Features

MetaLine 785 is a semi-soft, elastomeric coating product developed for customer-specific self-processing by spraying, casting or injection. The hardness is approximately 85 Shore A.

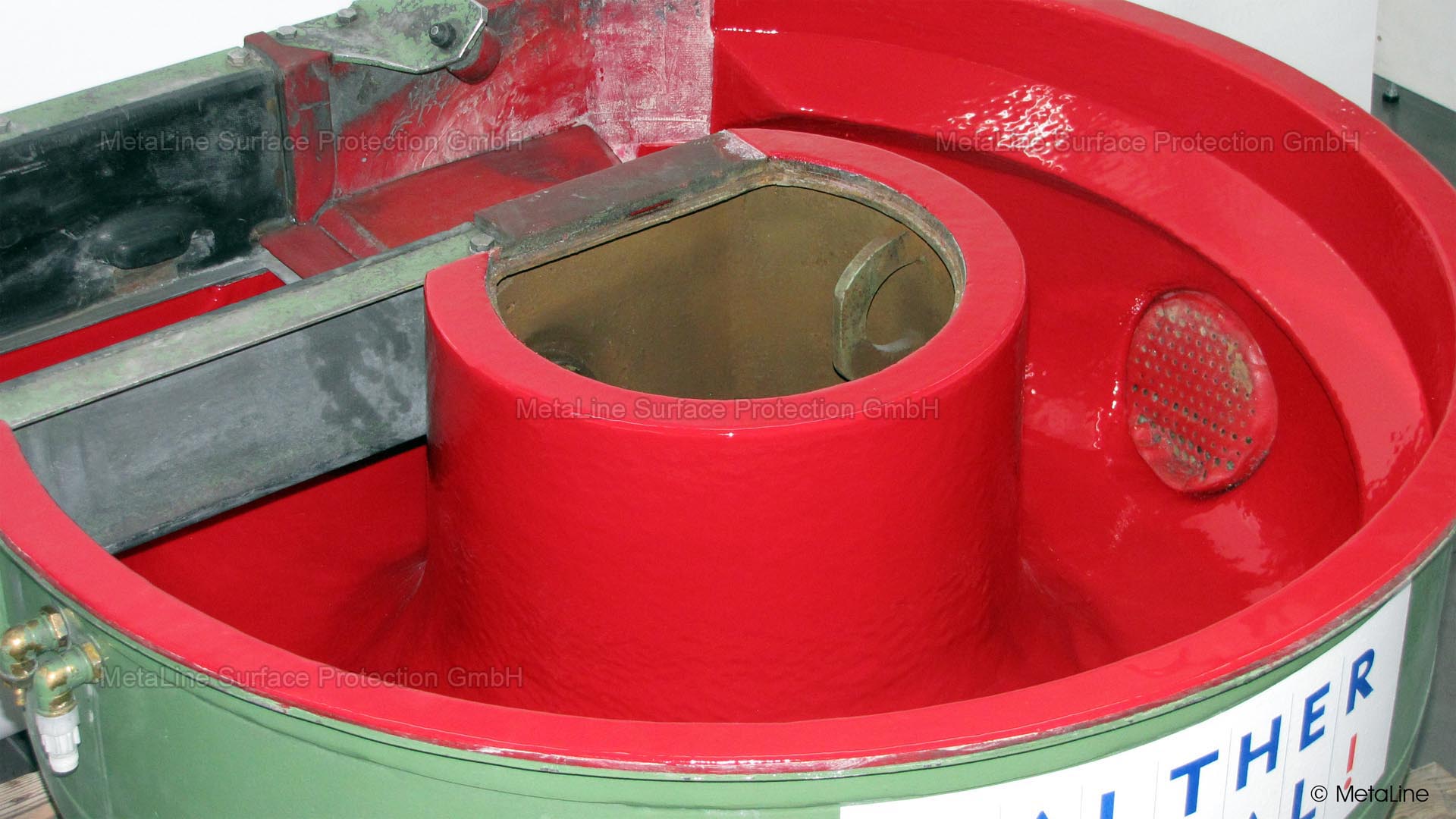

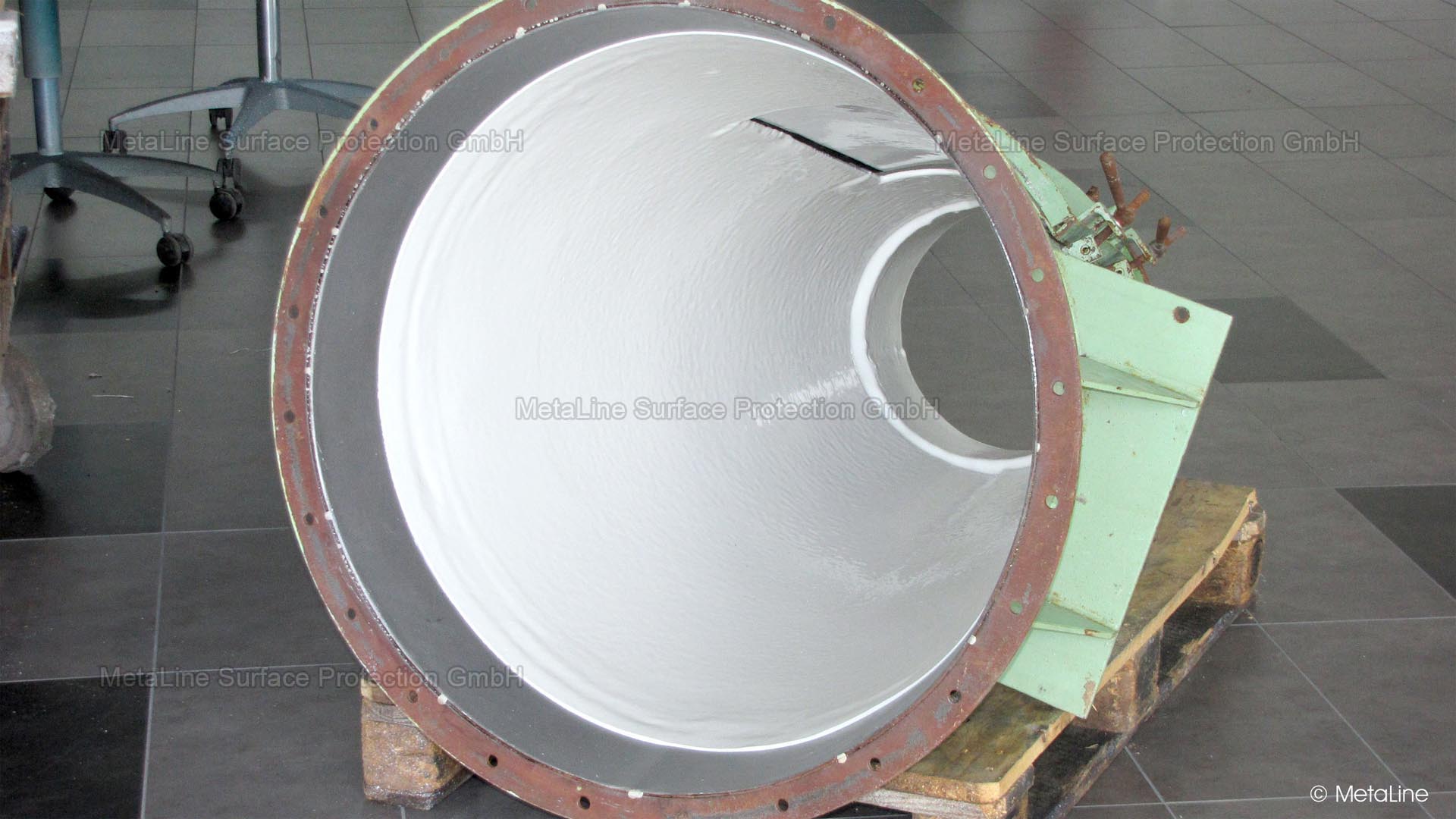

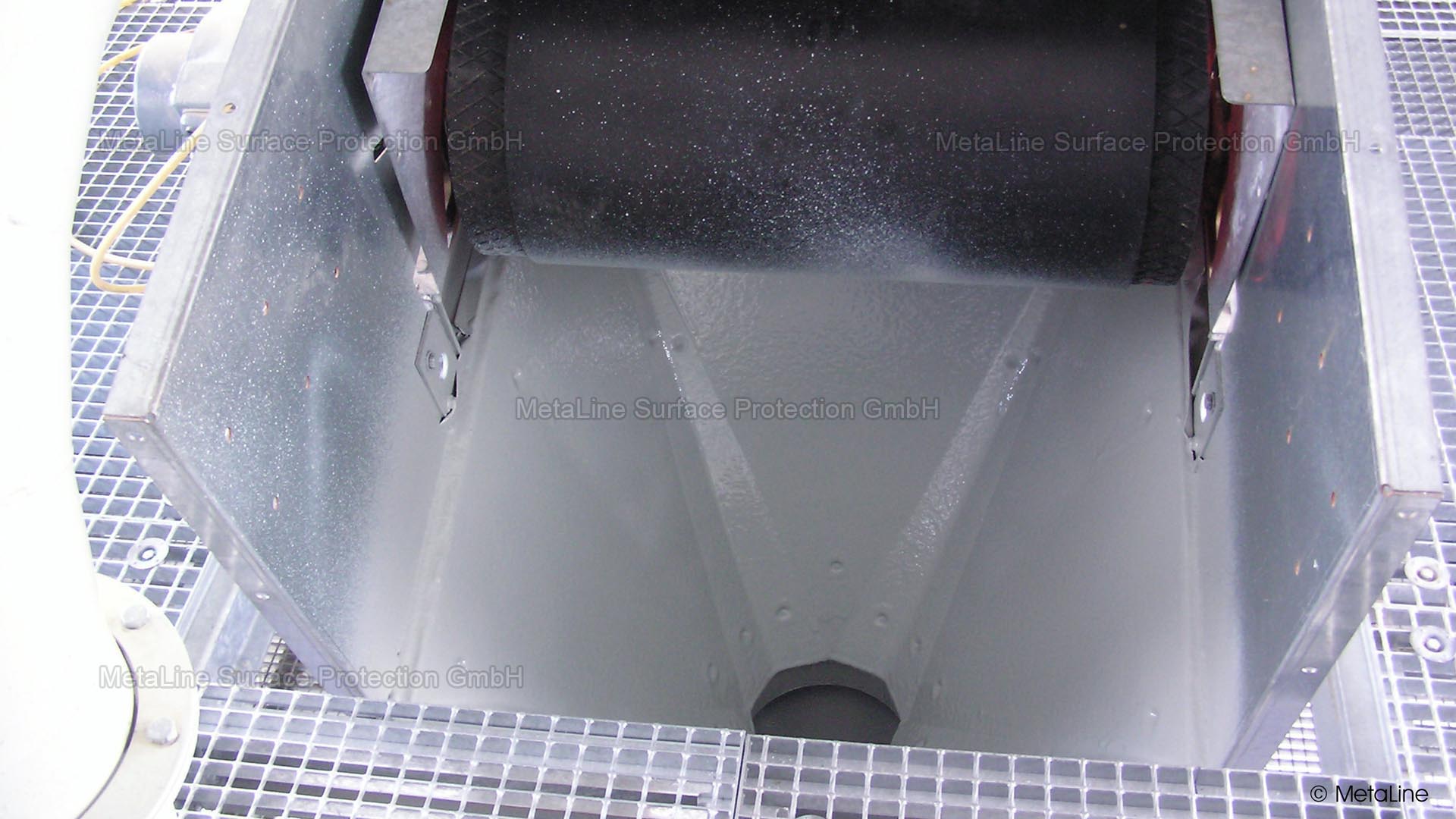

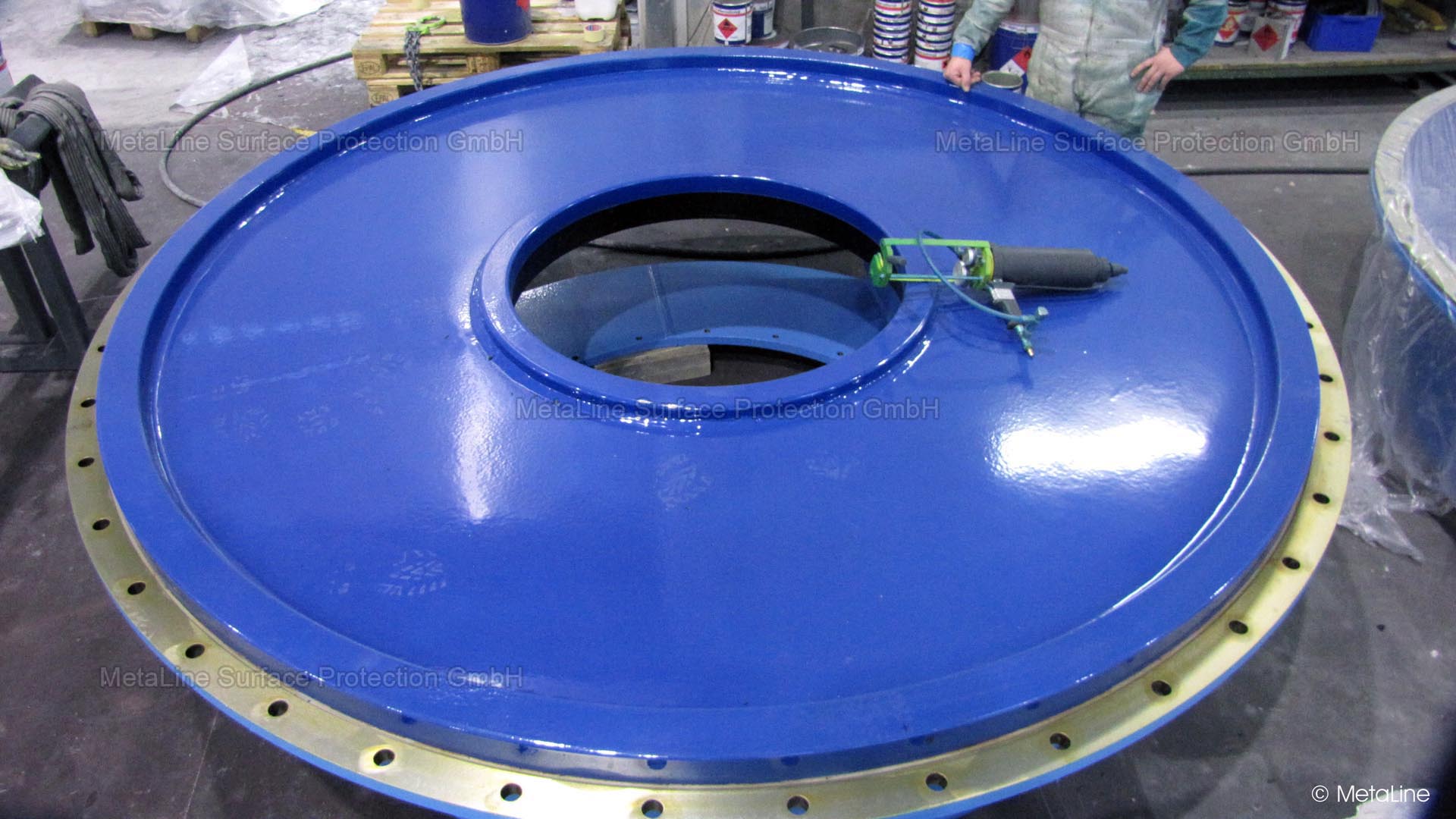

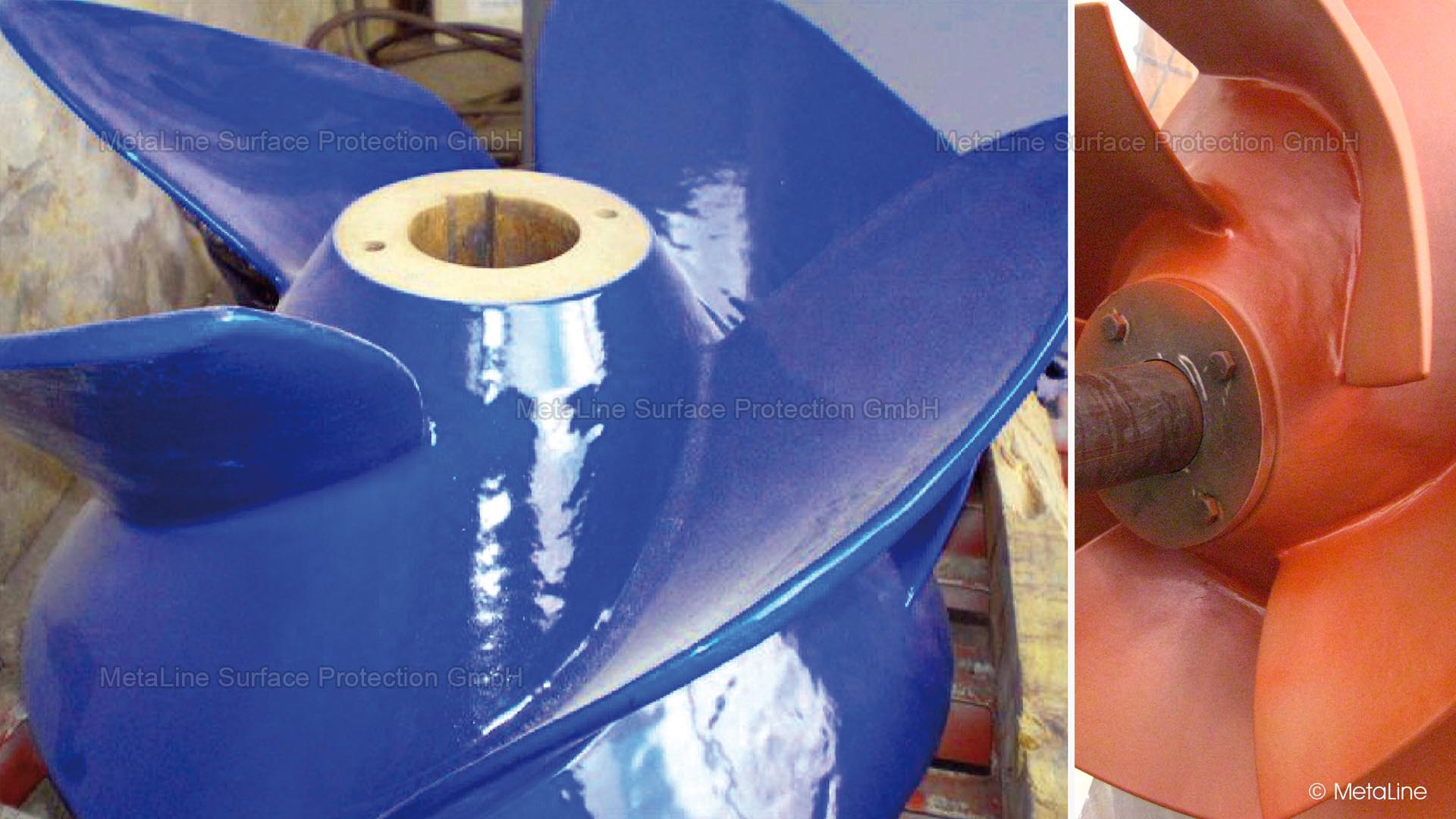

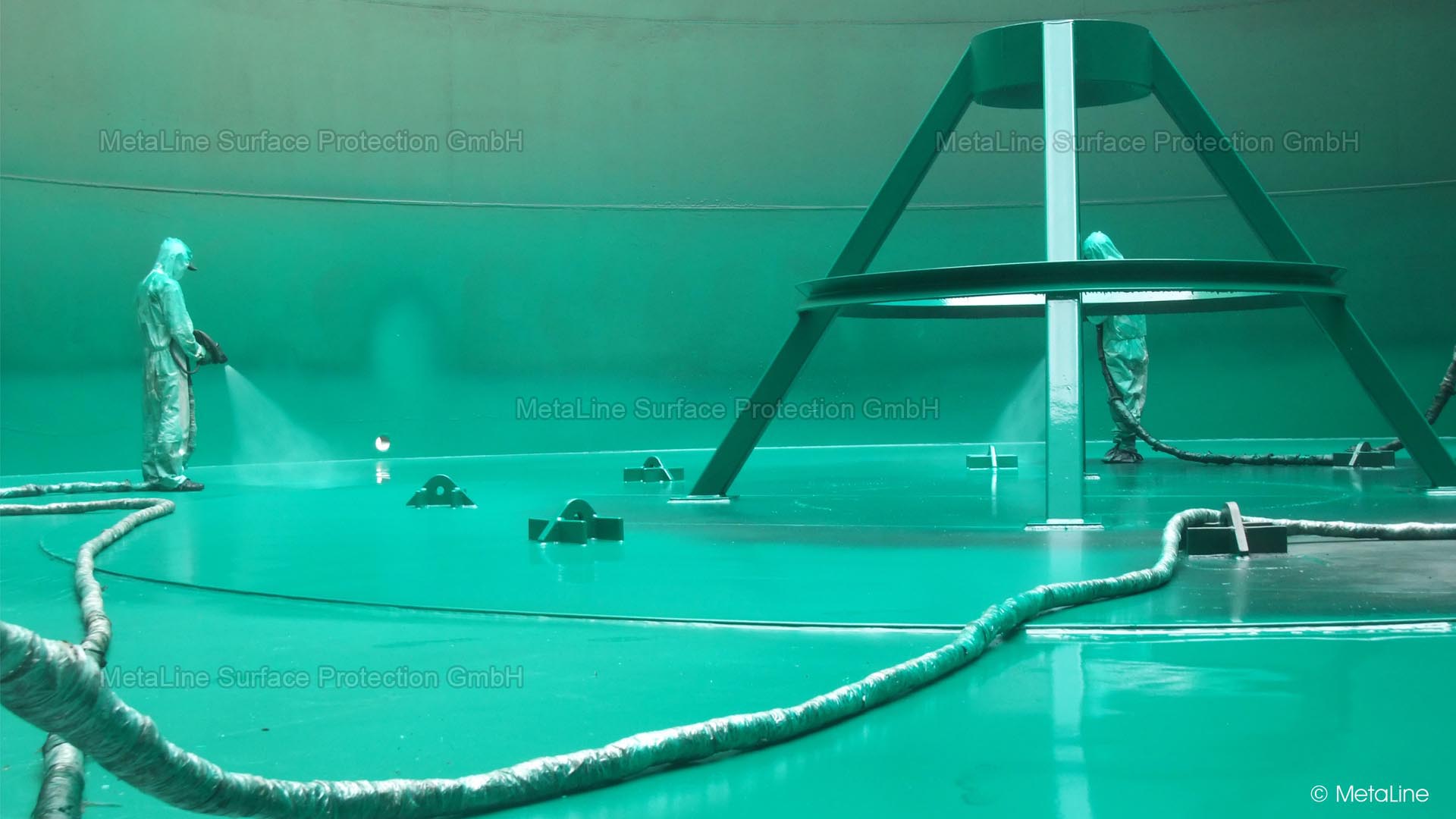

The main field of application are wear protective coatings!

Furthermore suitable for the permanent repair or coating of rubber and metal components to protect them from the most aggressive dynamic effects caused by

- impact

- shock

- wear & tear

The solvent-free and non-toxic product is preferably sprayed on by means of the MetaLine APPLICATOR S700. It adheres enduringly and absolutely corrosion-resistant to almost all hard and elastic structures. It polymerizes within hours to a rubber-like material with exceptionally high resistance against erosion, corrosion, cavitation and structural loss.

MetaLine 785 is suitable for dry and wet applications. The surface is acting thermally and electrically insulating and may be processed by machining. Temperature resistance amounts to a maximum of 120 °C (250 °F) with dry stressing. Drug and food compliance according to FDA regulations is available.

Technical data

| Material basis | solvent-free elastomers on modified PUR-basis |

| Type of reaction | 2-component material, self-mixing by means of a static mixer |

| Type of application | cartridge spraying, casting and injection |

| Processing tools | MetaLine Applicator S-700 |

| Working conditions | may be processed under high heat and high humidity |

| Thermal treatment | no post-treatment necessary |

| Properties | elastic, impact-damping, slip-resistant |

| Characteristics | resistant against wear, erosion, corrosion, cavitation |

| Layer thickness | 1.0 mm (40 mils) up to infinite |

| Number of layers | processable in one single operation |

| Static surface friction my(0) | approx. 0.6 |

| Shrinking / swelling | not measurable |

| Chemical resistance | usually ph 3-11 |

| Mechanical processability | machinable with most processes |

| Area weight | 1.05 kg per m²/mm (0.22 lb per 40 mils/sqft) film thickness |

| Ready for use | as from 12 hours |

| Color | light grey, dark grey, blue, black, red, yellow, green, natural |

| Substrate preparation | mechanical roughing or gritblasting / degreasing / priming |

| Food compatibility | according to FDA 177.1680 (title 21), EU 1935/2004 |

| Drinking water compatibility | according to British Standard BS 6920 and Australian Standard AZ/NS 4020/2005 |

| Container size | double cartridge with 1.05 kg (2.3 lbs) including mixer/spray nozzle |

| Shelf-life | at least 18 months |

| Availability | immediately ex warehouse |