Cylindrical, conical or stepped feederbowls – MetaLine is unique when it comes to adapting the equipment surface characteristics to the parts you have to feed

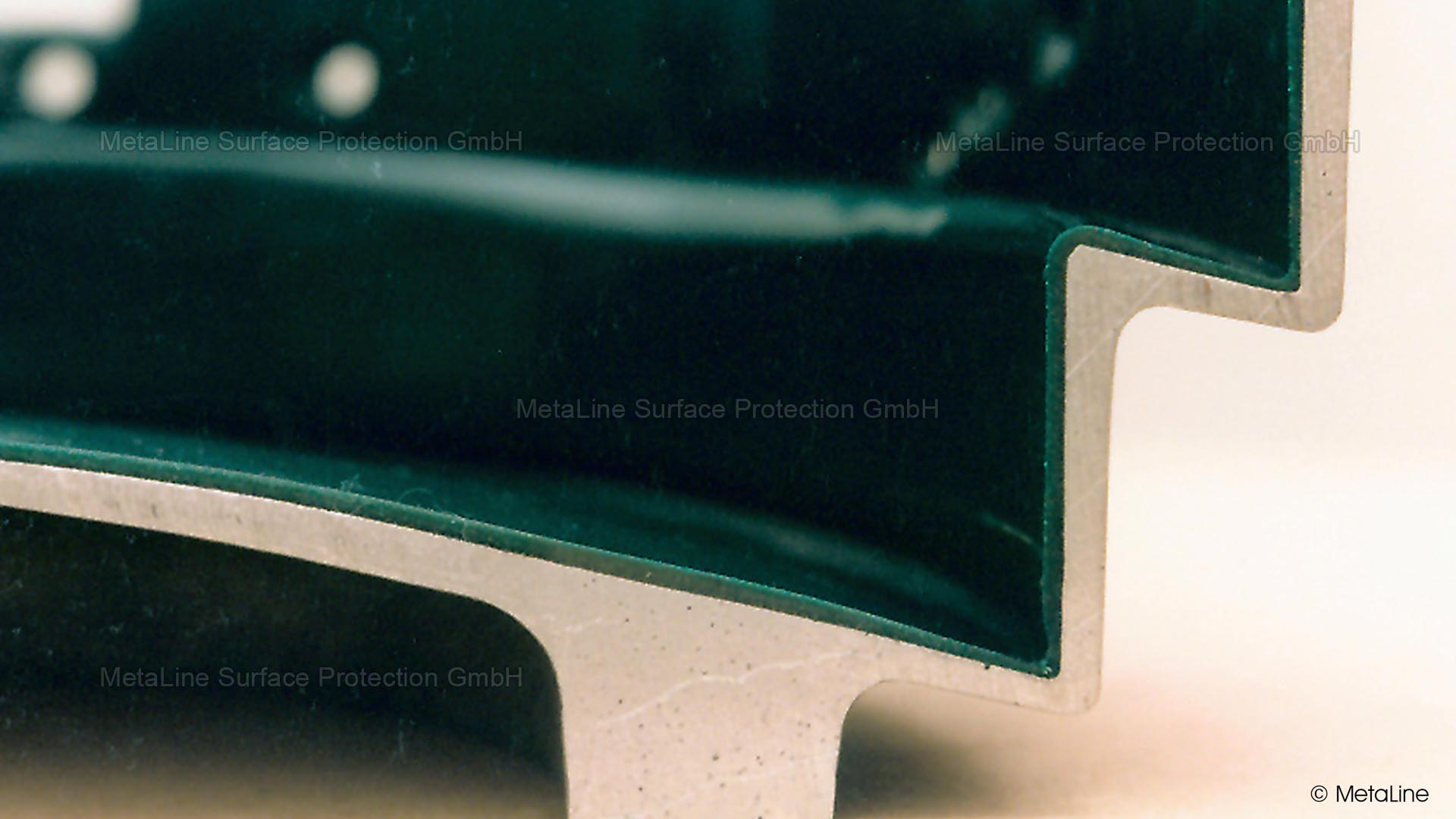

Bowlfeeder coating – uniform, edge-true geometry! The MetaLine spray coating shows its perfection

Screw feeding systems – MetaLine is the lining standard for most European equipment manufacturers

Bowlfeeder lining – how long MetaLine coatings will last? In many cases longer than the life cycle of the feeded part . . .

Bowl feeder coatings with a maximum scratch protection concept – coated girders and beams

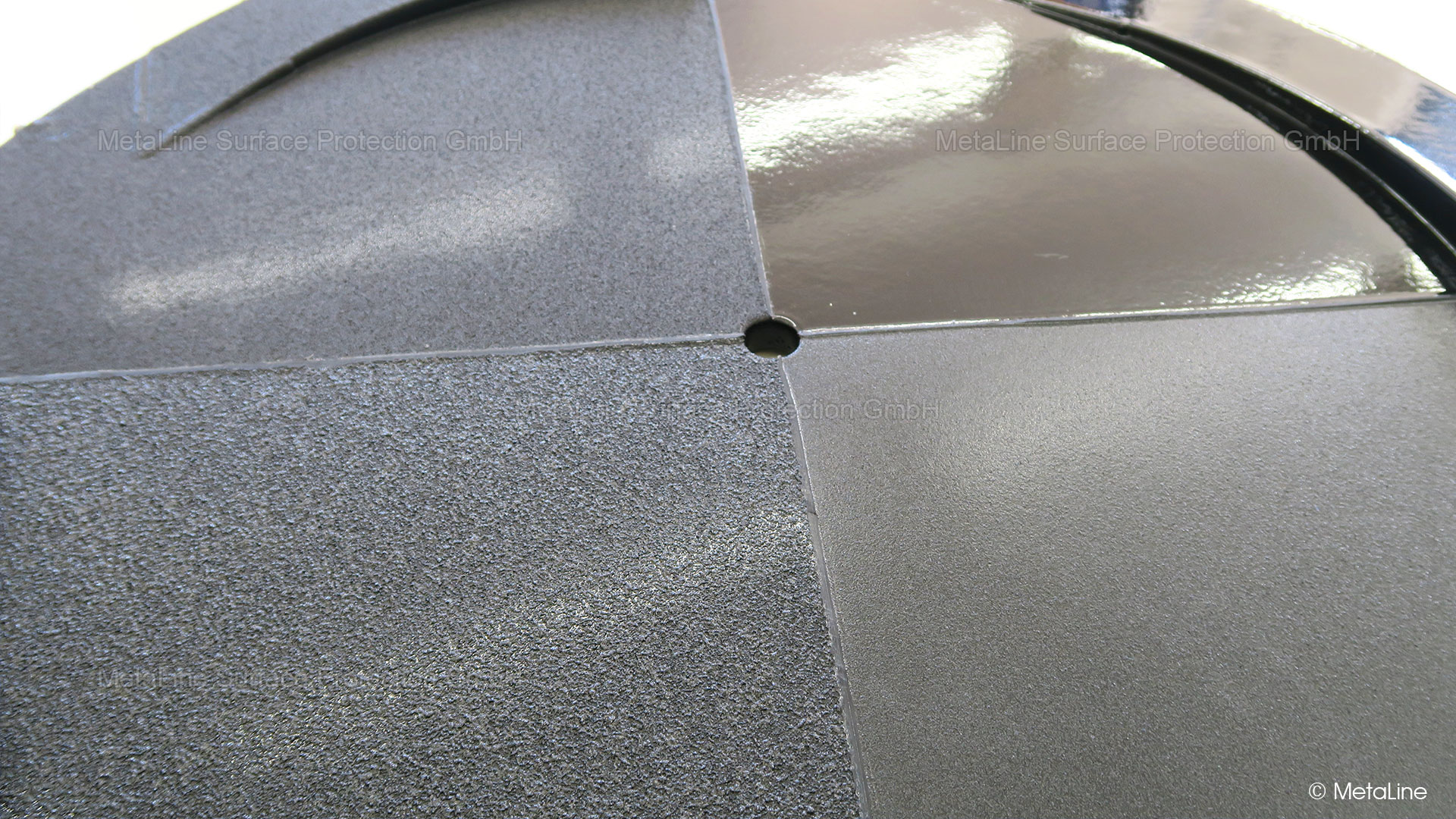

Irrespective if smooth or structured – MetaLine offers individual surface adaptions for your feeding problem

Pharmaceutical coatings – FDA-compliant services for food, drugs and medical engineering

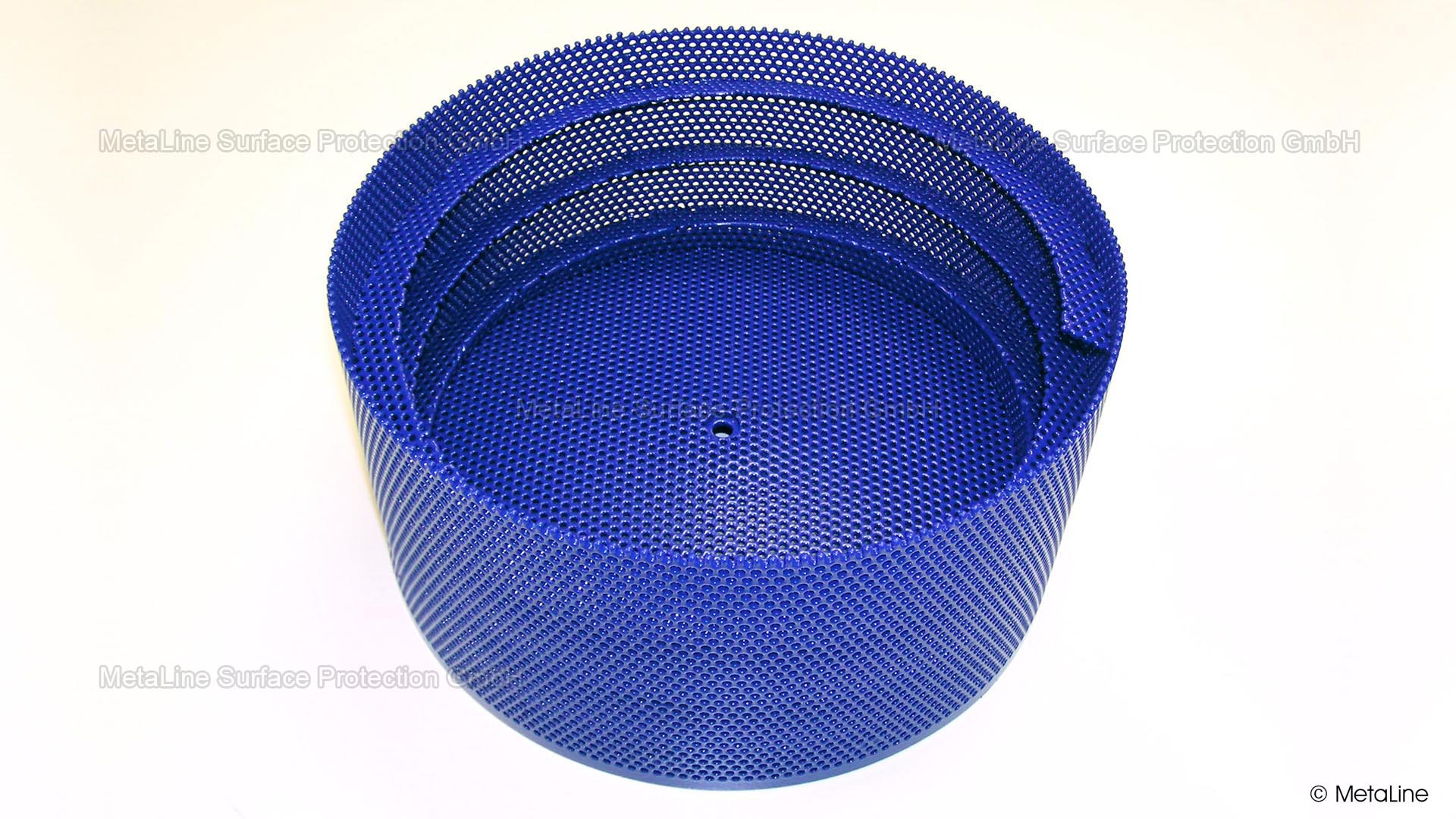

Vibratory bowl coating – a special design being punctured. Nevertheless successfully coated with 1,5 mm MetaLine 590

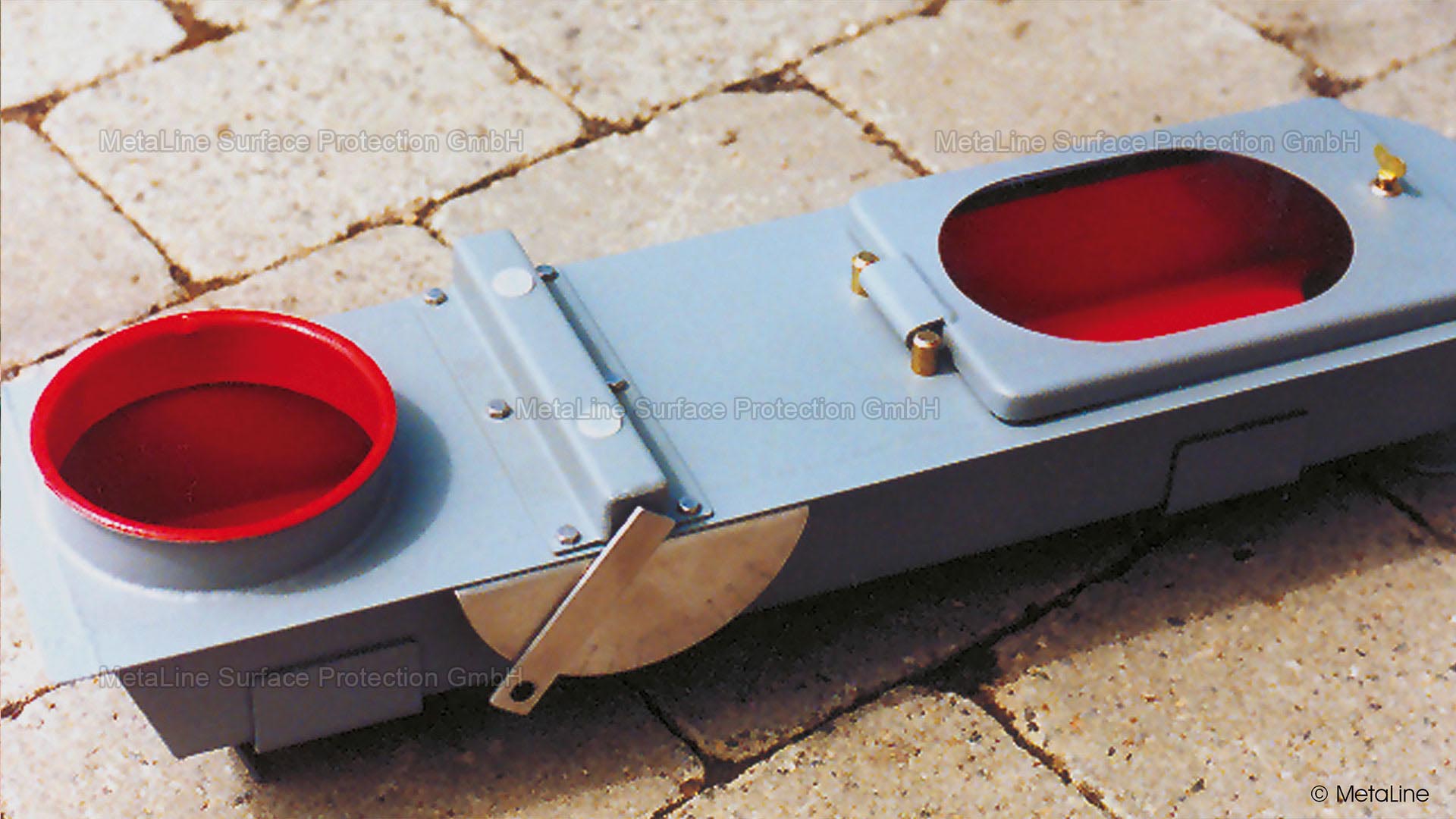

Linear dosing device – coated seamlessly on the complete inside with 2 mm of MetaLine 580 – that is truly a difficult work but not a real problem for MetaLine and its crew

Pharma coatings – small hoppers for medical engineering purposes electroplated on the outside and MetaLine coated on the inside

Elevator feeder – MetaLine coatings help irrespective of the inclination. We can combine soft-touch characteristics with different degrees of low or high surface friction levels

Feeder coating – if your goods have to be manipulated and guided smoothly, MetaLine with its elastomeric surface protective coatings is the first choice

Bulkfeeder coating – noise reducing and non-scratching characteristics are a prime issue. This hopper was optimized with a MetaLine 795 coating to fullfill these demands when feeding large plastic caps

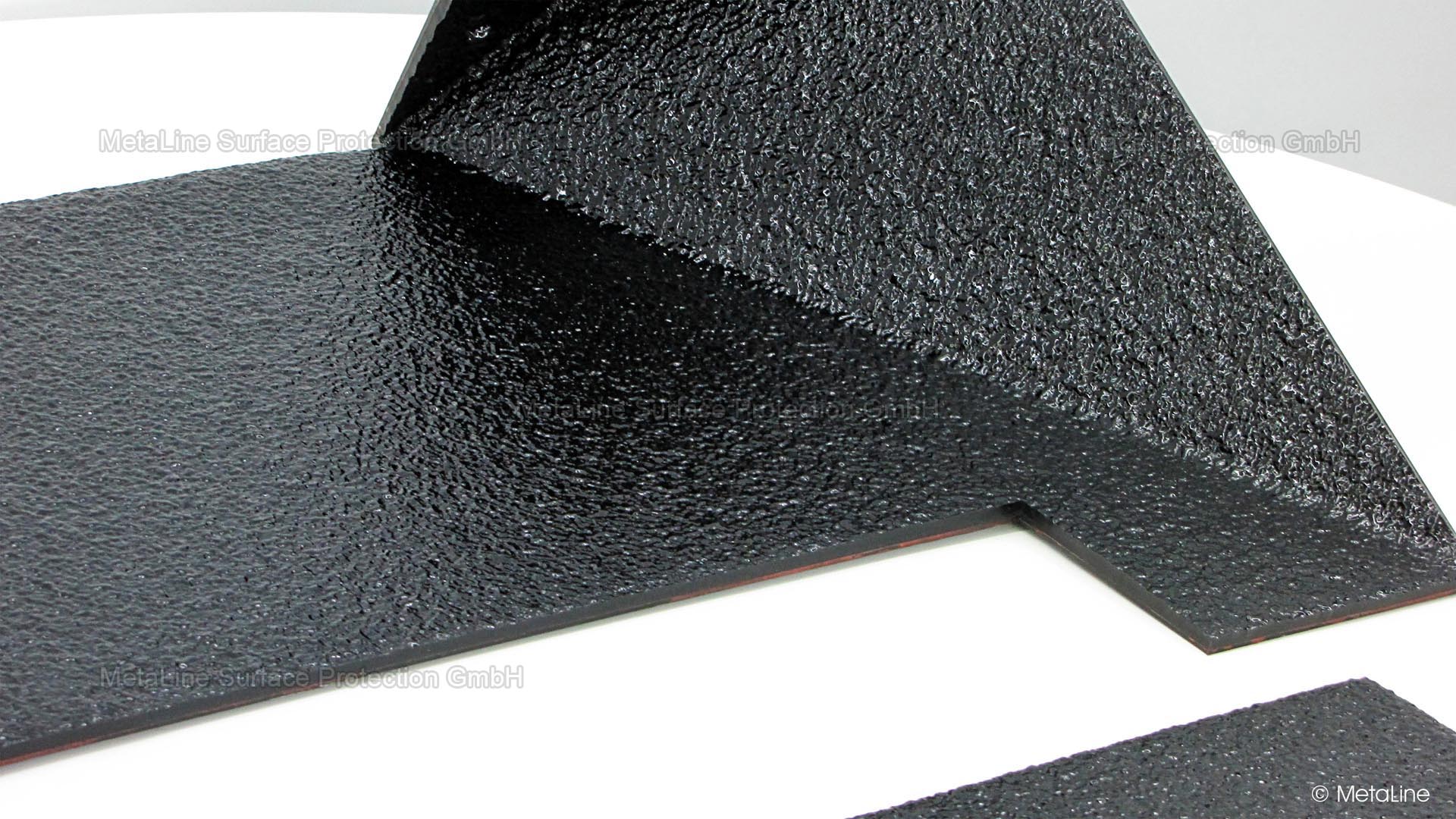

Structured coating – MetaLine 795 as highly profiled, feed enhancing coating to prevent oily bulk materials sticking to the surface

MetaLine in supply storage

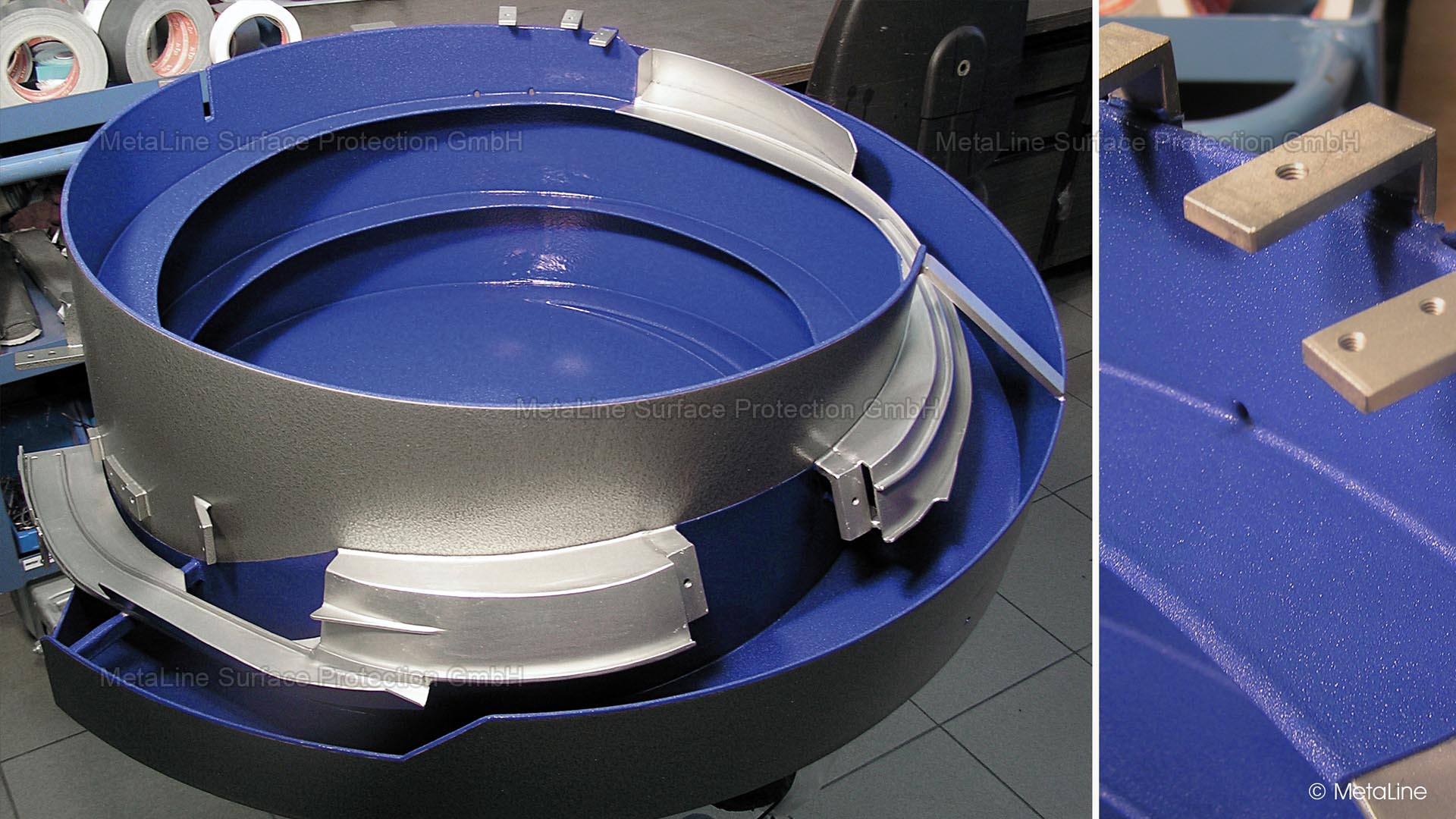

Stepped vibratory bowlfeeder coating – even in multiple levels MetaLine coating feeds to the very best. This equipment has been coated with MetaLine 590 in a thickness of 1.5 mm. At the end a fine structure optimizes the feeding characteristics

An external helix conveyor with extraordinary dimensions