Discharge pipe coating – the brand MetaLine stands for the protection against wear & tear, corrosion, chemical attack, stickiness or scratching. It’s not that we can solve every problem – please do not have that expectation to a surface specialist like us...

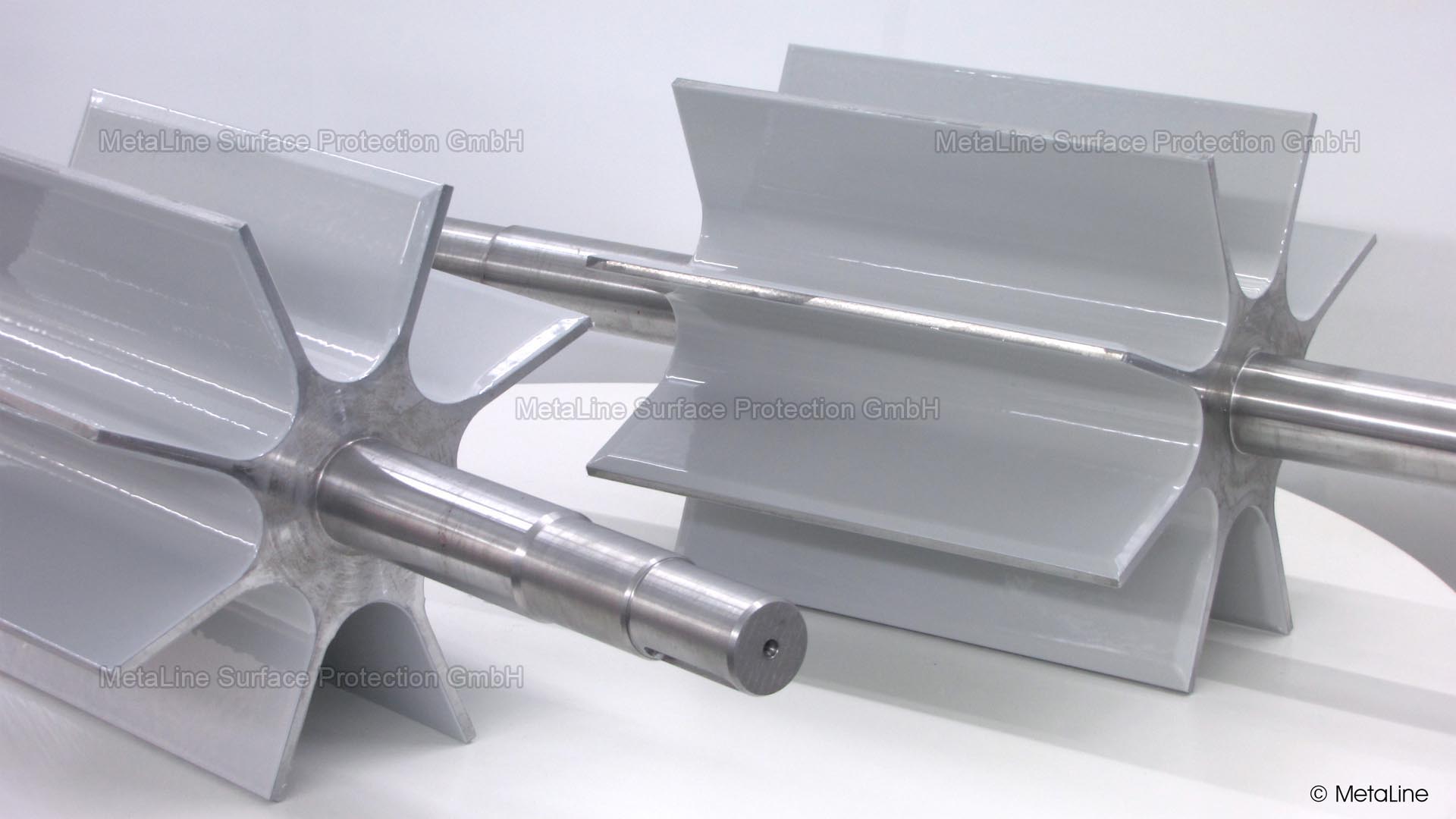

External helix feeder coated all-round with MetaLine Series 500 – there is no better example for superior results achieved with seamlessly sprayed on MetaLine

Cargo gate coating – a 5 mm thick protective skin sprayed out of MetaLine 795 prevents stickiness and wear at the 42 huge cargo chutes of this bulk carrier loading system

Sieve tray coated seamlessly, wear-resistant and sliding with MetaLine 795

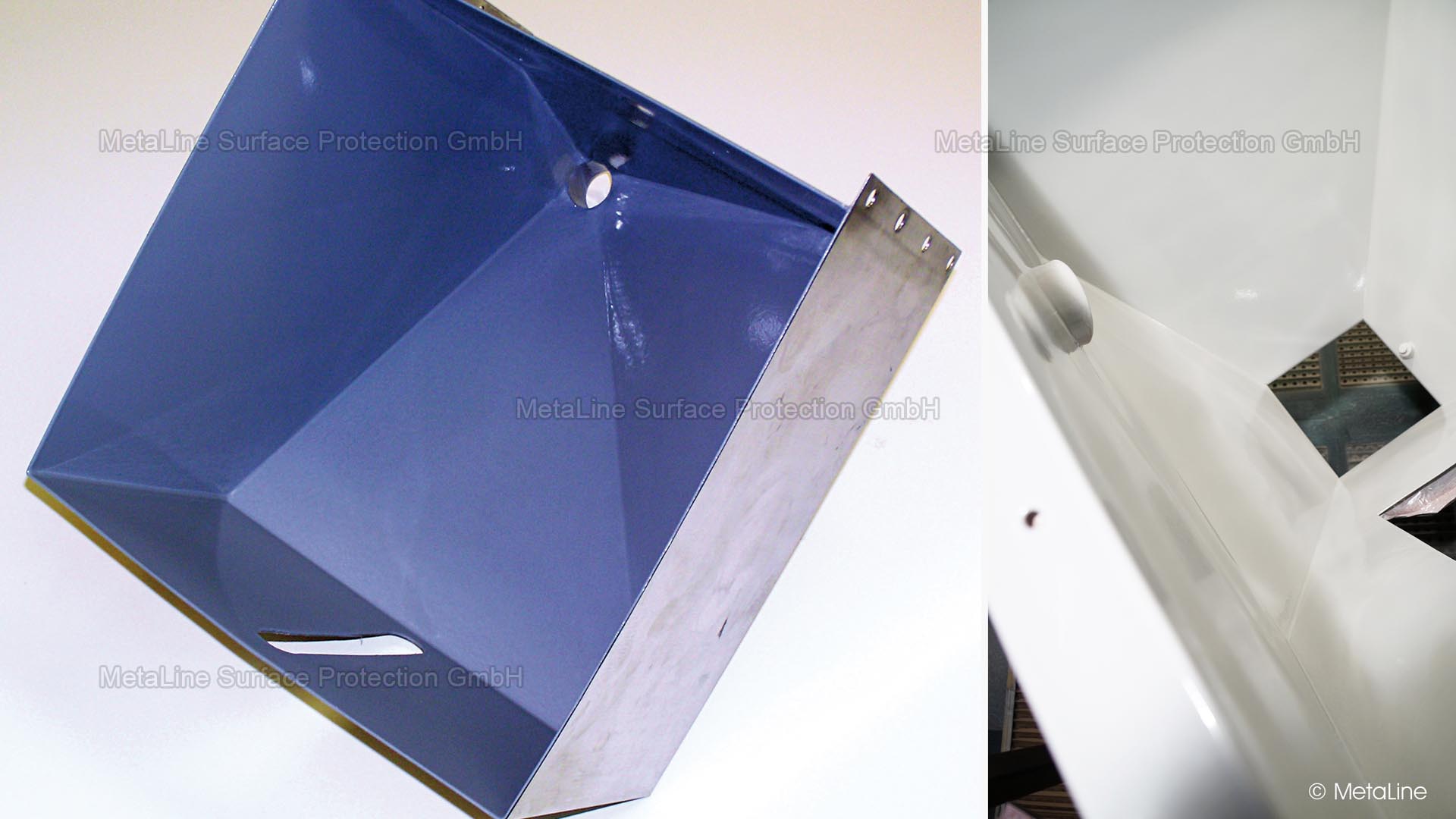

Precision par excellence – feeding container of a renowned crystal manufacturer coated with 0.5 mm MetaLine 795 to assure good sliding behavior

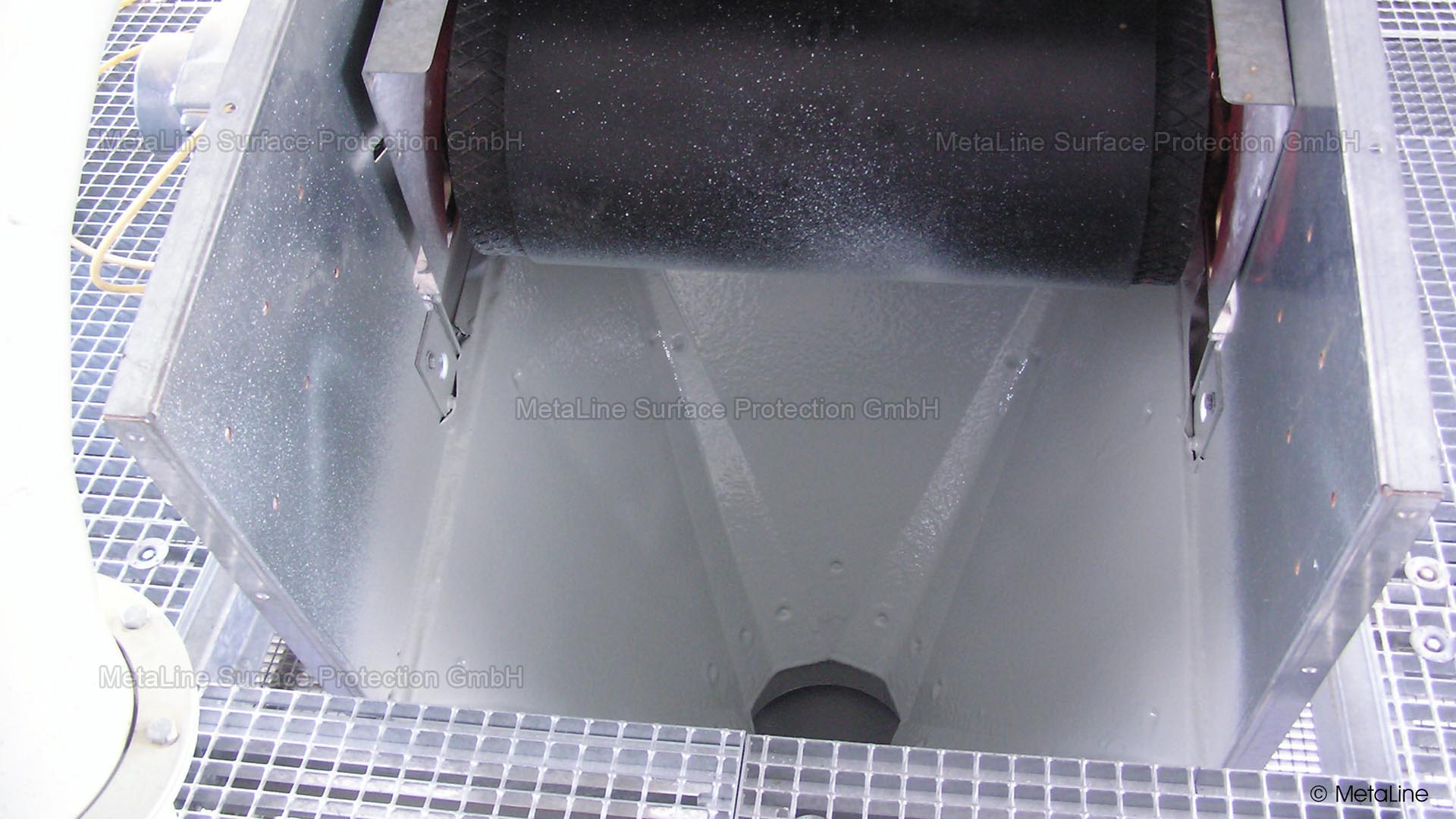

Bulk materials at their most aggressive – MetaLine 785 applied in a 8 mm layer fighting a constant battle against ready-mixed concrete

Funnel coating – no matter what contur the substrate has – the elastomeric MetaLine Series 700 Coating System is a superior tool with an outstanding wear resistance...

Feeding chute for grain processing – coated with MetaLine elastomeric armoring

Mill casing coated with MetaLine 785 for pure mineral manufacturing – without metal and ferrite

Filling hopper coating – MetaLine 598 is used as an easy to clean, flow supporting non stick coating for the corn storage

Feed hopper beneath a conveyor belt for gravel feeding – coated with 8 mm MetaLine 785

Feeding chute in a starch mill – coated with 15 mm MetaLine 785 to withstand loads of 350.000 tons of potatoes per season

Vibratory chute for dry food coated with 3 mm MetaLine 785

Teleskop-Rohrpaket beschichtet mit 2 mm MetaLine 795 als Anti-Haftbeschichtung und Verschleißschutz für die Zementfertigung

At the end wear resistant linings are a question of trust. Decide for real surface specialist and not for sole product vendors. MetaLine – for almost 6 decades just the one!

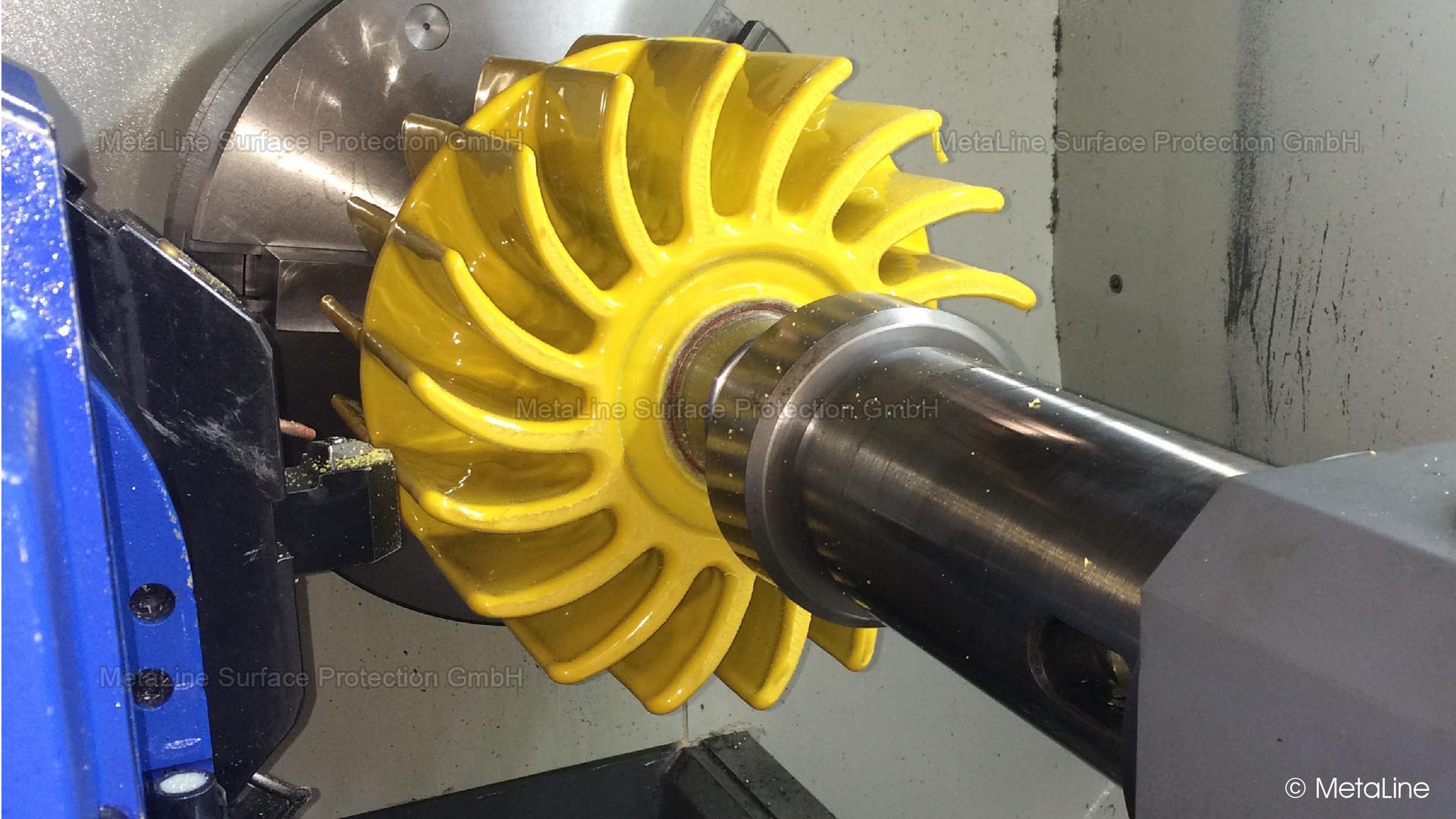

Rotary valve coating – MetaLine 795 in a thickness of 1 mm protects this runner of a rotary valve from material build up and sticky products