Sludge mixer protection – nothing you would like to dip your hand in. Our MetaLine 785 protective coating is not that choosy and protects, protects, protects...

Pipeline coating – MetaLine 785 is being used on site to seal and repair this sewage pipe made from concrete

Waterfilter coating – this equipment would typically just be scrap. However the ceramic based surface renewing systems MetaLine Series XL repairs the existing damages. A protective topcoat with MetaLine Series 700 prevents future failure and destruction for a very long period

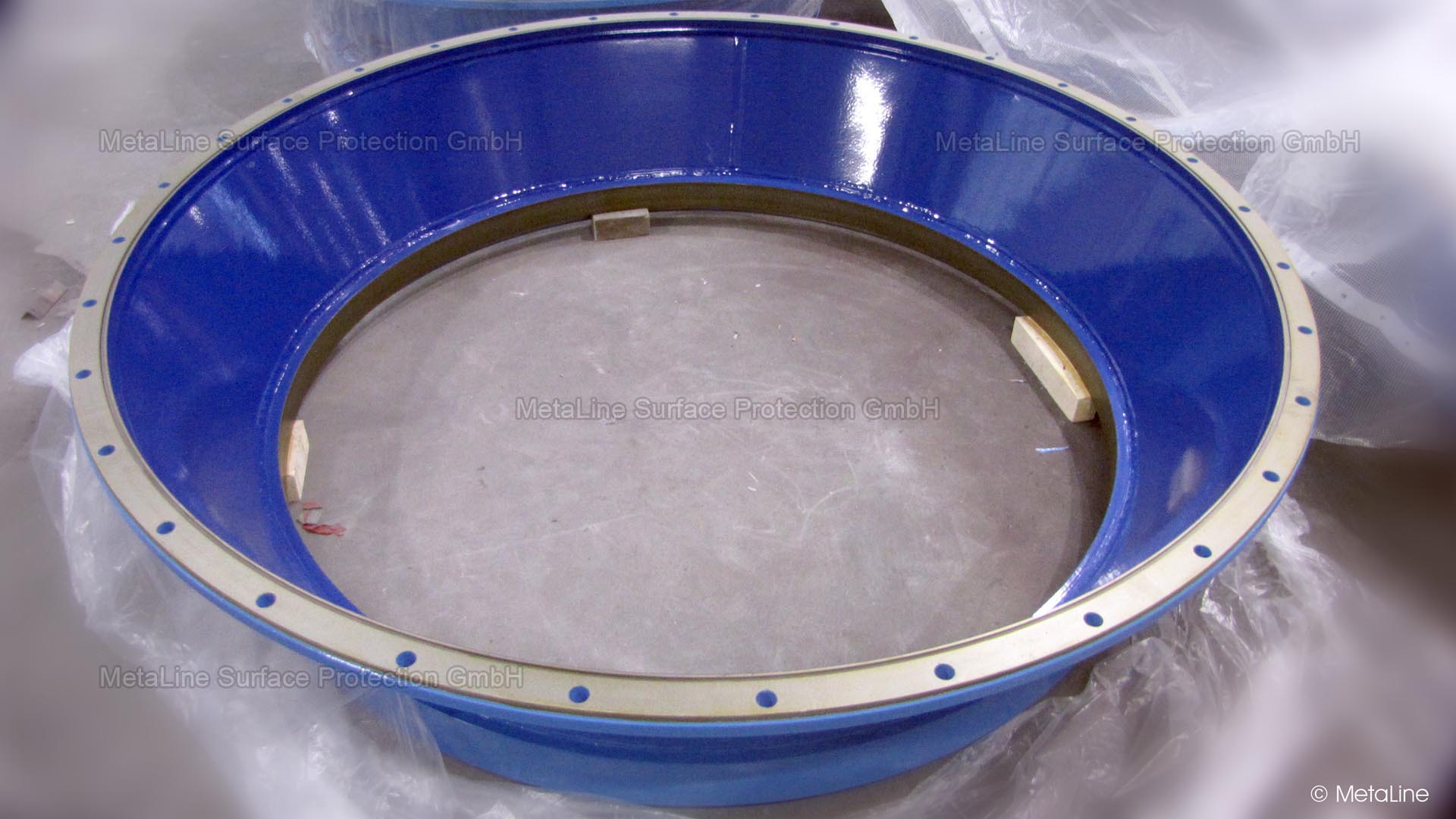

Filtercoating – multi-step MetaLine corrosion protection concept. One of the most important characteristics is the impact resistance of our elastomeric coating system. Injuries during assembly and removal of the filter cartridges are prevented!

During coating with MetaLine Series 700. Processing was done due to the part size with a 2-component high-pressure hot-spray gun

High-pressure ball valve of a drinking water pipe in Saudi Arabia – coated on the inside with 5 mm MetaLine 785

Shut-off valve coated with MetaLine 785 – permanent protection against solid impact and corrosion

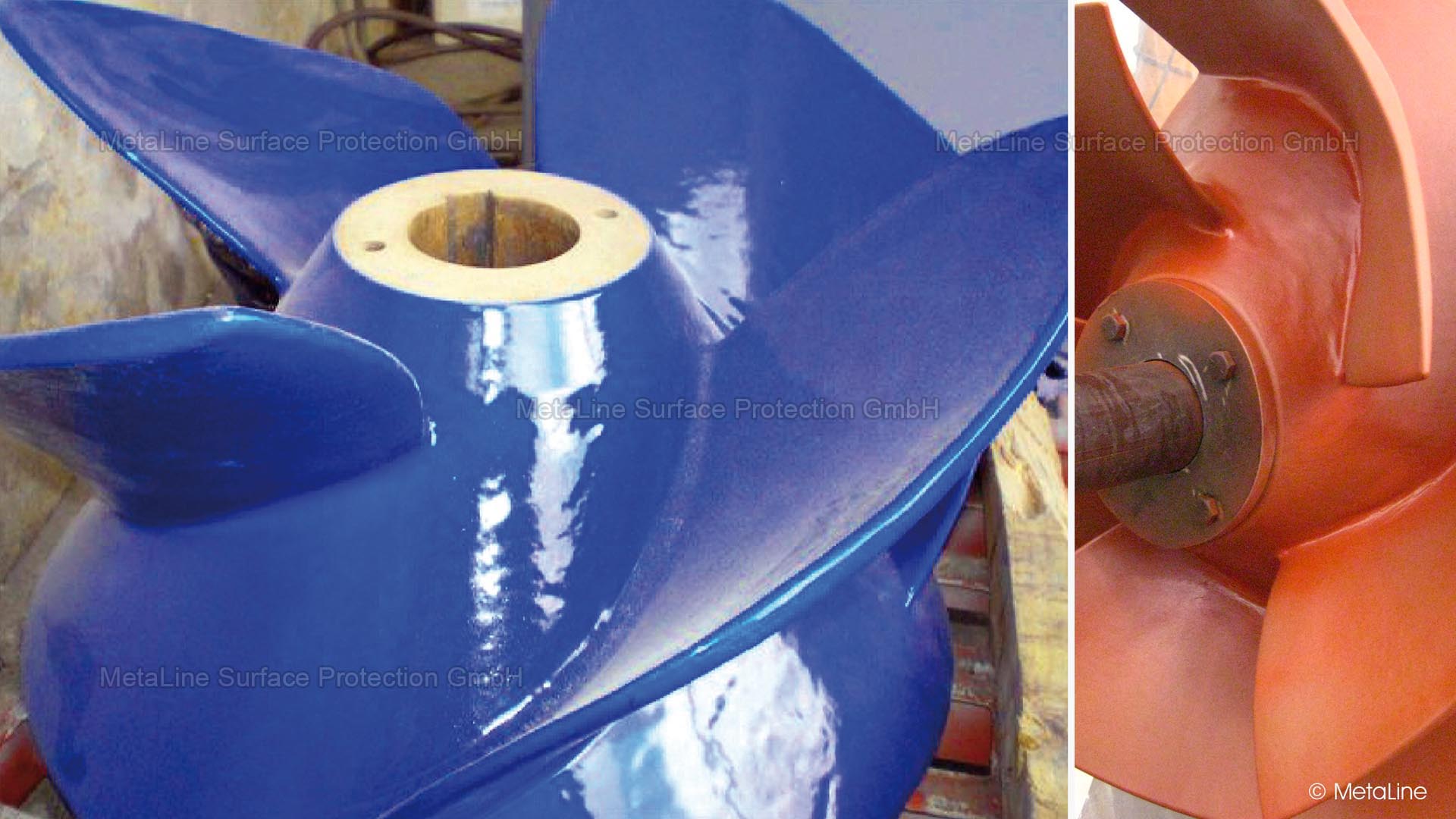

Agitator protective coating - this mixer manufactured by KSB Germany had been severely injured by an impacting foreign object and the FRP structure has suffered. A spare part would have costed about 3.000,- EUR plus a longer transport time. MetaLine 785 has solved the problem directly in Malaysia, plus added an improved impact resistance to the full wing structure

Pump component of a drinking water supply in Lisbon – coated with 2 mm MetaLine Series 700

Protective coating – a 3 mm thick, seamless lining with MetaLine 785 protects this water-inlet from mechanical as well as chemical aggression

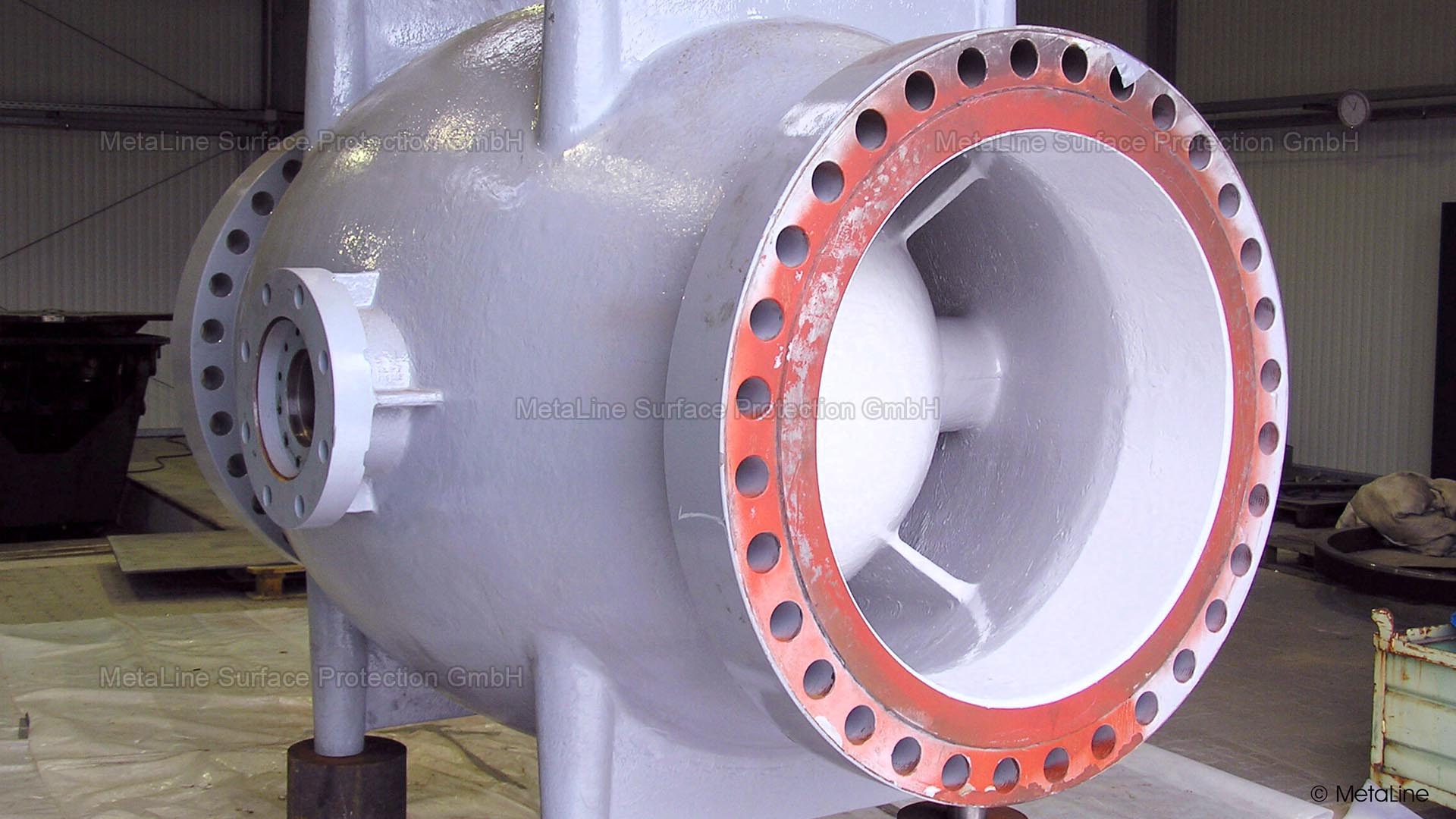

Pump coating – 5 mm of MetaLine 785 protect this hardmetal pump casing from a south German sewage treatment plant

Pump impeller coating – besides its unbelievable erosion and cavitation resistance, MetaLine Series 700 can be machined by milling, drilling or lathe operation. No special tools or treatments are required. Choose the typical machining figures as for an 80 Shore A natural rubber to receive perfect results

Detailed view of seamless application with MetaLine Series 700

Concrete clarifying basin seamlessly coated with MetaLine 785