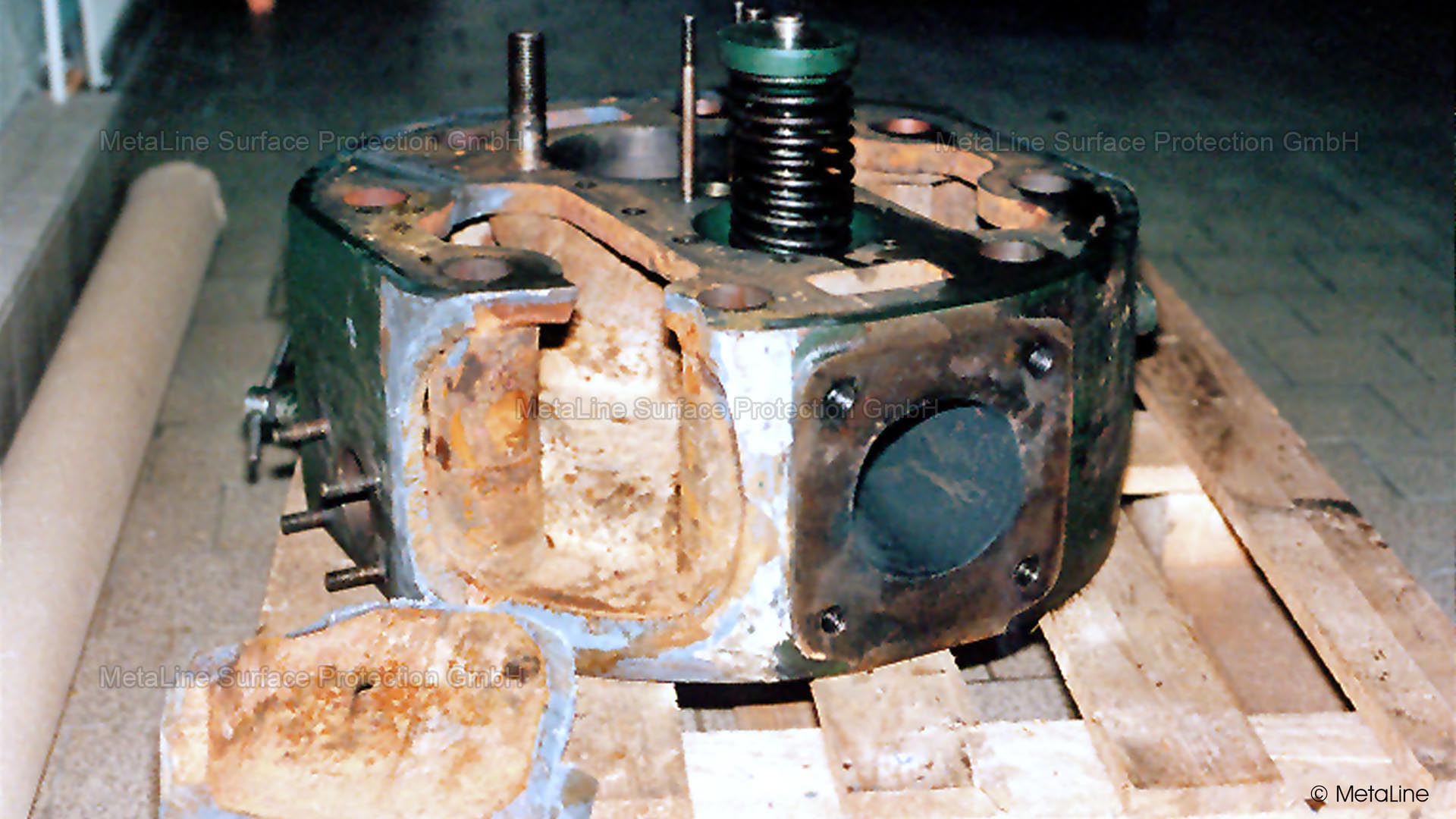

Breakage repair - enormous breakage damage. The broken part is essential for a repair. Without this, a repair is no longer practical, as the entire material statics are irreparably disturbed. Unfortunately, MetaLine cannot perform any chemical miracles!

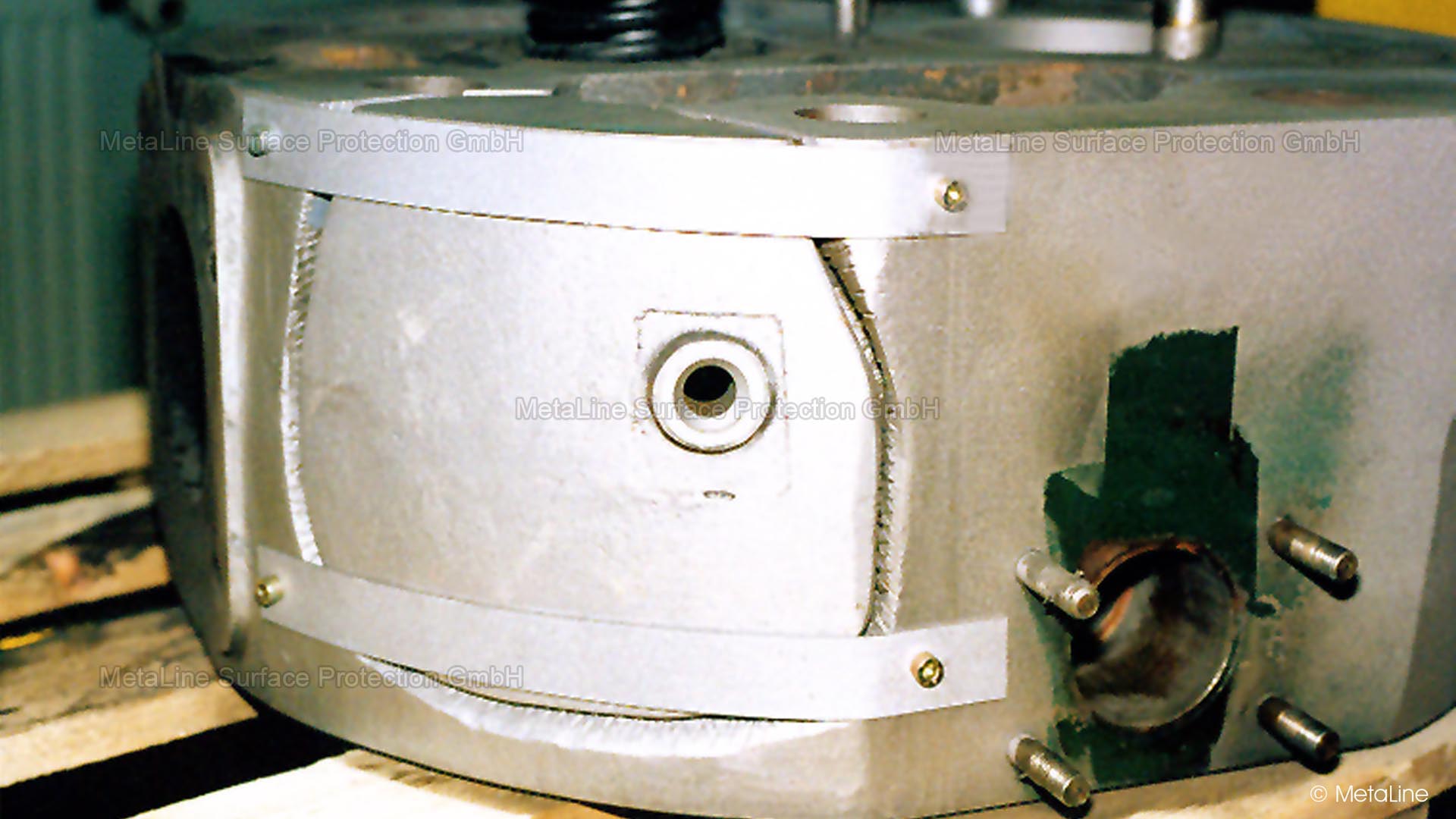

Housing repair - the damaged area was mechanically prepared and sandblasted. Metallic reinforcement bars secure the statics and the MetaLine SXL repair material ensures sealing. Physics and chemistry in sensible symbiosis!

Breakage repair - during the repair measure with the MetaLine repair ceramic SXL. To absorb the operational thermal expansion in the casting, 2 additional tension bars must be installed!

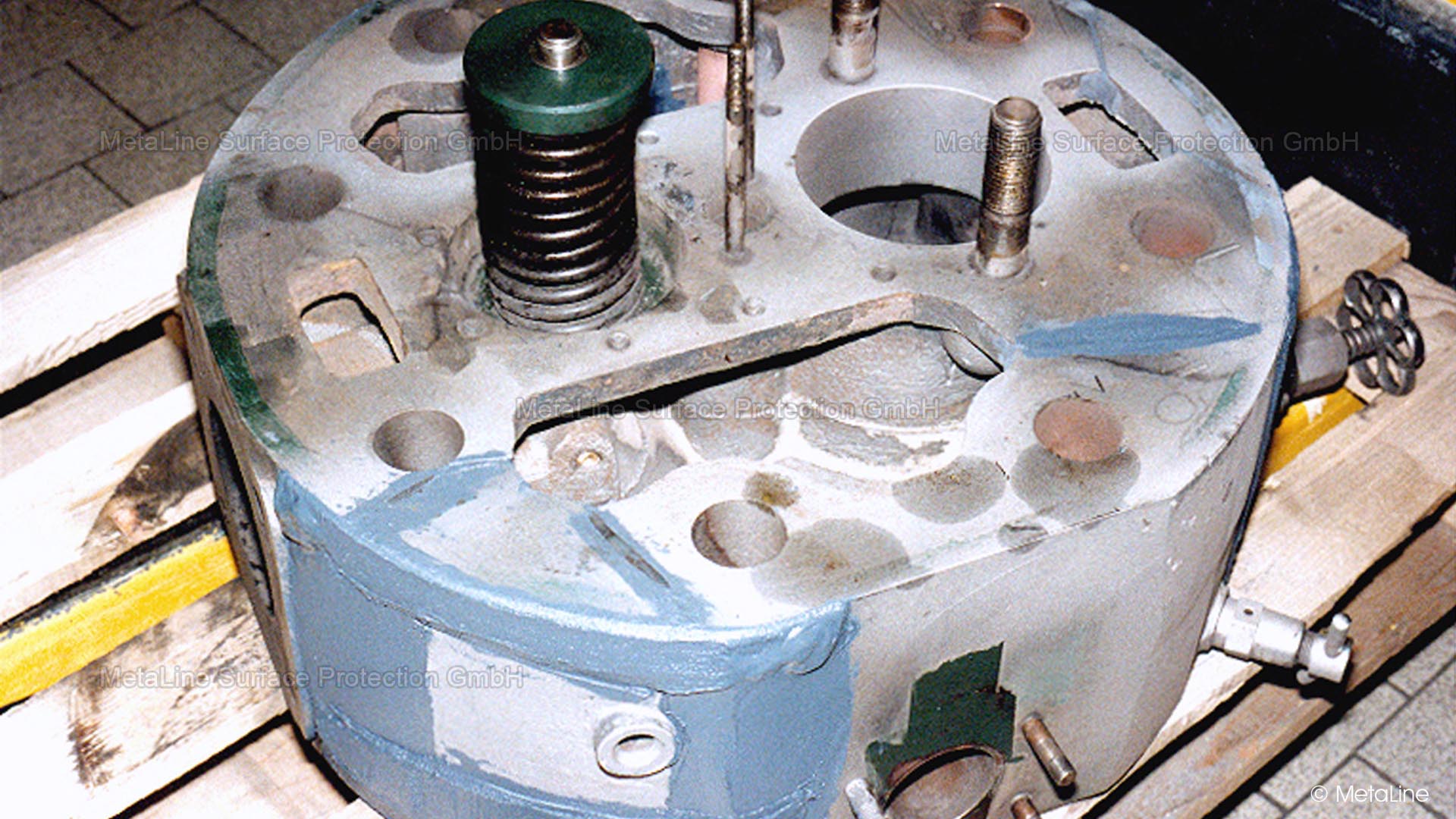

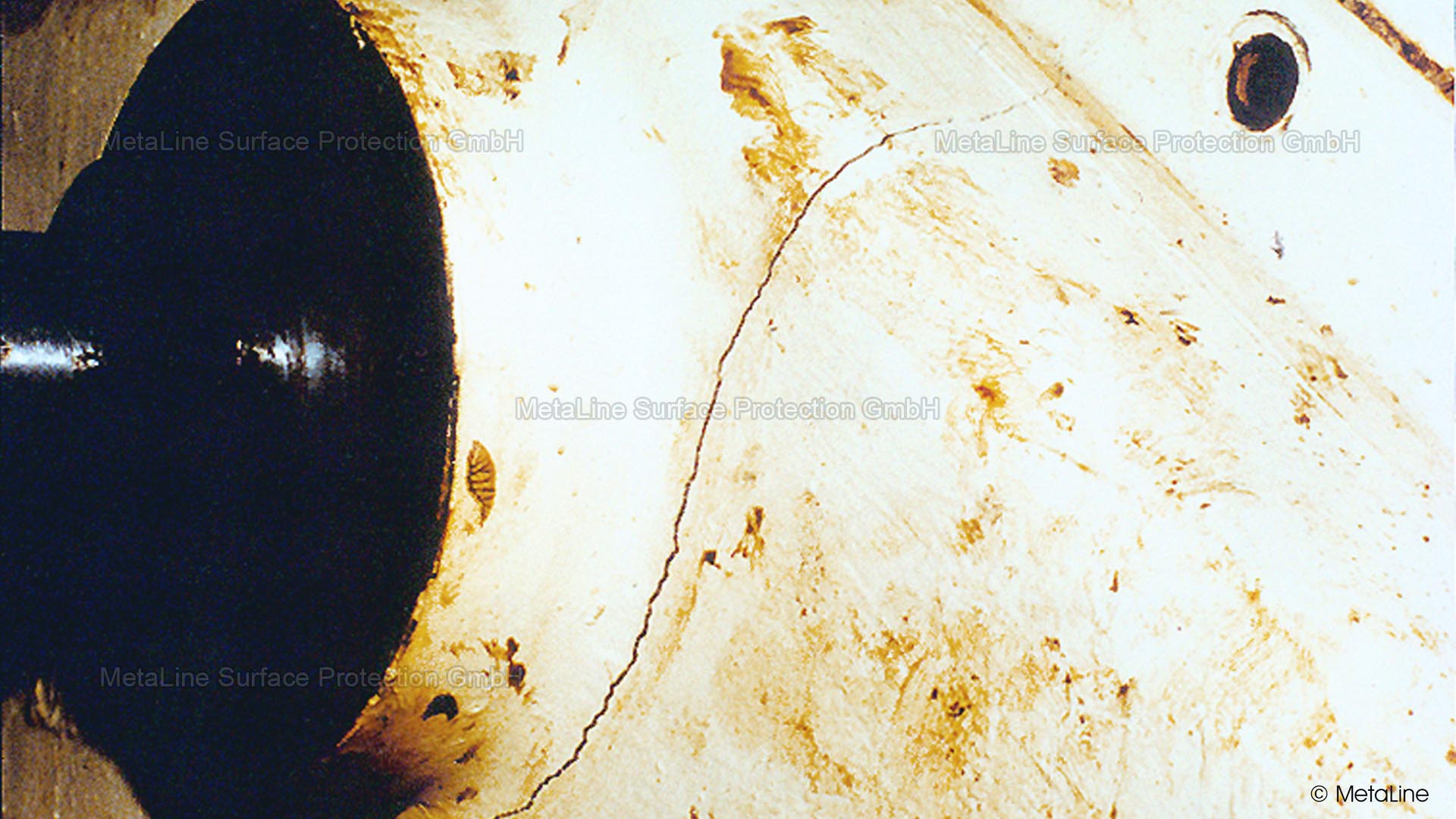

Housing seal - massive cavitation damage has led to a weakening of the structure and thus to breakage. The existing crack ends were properly drilled out. Unfortunately, the customer did not want to carry out mechanical reinforcement for functional reasons. A negligent technical compromise!

Housing fracture repair - the entire defect was filled with MetaLine repair ceramic SXL. A metallic mesh was incorporated inside. But that is not enough! It should have been reinforced with a steel plate at least on one side, better on both sides . . .

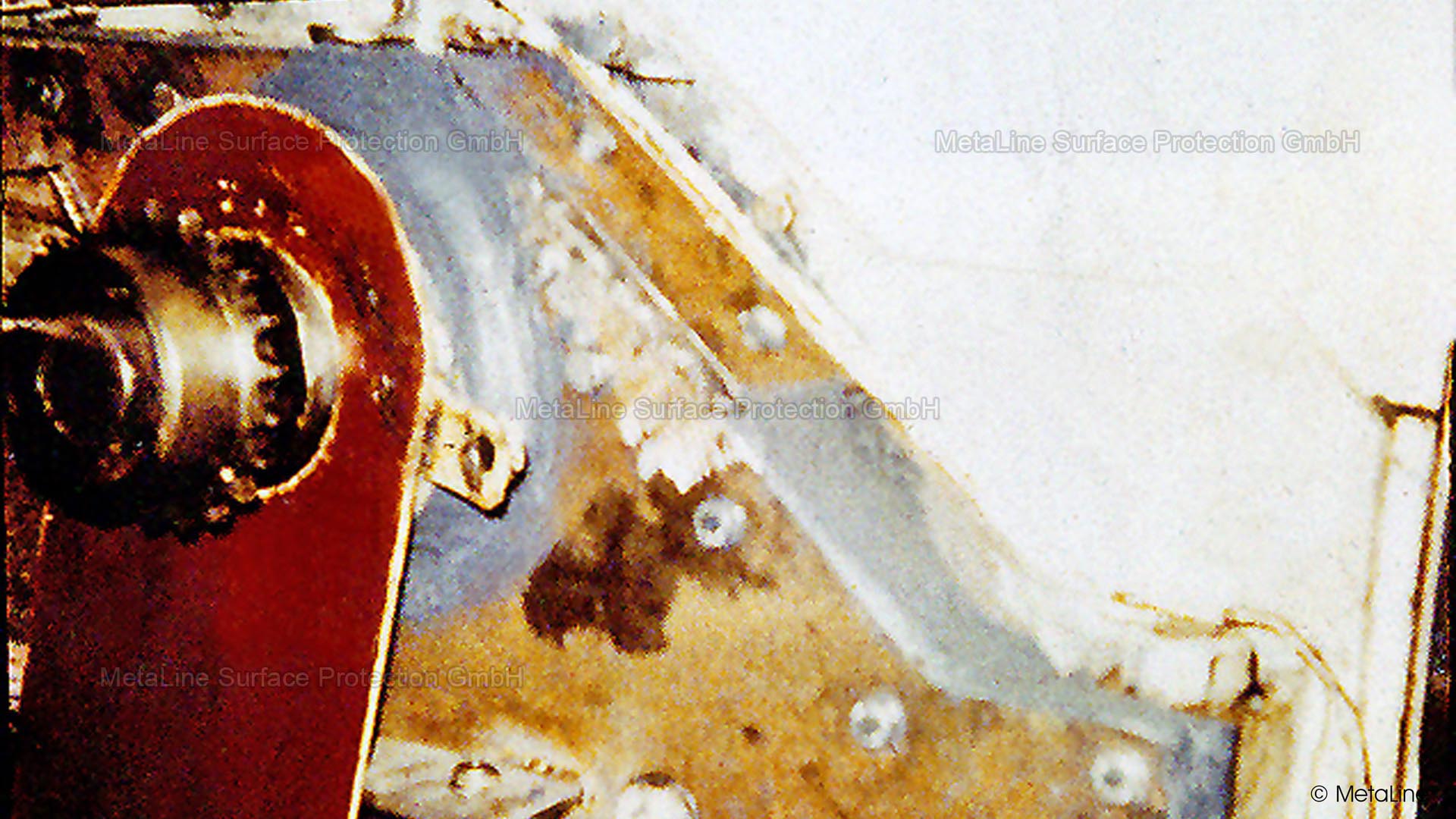

Housing breakage - this is also part of a successful on-site repair. If the surface temperature is too low, the housing must be enclosed and heated for the duration of the repair. At temperatures below +15 °C, the risk of detachment increases exponentially!

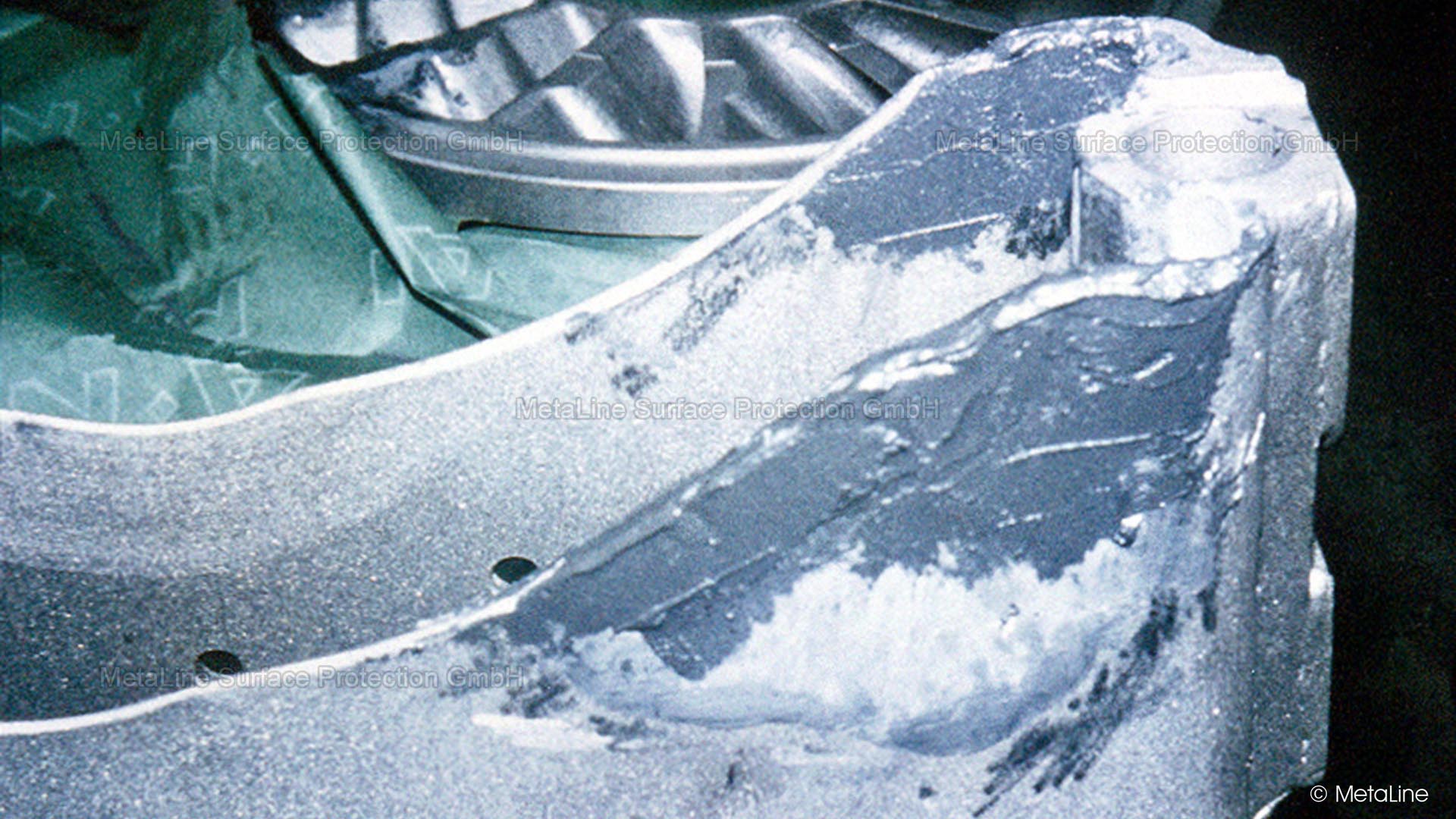

Housing crack repair - a base of a hydraulic press weighing several tons - cracked! Conventionally only repairable by “metal stitching”. However, the customer decided to repair it with our polymer technology for reasons of availability

Crack restoration - fitting of the required steel reinforcement using MetaLine repair ceramic SXL - in this case on the inside and outside of the housing. The operating load is too high for one-sided reinforcement . . .

Crack sealing - successful crack repair with MetaLine! The process is also available for the repair of injection molds. We apologize for the poor image quality - unfortunately the components cannot always be put “in the right light”!