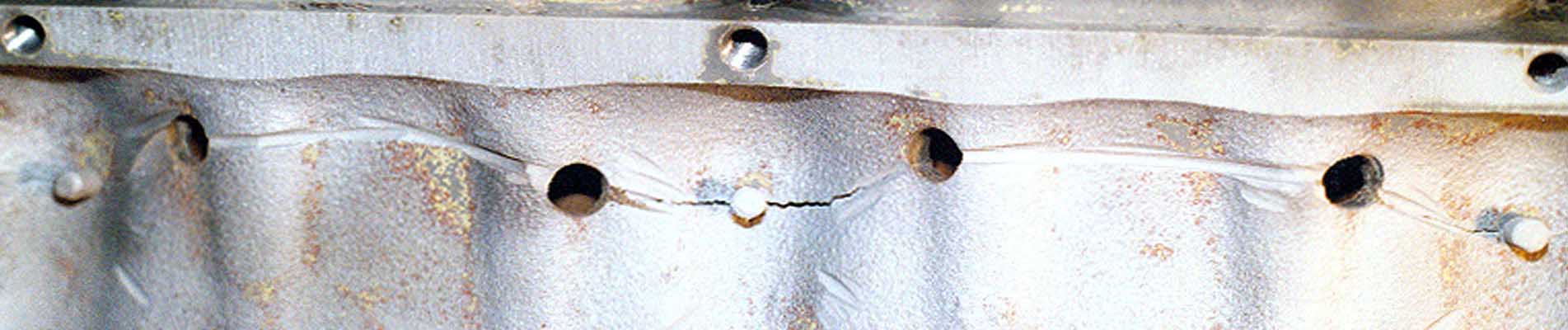

Crack repair - tractor engine block cracked by frost. The crack ends were drilled out, the crack was grinded into a V-shape and expansion bolts were used along the crack to expand the crack to the expected operating temperature

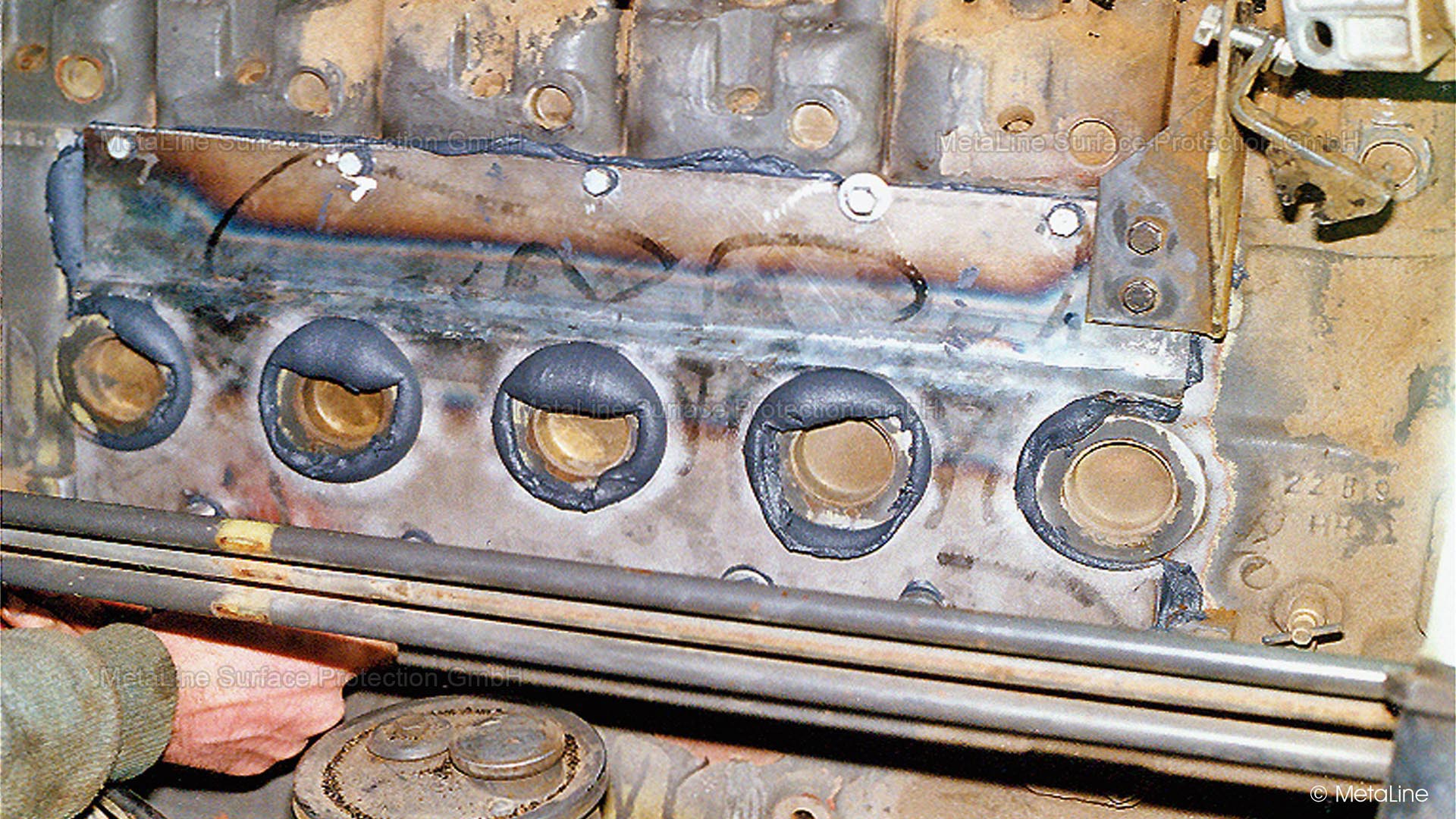

Housing crack repair - a precisely fitting steel reinforcement plate was made. The rear side and the repair area on the engine block were then sandblasted. After chemical degreasing with MetaLine 990, the MetaLine repair ceramic SXL was applied

Crack sealing - prior the MetaLine SXL started to solidify, the reinforcement plate was aligned, firmly screwed in place and then the excess repair ceramic was removed again. A professional repair that takes time - not necessarily quick and easy!

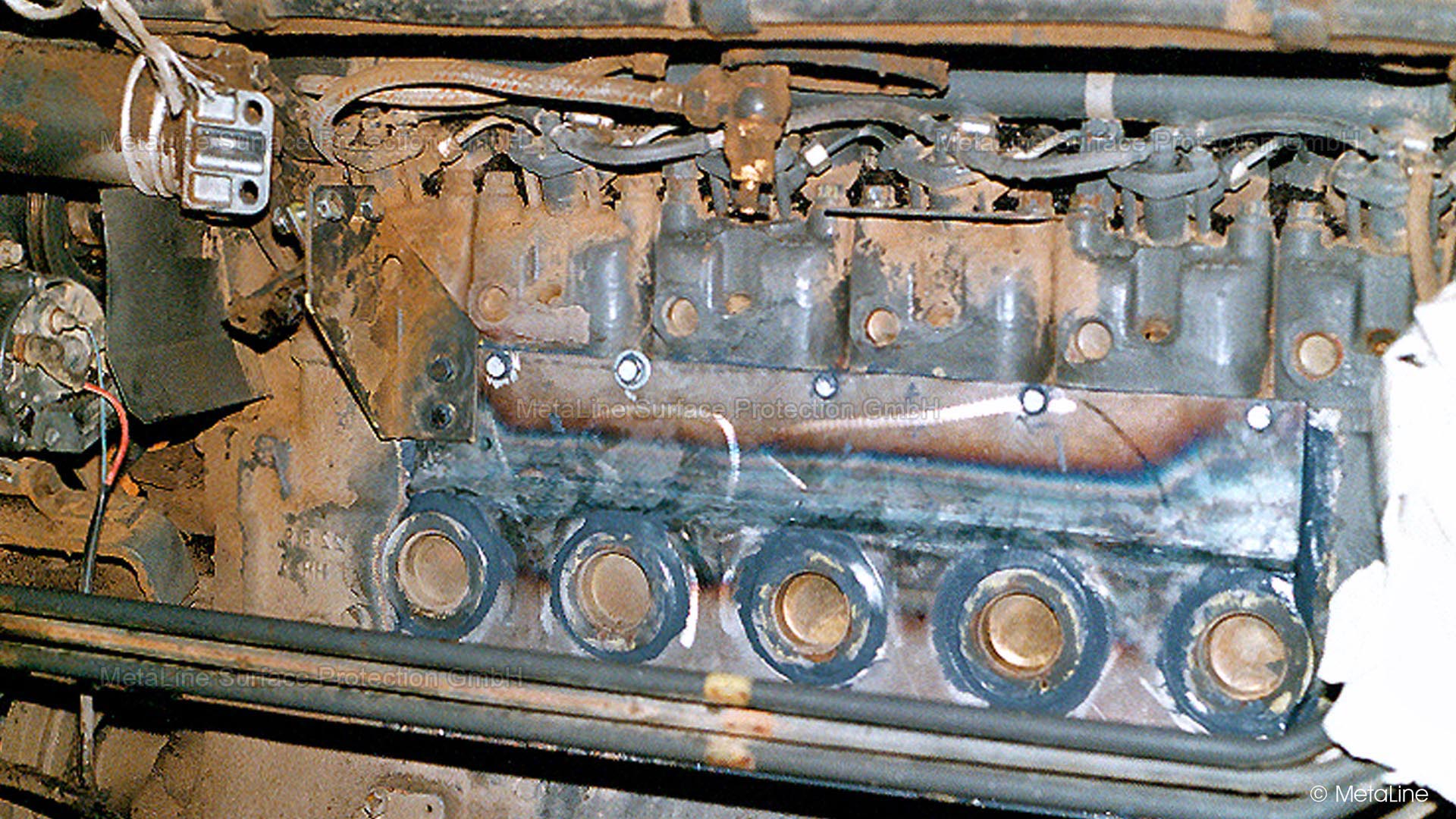

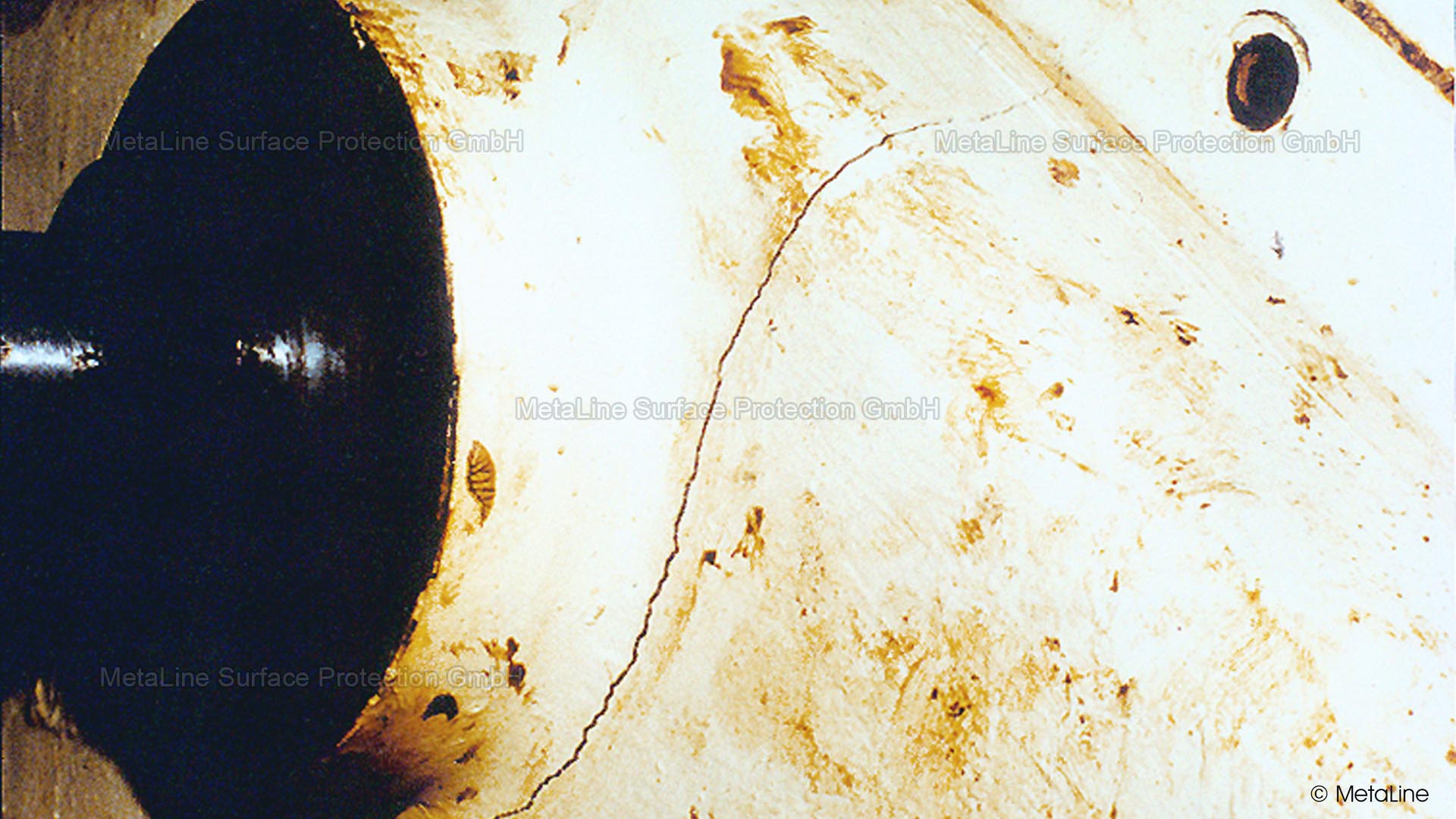

Hairline crack repair - a Rolls Royce Phantom III - beautiful but unfortunately defective. Frost damage caused a hairline crack in the cooling circuit. The aim of the repair was to prevent the complete destruction of the engine block - and thus the loss of the “matching number status” in any case

Engine block repair - the crack in the cylinder head was sealed with the repair ceramic SXL and a metallic reinforcing mesh. All work was carried out with minimal intervention. Technically not the best possible repair - but value-neutral!

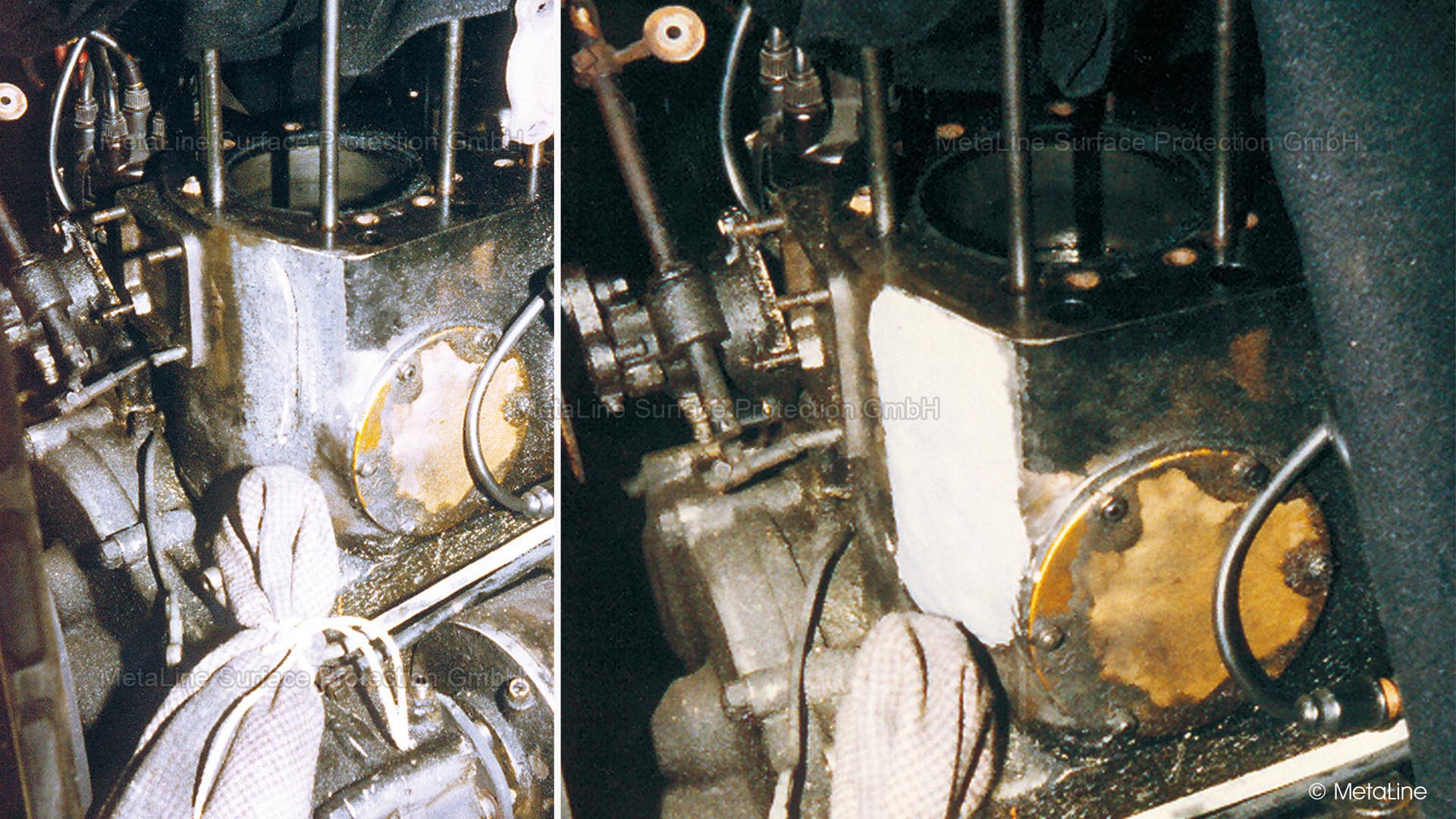

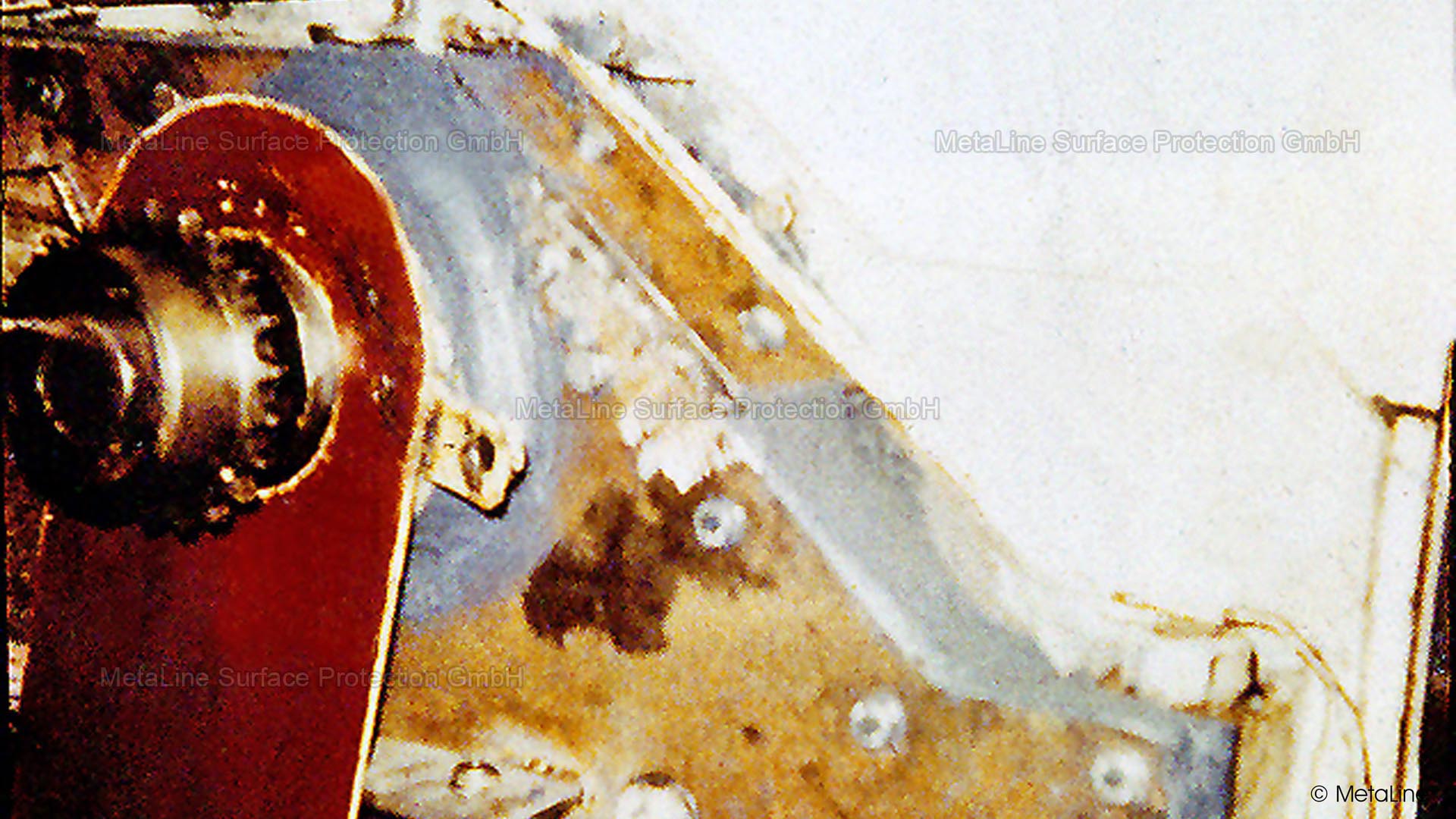

Housing crack repair - a base of a hydraulic press weighing several tons - cracked! Conventionally only repairable by “metal stitching”. However, the customer decided to repair it with our polymer technology for reasons of availability

Crack restoration - fitting of the required steel reinforcement using MetaLine repair ceramic SXL - in this case on the inside and outside of the housing. The operating load is too high for one-sided reinforcement . . .

Crack sealing - successful crack repair with MetaLine! The process is also available for the repair of injection molds. We apologize for the poor image quality - unfortunately the components cannot always be put “in the right light”!