Mining coatings – MetaLine wear protective coatings are problem solutions which have been purely developed for on-site applications – under all climatic conditions

Flotation cell coating - this is how professional wear protection must be designed. Completely seamless, elastomeric, erosion-resistant and repairable on site at any time ...

Floatation cell repair – MetaLine coatings can be repaired and overcoated with itself anytime – simply, economical and efficient!

Flotation tank coating - during on-site coating of an installed flotation bottom tank with MetaLine 785. Coating thickness approx. 5 mm. Precise execution is a decisive factor for longevity. Compromises at this point unfortunately mean a considerable functional risk!

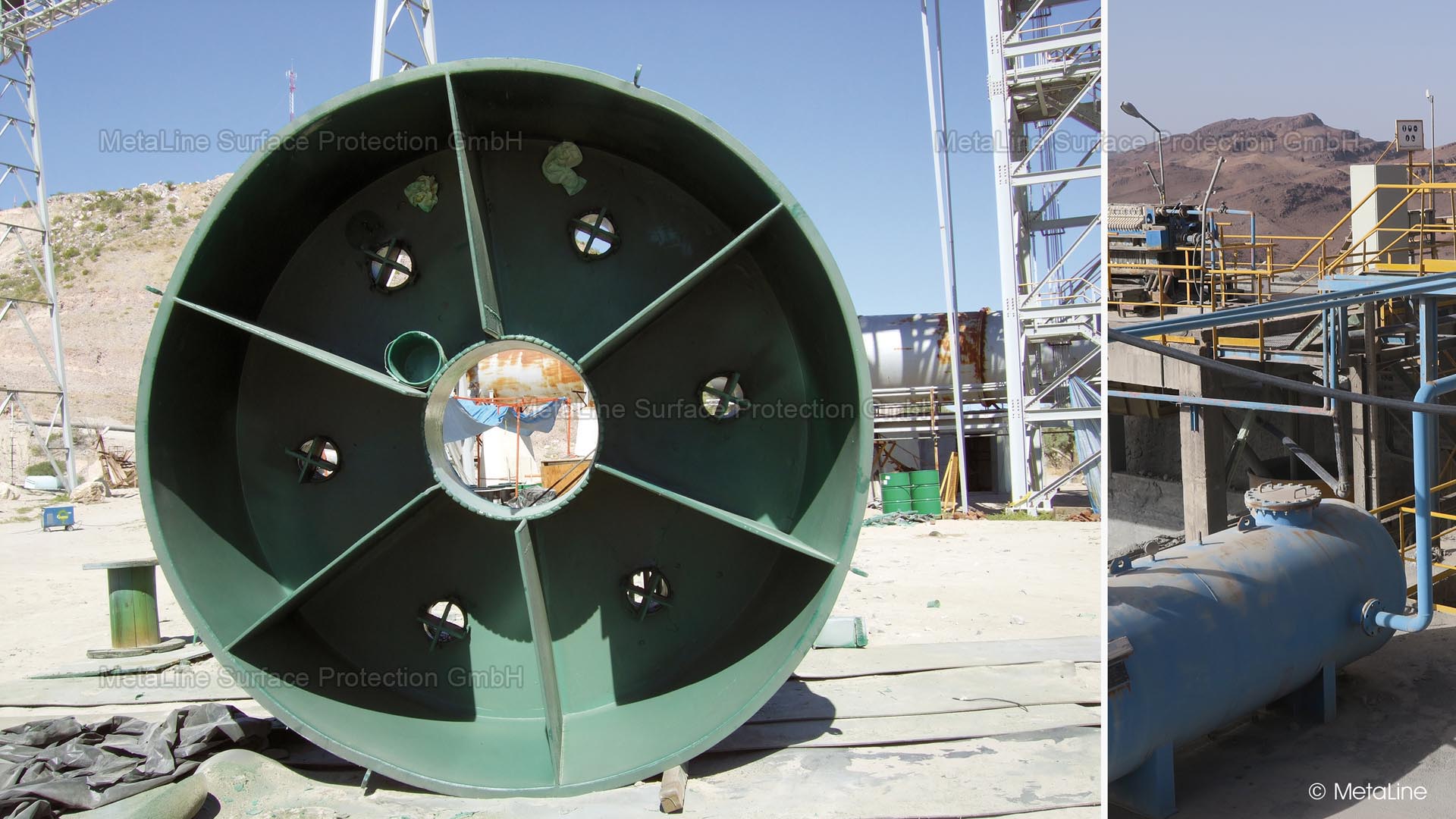

Flotation lining - manifold of a flotation plant protective coated with MetaLine 785 - inside and outside. A geometry which cannot be covered with natural rubber. Only sprayable solutions can help here - the specialty of MetaLine!

Flotation cell coating - yes it's true! There are extremely many application pictures on our website! But how else should we document and prove our decades of experience and competence? We do not promise you simple solutions - but good ones!

Magnetic separator coating – MetaLine Series 700 is a proven surface protection concept in the overall technology of solids decantering, as on this magnet separator of the brand Eriez

Flotation coating - MetaLine Series 700 is used in the extraction of all types of mineral resources. Our focus is on solving problems - you won't find MetaLine on large-scale projects!

Heavy duty corrosion protection coating – MetaLine Serie 700 is much more than a simple anti-corrosion system. The tear resistant elastic skin resists various mechanical influences and permanent stress

Agitator coating – MetaLine 785 in a total thickness of only 4 mm (160 mils) protects theses heavy mixer shafts from wear and chemical attack

Agitator protective coating - if necessary, MetaLine Series 785 can also be applied outdoors - not an ideal location, but technically possible! But please contact us beforehand if you would like to realize such a project!

Spiral concentrator coating – MetaLine protective coatings can be bonded safely to various substrates. Here on a concentrator made out of GFRP

Spiral concentrator lining – there is hardly a more convincing technical argument for a sprayable elastomeric lining as with this shape. MetaLine 785 can be applied absolutely free of tension, without any seams and in every desired thickness. MetaLine – the more modern way of creating rubber characteristics...

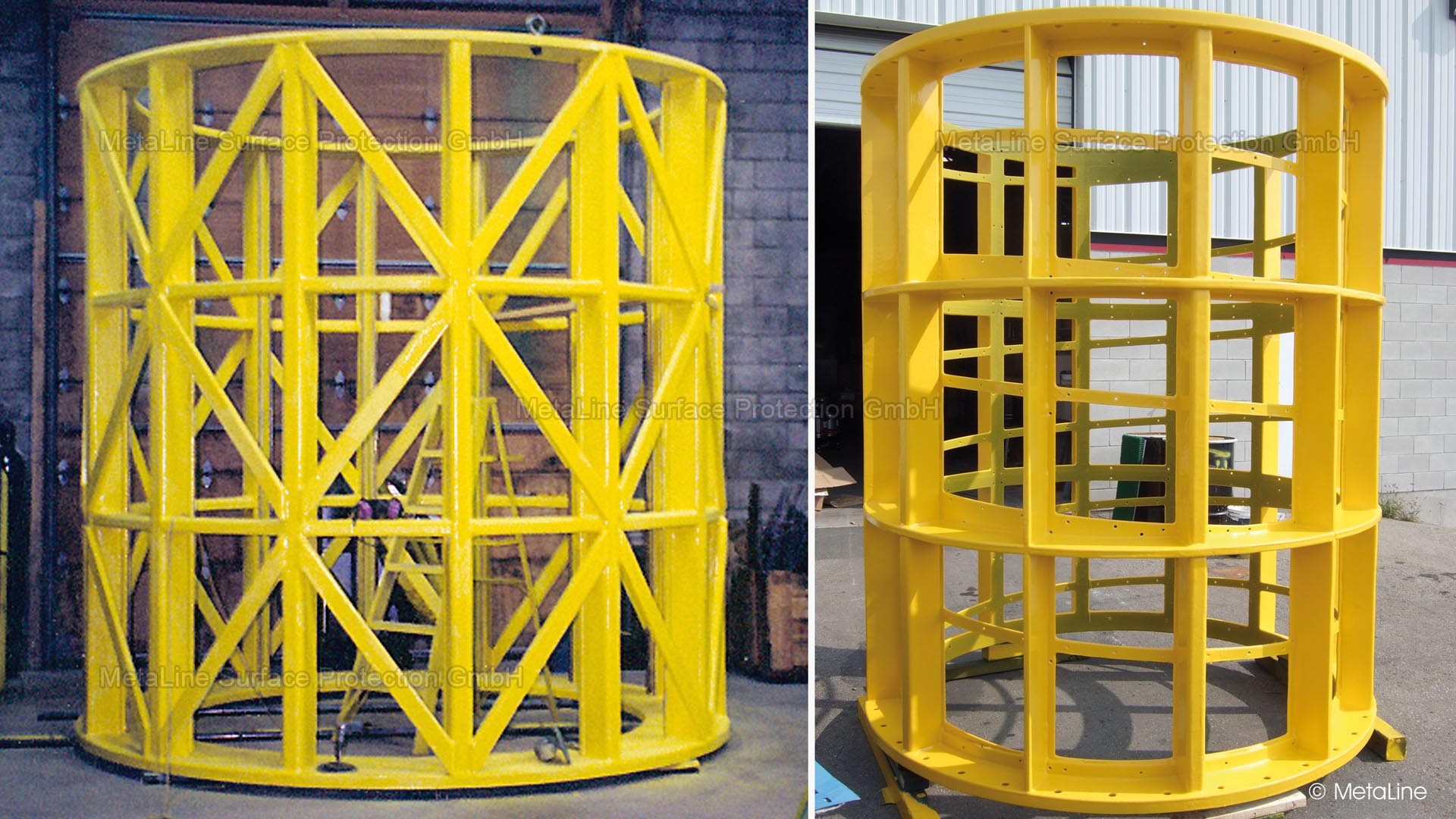

Drum screen coating - screen frame construction during on-site recoating with an elastomeric MetaLine coating. A complex geometry that requires precise preparation and execution. You can't do it without attention to detail!

Drum screen lining - coating of the complete frame construction of a drum screen with 3 mm MetaLine 785. The quality control afterwards is almost as complex as the coating itself

Funnel coating – MetaLine Series 700 is the first choice if complex surfaces have to be protected on-site against wear and loss of static strength

Slurry coating - parts of a Chilean copper mine during coating with MetaLine 785, applied with a 2-component high-pressure spray machine

Internal pipe coating - 12 meter (39 ft) long pipes coated on the inside with 15 mm (0.6 inch) MetaLine 785, applied using a coating satellite

Pipe protection – for the most severe cases. MetaLine 785 applied thick as a thumb to fight the most abrasive slurry conditions locally ...

Floatation cell lining - system protected with MetaLine 785. The MetaLine cartridge spray system is unbeatable, especially for repairing existing linings. Can be applied at 100 % humidity ...

Flotation cell coating – several with MetaLine 785 protected flotation cells wait for their final installation on the mine site...

Elastomeric lining- complex surface structures are a weak point for common rubber linings but however a strength of sprayable MetaLine Elastomers of the Series 700 – just seamless really fits

Flotationtank coating – even after long usage a convincing picture. MetaLine Series 700 – because there is no rubberlining which can be more seamless

A coating with MetaLine 785 in a thickness of 3 mm protects this floatation cell against erosion and corrosion

{/show}

Floatation coating – a full equipment line which had been coated with MetaLine 785. After 2 years of operation the belorussian potassium mine reported about no signs of wear or abrasion on the coating. MetaLine received a written customer reference including a confirmation about the perfect suitability of MetaLine coating systems for floatation equipment

Screw coating - screw conveyor of a copper mine during protective coating with 15 mm (0.6 inch) MetaLine 785

Screen box coating - Multi-deck screening machine (banana screen) completely protective coated with 2 to 6 mm (80 to 240 mils) MetaLine 785. No open edges, screw heads or other unprotected parts . . .

Suction dredger coating - no matter what surface geometry needs to be protected. Here the rubber pipes of a suction dredger. A case for MetaLine

Support beam protection – MetaLine 785 as an elastomeric non-slip corrosion protective coating on this support beam in an iron ore mine

Excavator bucket coating - not for the faint-hearted. MetaLine 795 in a layer thickness of approx. 8 mm as a pure non-stick coating on this digging bucket