Decanter coating - a thick layer of approx. 8 mm (5/16’’) MetaLine repair ceramic CXL maintains the statics of the discharge chamber of this decanter as a target wear layer

Decanter housing coating - MetaLine 795 insulates this decanter housing from mechanical and chemical attack. The rubber-like surface properties are insensitive to vibration and protect the substrate from impact loads. In addition, the structure-borne sound behavior is improved and a noticeable noise reduction is achieved

Centrifuge protective coating - the brushable MetaLine repair ceramic KXL protects and preserves the metallic structure and extends system service life in the event of highly corrosive effects. It also reduces adhesion to the centrifuges

Centrifuge coating - a good solution for certain sticky media. MetaLine 795 as a rubber-like non-stick coating in separation technology. Applicable up to a peripheral speed of 30 meters (100 feet) per second and in a pH range of 3-11

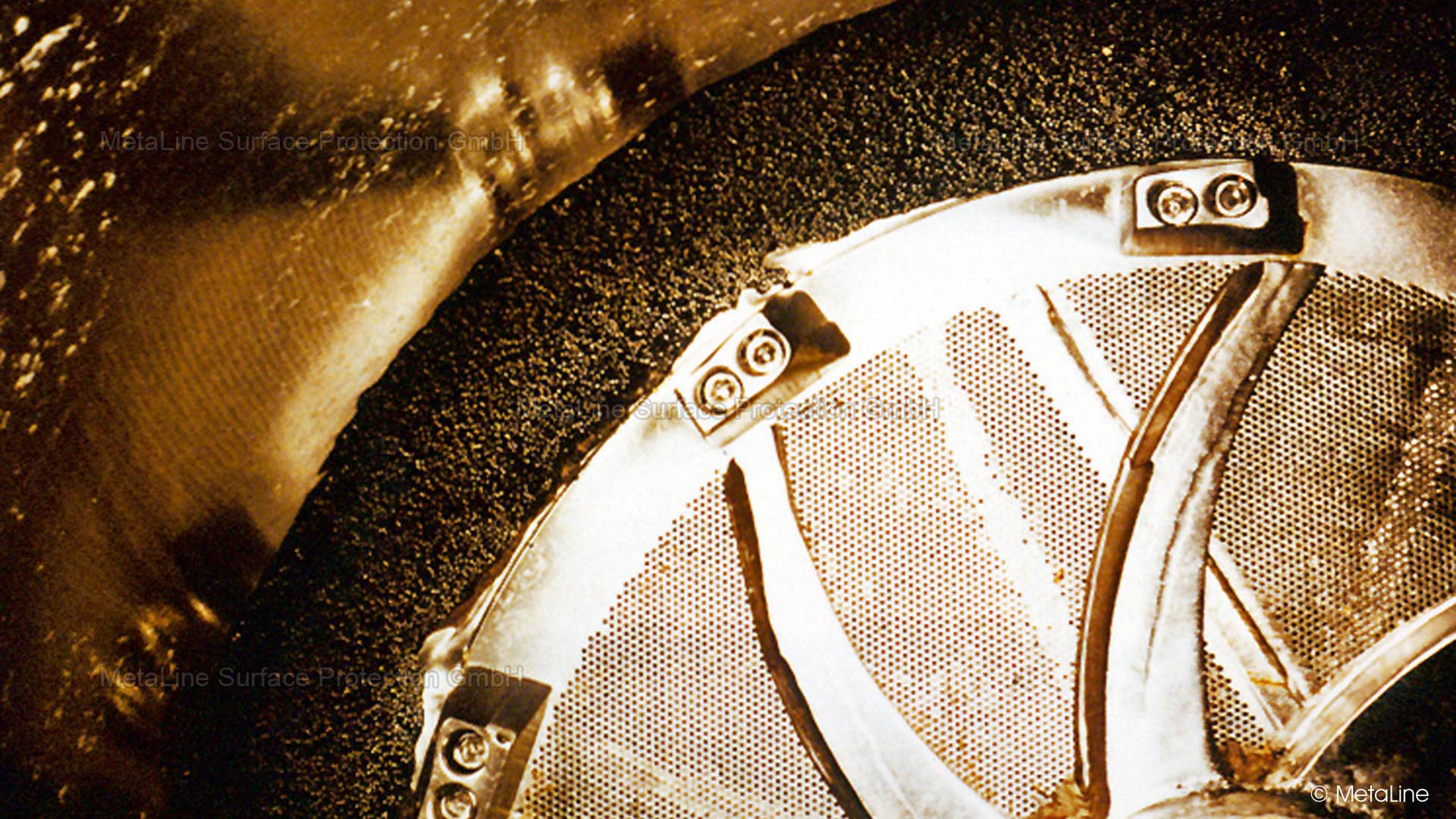

Centrifuge coating - synthetic carbide armoring with MetaLine repair ceramics CXL - pasty filling with a layer thickness of approx. 8 mm (5/16’’). Admittedly a repair solution and not a constructive optimization - but more is not possible on site in the installed state!

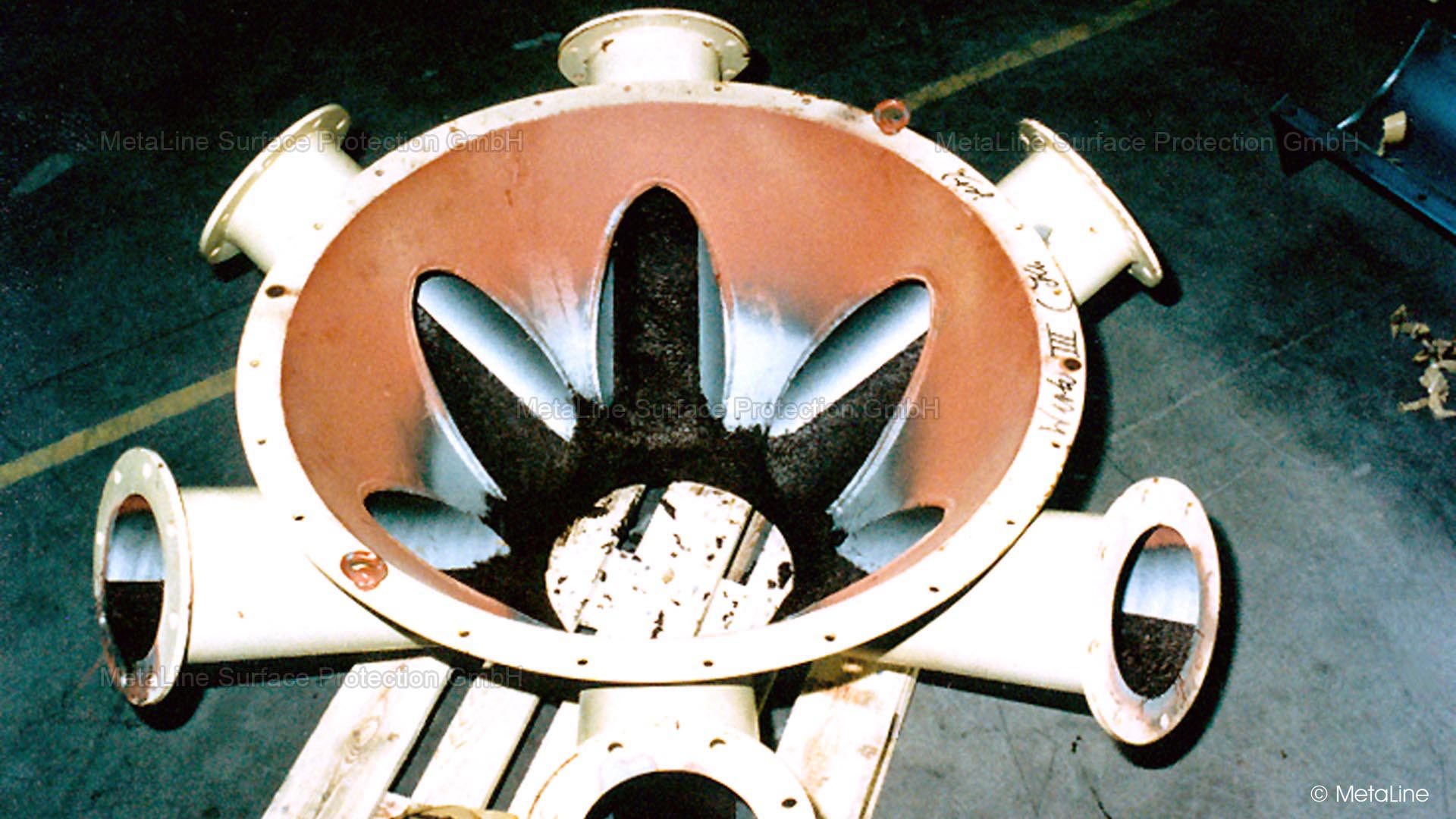

Pulper coating - Pulper in a paper mill during coating work with the MetaLine repair ceramic CXL. Our products can do more than those of our competitors! But they also require more craftsmanship and more precision in substrate preparation. Nothing comes from nothing!

Wear plate repair - some components are barely recognizable even at second glance. Do you have any questions about this image or this application? Simply take a screen shot and send it to us by email. We will be happy to explain the application to you!

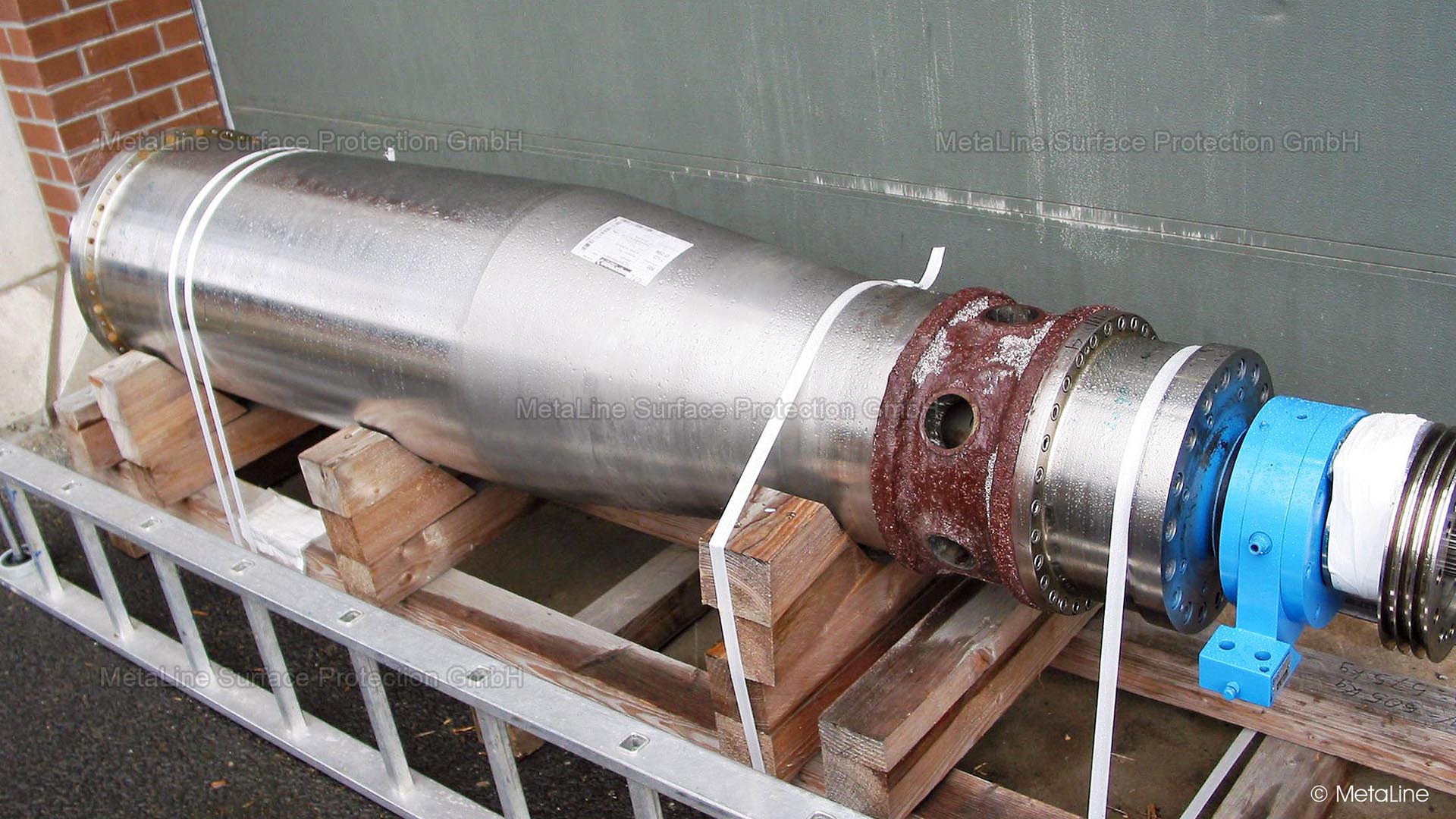

Seperator repair - inlet manifold during protective coating with MetaLine repair ceramic CXL. Application by hand benefits the application in the installed state. However, we would not describe it as a "do-it-yourself" technology. A certain basic knowledge is essential for professional installation

Separator coating - For the correct design and calculation of a coating, we need information - a lot of information. That's why we ask a lot of questions to give you the best possible result. Of course, there are simpler ways - and worse!

Coating repair - a combination of bonded carbide plates and gap filling with our MetaLine repair ceramics SXL and CXL. Why were 2 different materials used? We will be happy to answer this question in a phone call. We do not want to publish all the tricks on the Internet free of charge . . .

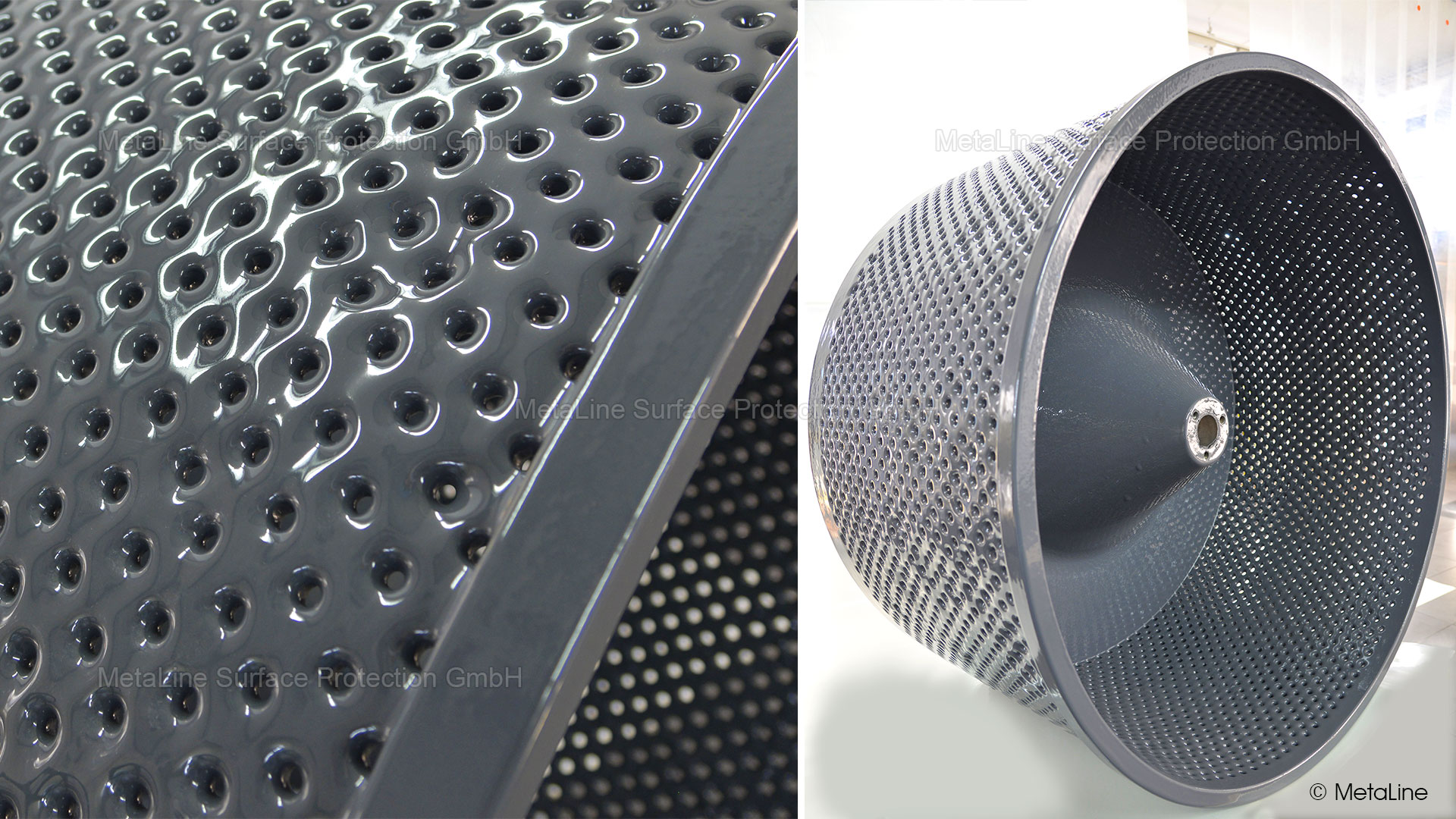

Centrifuge basket coating – the uniform and, above all, non-porous coating of the inside of the holes is crucial to ensure a closed protection concept for the metal structure!