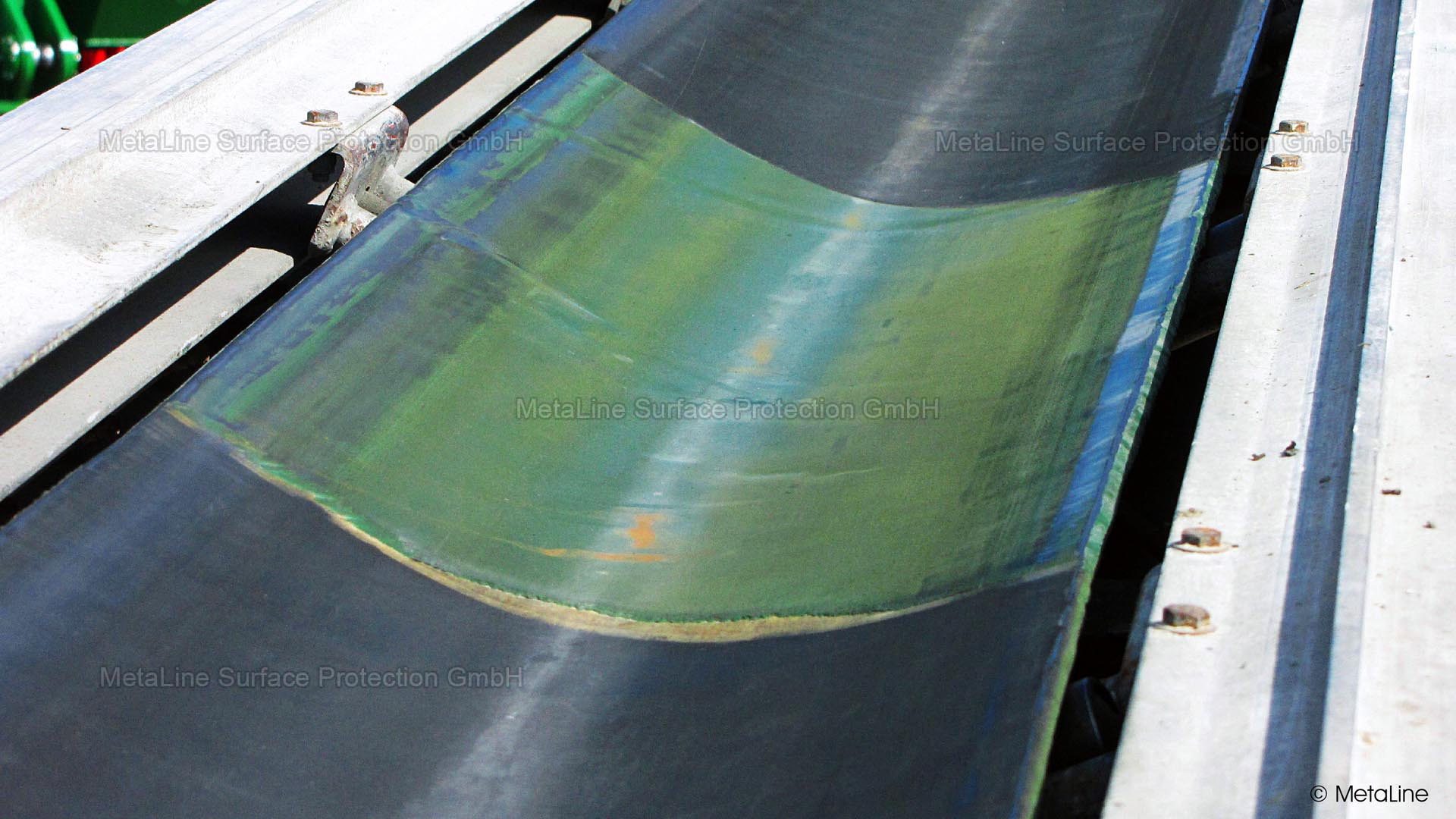

Non-stick coating for coal transport – problem solved with MetaLine 795

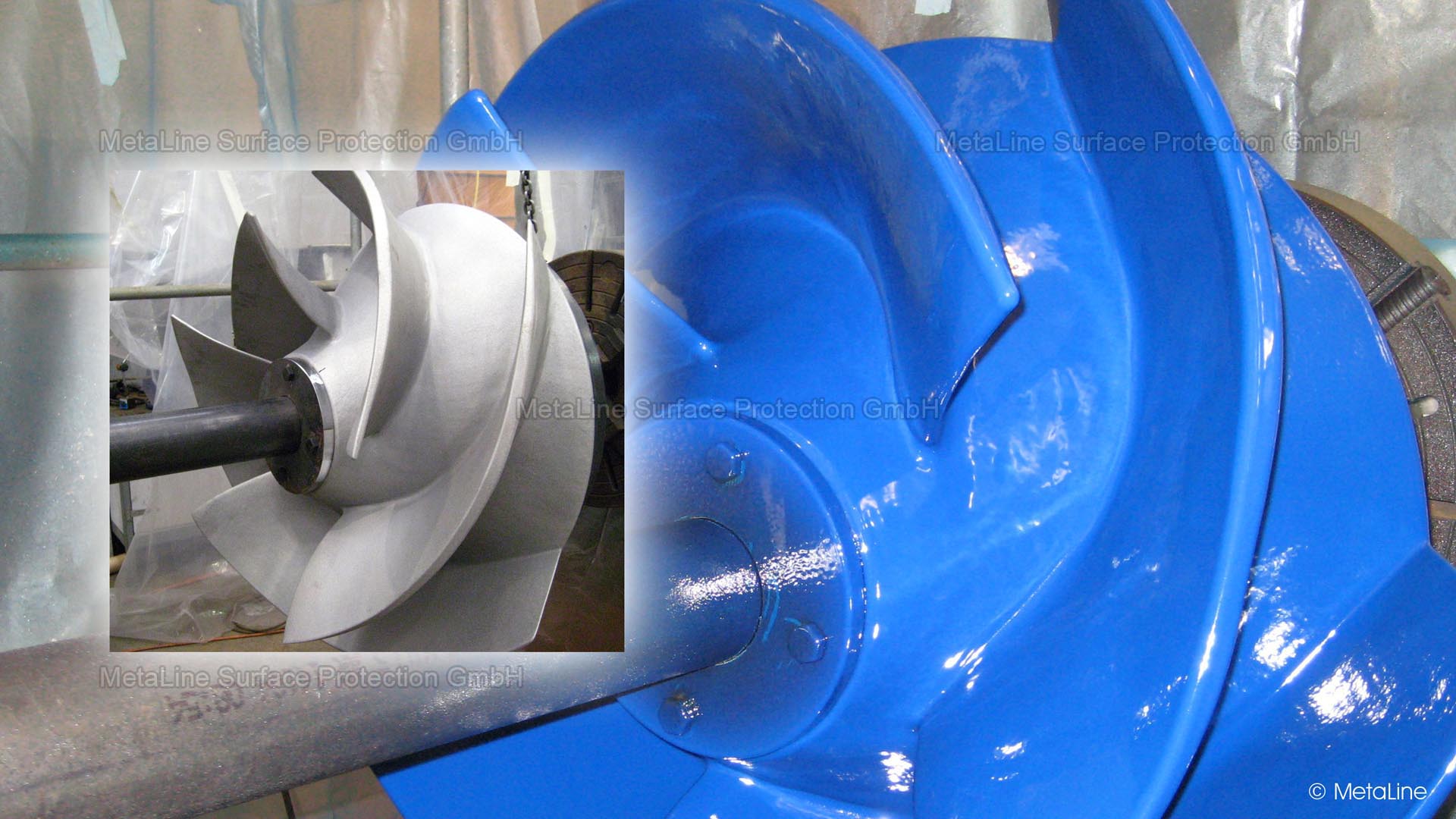

Coating with MetaLine 795 results in a lower friction coefficient – non-stick features with elastic memory

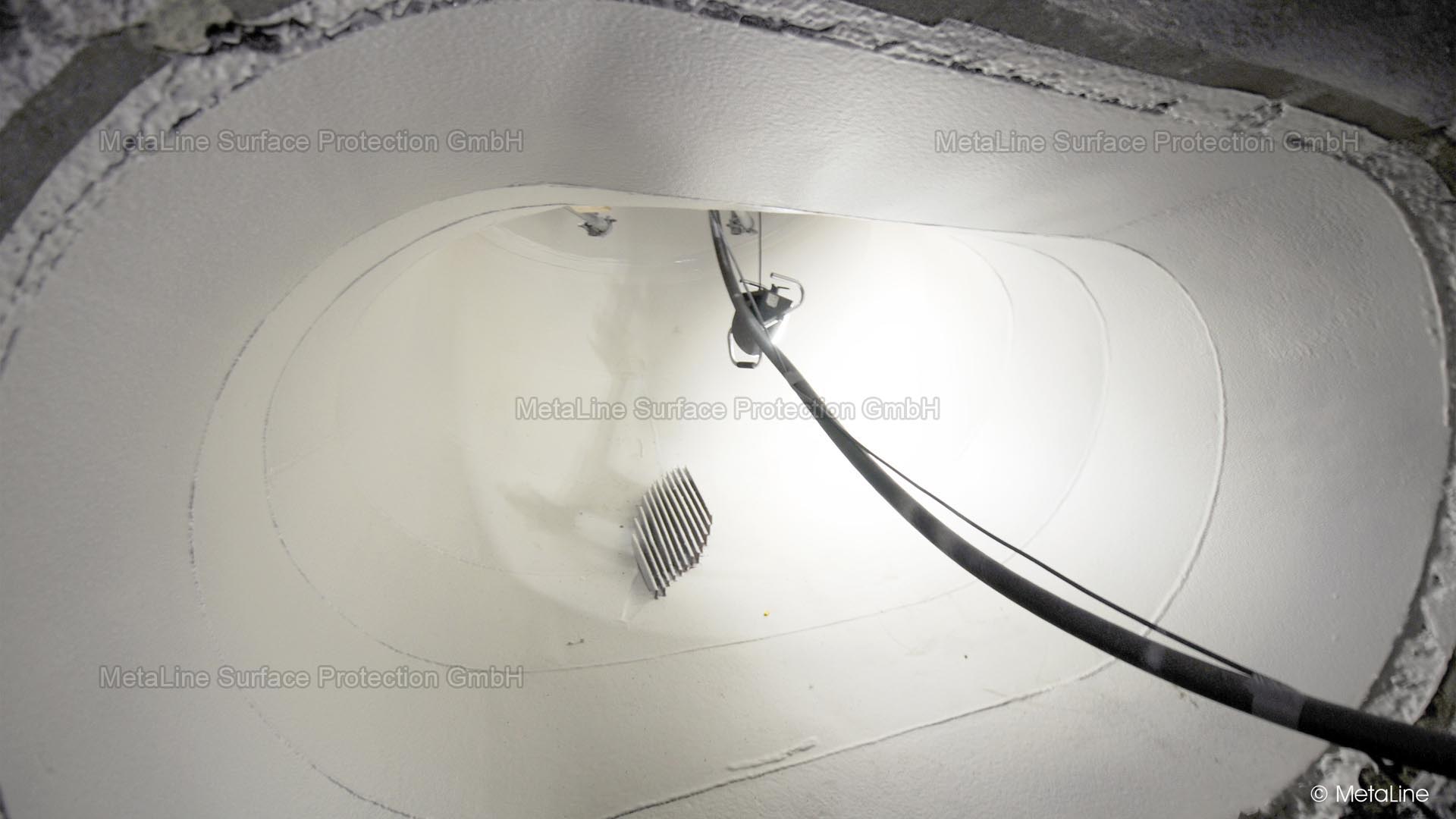

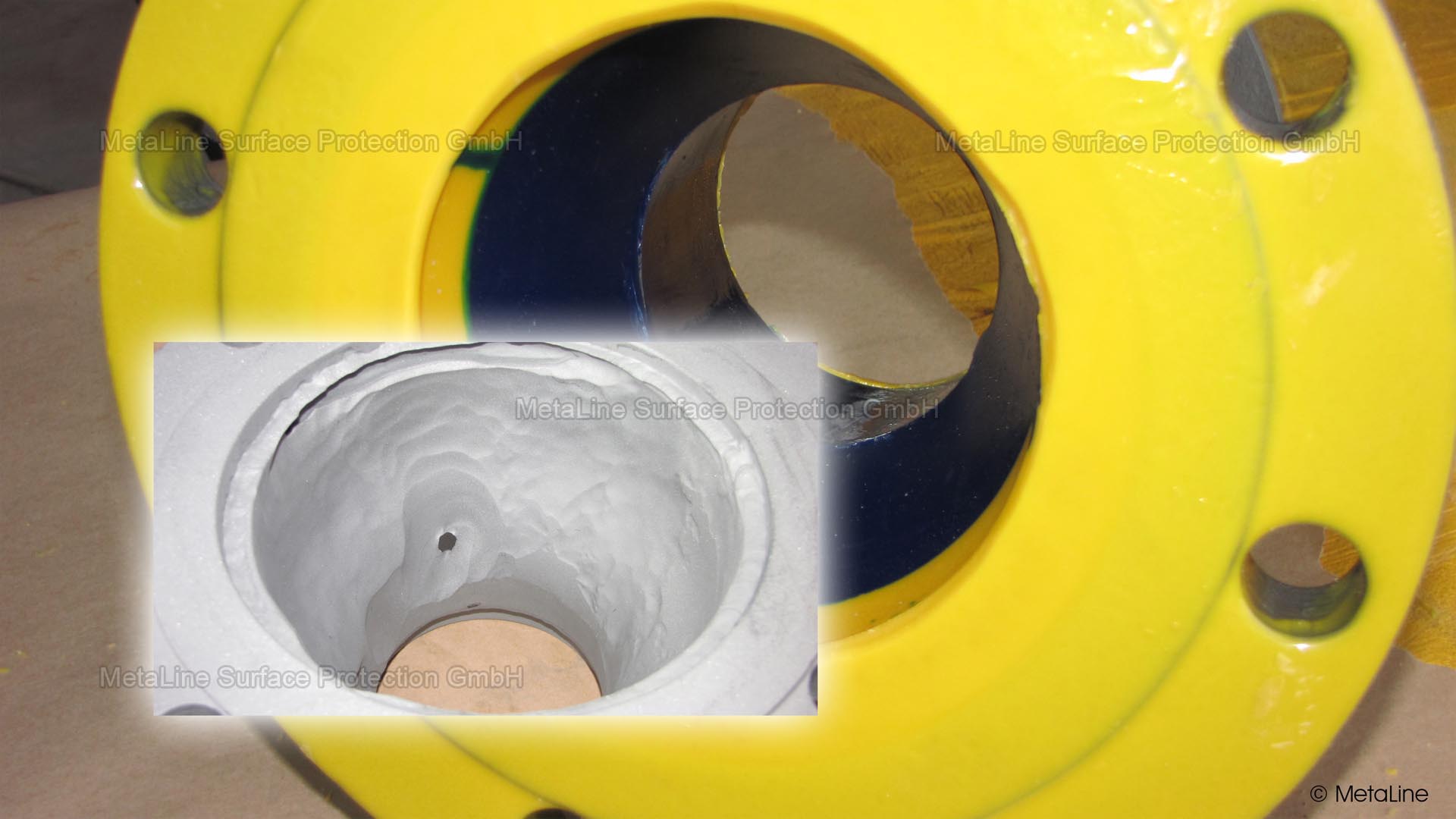

Filter body coating – what is special about this picture? That we do not use brushes or trowels anymore like our competitors. MetaLine is sprayed on precisely, even, homogeneously and quick. A garden fence can still be brushed in the 21st century – but a technical challenge like that requires a more appropriate application method...

Rubber coating - MetaLine 785 for subsequent sealing and waterproofing of this natural rubber lining in a flue gas desulphurization system. A synthetic MetaLine polymer rubber coating is seamless, absolutely tension-free and has a significantly lower weight per unit area.

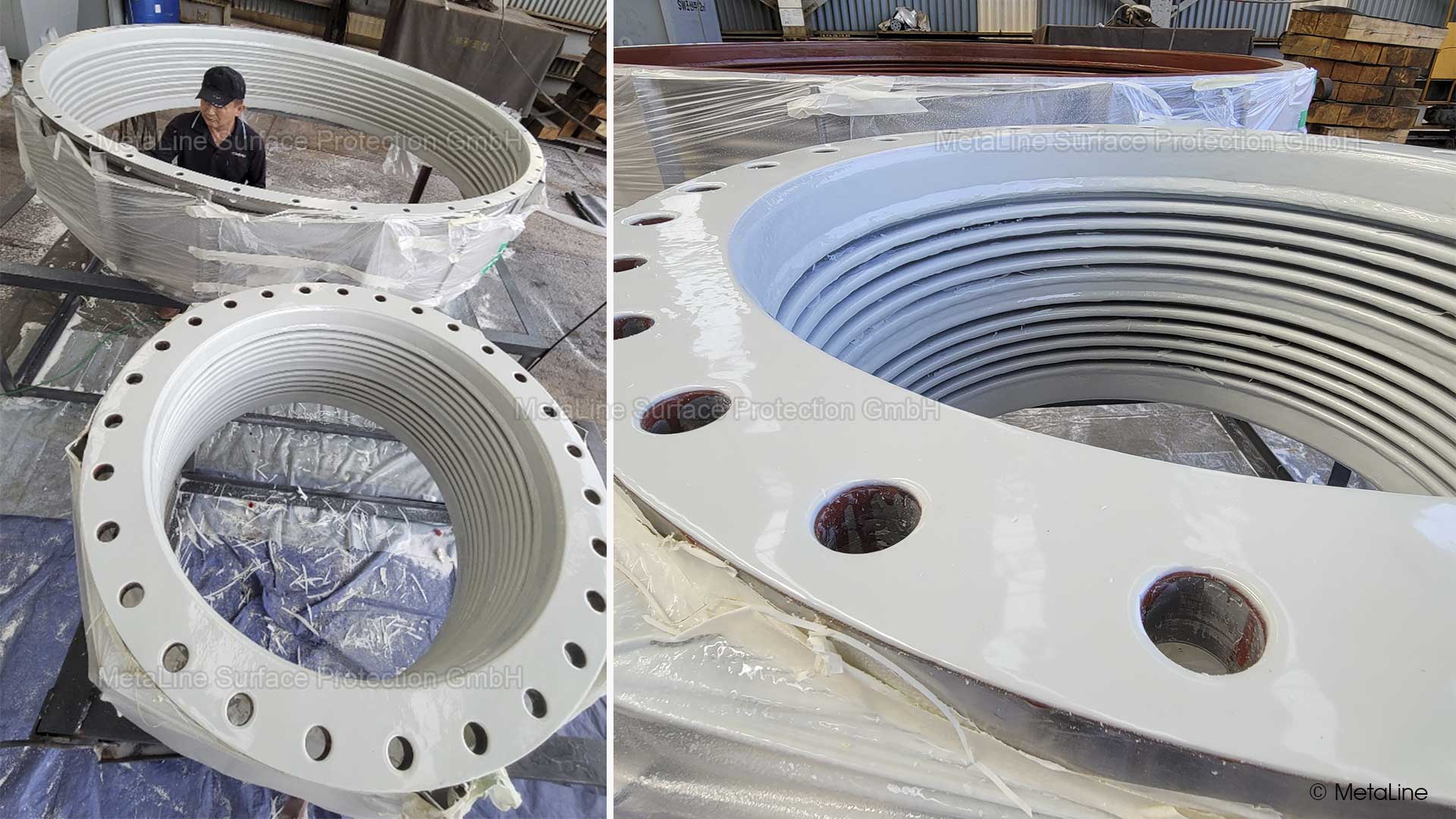

A different kind of cooling water transport – protected with MetaLine 785

Reducer coated with 5 mm MetaLine 785

Cooling water pipe coating – MetaLine 785 resists all forms of water flow including impacting particles. Cooling water inlets of power plants can be perfectly protected with this rubberlike skin

Pipe bends for ash feeding coated with MetaLine

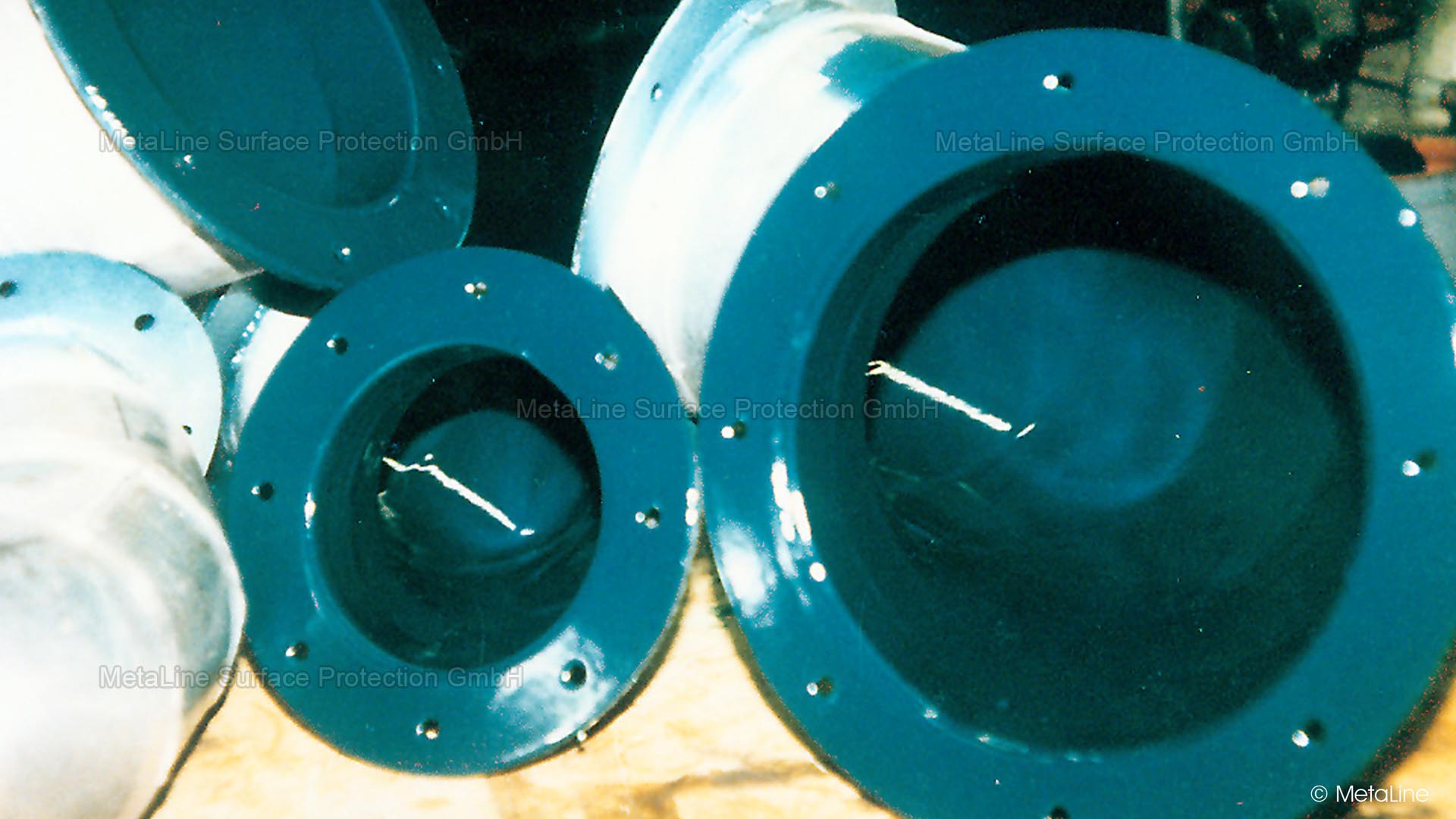

GFRP-coating – composite pipes have a higher thermal expansion or shrinkage when exposed to temperature changes compared to metals. Hairline cracking and substantial wear in combination with colliding solids are constant problems. MetaLine Series 700 with its elasticity between 275 % and 650 % fulfill these demands in a remarkable manner. With a top coat of MetaLine Series 700 the plastics may still crack but will never ever leak in any way!

Corrosion protection – if your protection needs in pipes goes beyond ordinary corrosion protection, MetaLine with its rubberlike impact absorbing characteristics comes into the game

Liquid rubber lining – that is the unique selling position of MetaLine. To realize seamless elastomeric coatings without vulcanization in-situ and to become independent from contractors and expensive application equipment...

Repairing longitudinal cracks and coating of joints on conveyors – an important issue with MetaLine 760 for coal feeding

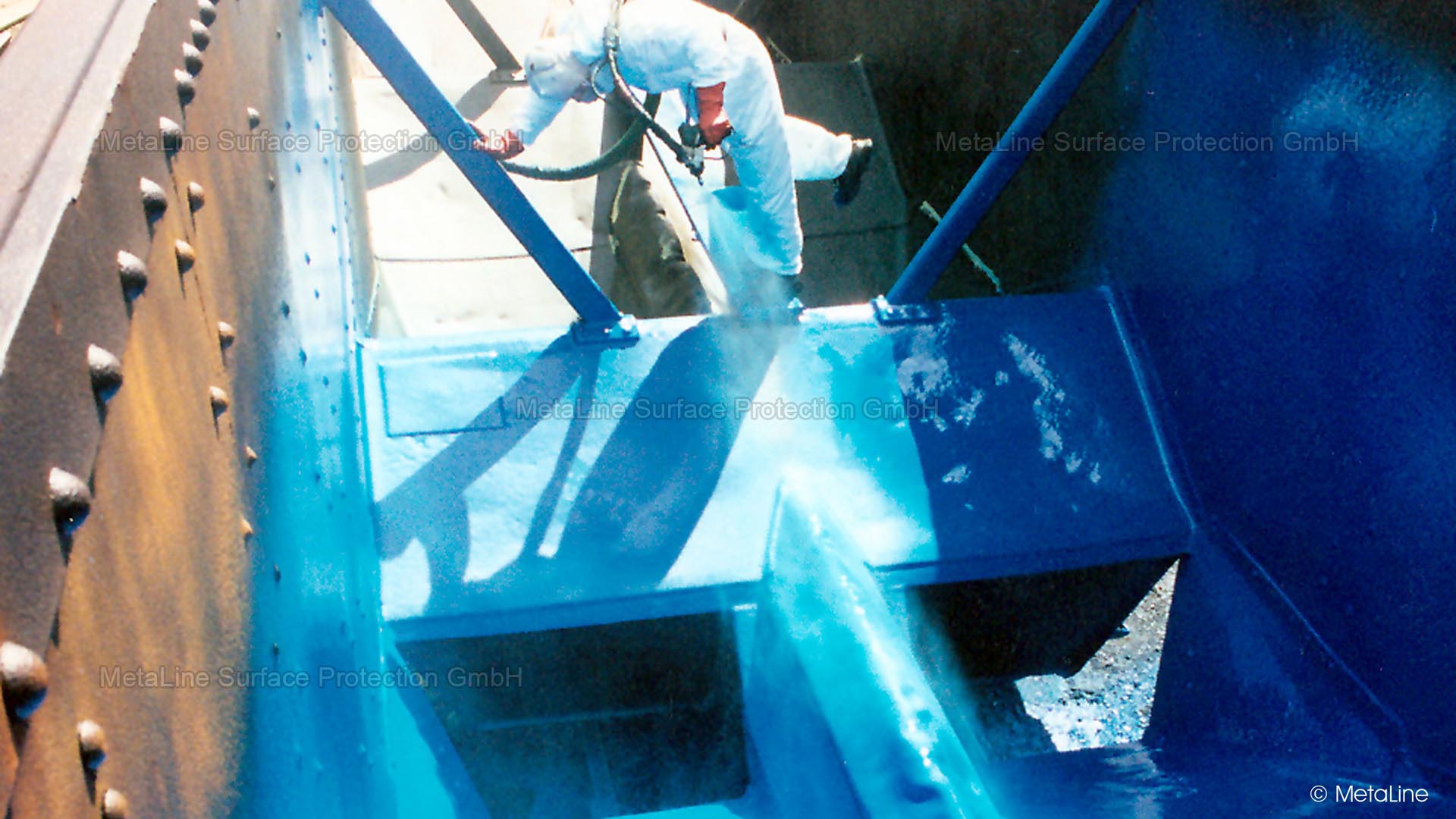

GAVO (gas preheaters) – flue gas washing of an Austrian power plant during MetaLine repair coating

During substrate preparation – flame treating for removing capillary humidity

Ready – MetaLine protects against corrosion, chemical attack and surface destruction

Heat exchanger coating – the bottom plate of this heat exchanger model is treated ex works with MetaLine 785 to prevent electro-chemical corrosion. MetaLine’s Original Equipment Manufacturer activities are remarkable for a coating system which originally had been designed as repair technology

Corrosion protective coating – a treatment with MetaLine 100 XTM protects this compressor casing from corrosion, abrasion and chemical attack

Coating technology – None who is not talking about quality and be famous for his quality. However MetaLine prefers to talk about Know-How. To have more knowledge than others. To have more knowledge than others because we concentrate on a small product portfolio. Less products simply means to know more about each individual product? This is where real quality starts...