Tidal turbine coating - not only huge but also unusual. At a depth of 30 meters (95 ft), this tidal turbine coated with MetaLine 785 will permanently generate electricity - together with over 100 other machines! We are proud that the customer in Southeast Asia has placed its trust in MetaLine

MetaLine Series 700 protective coatings in pump storage hydroelectric power plants – firmly established

MetaLine Series 700 for components immersed in saltwater – heavy elastic corrosion protection in conjunction with excellent resistance against erosion and cavitation

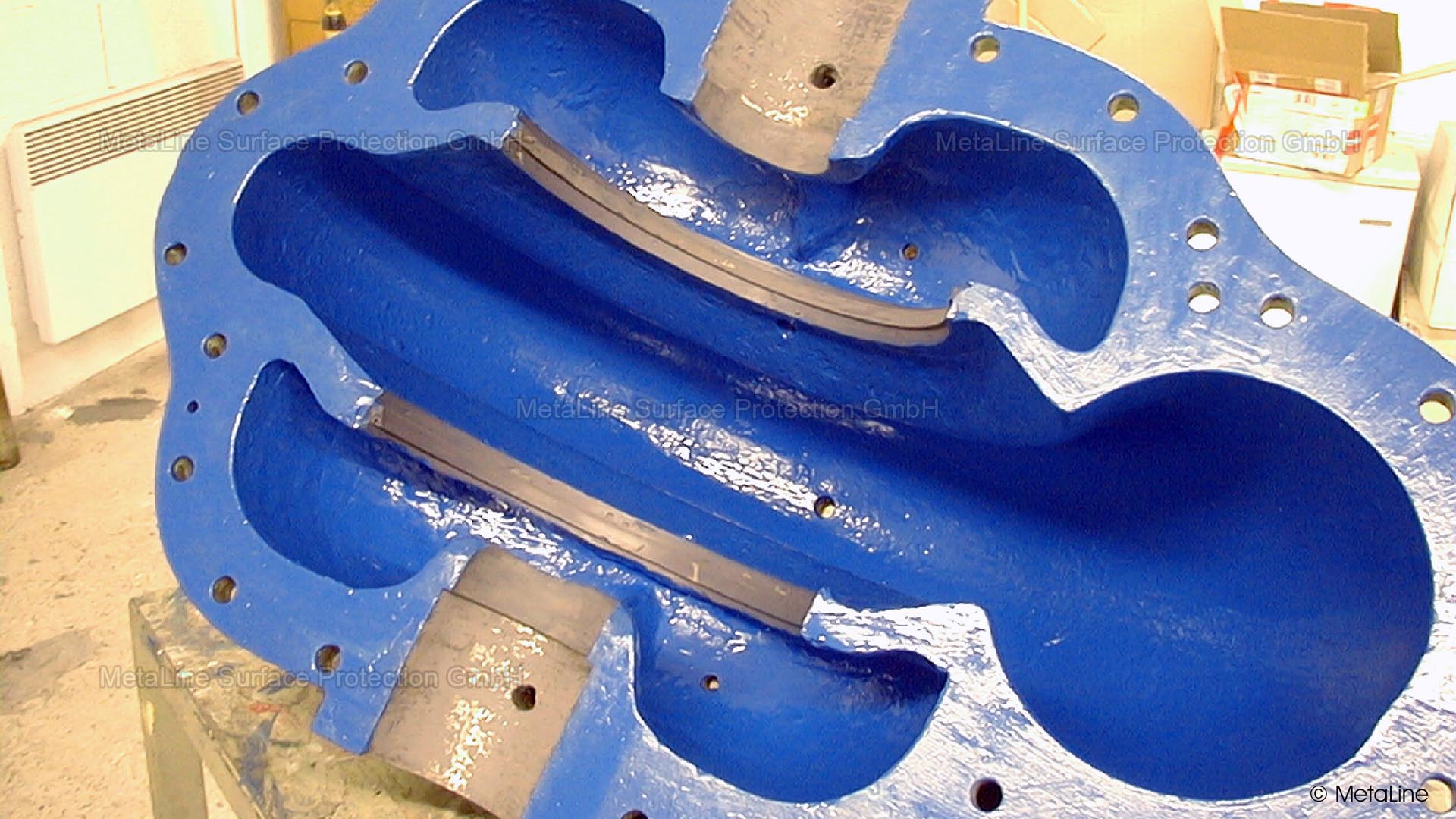

Bio mass pump for bio gas production – protected with 4 mm MetaLine 785 against wear caused by stones, soil, sand and other foreign materials

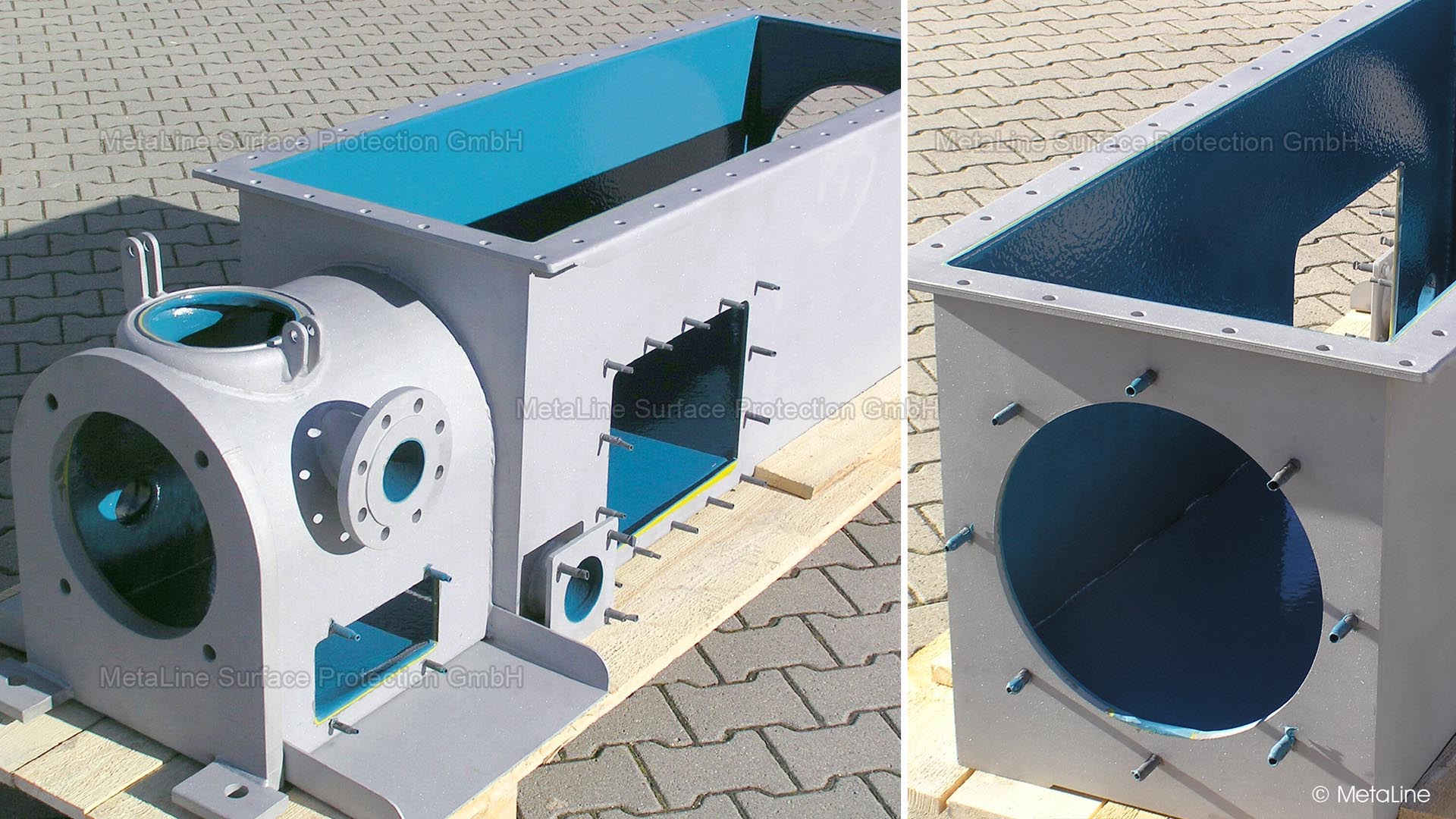

Biomass feeding – MetaLine 785 protects the casing of this biomass feeder from wear and chemical corrosion. 5 mm coating thickness makes the difference...

Hydroelectric power is absolutely environment-friendly but a power in its own right – MetaLine Series 700 coatings protect against cavitation and erosion

Tide turbine coating – this epoxy-resin based wing of a tide turbine is coated with a 1,5 mm tick MetaLine 795 coating to protect against sand erosion as well as marine growth. The extraordinary smoothness is a benchbark in MetaLine's quality philosophy...

Biomass treatment module – the manufacturer of these modules uses a 3 mm thick elastomeric MetaLine 699 coating which is applied by casting. Chemical corrosion as well as wear are constantly reduced

Especially exposed components in off-shore wind engineering – protected with MetaLine 795 against saltwater and aggressive atmospheric conditions