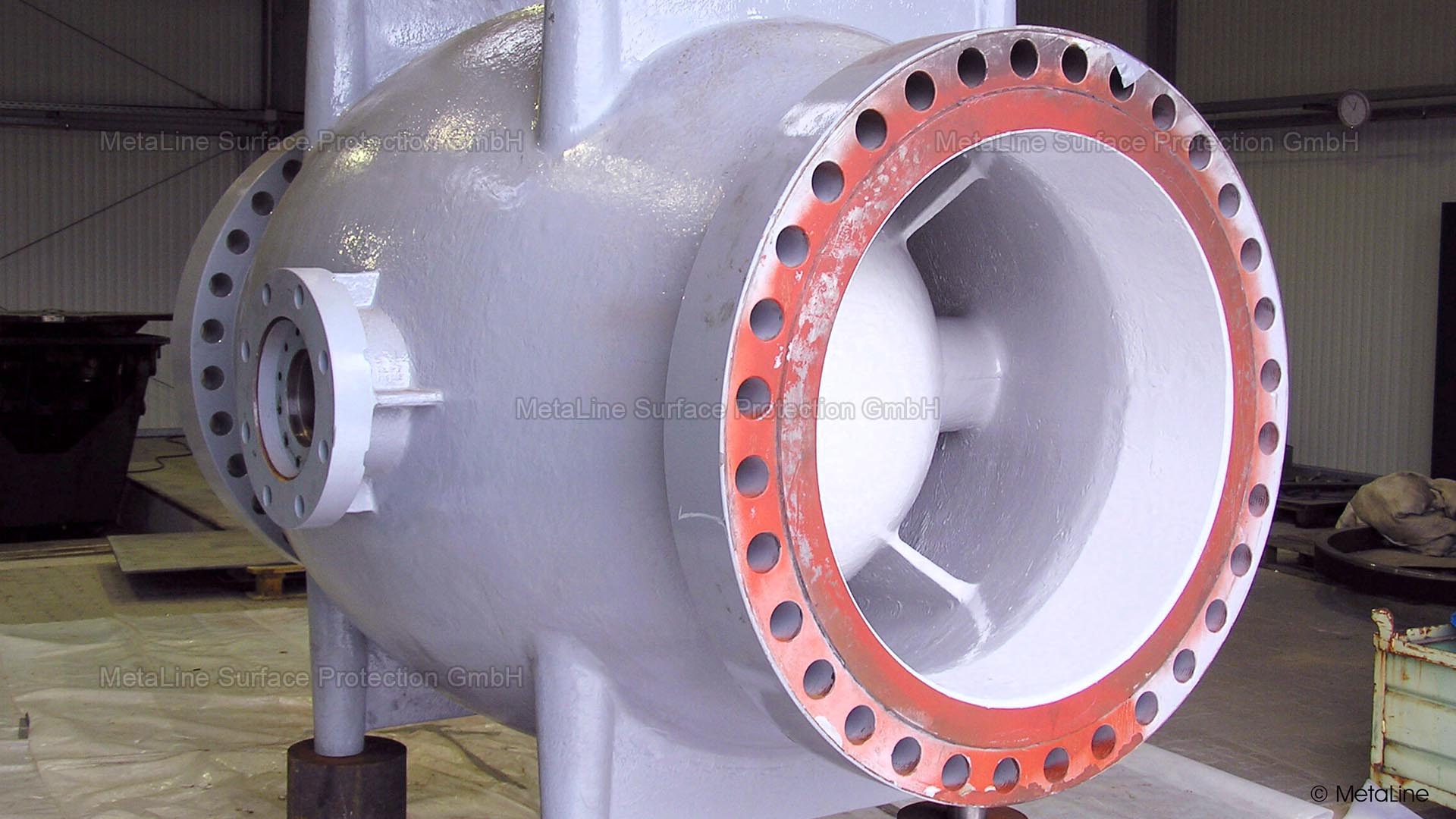

Large plunger valve for drinking water pipeline

Sealing and wear protection on the inside with 5 mm MetaLine 785

Tested with 150 bar test pressure

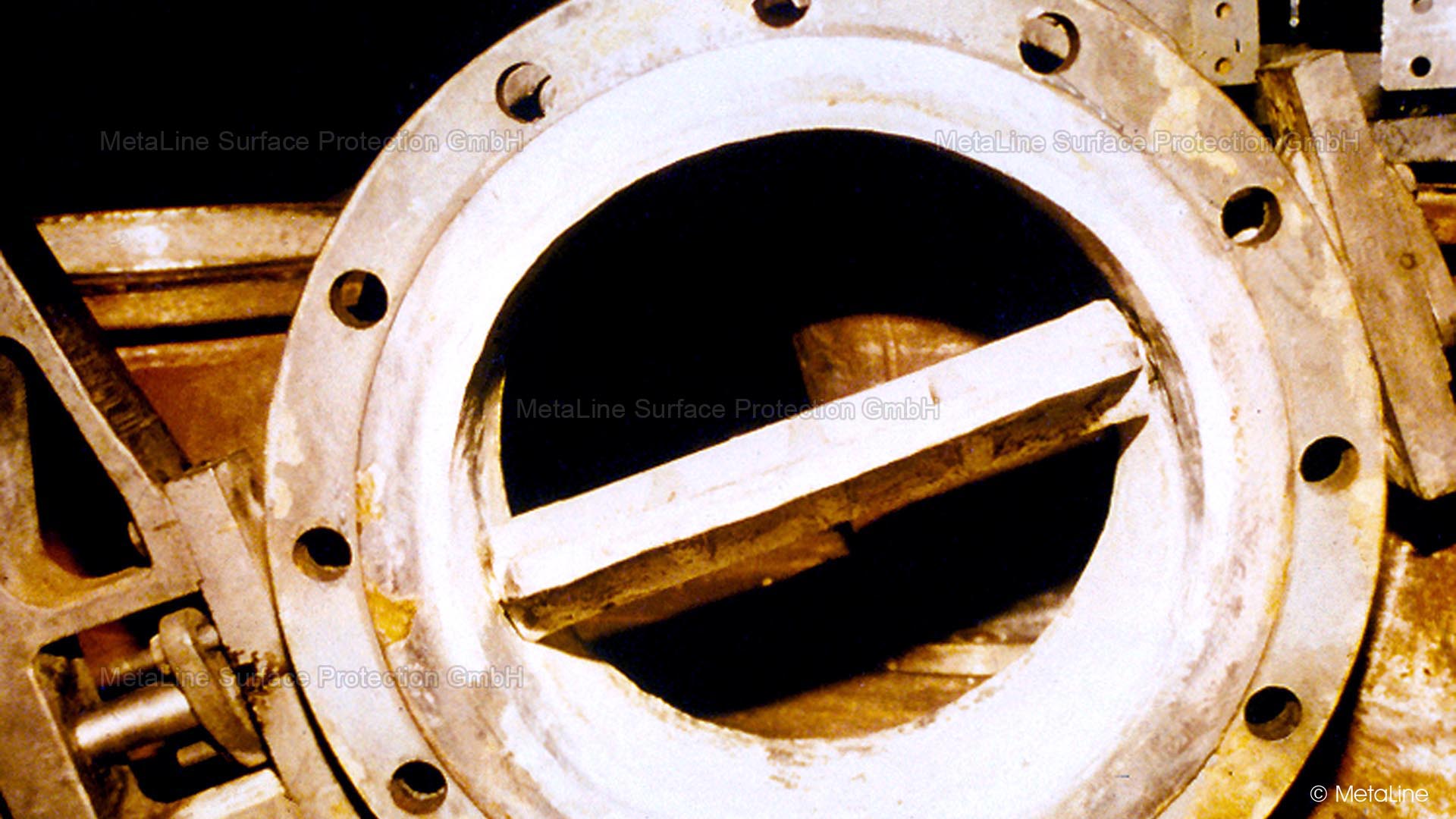

Corroded throttle valve and casing

Removed and blasted throttle valve

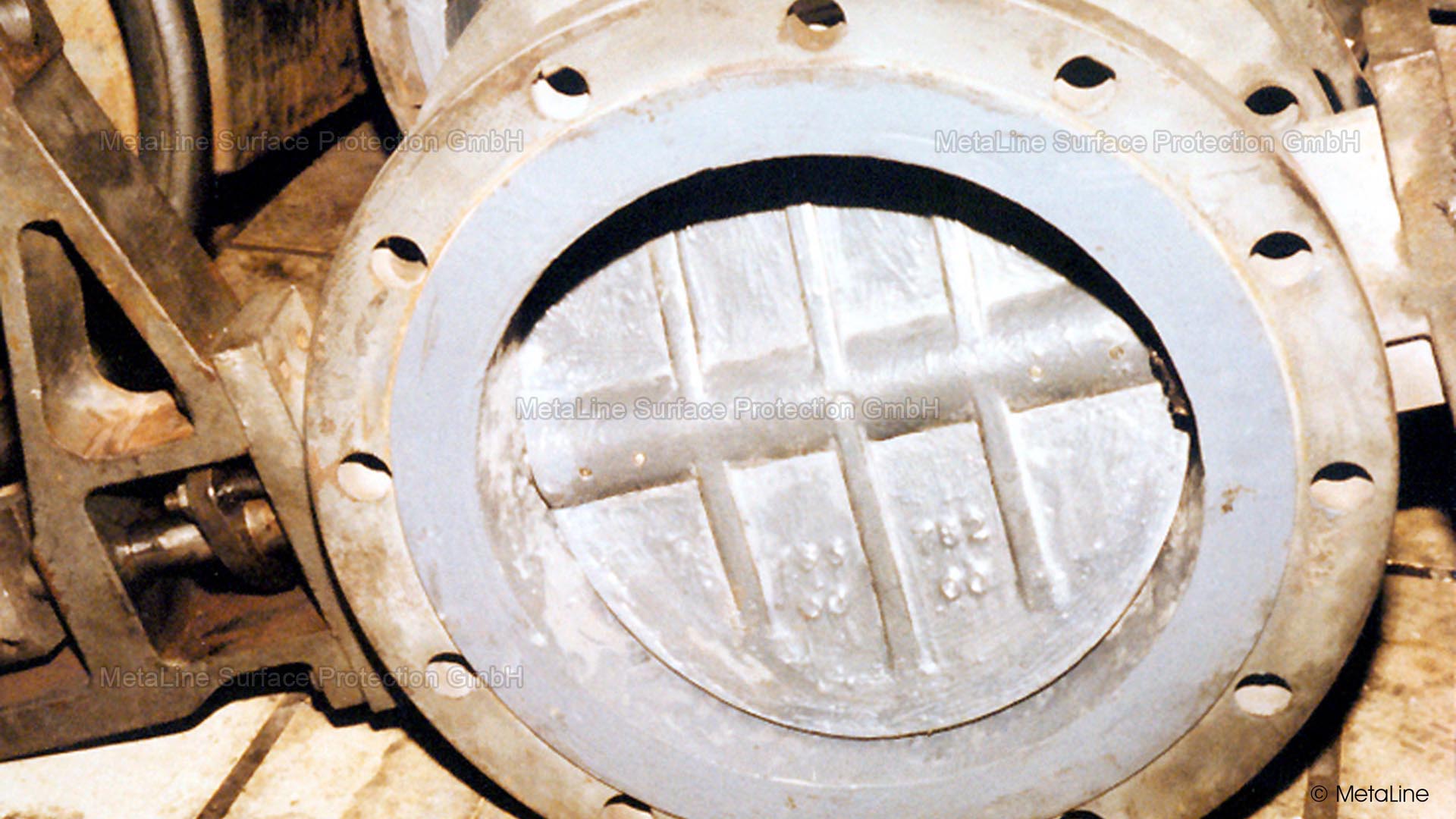

All-round coated throttle valve

Valve coating – MetaLine 795 used as heavy protective coating to protect against atmospheric corrosion in tropical costal areas

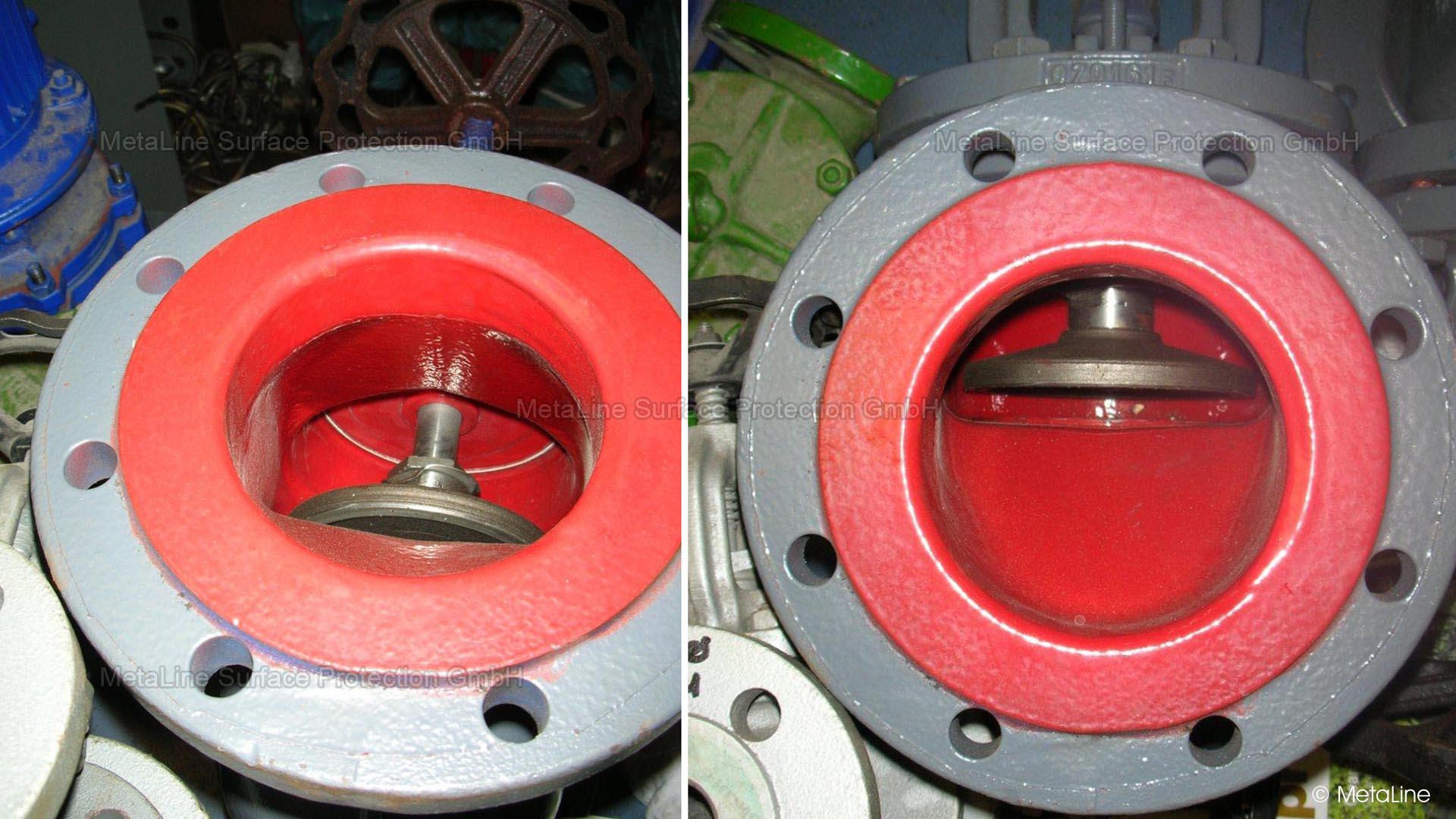

Typical damage scenario (cavitation) if no protective coating is applied. The next picture shows how it should be done

MetaLine's cavitation protective coat has been applied by the customer himself - technically welldone, optically not the first choice

Valve coating – Pitting corrosion of the most severe character! Damages like that typically have to be pre-treated by trowelable compounds. However not with MetaLine Series 700. This coating system has self-leveling properties and smoothens itself. Repairing and coating in one single step!

Butterfly valve coating – 2 pcs of butterfly discs during the polymeric rubber lining with MetaLine 785. More wear resistant compared to natural rubber, cold applicable and in addition available in a non-stick version. MetaLine - a real alternative to vulcanized rubber...

Stop valve flexibly coated with MetaLine – particularly effective corrosion protection

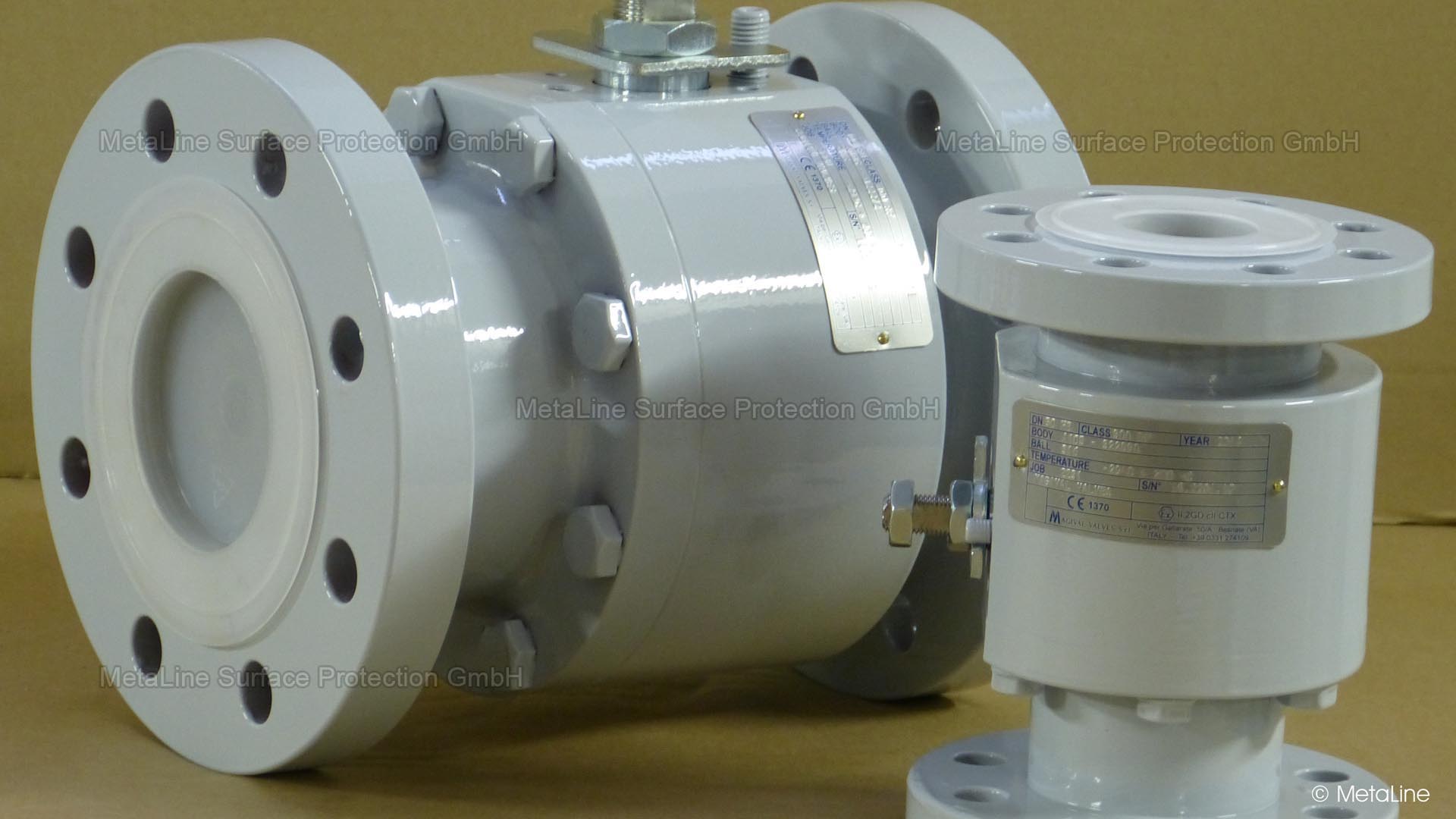

Valve coating – MetaLine 785 as seamless elastomeric inside lining of this saltwater valve

Large valve coated and protected with MetaLine 785 by the manufacturer

Valve coating – MetaLine 785 in tropical on-site use to repair a rubber gasket in a valve

Valve coating – MetaLine 785 is a perfect longlife coating solution to protetct inside and outside areas of valves

Fitting coatings – protection, insulation, function. MetaLine coatings solve most difficult protection demands