Constantly in use, constantly stressed, and with little time for maintenance – the typical lifecycle of a Francis or Kaplan impeller. Even minor irregularities created on these precision blade surfaces lead to flow-induced turbulence that can trigger additional wear and tear. Instead of "stress-loaded" welding, alternative repair technologies should also be considered.

Ask us about: francis impellers, kaplan impellers, pump impellers, rotors, water brakes

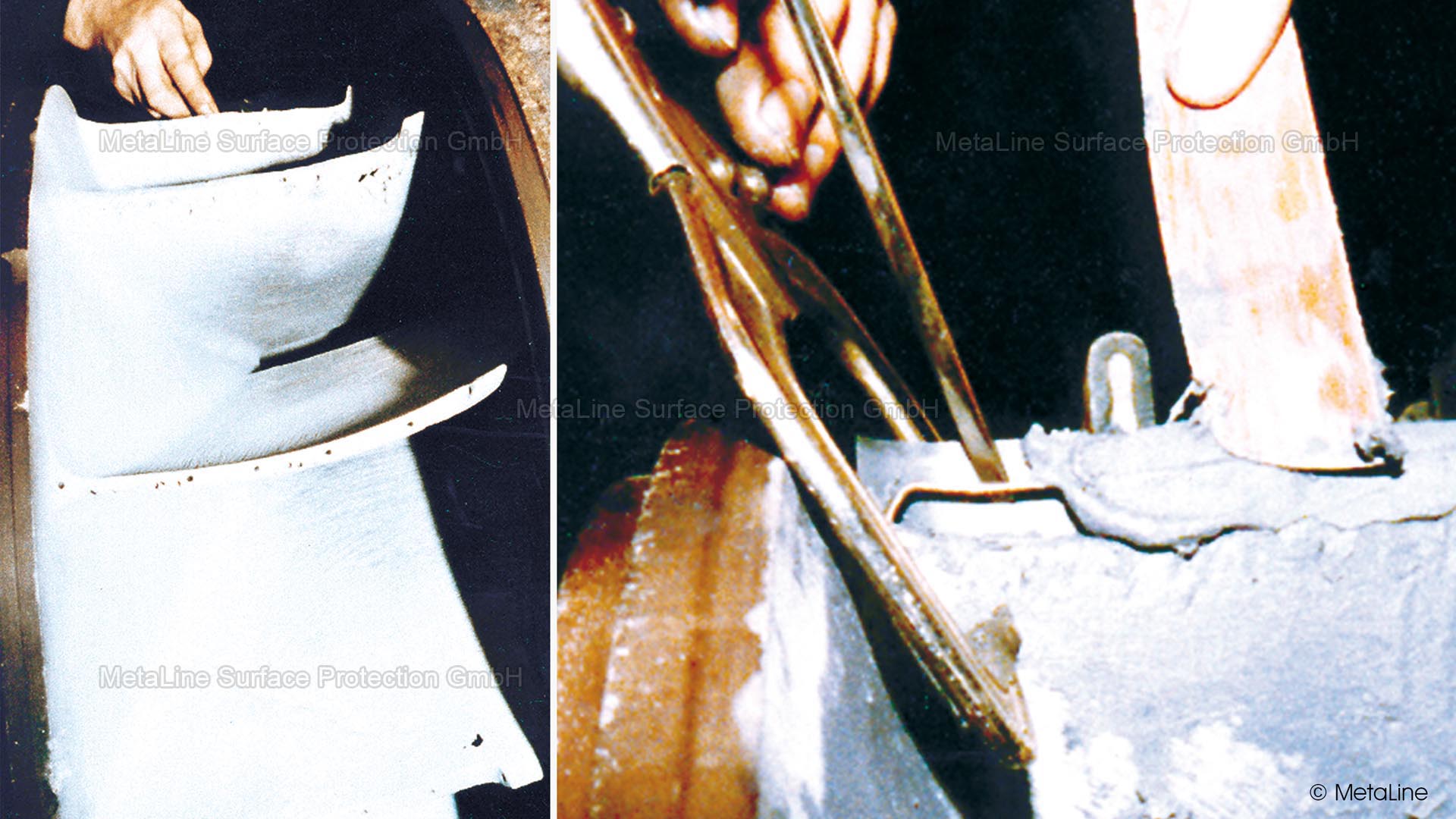

MetaLine Series 700 – Sprayable / OEM Manufacturer quality MetaLine Series 700 coatings absorb destructive impact energy and vibrations through a permanently elastic material behavior. The coating thickness is individually adapted to the load parameters and flow conditions of the turbine design. The particularly smooth surface structure prevents turbulence and is exceptionally cavitation-resistant. MetaLine Series XL – Trowel- or brushable / Repair quality MetaLine Series XL are low-weight, flat-coat or brush-on repair materials. They serve to recontour partial erosion states. Due to the completely temperature-free processing, no surface tensions arise. The materials are electrochemically neutral and do not lead to bi-metal corrosion. Installation does not require trained hands and can be implemented insitu without dismantling the runner.