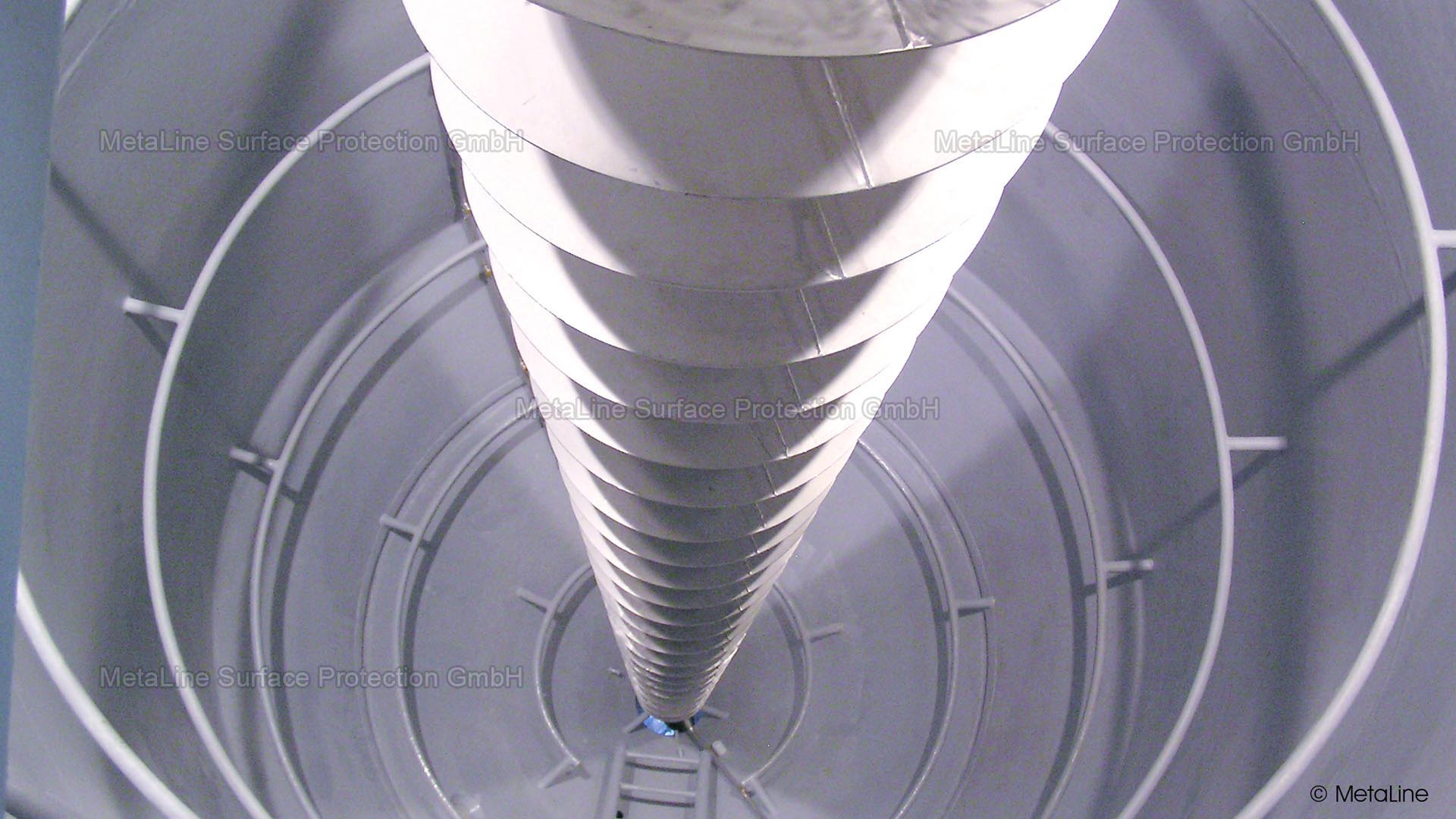

Conveyor worm coating – a conveyor worm more than 10 meters long coated with a combination of MetaLine 785 and 795. The field of application is a municipal bio-waste disposal facility

Pump optimization – a rock catcher attached to a pump housing for biogas plants. 4 mm MetaLine 785 protect the steel against corrosion and structural loss

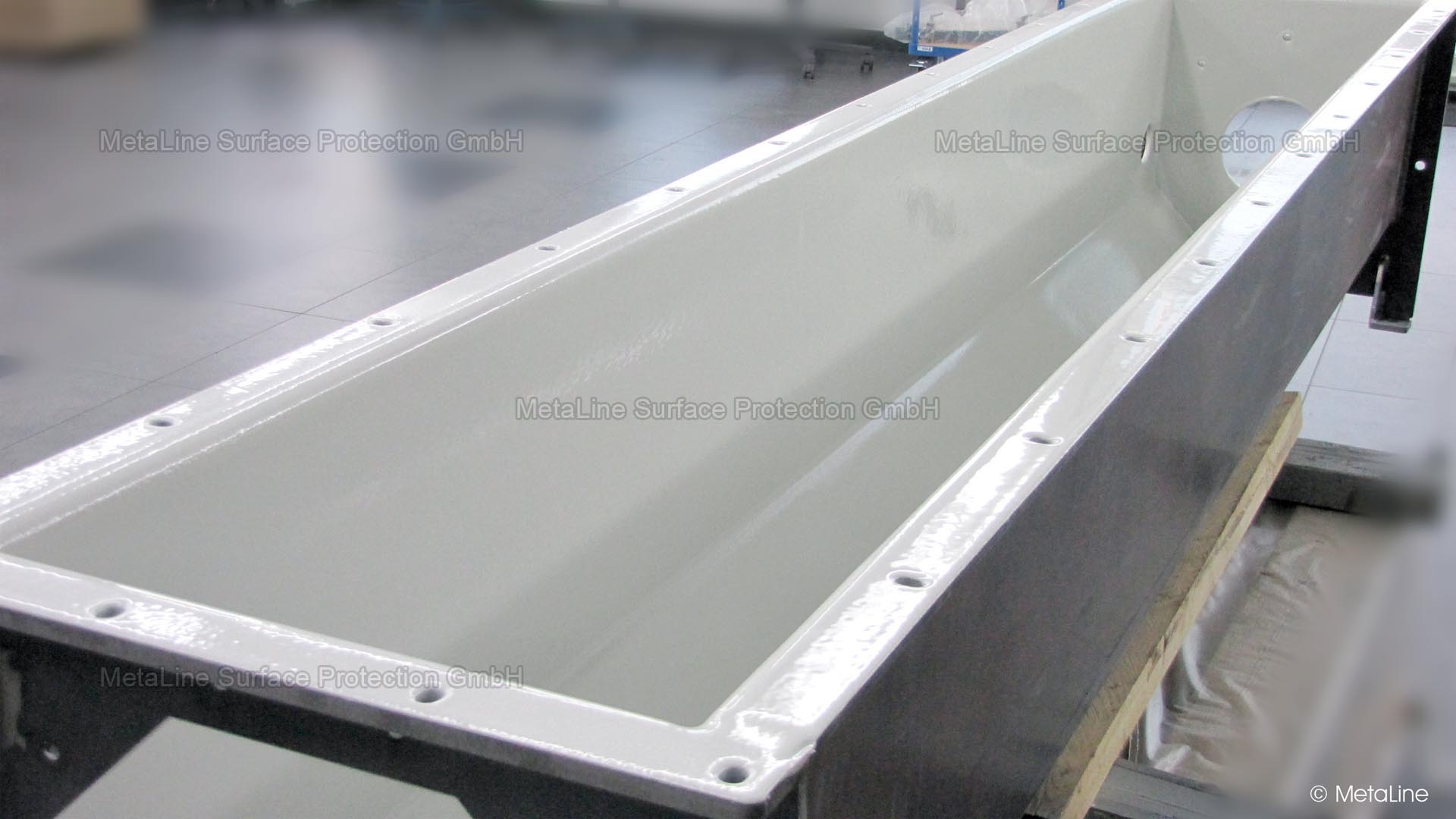

Silage conveying – MetaLine 785 protects the trough housing of this corn silage conveyor against wear and aggression. A layer thickness of 5 mm makes the difference . . .

Screwfeedercoating – MetaLine 785 does not only impress by its superior abrasion resistance but as well by its perfect surface characteristics

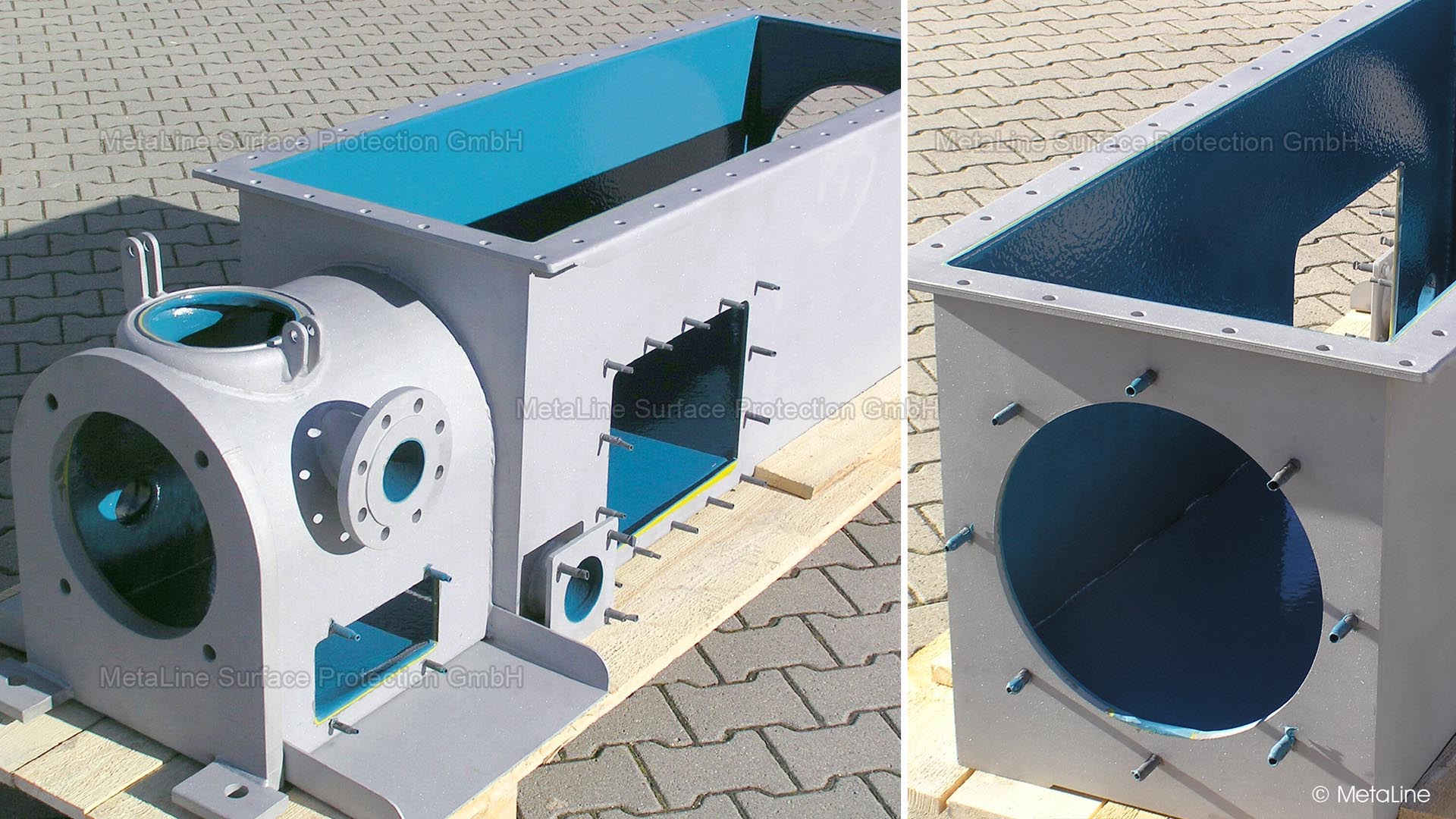

Snailbody coating – instead of using stainless steel a coating with 3 mm MetaLine 785 will even resist salty environments. MetaLine coatings are a real alternative in the construction of biogas systems...

Tank dome coating – good rubber technology may have a fantastic appearance as well. Particularly if instead of vulcanized black natural rubber, a polymerizing MetaLine Elastomer is being used. The advantages? Seamless, tension-free, variable thicknesses, cold curing...

Biomass conveyor – the module is coated by the manufacturer ex-works in the floor area with a 3 mm strong elastomeric cast coating consisting of MetaLine 699. Biocorrosion, chemical attacks and mechanical wear are permanently minimized

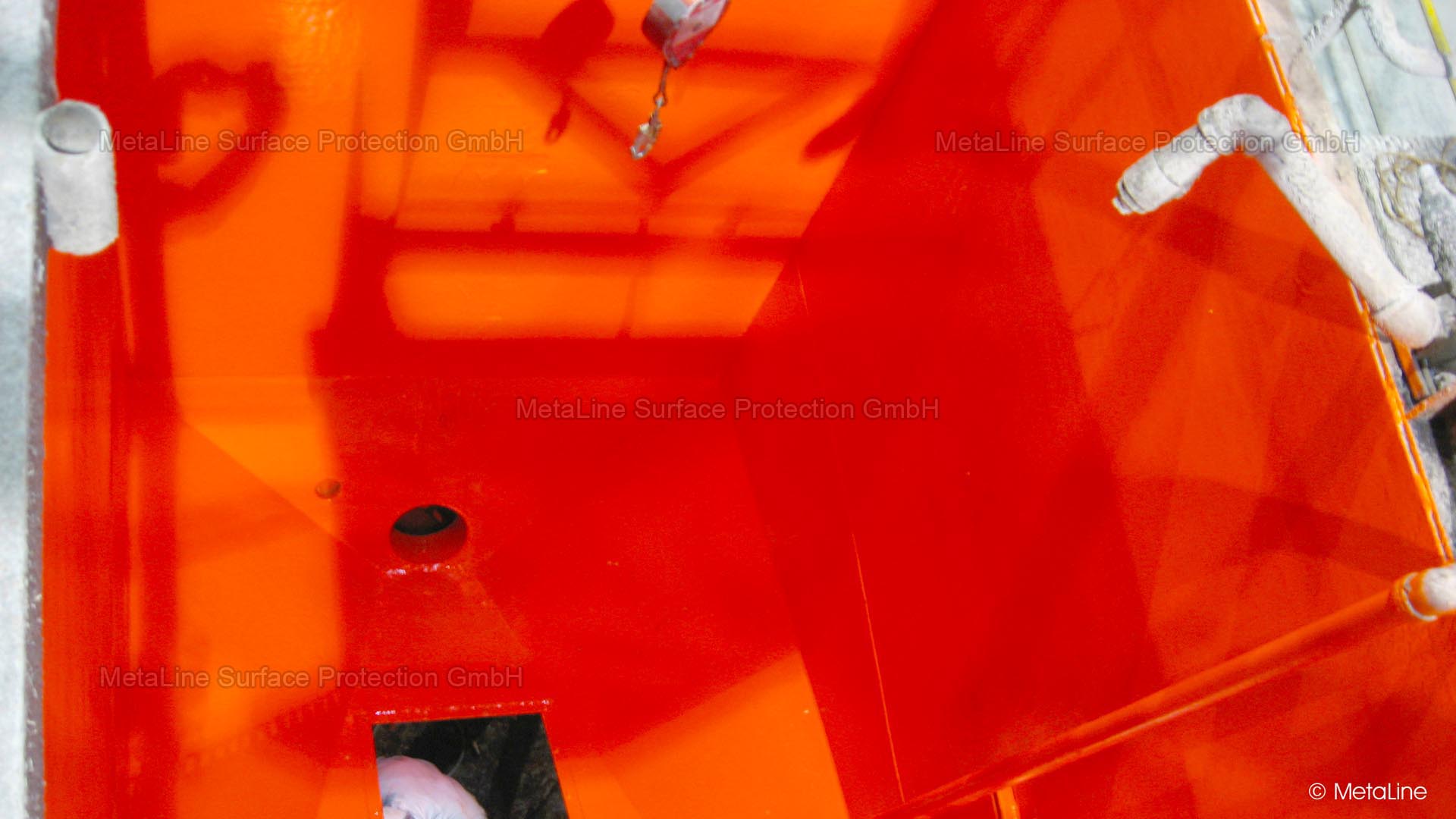

Container lining – smooth, non-adhesive, biologically resistant. MetaLine 795 is the perfect choice when it comes to composting waste. Permanent resistance against biomasses and their segregation is provided

Rubber coating of containers – lining of metallic silos with MetaLine. Chemical attacks are thus prevented securely