Synthetic repair processes are not yet omnipresent in mechanical engineering - but are being used more and more. What's wrong with the supplier who has the longest experience in this field? MetaLine - polymer solutions for metallic problems since 1960. No one has done more pioneering work . . .

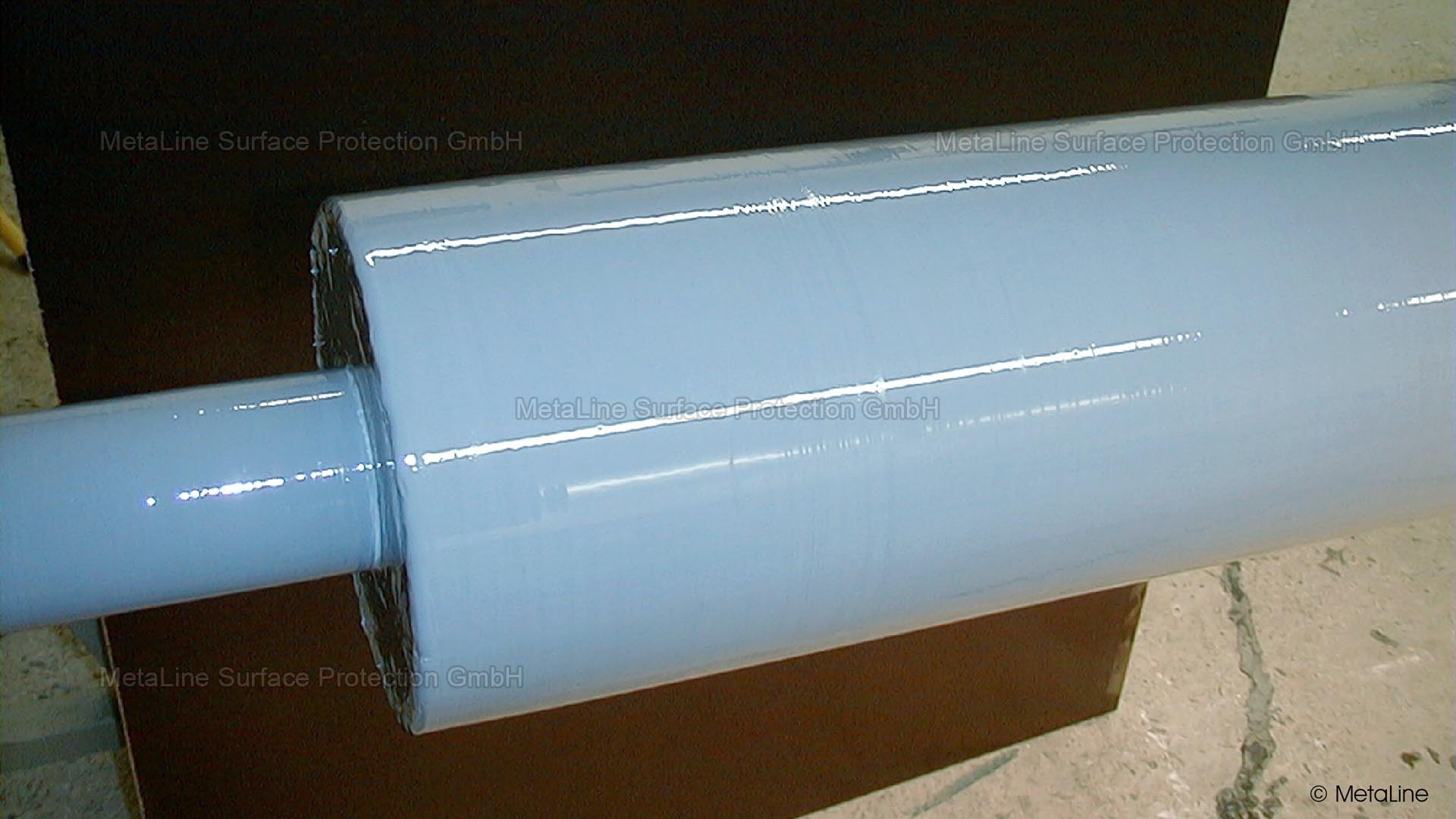

Protective coating of a ship's shaft with our synthetic ceramic MetaLine KXL. Impressive and functionally a good solution - but physically the elastomers of our MetaLine Series 700 are even more impressive here - because we can additionally protect against impact and shock effects

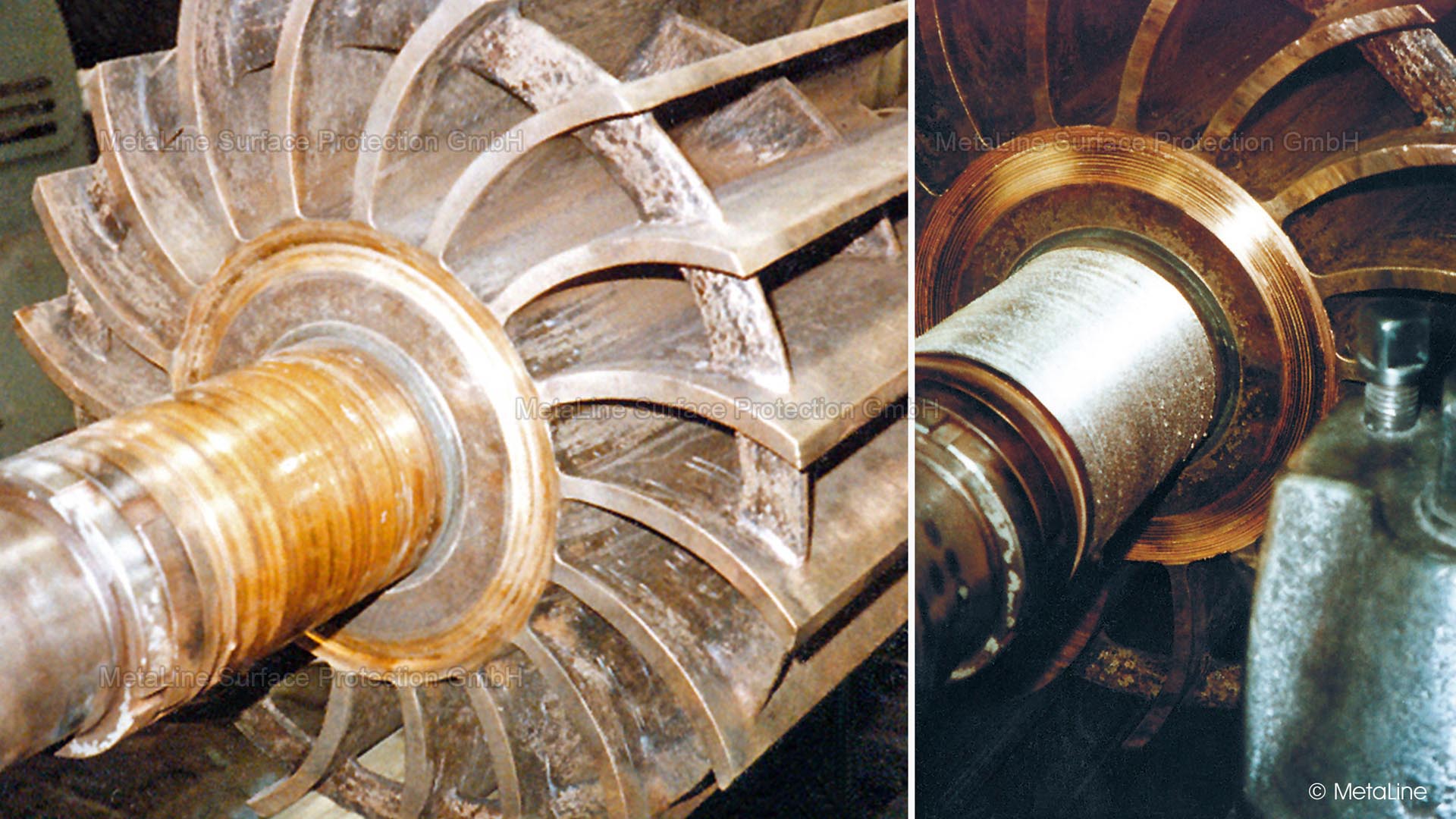

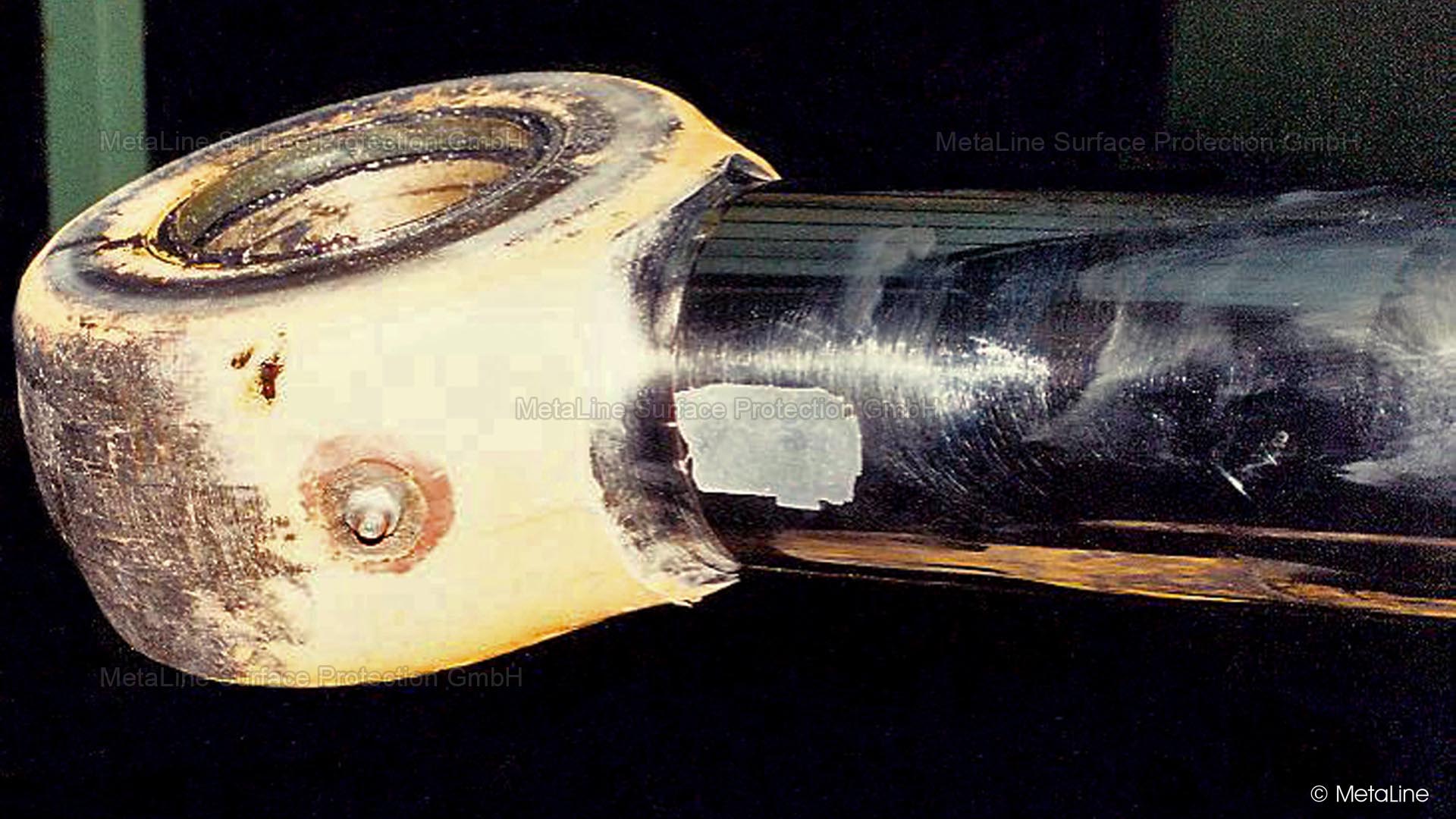

Shaft repair - worn-in bearing area on this vacuum pump. A solvable problem if a professional preparation and a precise execution takes place. Unfortunately, this flaw is often attached to do-it-yourself procedures. MetaLine repair ceramics for such an application is neither quick nor easy - but functional!

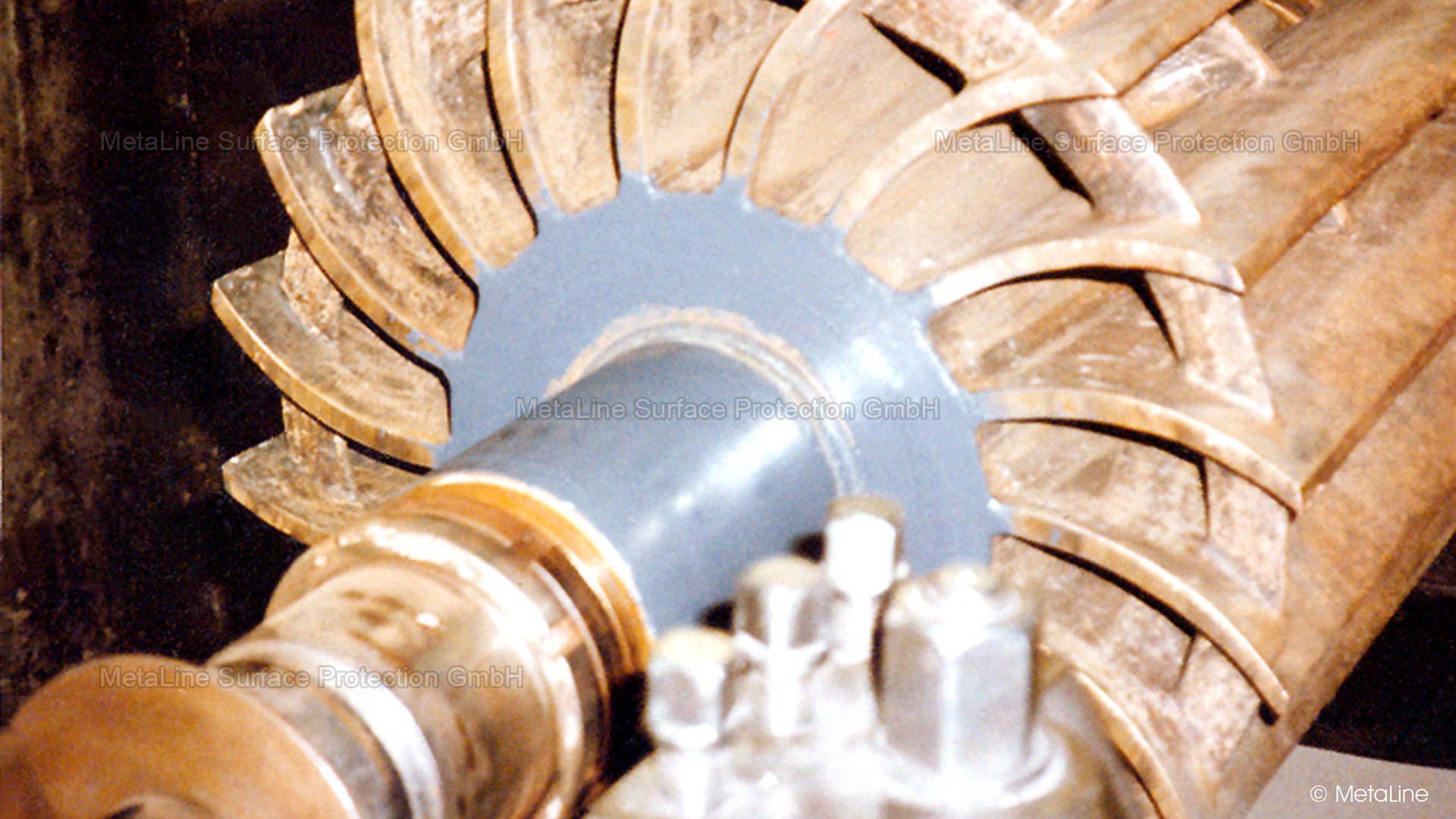

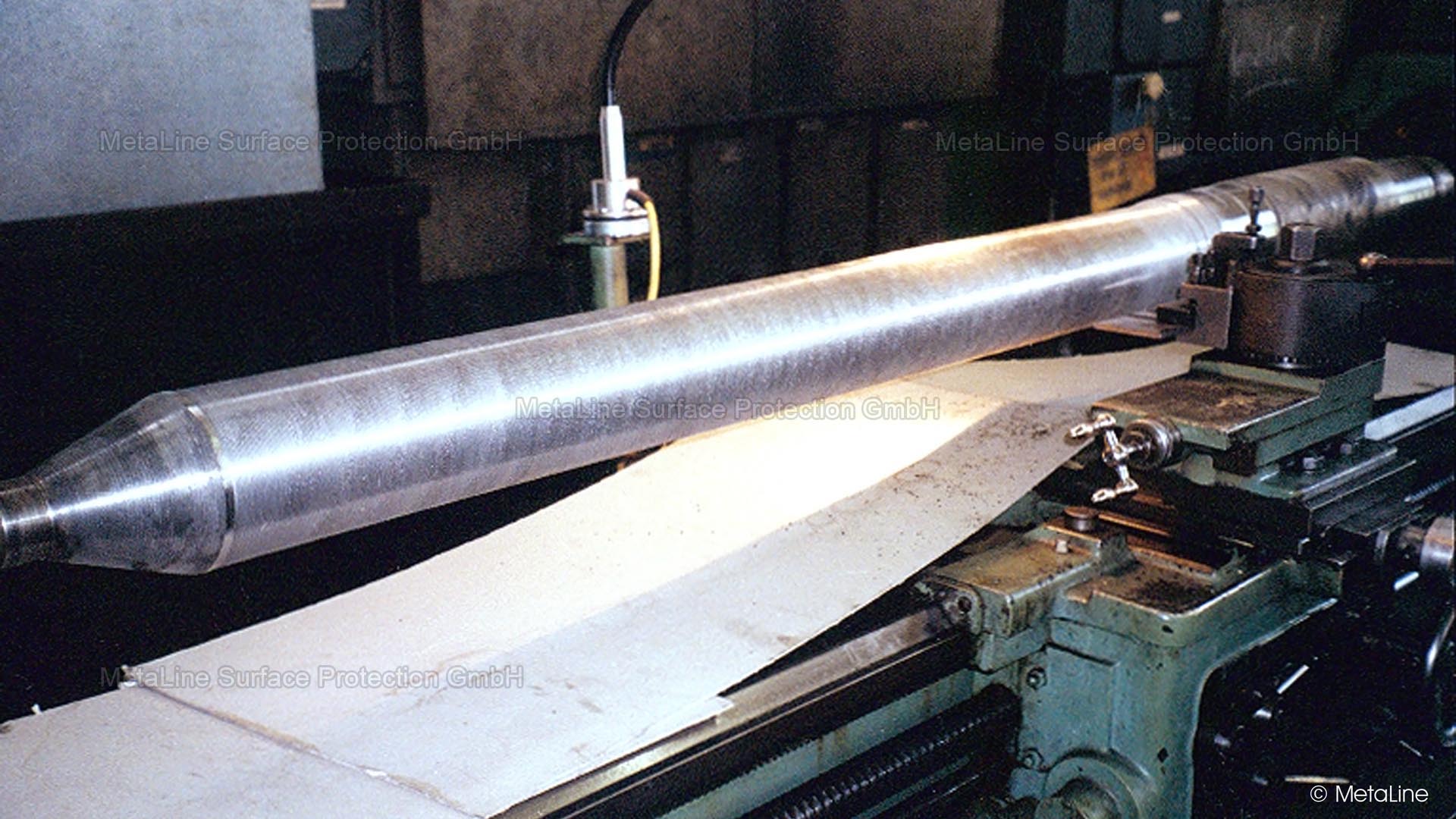

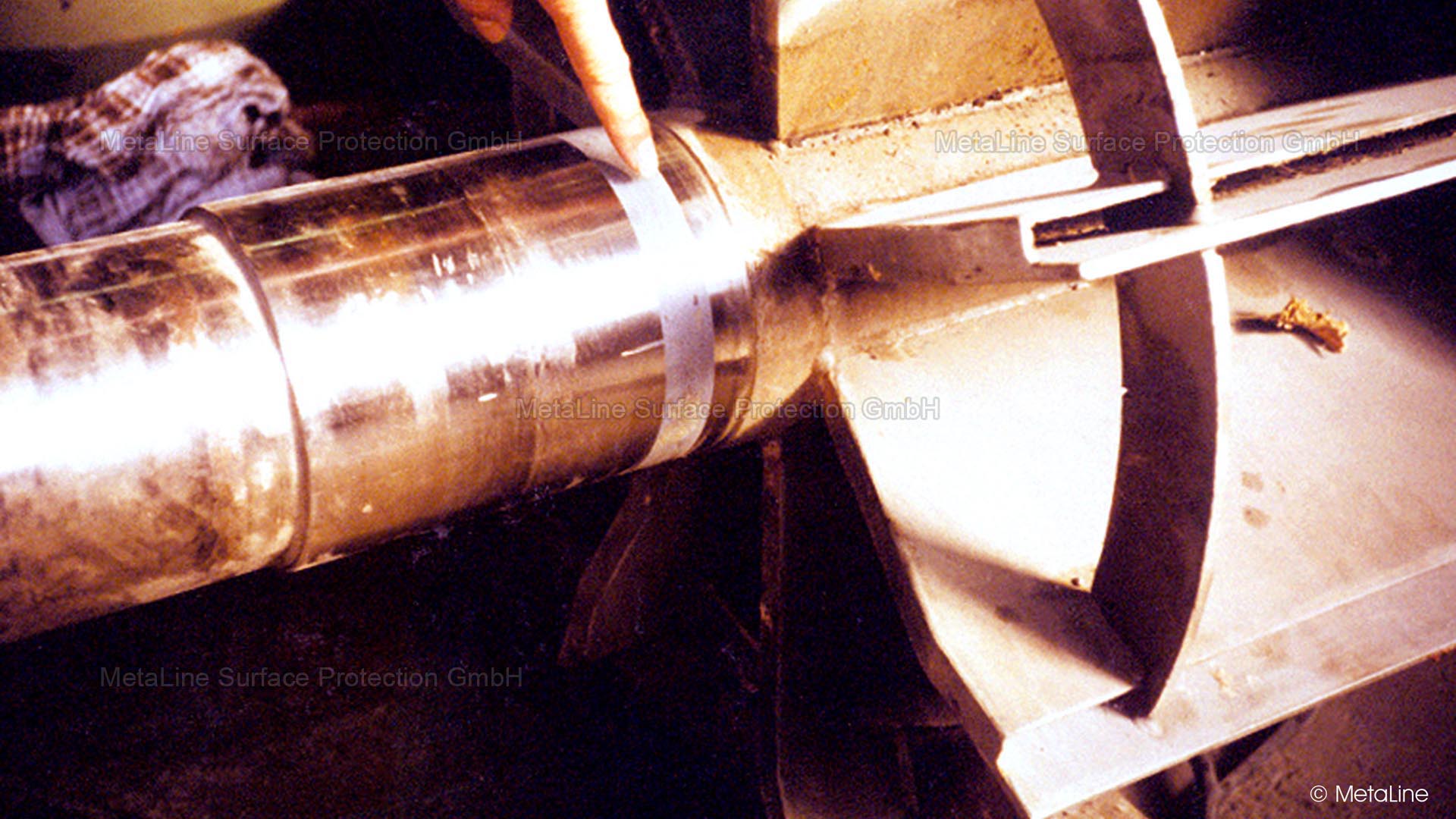

Shaft coating - a new ceramic bearing area executed with the trowelable MetaLine repair ceramic SXL. The finishing is done with diamond tools. Why? What is supposed to be wear-resistant naturally also has a wearing effect on conventional tool steel. There is no better proof of the linear wear protection function of our process!

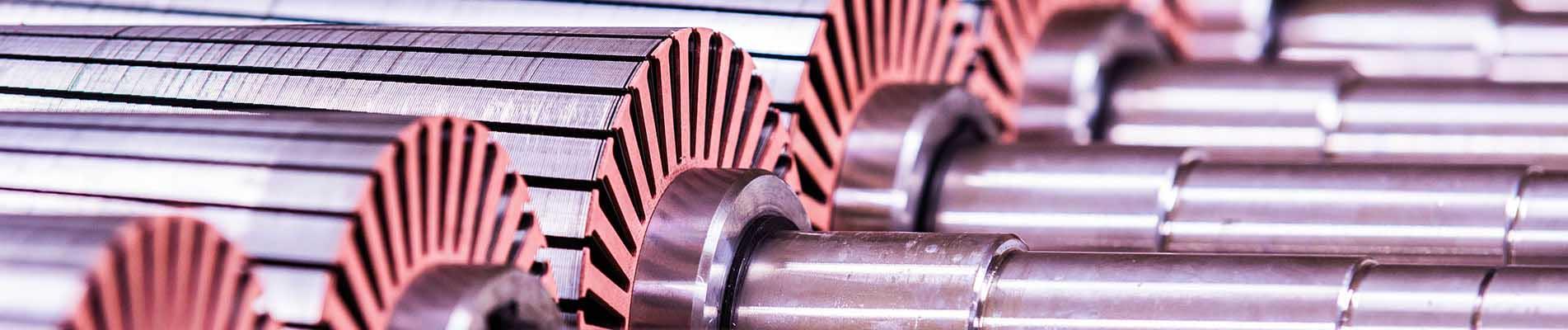

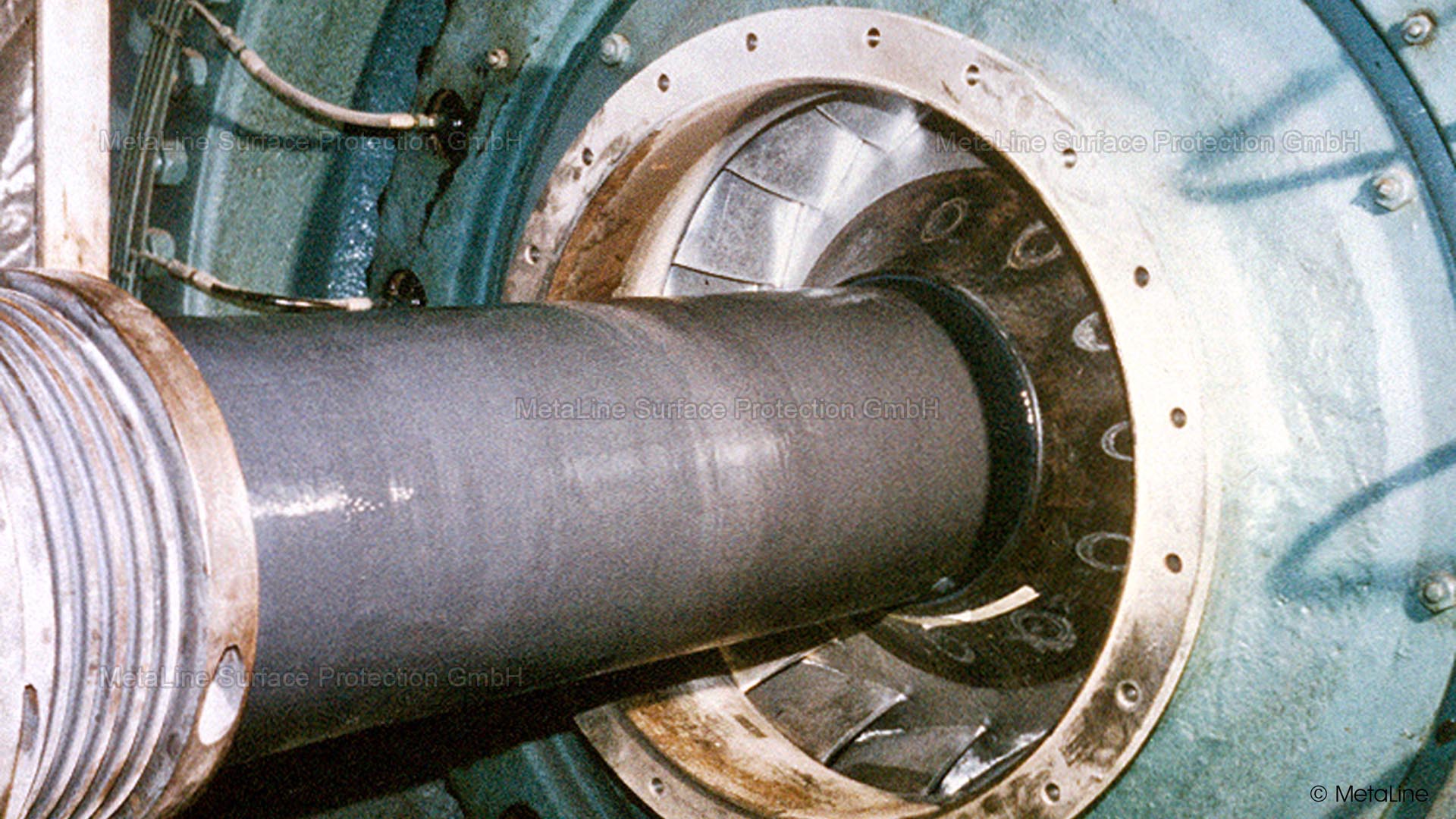

Shaft repair – this is a typical application for MetaLine Ceramic Repair compounds SXL. Electrically insulating and free of fretting corrosion

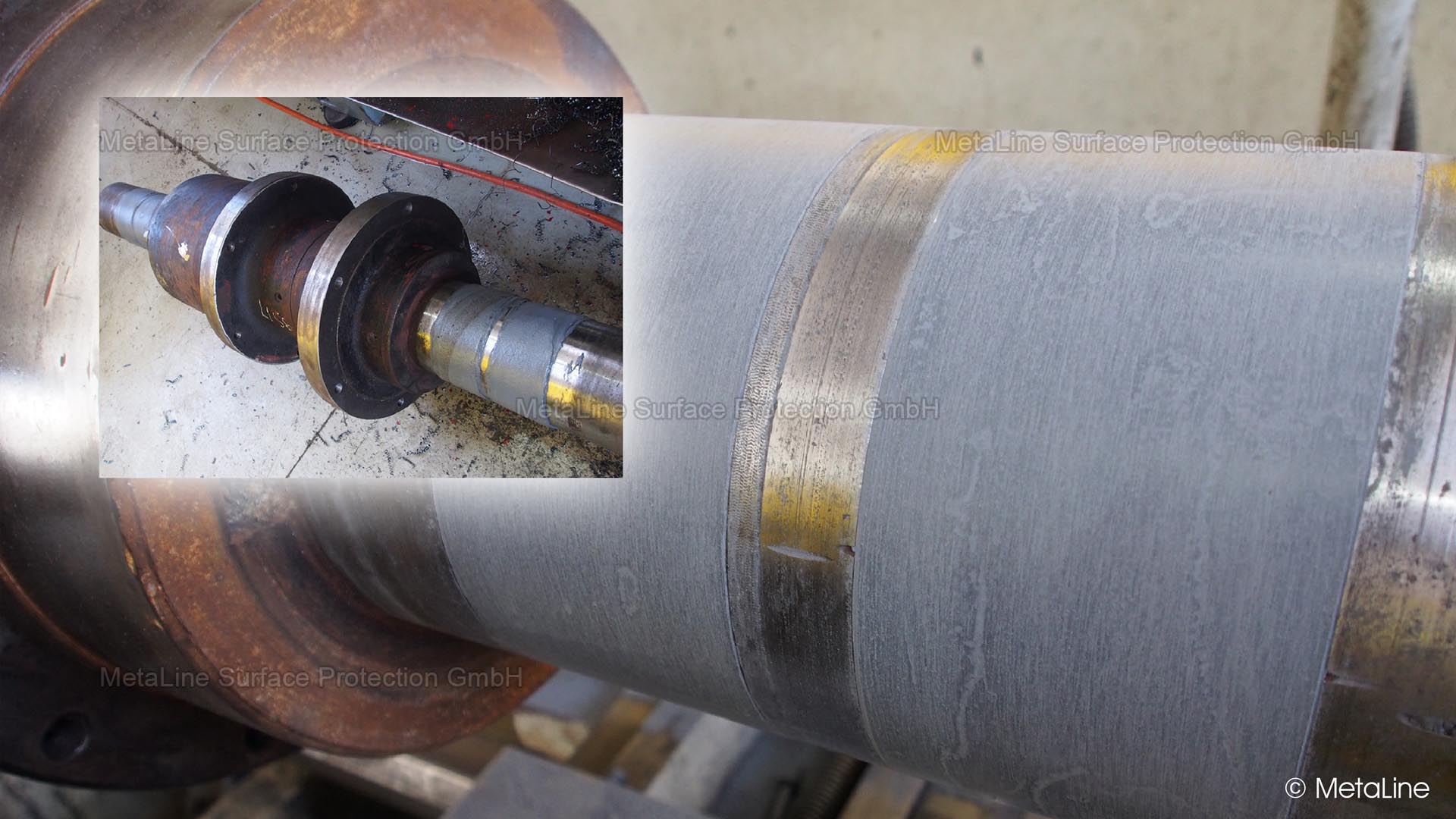

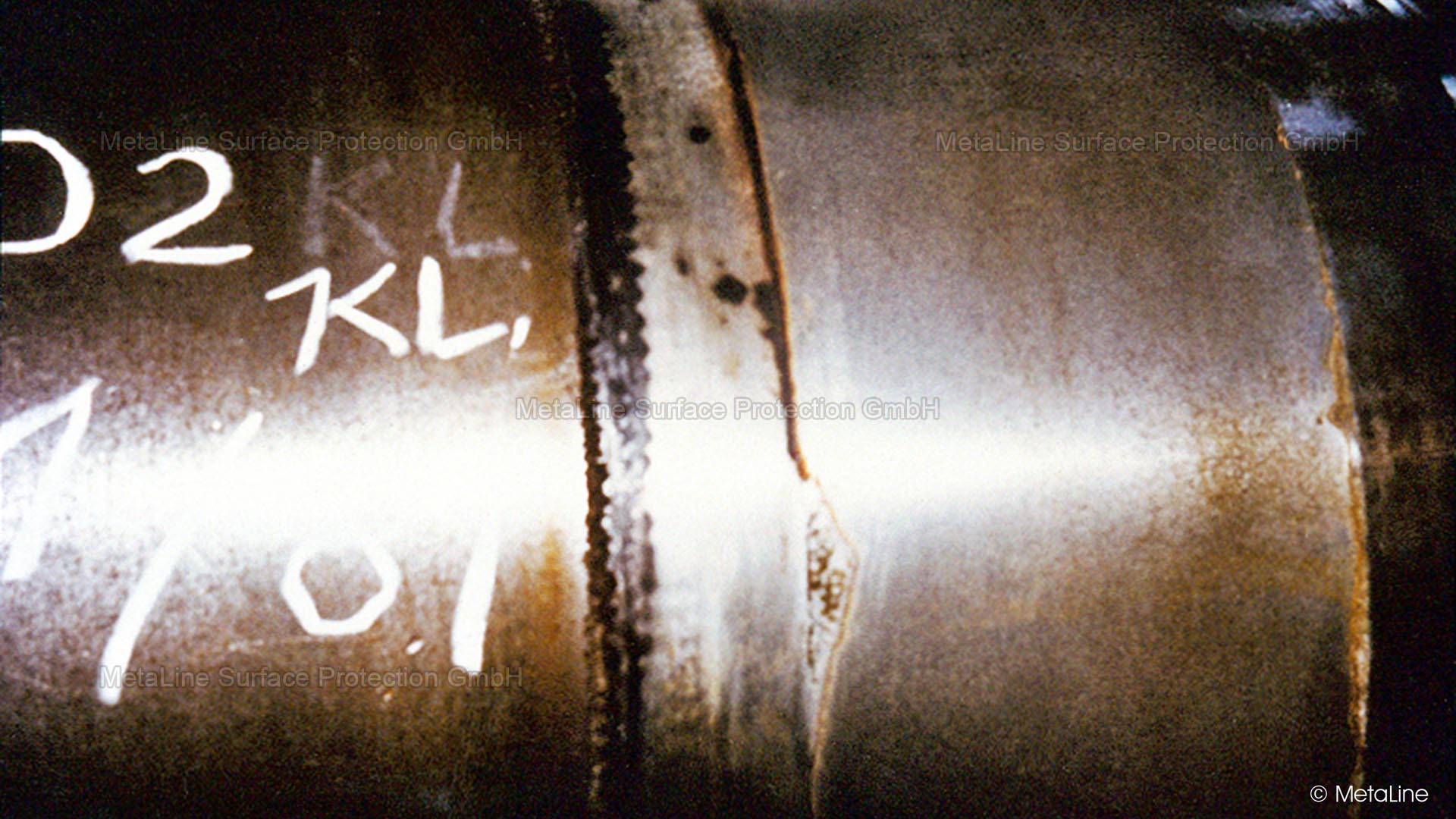

Shaft repair - here a partially worn-in shaft for reworking. Subsequently, a full-surface coating is applied to integrate additional corrosion protection

During coating with MetaLine repair ceramic KXL. A keyway seat repair can also be carried out in this process

Bearing journal repair - bearing journal coated with MetaLine repair ceramic KXL. Corrosion resistant and due to the electrically insulating properties an absolute protection against fretting corrosion

Shaft protection - bi-metal corrosion on this turbine drive shaft. Not an easy case and not an easy solution - despite MetaLine repair ceramics

Shaft repair – Self-extracting grit blasting of the repair surface with sharp-edged high-grade corundum (Al2O3). No other pretreatment is better suited to ensure sufficient adhesion for the expected load

Shaft repair coating – hydro-turbine shaft after the protection treatment with 1 mm of MetaLine KXL

Hydraulic ram repair – not an easy task but with the help of MetaLine SXL Repair Compound a real alternative to common chromium repairs

Bearing seat repair – trowelable MetaLine SXL has been successfully used to overhaule this damaged bearing area

Shaft coating – brushable MetaLine KXL protects this shaft from corrosion and chemical attack

Shaft protective coatings - it looks so simple, but without experience and routine such applications are very difficult. Ask us!

Shaft protection coatings - if nothing else works - then also in the installed condition. Polymer technology makes it possible!