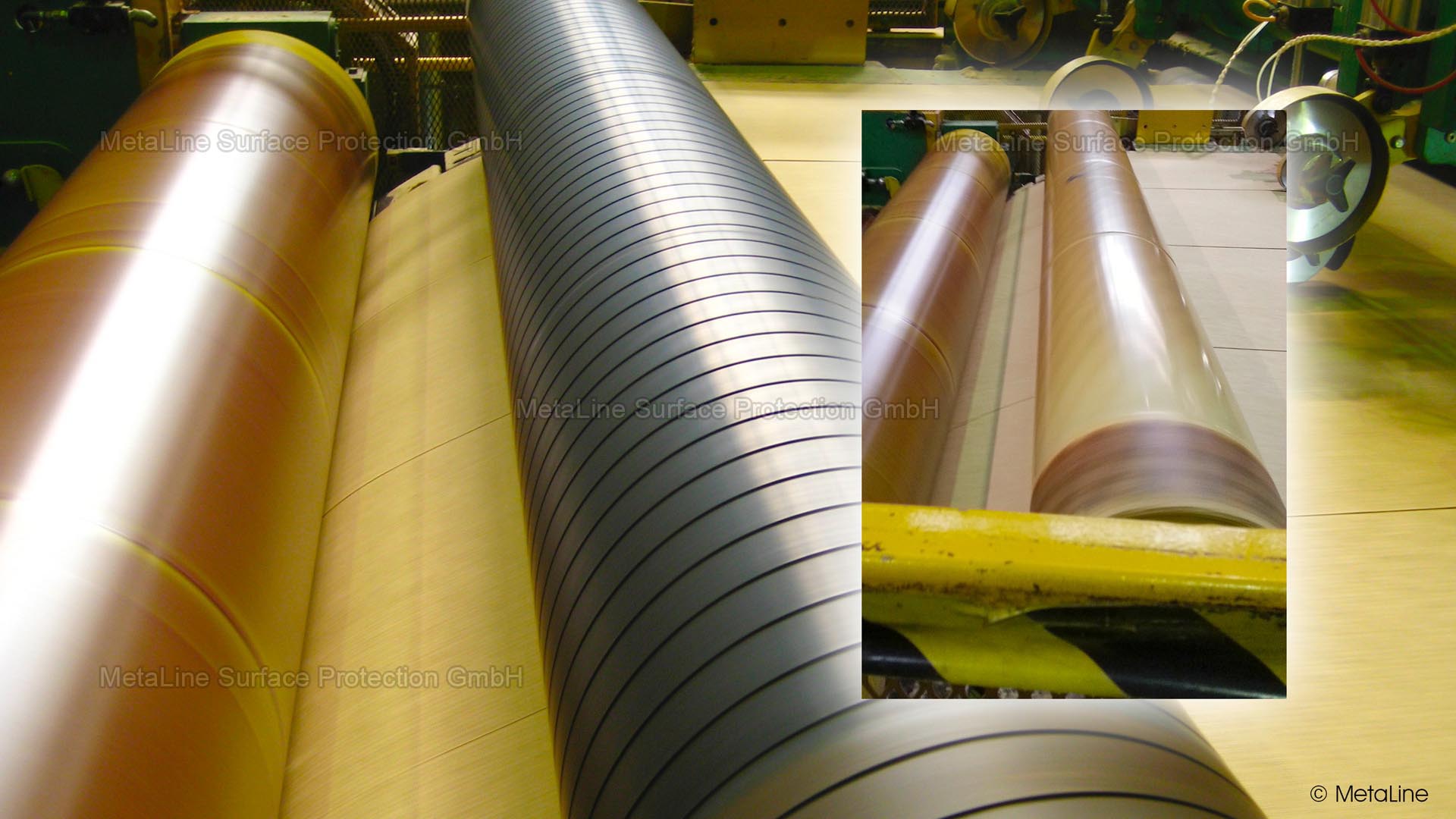

Protective coverings of cylinders and rollers are subject to severe aging due to the permanent flexing work. Glued, shrunk-on or cold vulcanized rubber linings tend to seam or detach. Material sticking to it is also a permanent source of annoying malfunction. Conventional coatings cannot be repaired at all. In addition, designers wish to exert influence in the static and sliding friction values.

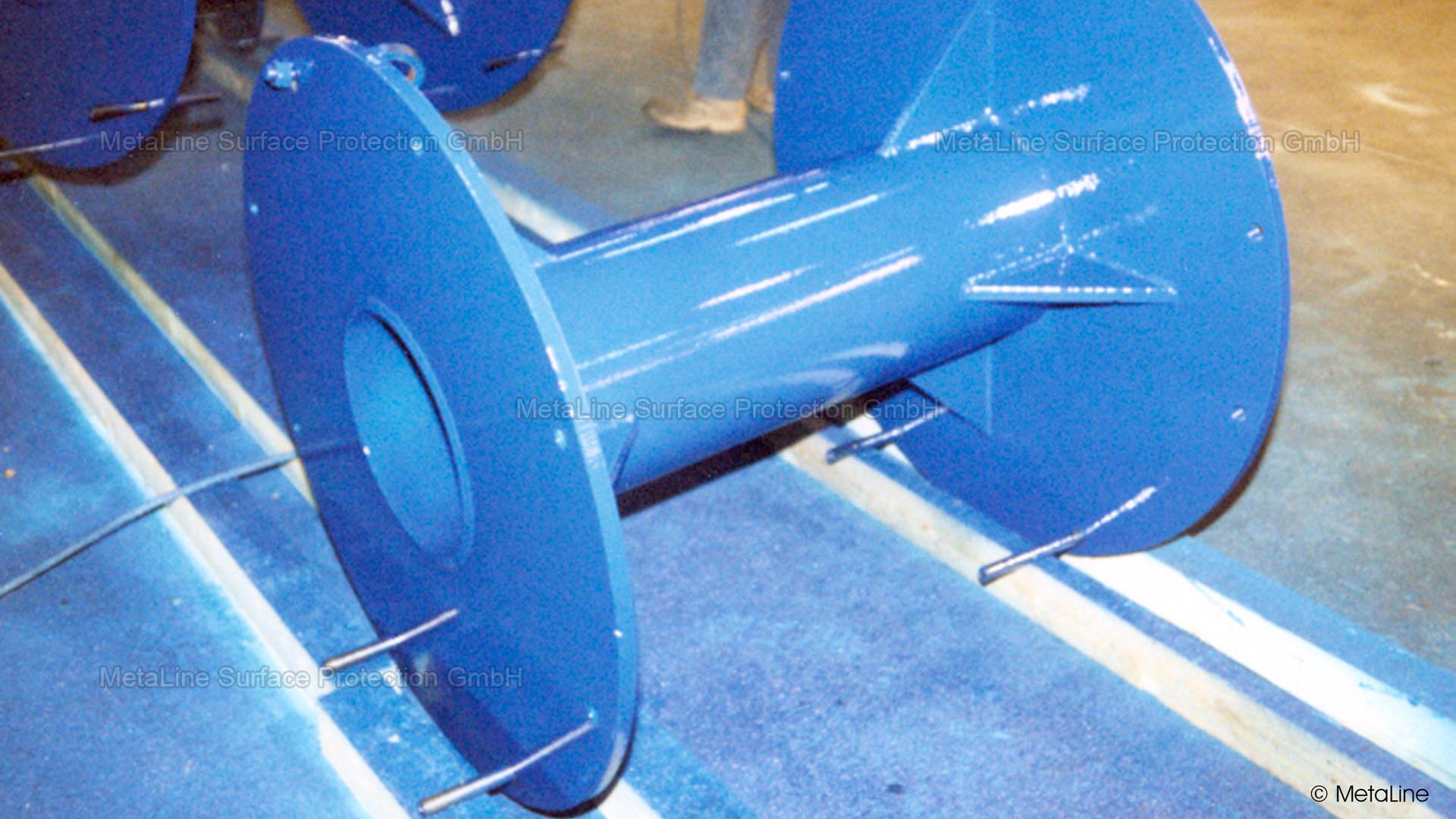

Ask us about: drive rollers (FDA approved coating), vacuum rollers, textile rollers (drive / deflection elements), paper feeding roller, cable reels, pulley lagging, frictional wheels, track rolls, cable sheaves, diabolo rollers, idler pulleys, drive sprockets

We have a solution for problems with gliding on rollers / bearings! Scope of application: Drive rollers (FDA approved coating) Vacuum rollers Textile rollers (drive / deflection elements) Paper feeding roller Cable reels Pulley lagging Frictional wheels Diabolo rollers MetaLine - Technical solutions in detail METALINE SERIES 500/700 MetaLine Series 500/700 coatings fit like a second skin on rotationally symmetrical components. The coating is applied seamlessly and can thus not burst. Detachment is nearly impossible thanks to the enormous adhesion of up to 18 N/mm². Static friction values of my(0) = 0.7 guarantee secure actuation and transport – even with oily or dusty applications. Coating – even on spherical-shaped rollers – is possible without any problems in any desired layer thickness and color.

MetaLine Series 700 – MetaLine Series 700 coatings fit like a second skin on rotationally symmetrical components. The surface is seamless and cannot burst. Detachment is nearly impossible thanks to the enormous adhesion of up to 18 N/mm² (2,600 psi). Static friction values of up to my(0) = 0.7 guarantee safe propulsion and transport – even with oily or dusty applications. The coating of all forms of rollers is easily possible in almost all desired layer thicknesses and colors.