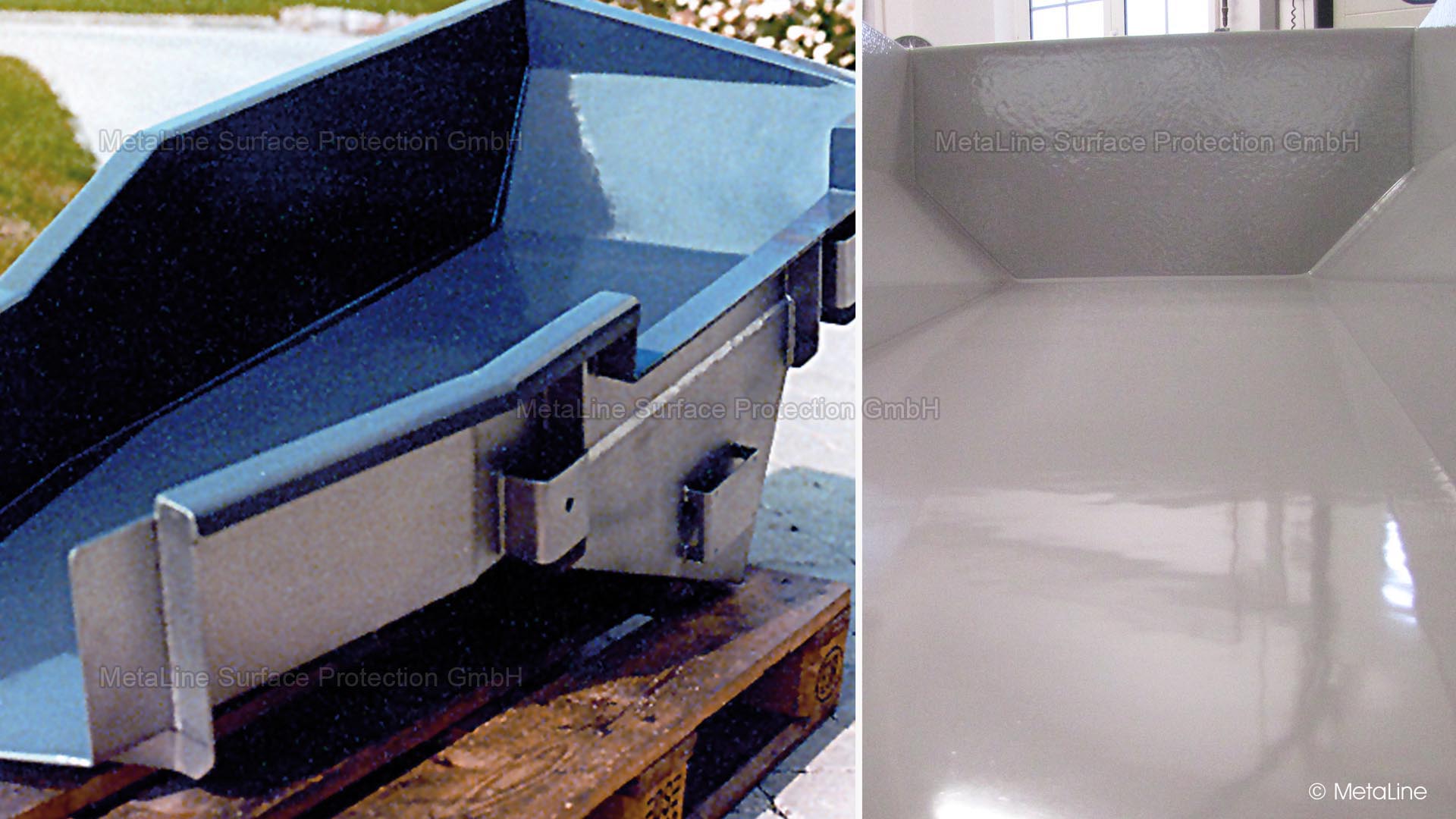

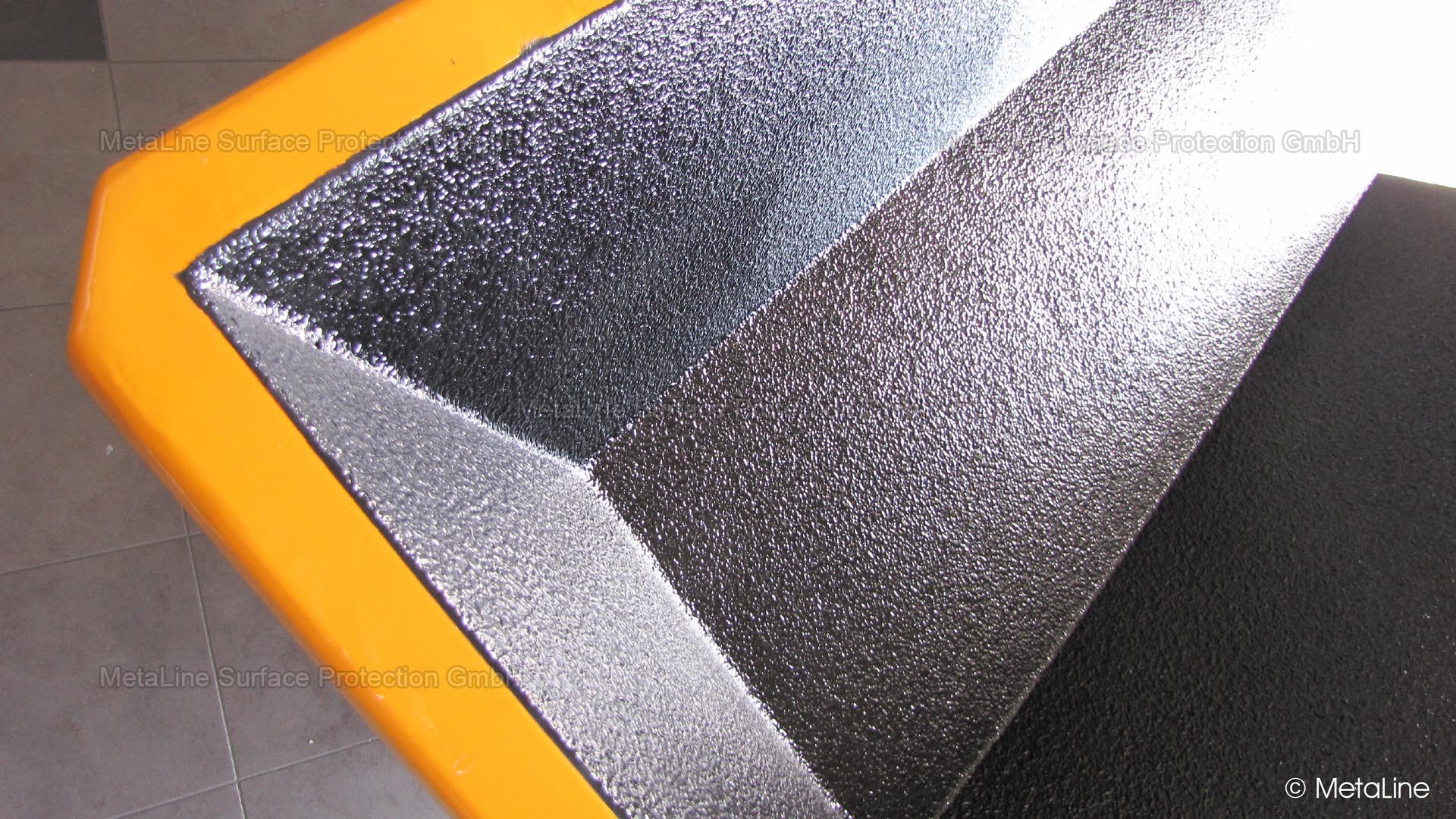

Trough-shaped vibrating feeders are subject to very different stresses. In the edge area, the conveyed material tends to stick or jam. In the center area, the filling causes a rather high impact and bouncing effect. The continuous sliding over it leads to a cut-like load.

Hot parts, as for example in electroplating technology, reduce the lifetime additionally. In addition, the vast majority of systems generate a deafening noise.

Ask us about: tubular conveyors, conveyors / slides / trays, vibratory trough dosing devices, drag conveyors, vibrating tables, linear feeders

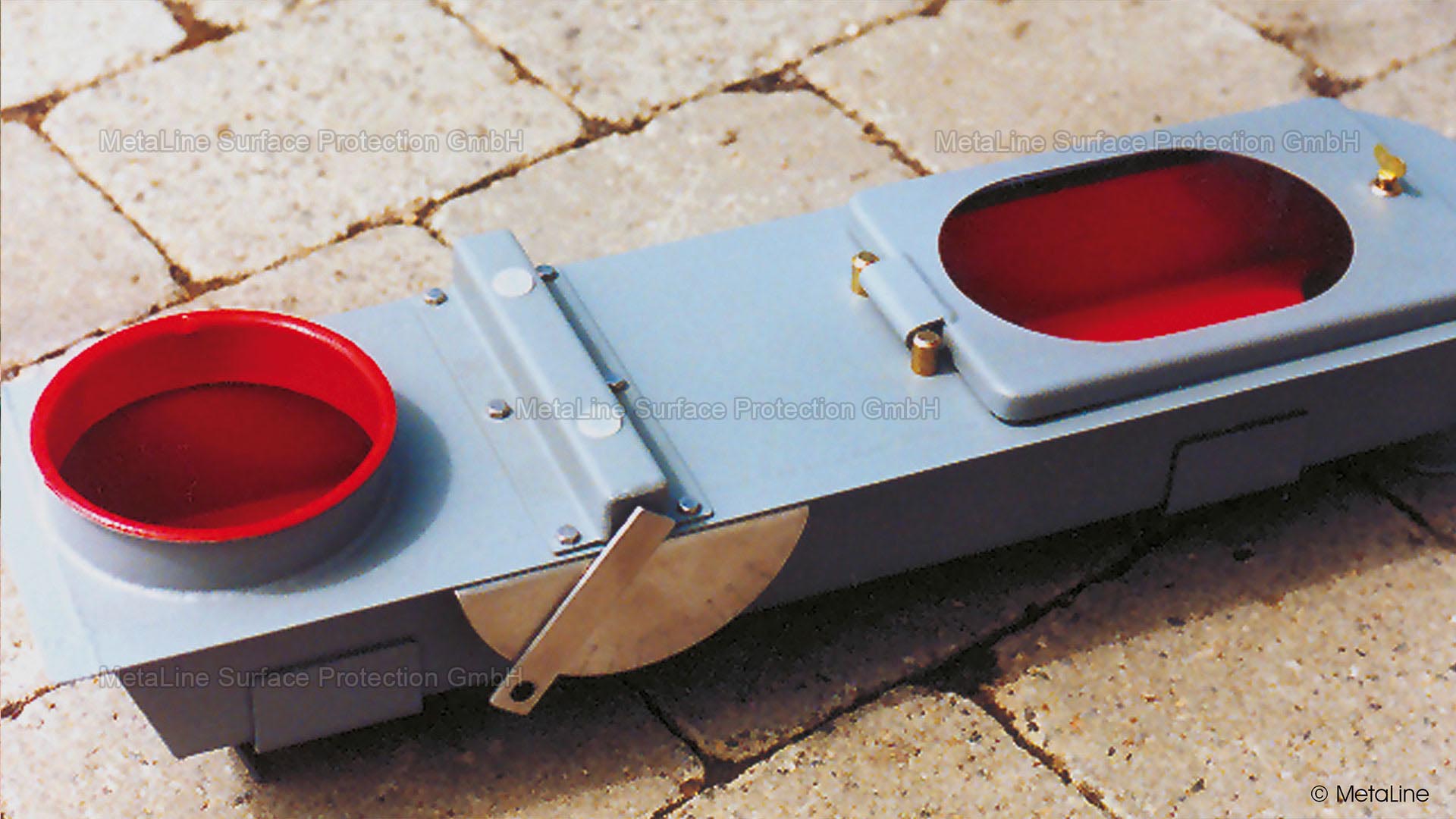

We have a solution for conveying problems in vibration conveyors! Scope of application: Pipe conveyors Chutes / slides / trays Feeding troughs Vibratory trough dosing devices Vibrating tables Linear feeding lines MetaLine - Technical solutions in detail METALINE SERIES 700 MetaLine Series 700 coatings resist influences caused by impact, grinding and scratching. Permanent usage temperature may reach up to 140°C. Due to seamless lining, borderline penetration or carry-over of parts is avoided and thus single-variety transport ensured. After application of MetaLine, the surface shows very low static friction (anti-sticking features) and is easy to clean.

MetaLine Series 700 – MetaLine Series 700 coatings resist impact, sliding or scratching effects. The continuous operating temperature can be up to 120 °C (250 °F). There is no delamination or parts migrating under the seamless lining - a sorted transport is ensured. The surface can be equipped with a very low static friction (non-stick effect) so that complete self-draining is supported. The coatings are easy to clean and dampens metallic impact noises.