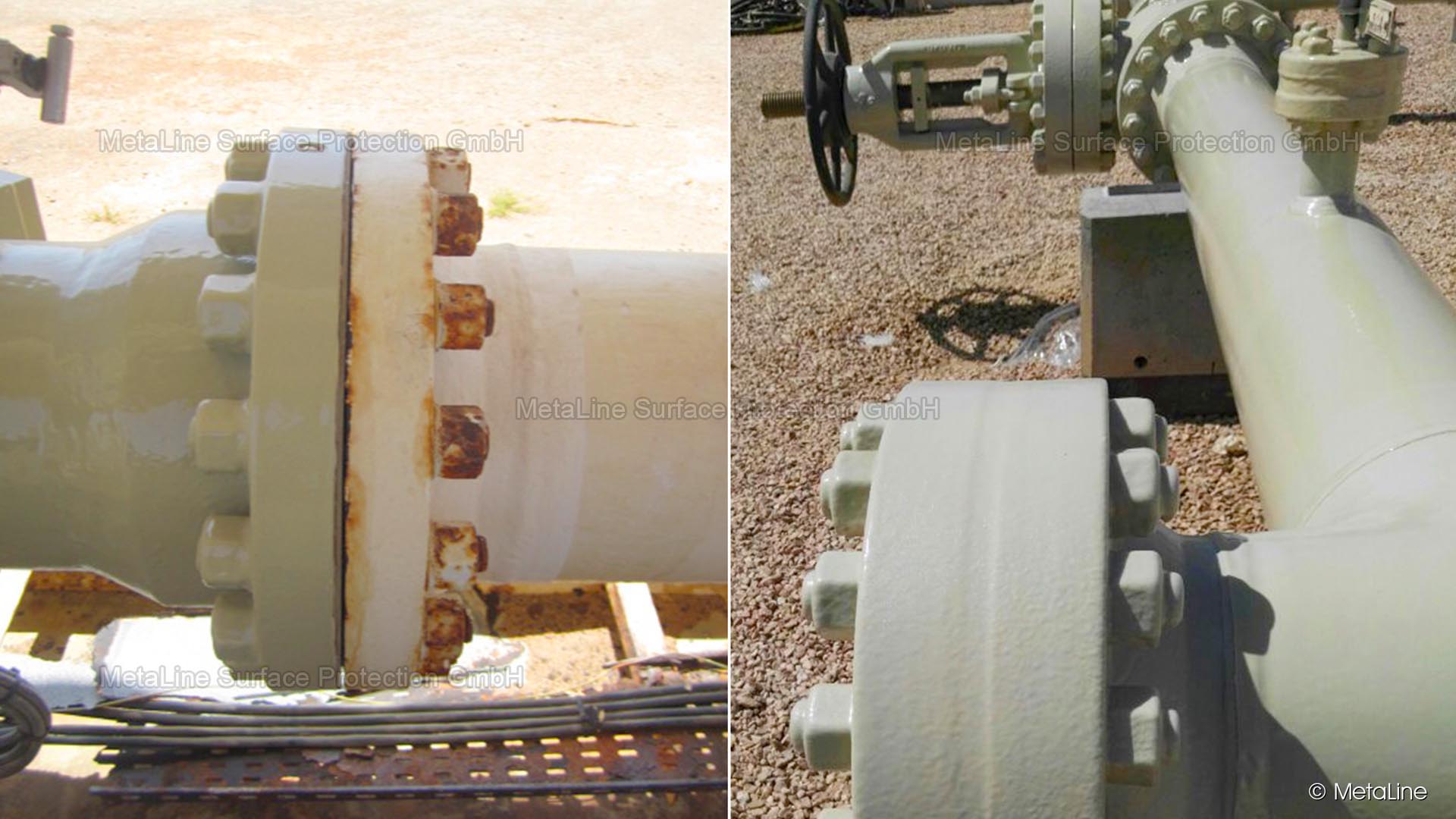

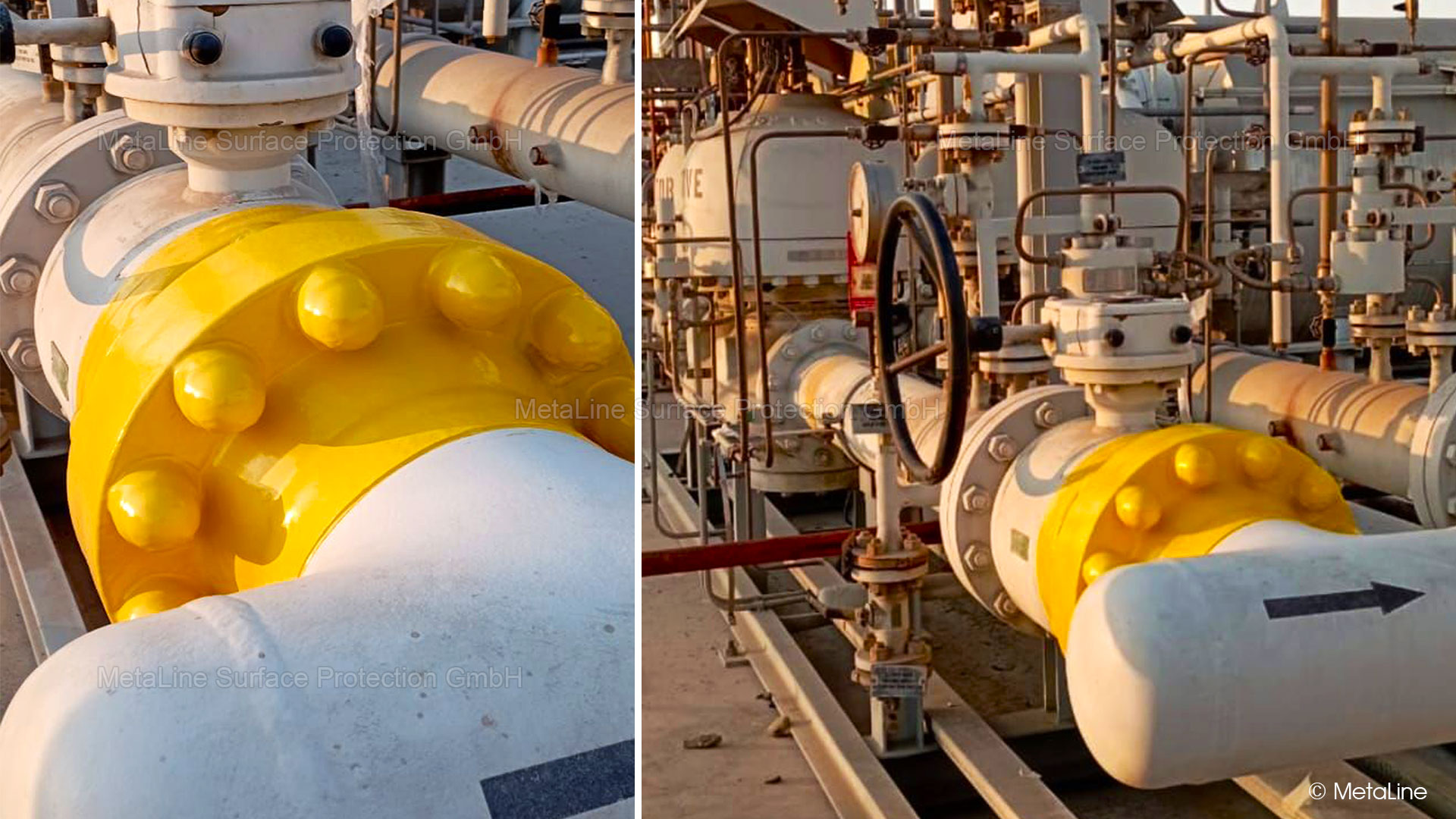

Flange encapsulation - protected and then still accessible if required! MetaLine 785 allows atmospheric encapsulation and complete corrosion protection. If required, also under water. At the same time, the encapsulation can also be opened and closed again!

Flange sealing system - an ingenious concept to protect flanges and their bolted joints from atmospheric corrosion. Simply spray over and encapsulate. Since no bonding agent is used, a detachable bond to the substrate is created

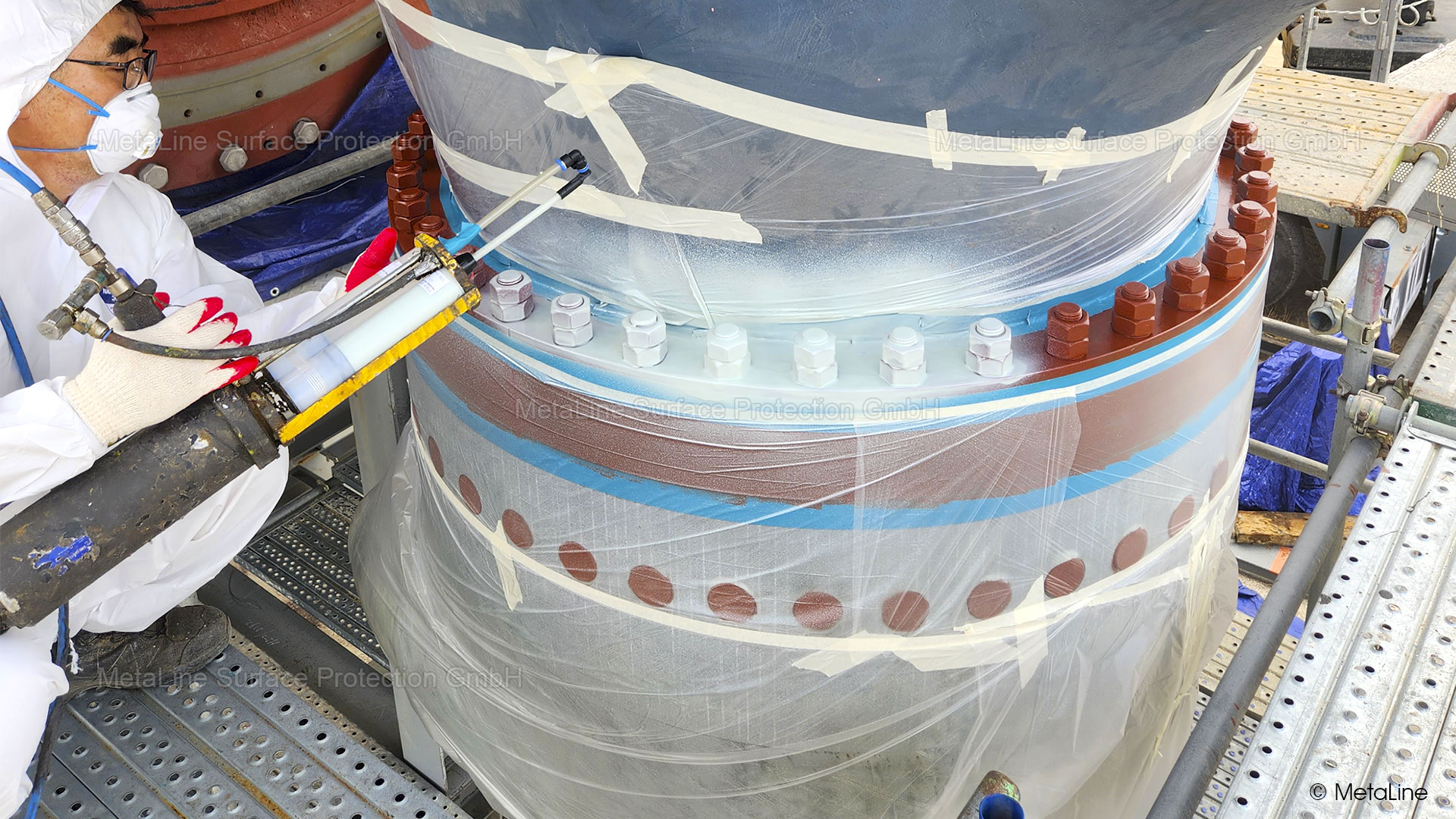

The elastomeric protective skin can be cut open and pushed back at any time to perform inspection work. Afterwards, simply push back and seal the cut. Already touch-dry after 5 minutes, so that outdoor applications can be carried out even in bad weather ...

Translucent coating – peelable with an inside view as with a pipe inspection glass. What a unique MetaLine idea! Control your coating during its protection function and stay well informed about the leakage status of your flange connection

Flange protection encapsulation - protected but still removable if required! MetaLine 785 is a milestone in the atmospheric and underwater encapsulation of high-quality flange connections. Unlike paint, the elastic skin cannot flake off!

Flange protective coating - the MetaLine concept is modular: Coating without adhesion - Coating with adhesion - Atmospheric corrosion protection - Underwater corrosion protection - Optical control of leaks - Electronic control of leaks by measuring probe. Everything your flange needs!

Trowelable "rubber" – without vulcanization or heat. Applicable in every desired thickness – even overhead. Extremely malleable and nice to work with. MetaLine offers a wear resistance far beyond the most special rubber formulations available

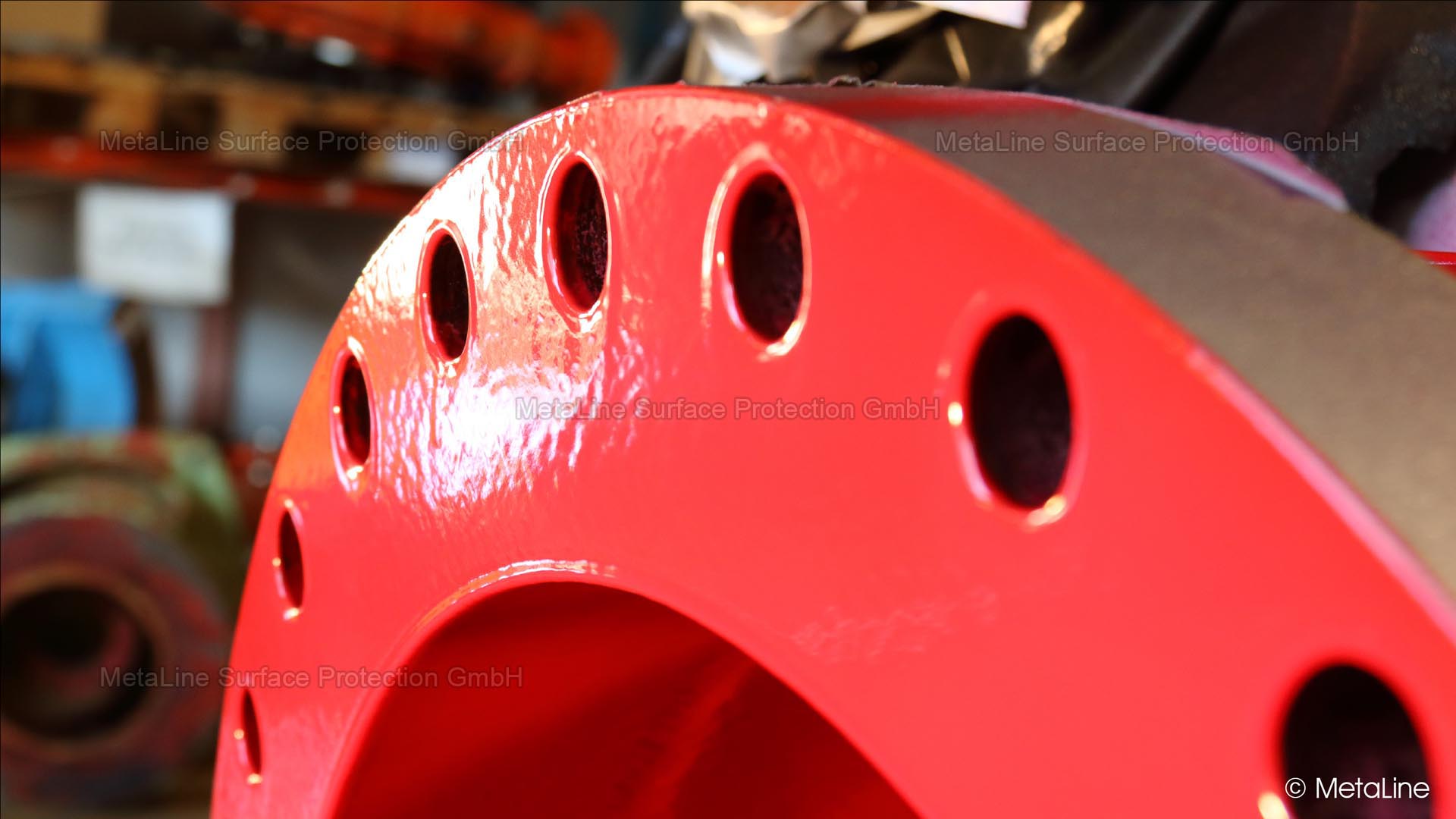

Flange protection - Textbook example for simultaneous internal lining and flange protection with MetaLine 785

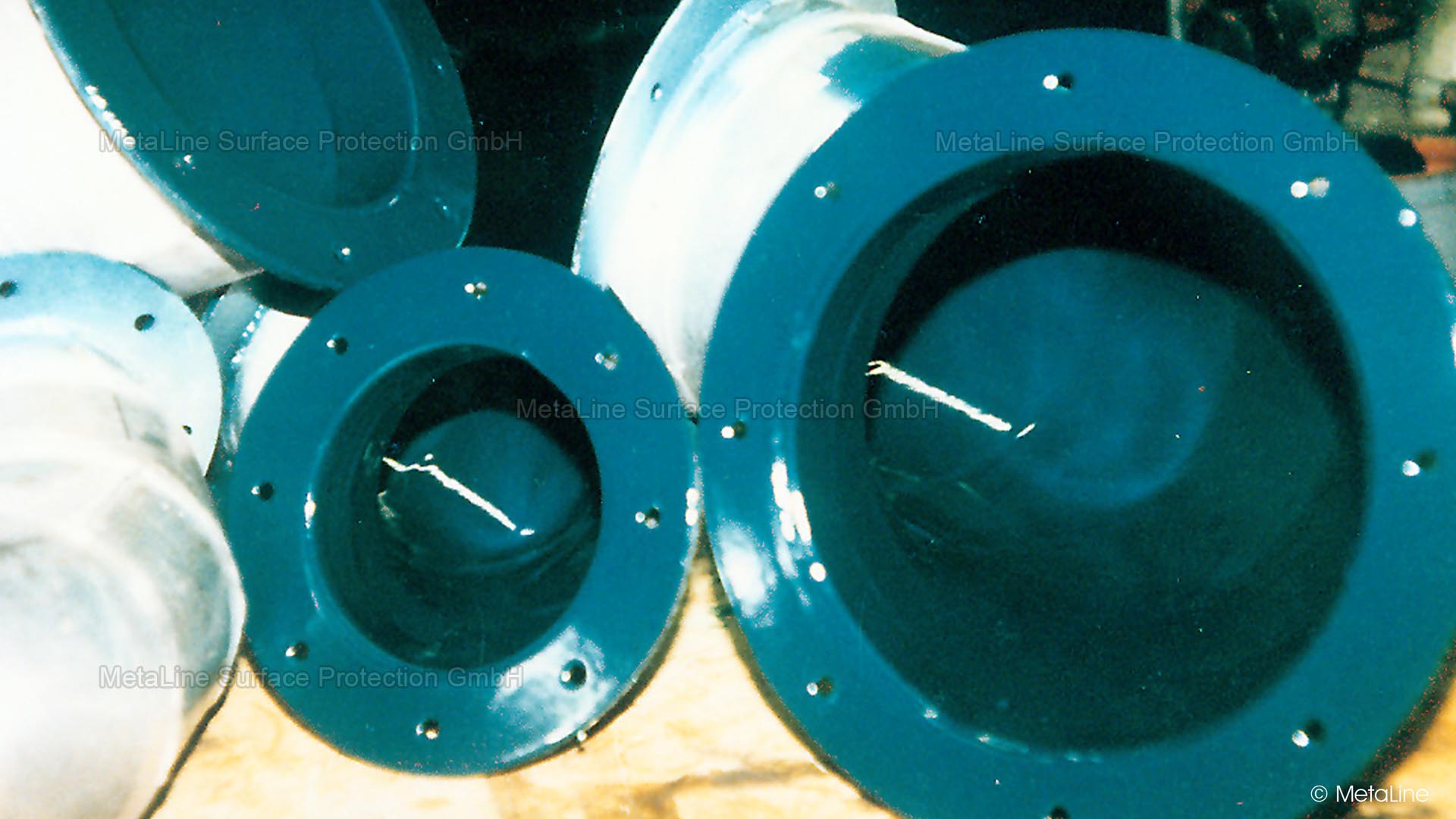

Rubber flange repair – MetaLine develops for more than 50 years repair technology to maintain and improve natural rubber linings. Different from metallic surfaces, there is practically no alternative to polymeric repair technology like the MetaLine 785 used here on the inner flange side of a blind plug

Flange coating – when the seamless character becomes an invincible technical advantage. MetaLine 785 can be applied internally and externally without any interruptions. NO natural rubber lining can do so . . .

Flange gasket - it doesn't get any more fitting than this! Seamless wear protection in a 12 meter (39 ft) pipe and infiltration protection at the flange by means of MetaLine 785

Flange recontouring - production of a seamless flange by cold casting with MetaLine 685

Flange coating - produced in a single operation - MetaLine 785 sprayed on with the modern cartridge spraying system

Flange repair - protection from the inside to the outside with 5 mm MetaLine 785 - technically unbeatable. Here on a huge pump of a French paper manufacturer

Flange repair - one material from start to finish. MetaLine 785 as wear protection lining and elastic flange sealant

Flange protective coating - a seamless skin that protects against corrosion and allows visual inspection at any time! In addition, measuring probes can be encapsulated which electronically report the smallest gas quantities to the control point. MetaLine is the market leader when it comes to intelligent technologies for the protection of high-quality flanges!