Features

From the very beginning, the brand name MetaLine has stood for innovative material ideas and extremely professional application and dosing concepts. Our clear focus is on spray application and uniform application by means of innovative spraying processes.

However, there are sometimes repair and coating applications that require other processing properties, such as trowelability. We have implemented these requirements in our MetaLine Series 600.

MetaLine Series 600 consists of 3 elastomeric products for customer-specific self-application:

- MetaLine 665, castable / trowelable, soft, 65 Shore A, packaging in cans and buckets

- MetaLine 685, castable / trowelable, semi-soft, 85 Shore A, packaging in cans and buckets

- MetaLine 695, castable / trowelable, semi-hard, 95 Shore A, packaging in cans and buckets

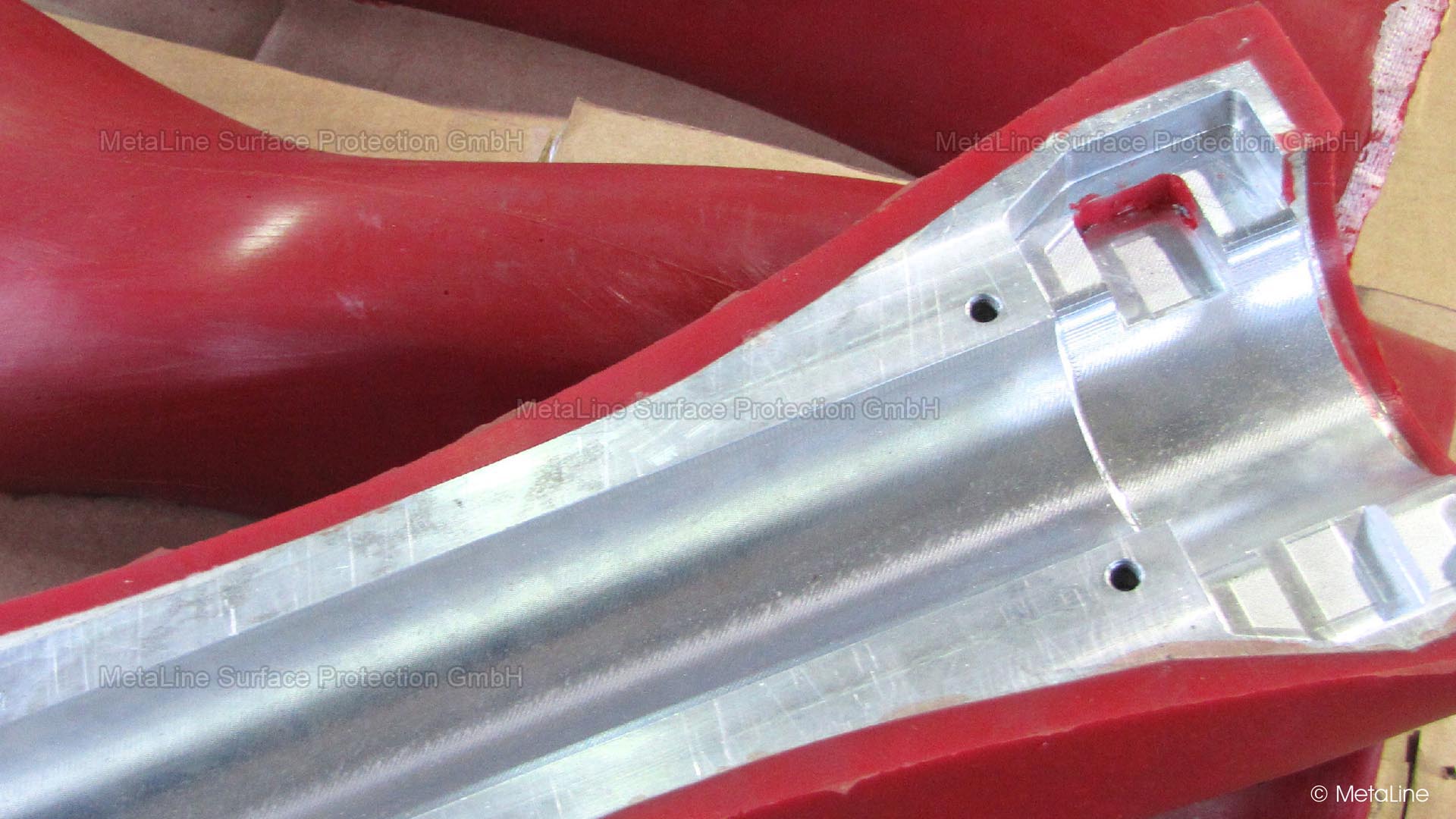

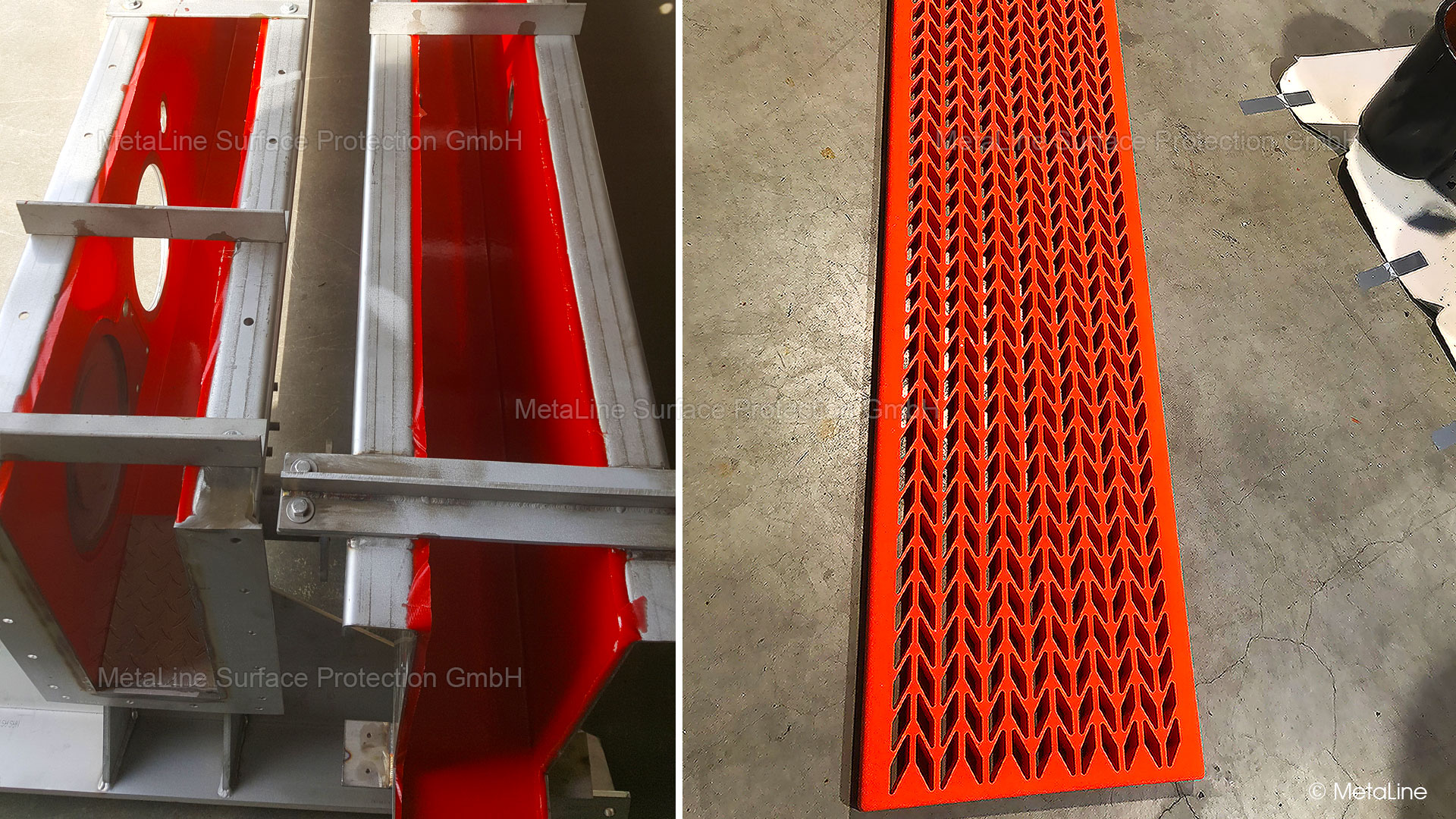

Main applications are cold casting operations of single parts and small series with a part weight between 50 grams (0.1 lbs) and 20 kg (44 lbs). The high tensile and tear strengths recommend the use in the area of heavy-duty surface protection to protect against dynamic effects caused by impact, shock, wear and erosion.

Process

MetaLine 665, 685, 695 are 2-component casting products for manual mixing. The processing time is approx. 30 minutes. Depending on the volume, the minimum wall thickness (mold spacing) is from 2 mm (80 mils) upwards.

Different MetaLine additives can be added to the materials during preparation to individually adapt the material properties. In particular, a thickening additive with which layer thicknesses of up to 25 mm (1 inch) can easily be applied vertically in a single operation.

Solidification takes place absolutely free of shrinkage and swelling - the precision of the results cannot be surpassed. All materials are solvent-free and non-toxic. No volatile substances are released during processing/curing!

Technical data

| Material basis | solvent-free elastomers on modified PUR basis |

| Type of reaction | 2-component materials for manual mixing |

| Type of application | depending on type - castable, injectable, trowelable or brushable |

| Processing tools | no special tools required |

| Working conditions | may be processed in any climatic conditions |

| Thermal treatment | no heat treatment required |

| Properties | elastic, impact-damping, slip-resistant |

| Characteristics | resistant against wear, erosion, corrosion, cavitation |

| Layer thickness | 0.4 mm (16 mils) up to infinite |

| Number of layers | castable in one single operation |

| Shrinking / swelling | not measurable |

| Chemical resistance | usually ph 3-11 |

| Mechanical processability | machinable with most processes |

| Area weight | 1.10 kg per m²/mm (0.22 lb per 40 mils/sqft) film thickness |

| Ready for use | minimum 24 hours |

| Color | individual color selection when mixing with MetaLine 930 pigments |

| Surface preparation | mechanical roughing or gritblasting / degreasing / priming |

| Container size | containers with 5.0 kg (11 lbs), 22.0 kg (48 lbs) |

| Shelf-life | at least 6 months |

| Availablility | on request |