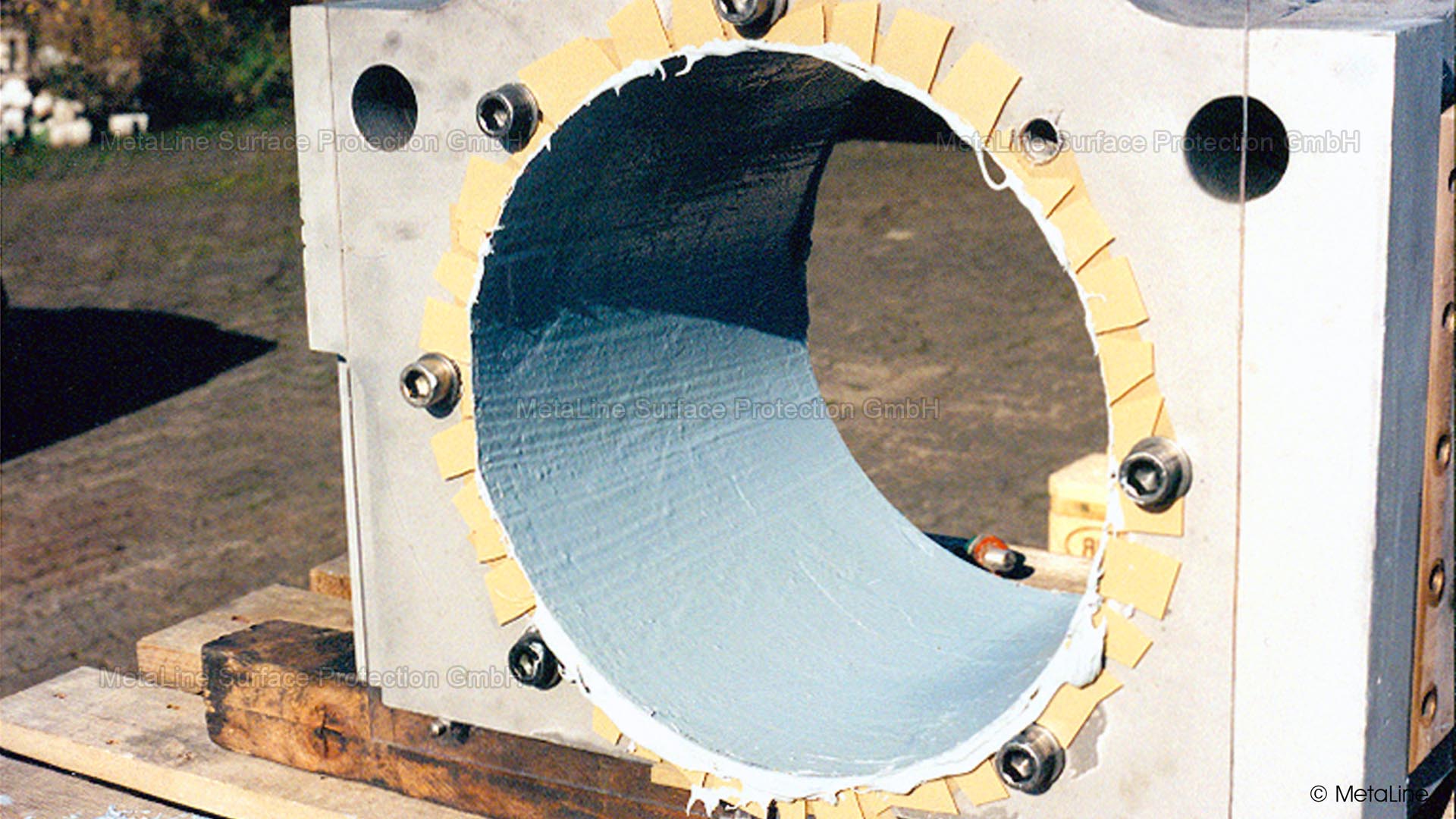

Bearing seat repair - the heavy bearing seat of a cold rolling press during substrate preparation for the subsequent coating application. In this case, the entire surface was roughened with ceramic abrasive to an R(z) of approx. 75 my

Bearing seat regeneration - the undersize was filled to + 1 mm (40 mils) with the ceramic MetaLine SXL using a template. Machining was carried out with diamond tools. This process can also be used to carry out alignment repairs

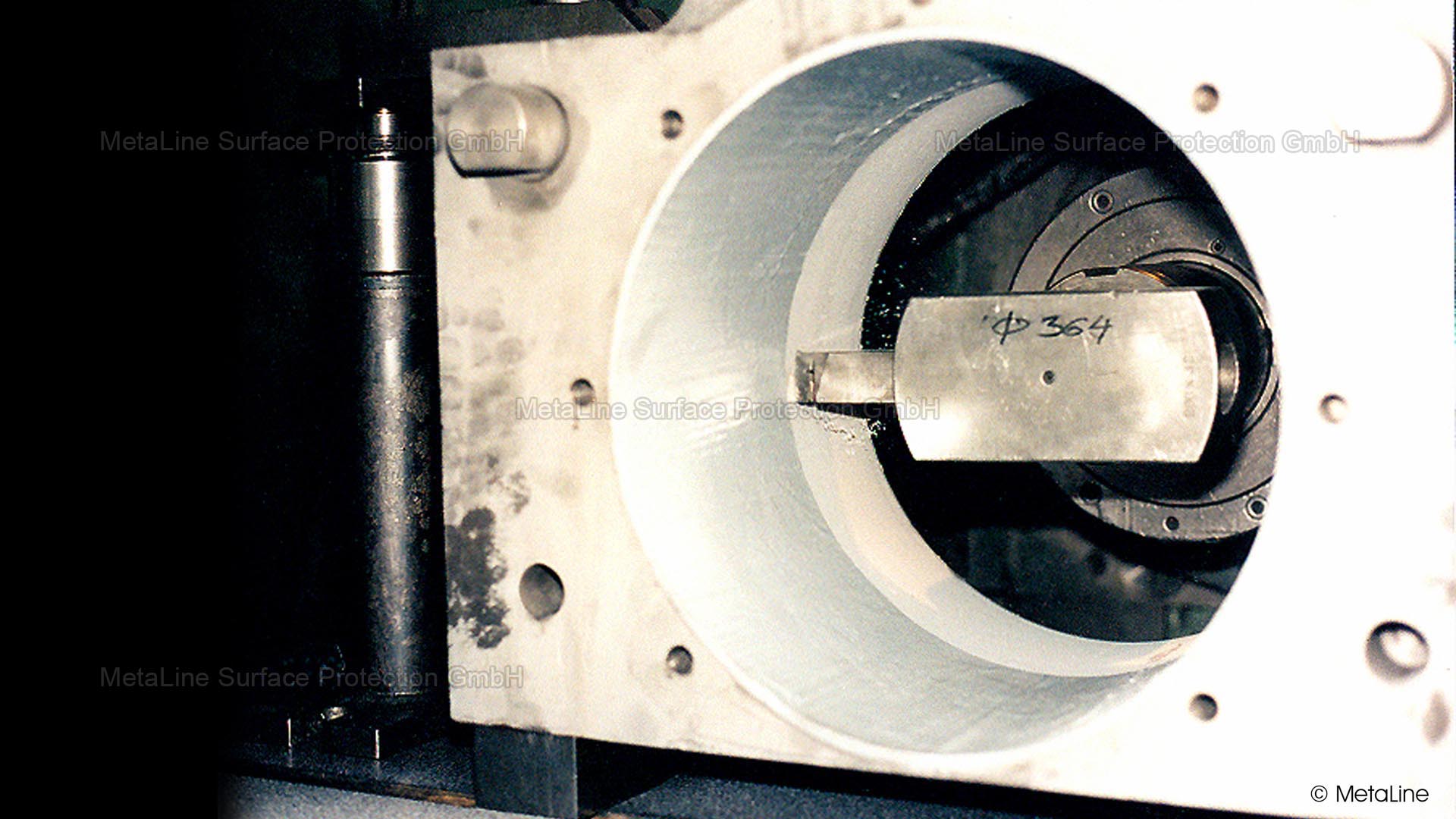

Bearing support reconditioning - here is a picture of the mechanical reworking. Ceramizing the bearing seat is a perfect method for solving fretting corrosion problems. Synthetic mating surfaces can no longer cause corrosion!

Bearing seat undersize - a bearing seat reconditioned with MetaLine SXL during machining. Only the second best solution! Instead of reworking, we recommend liquid molding the bearing seat using the original bearing. The difference is a higher contact area! More load-bearing surface means longer service life . . .

Bearing seat oversize - MetaLine SXL is a freely moldable ceramic repair compound. It hardens within a few hours through polymerization. After solidification, all processing and measuring methods can be used as for metallic structures

Metal filler - this term no longer hits the nail on the head! Metallic components are no longer included due to the threat of bi-metal corrosion, and a modern composite is more than just a decorative filler . . .

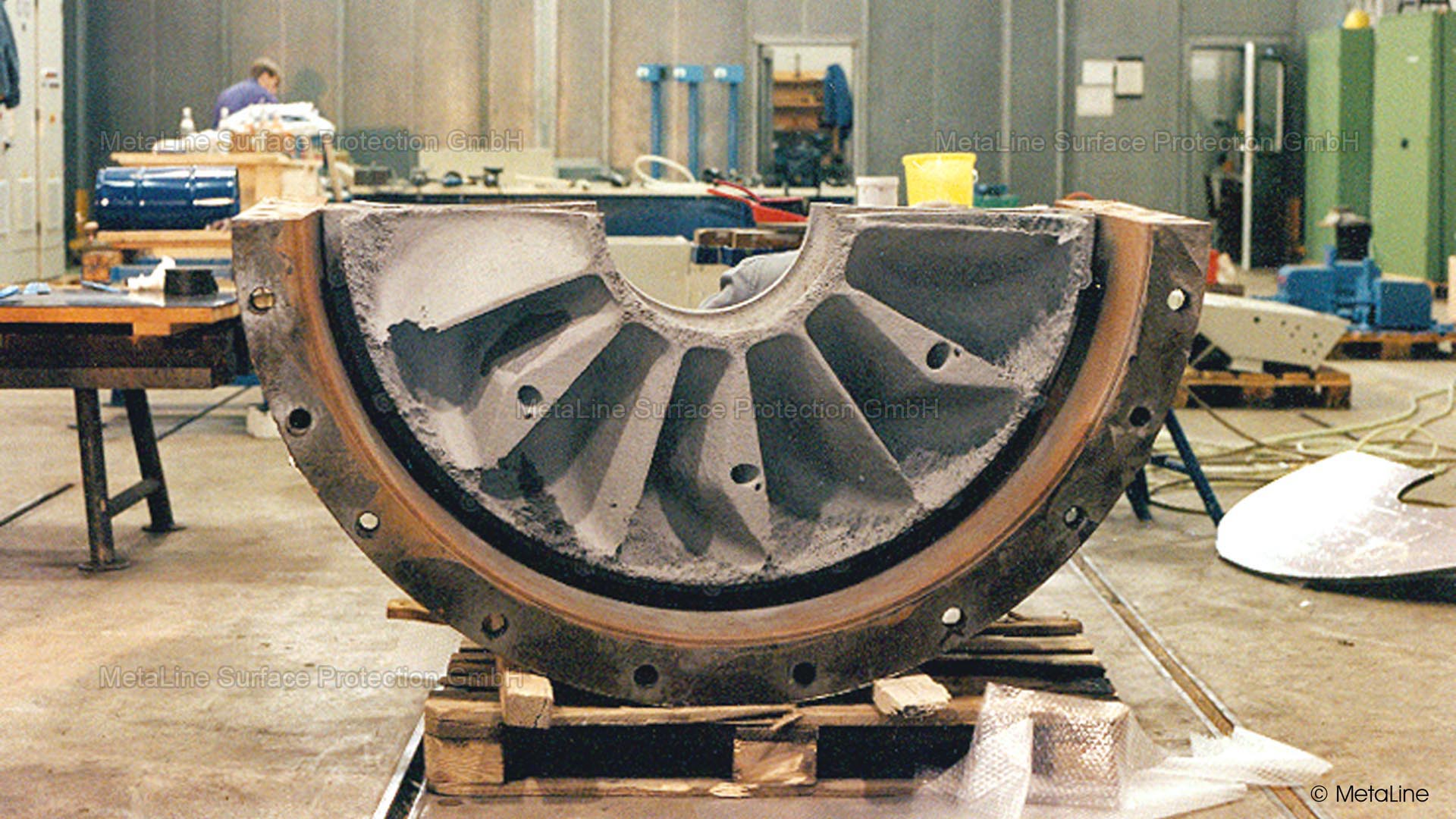

Bearing seat repair - washouts in the entire functional area including a rolling bearing seat outside any tolerance. Admittedly, this is not an everyday occurrence for us either! A repair was unavoidable due to the spare parts delivery time of 12 months!

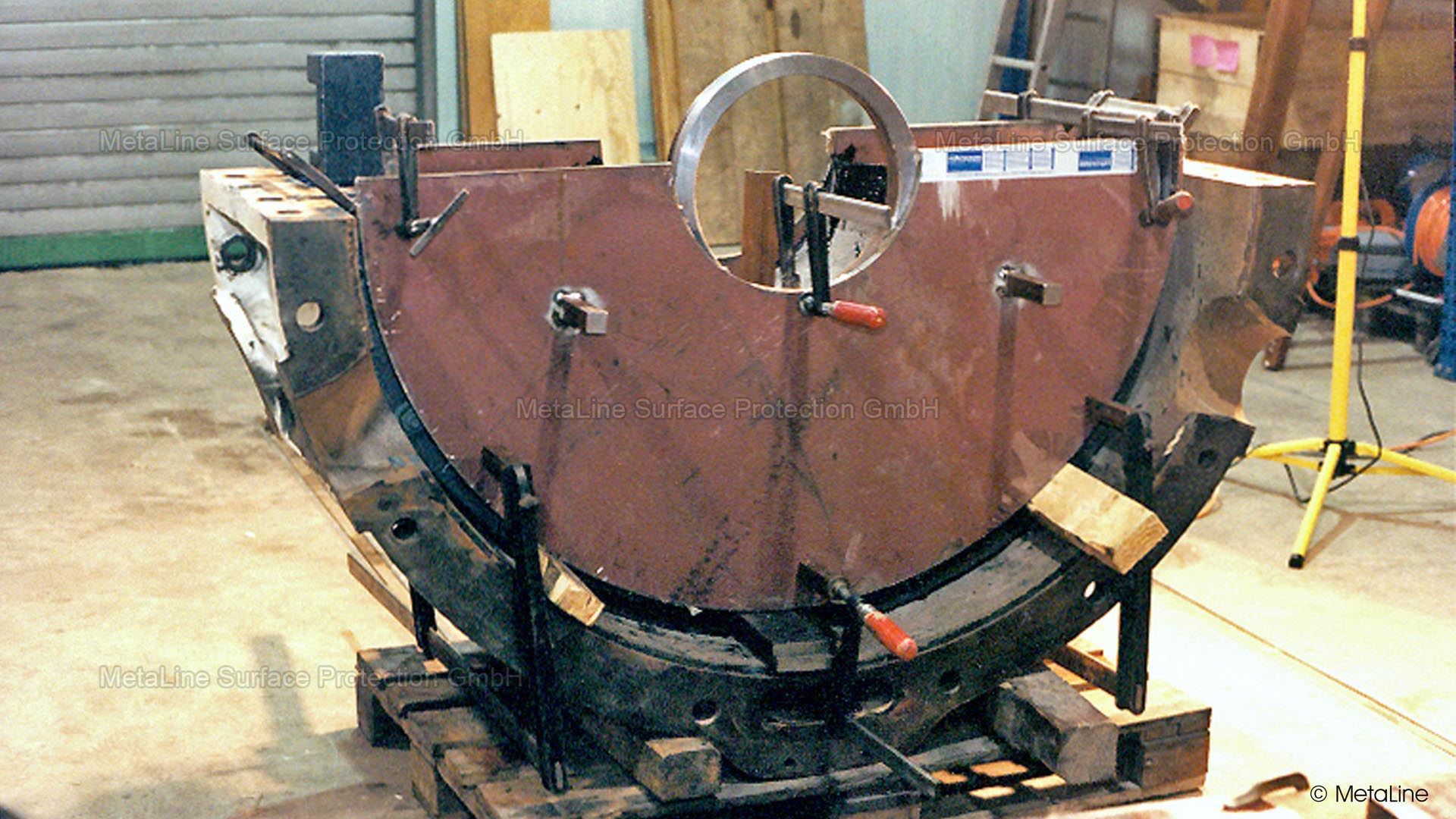

Bearing shell repair - the vertical sealing surfaces and the bearing seat were molded in paste form using a steel plate and a duplicate of the bearing ring. During the processing time of the MetaLine SXL, the fit of the templates was measured and adjusted to the exact dimension

Plain bearing seat repair - after demolding, the remaining surfaces were protected with the brushable repair ceramic MetaLine KXL to stop the severe corrosion attack. And the cost - less than 5% of the new part value!

Bearing sealing - the correct term for this Voith-Schneider marine drive on a car ferry would be a bearing seat seal. The water contamination caused by the leaking oil is very clearly documented in the picture

Cuttlas bearing repair – unfortunately not all repair steps were documented photographically. The most important thing, however, is that the work was carried out in dry dock, but in the installed state. Anything else would have caused enormous costs!

Bearing seat repair - bearing leakage sealed with MetaLine repair ceramic SXL. The material costs were less than 50 EURO. But cost is not everything - it also has to work. MetaLine analyzes very precisely and avoids risks beyond plausible physics!

Oversize bearing seat - a term that brings worry lines to the forehead of every technician. Especially when the diameter is as large as in the picture. Not for the faint-hearted . . .

Bearing seat seal - MetaLine technician Ralf Seidel applying the repair ceramic SXL. The surface was first partially blasted with the MetaLine Gritblasting gun SP1 and degreased with MetaLine 995

Bearing seat machining - of course, the seat had to be turned to size using a mobile machining center. However, MetaLine cannot carry out this type of work. Our focus is clearly on chemical processes in mechanical engineering . . .