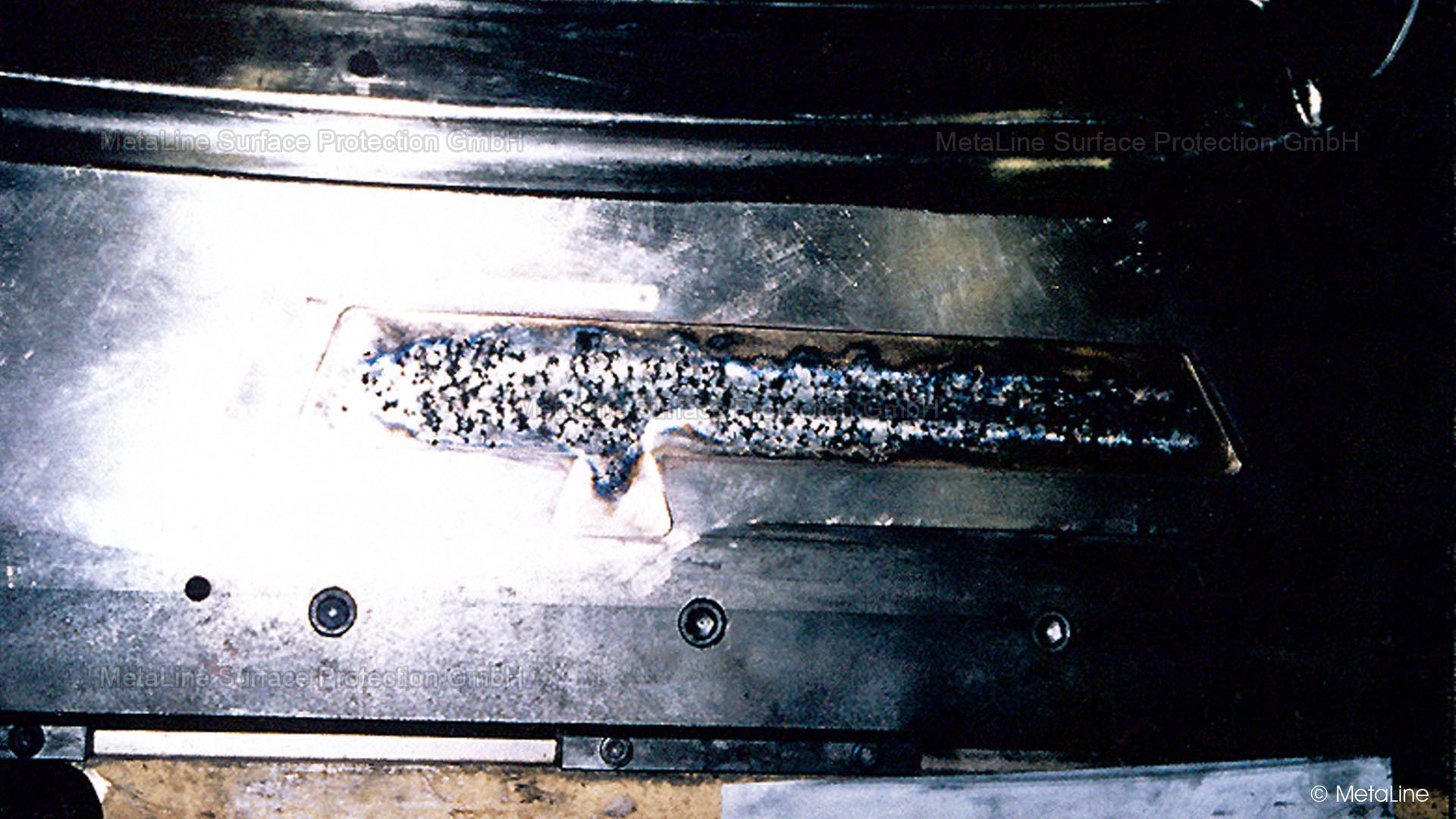

Removal of casting porosities - forming tool in a press shop for the production of automotive parts. Repairing the cavities is just as essential as removing them by grinding or milling. Simple “ filling” is no longer possible with this size and load . . .

Filling casting cavities - the imperfections were professionally processed, filled and scraped to size. Also an effort, but significantly less than a complete new production of the part

Porosity filling - the expert immediately recognizes that it is erosion/cavitation and not a cavity. However, the solution is the same as for porosity caused by casting. Synthetic regeneration with the ceramic-based MetaLine SXL

Ceramic filler - The type of leveling is a typical “do-it-yourself” finish. The professional would shorten the edge length. Not bad - but unfortunately not ideal either. Why are we showing it anyway? So that YOU can learn from it. Where else on a website is someone so critical of themselves?

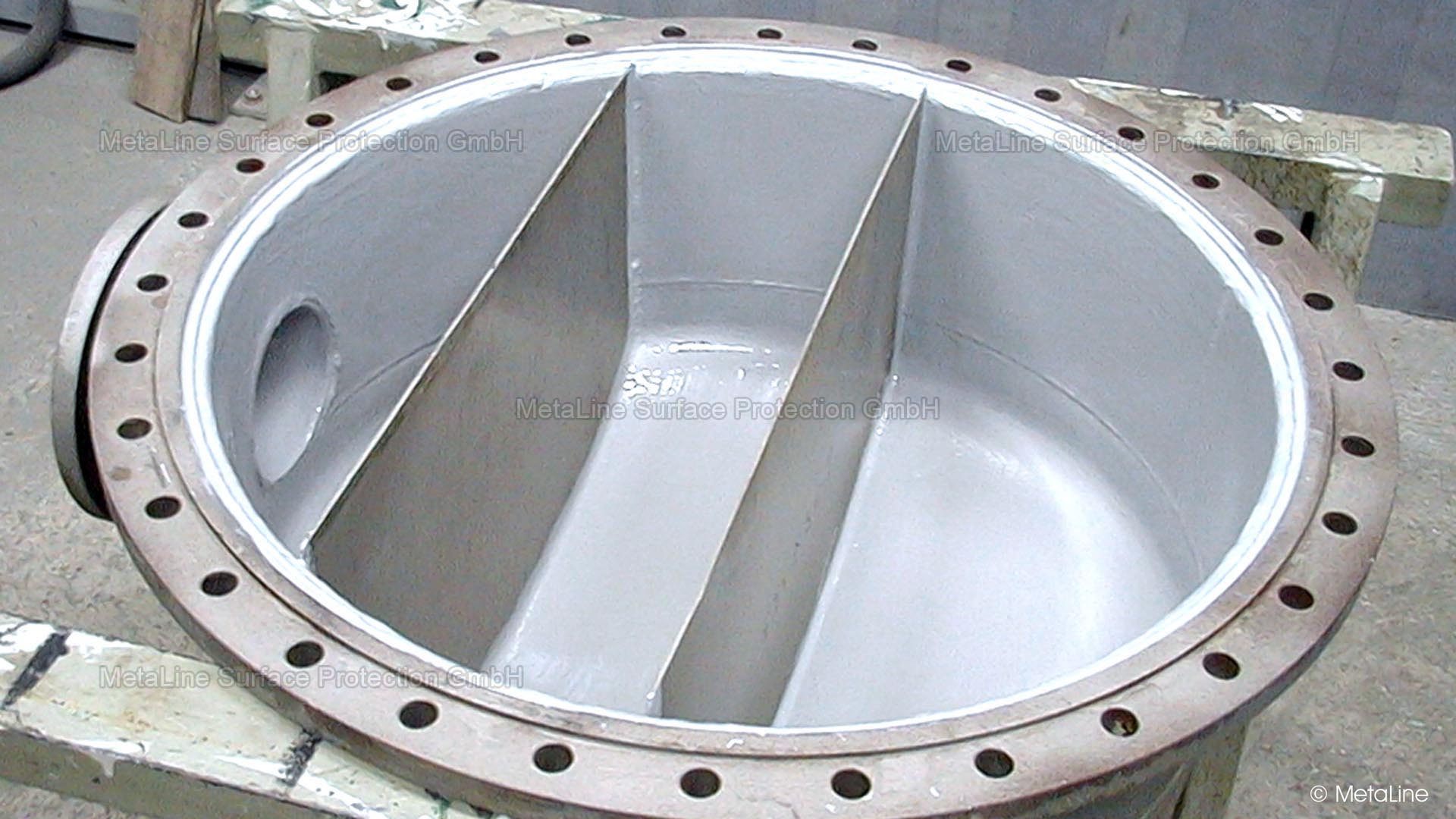

Filling shrinkage cavities - if the number of porosities becomes excessive, the only option is a complete overcoating. However, this should always be the last option, as the metallic surface character will of course change completely!

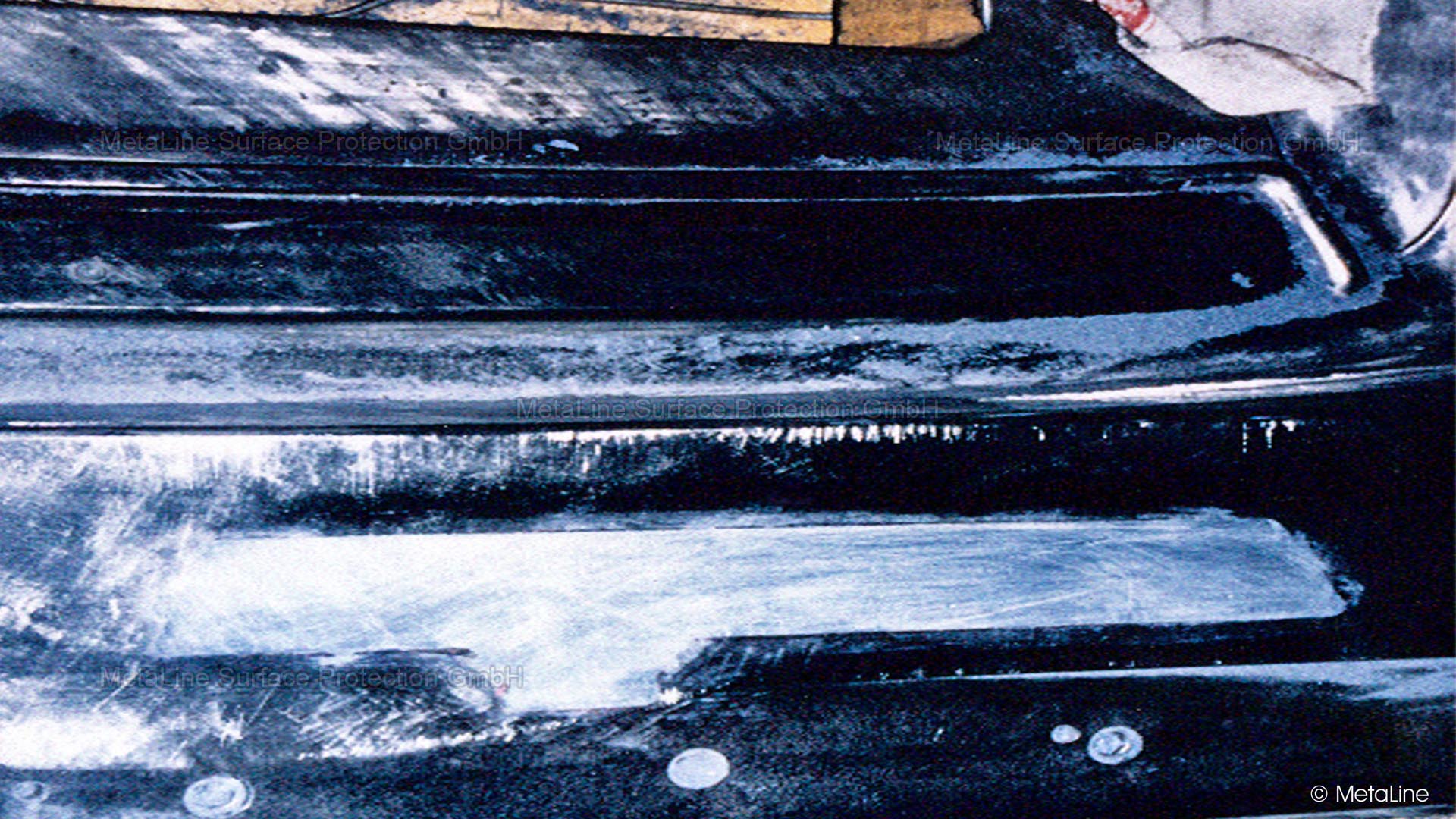

Flange porosities - the removal and filling of superficial porosities always requires mechanical preparation, capillary cleaning and drying. Everything else is make-up!

Oversize repair - compensation of flange porosities with the paste-like MetaLine repair ceramic SXL or the brushable version, the MetaLine repair ceramic KXL - depending on the condition of the substrate