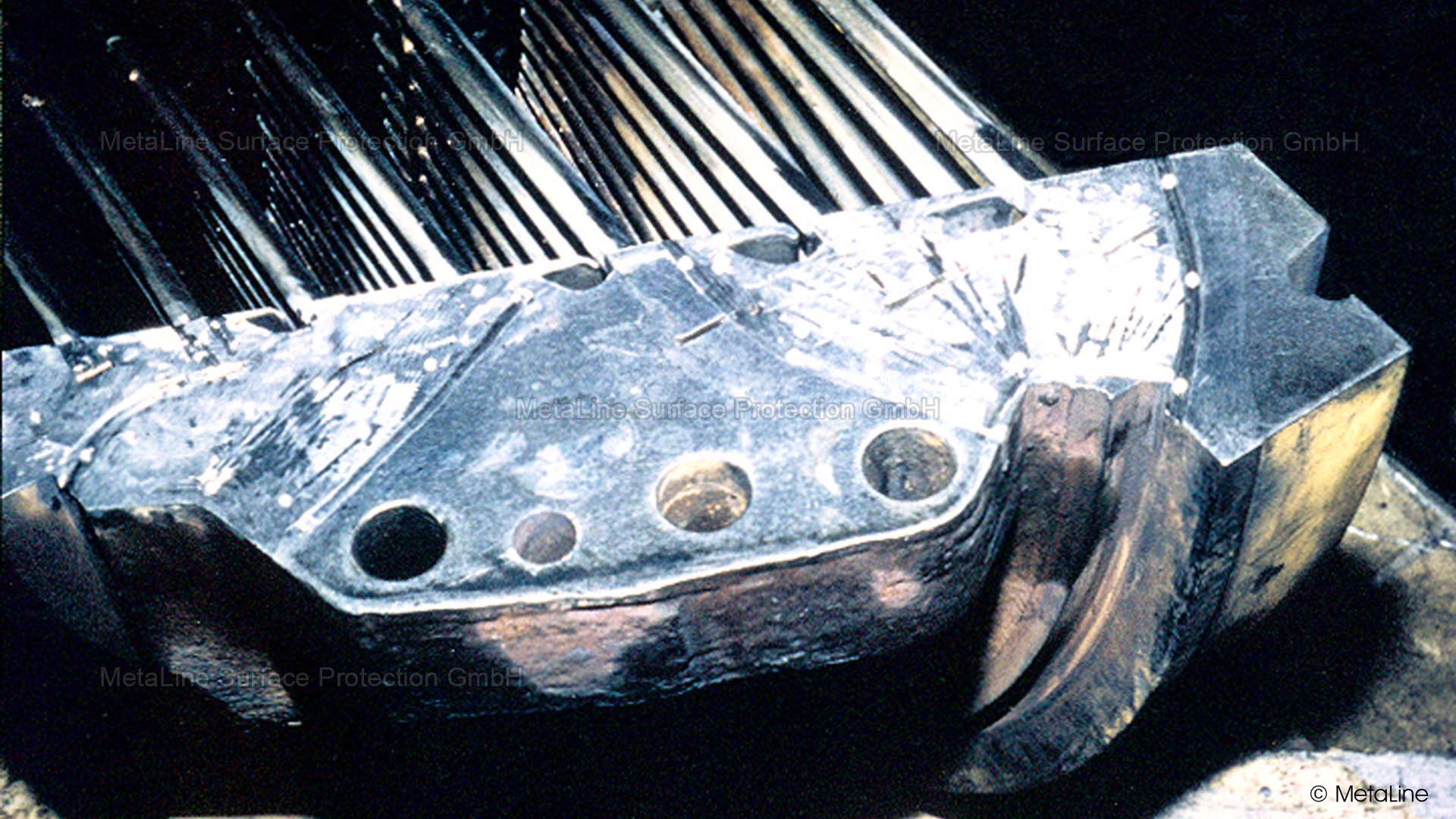

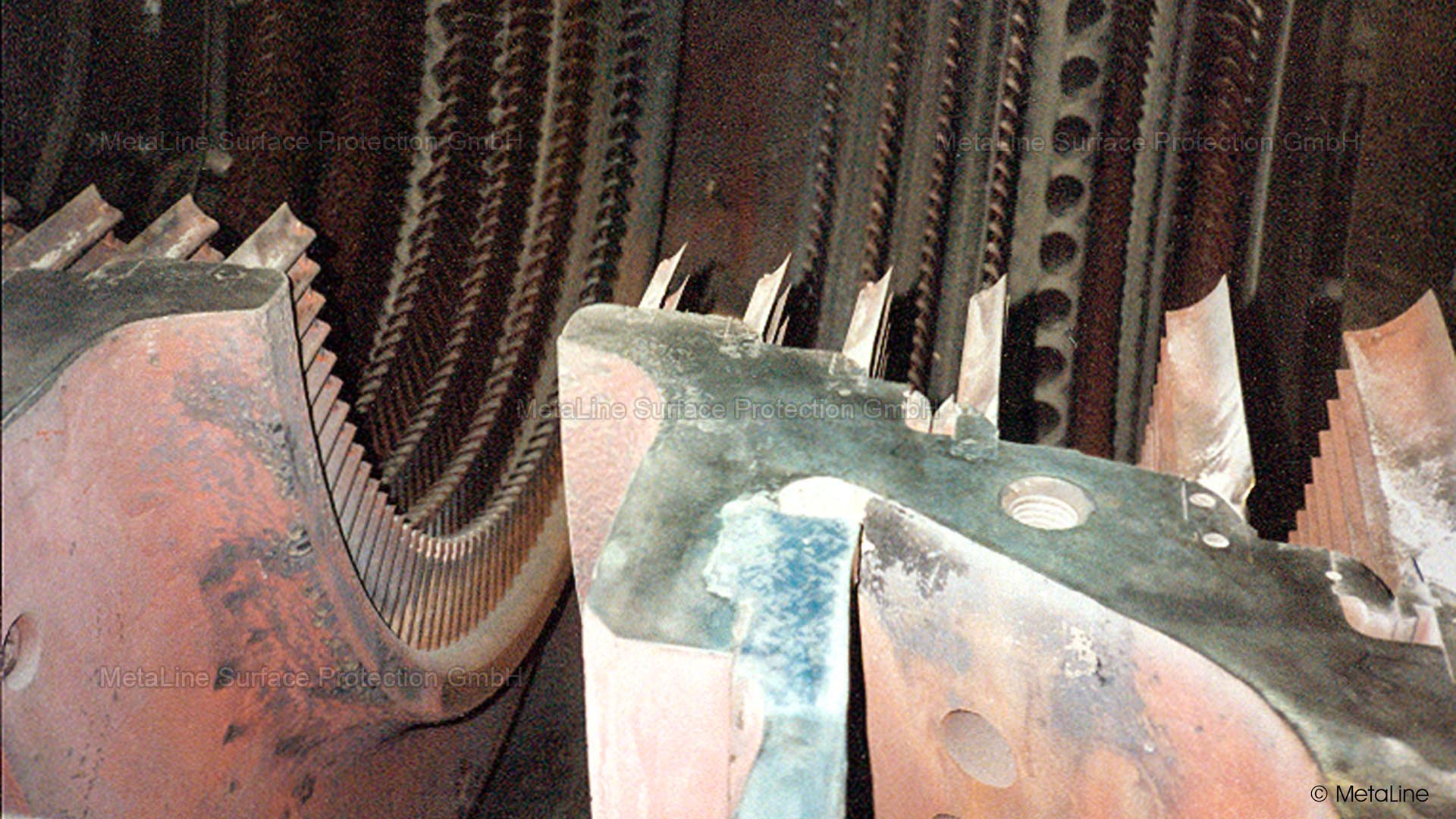

Insufficient dimensions of sealing faces and flanges represent major safety-relevant disturbances. Larger defects can only be eliminated permanently via mechanical treatments. However smaller dimensional discrepancies can be resealed synthetically. Good chemical and thermal resistance is required to produce a pressure-resistant, permanent seal. At the same time, to avoid bi-metal corrosion the electrochemical voltage series must be taken into account.

Ask us about: flanges, disorted flange faces, sealing surfaces, supports, plastic joints, split ducting, form gaskets in-situ

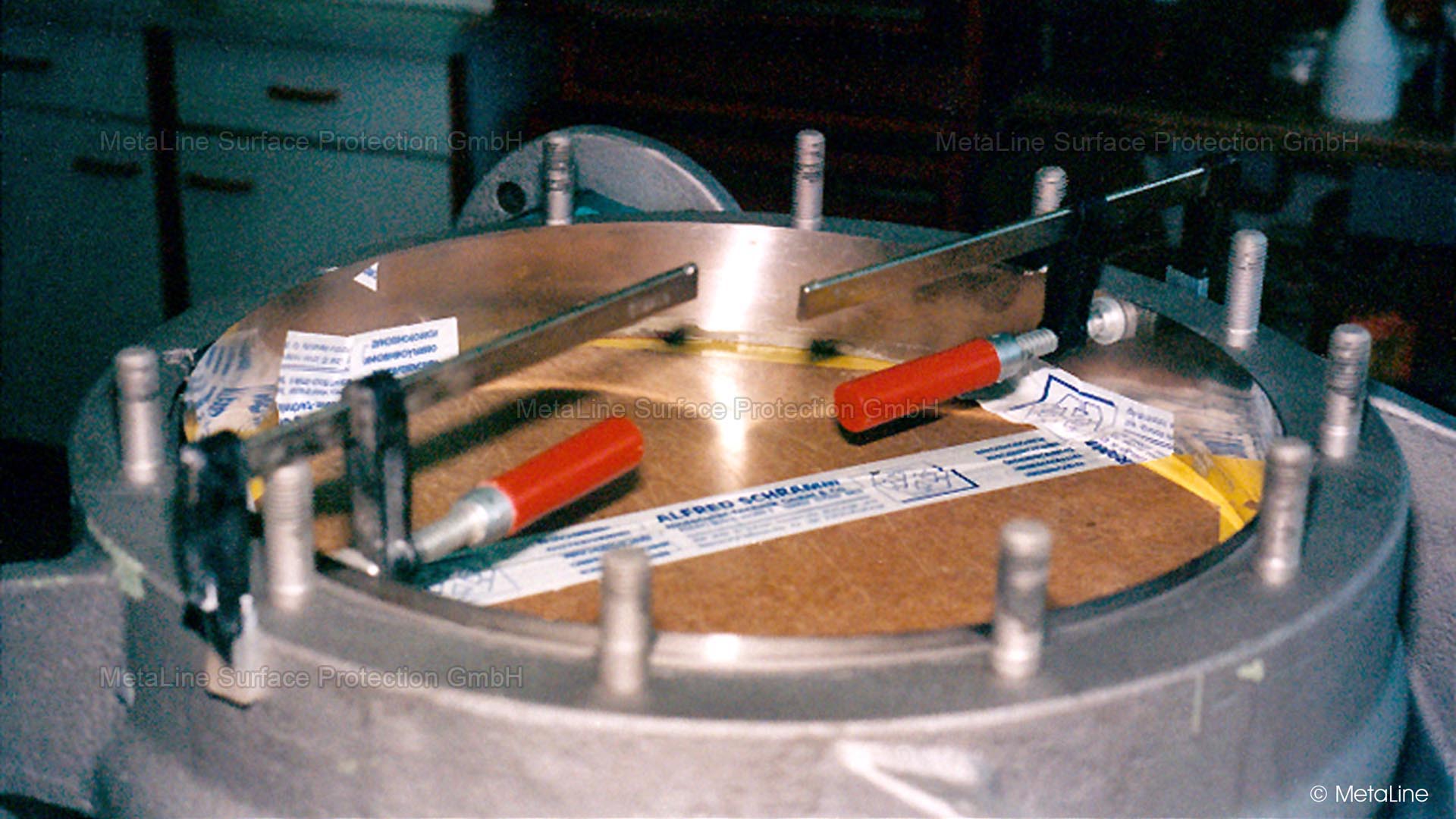

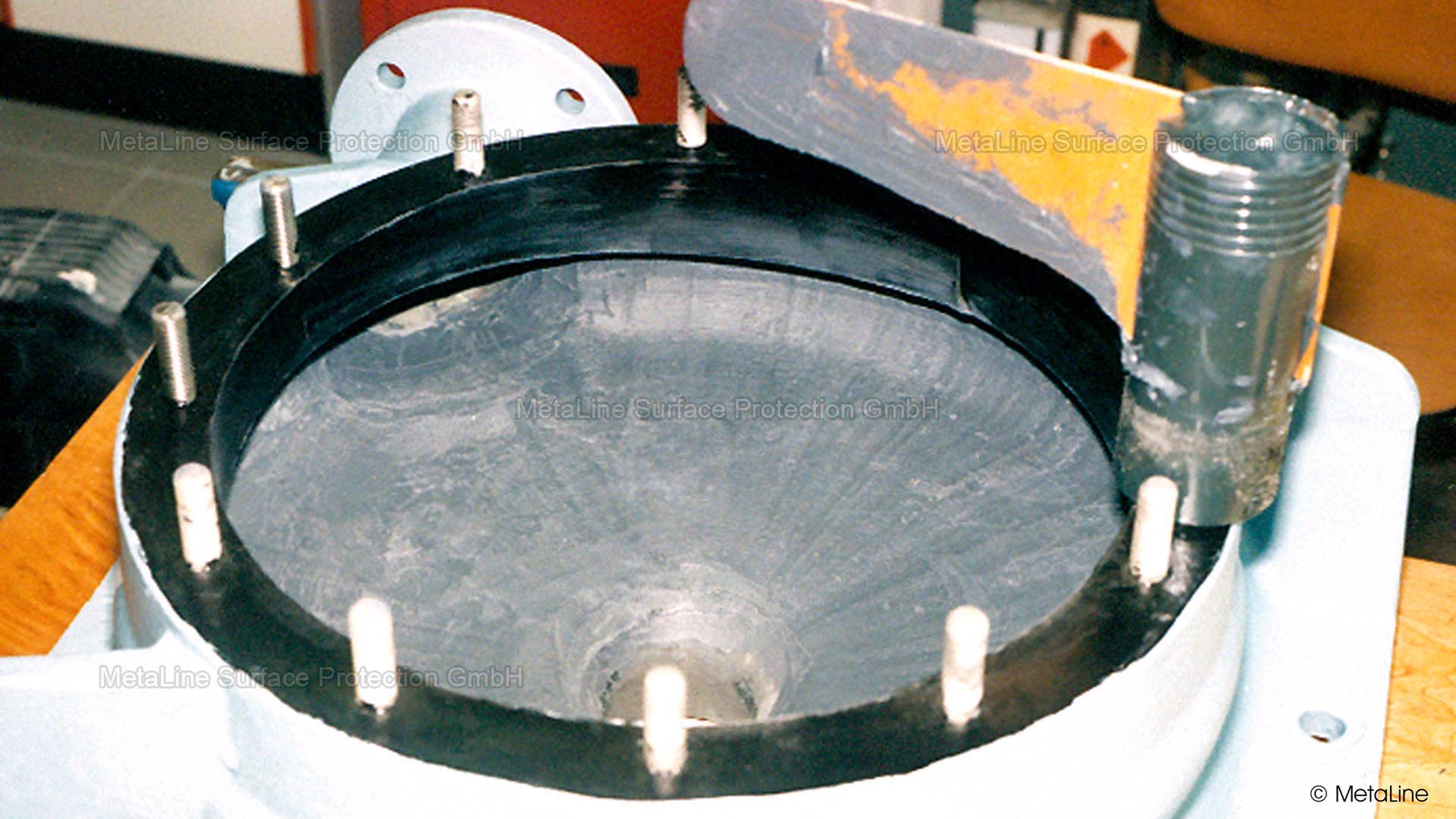

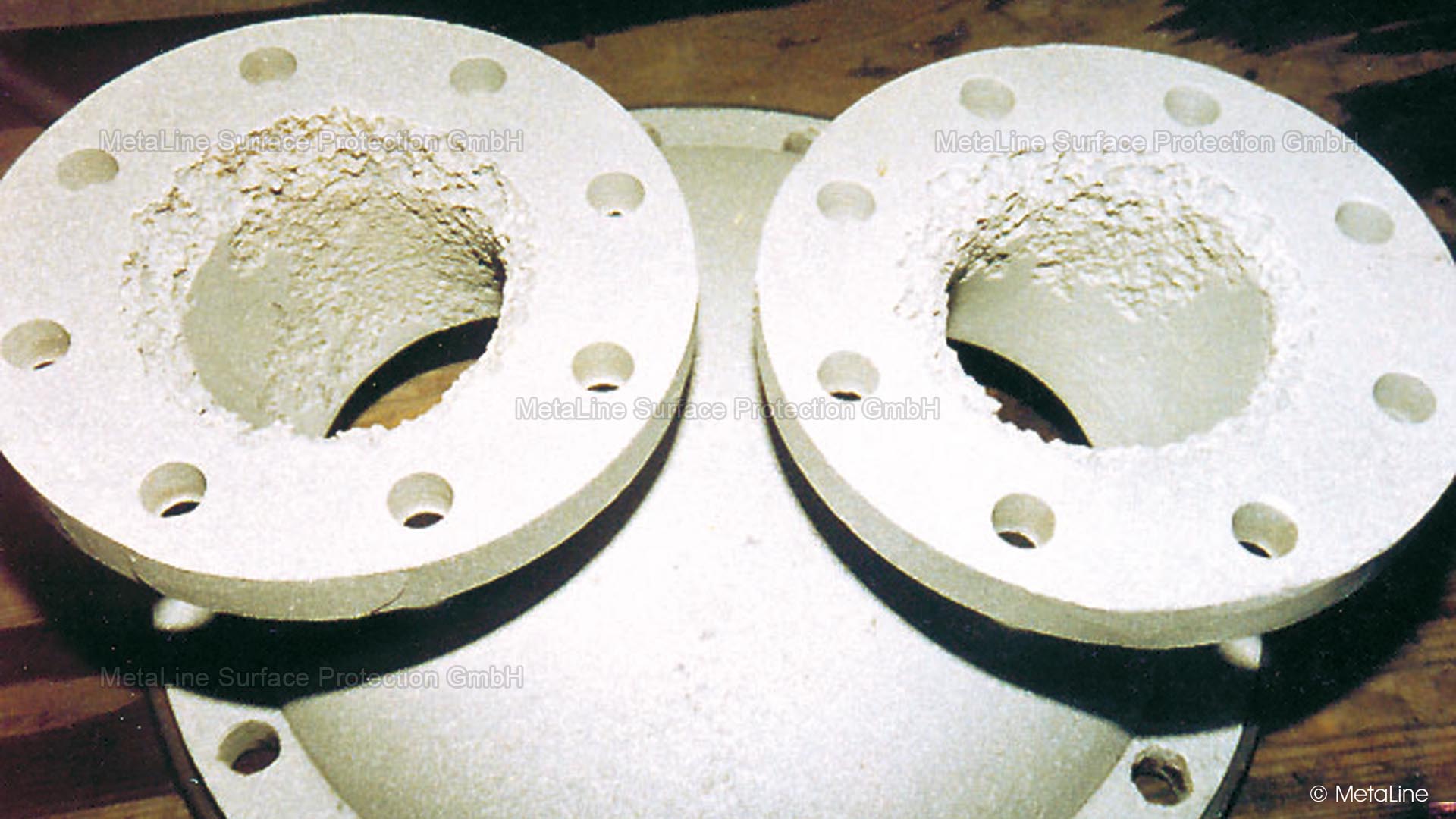

We have a solution for problems with leakage on flanges by means of repair compounds! Scope of application: Flanges Disorted flange faces Sealing surfaces Supports Plastic joints Split ducting Form gaskets in-situ MetaLine - Technical solutions in detail METALINE SERIES XL MetaLine Series XL offers metal-free, ceramic repair masses for re-contouring worn surfaces. A simple and proven method of flange repair is application of the material by trowel and simultaneous molding precisely to shape. To achieve this, directly after application the mating flange treated with separating agent is mounted and the ceramic repair compound molded to regain its shape. After solidification at ambient temperature a pressure and chemical-resistant permanent sealant results.

MetaLine Series XL – MetaLine Series XL are metal-free, ceramic repair compounds for the recontouring of worn surfaces. A simple and proven method for flange repair is the filling and accurate fitting simultaneously. To achieve this, directly after application, the mating flange treated with release agent is mounted and the repairing ceramic practically pressed into shape. After solidification at ambient temperature a pressure and chemical-resistant permanent sealant results.