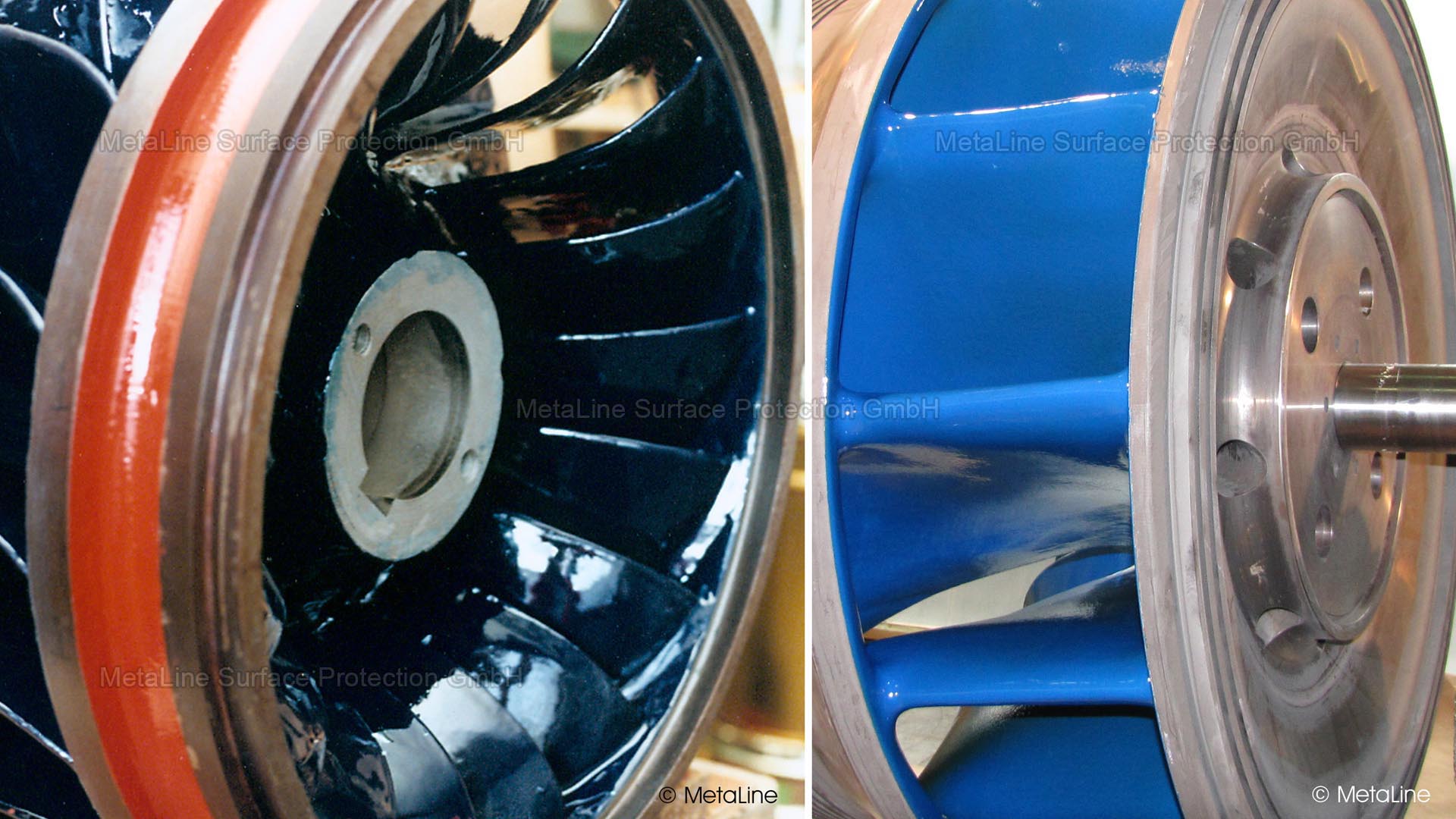

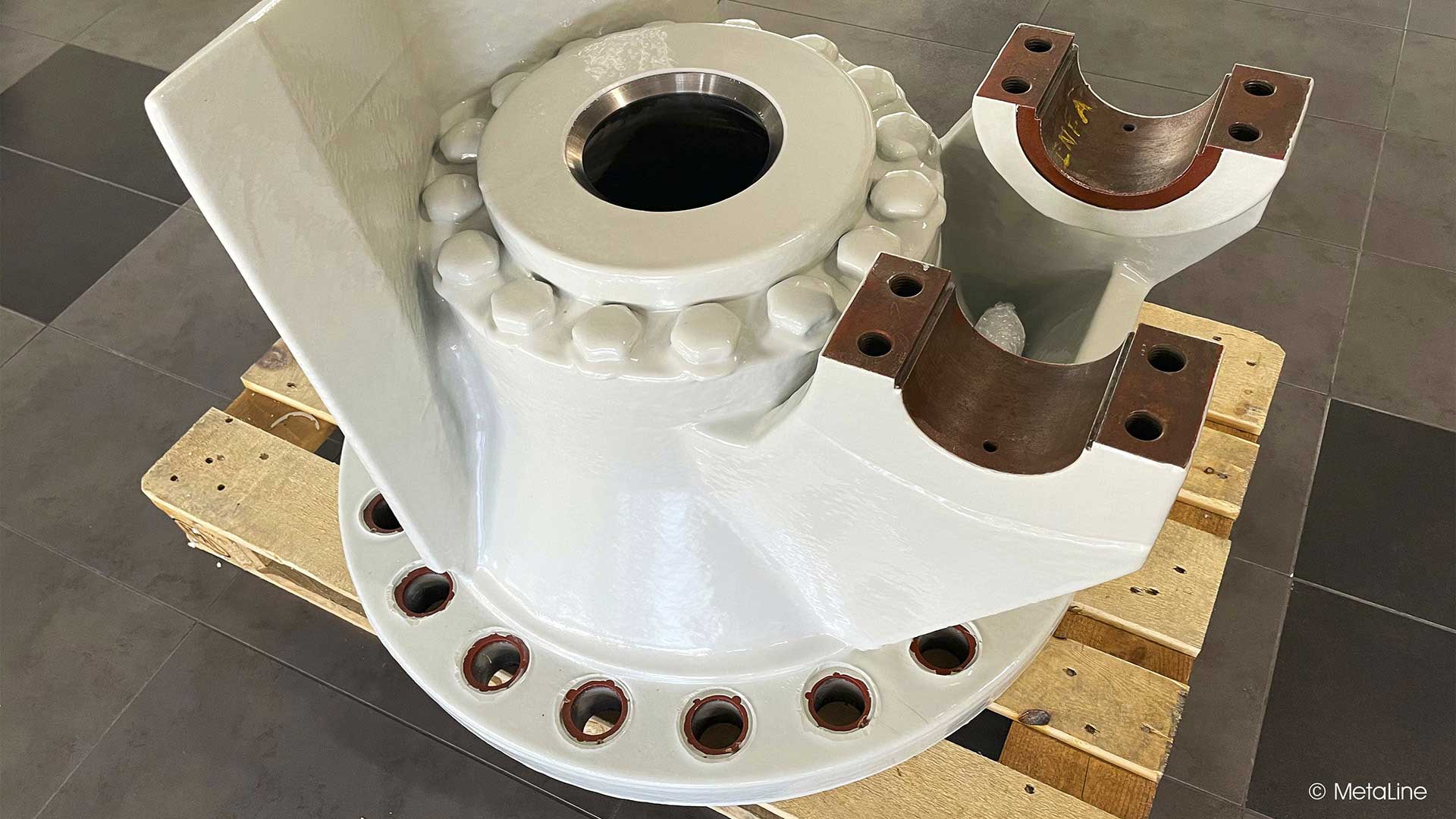

Francis turbine coating with MetaLine 785 – A 2.5 mm (100 mils) elastomeric OEM coating applied ex works by the turbine manufacturer to protect the turbine impeller against cavitation-induced pressure and tensile stress cycling.

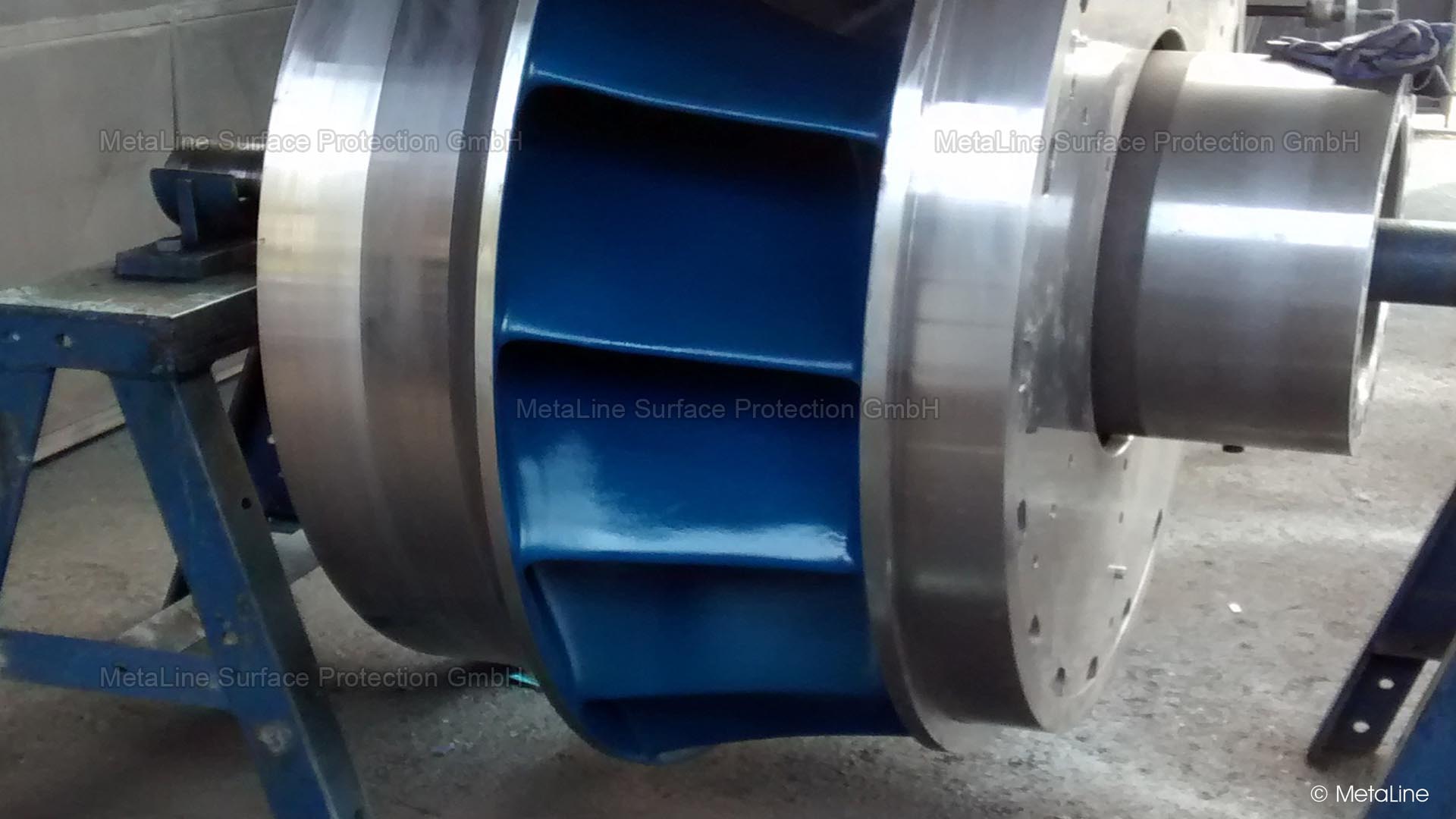

Francis turbine impeller coating with elastomeric spray coating – Smooth, high-performance coating system for Francis turbines, optimized for hydraulic efficiency and fluid flow. The sprayed elastomeric surface outperforms rough ceramic brush coatings commonly used in hydropower applications.

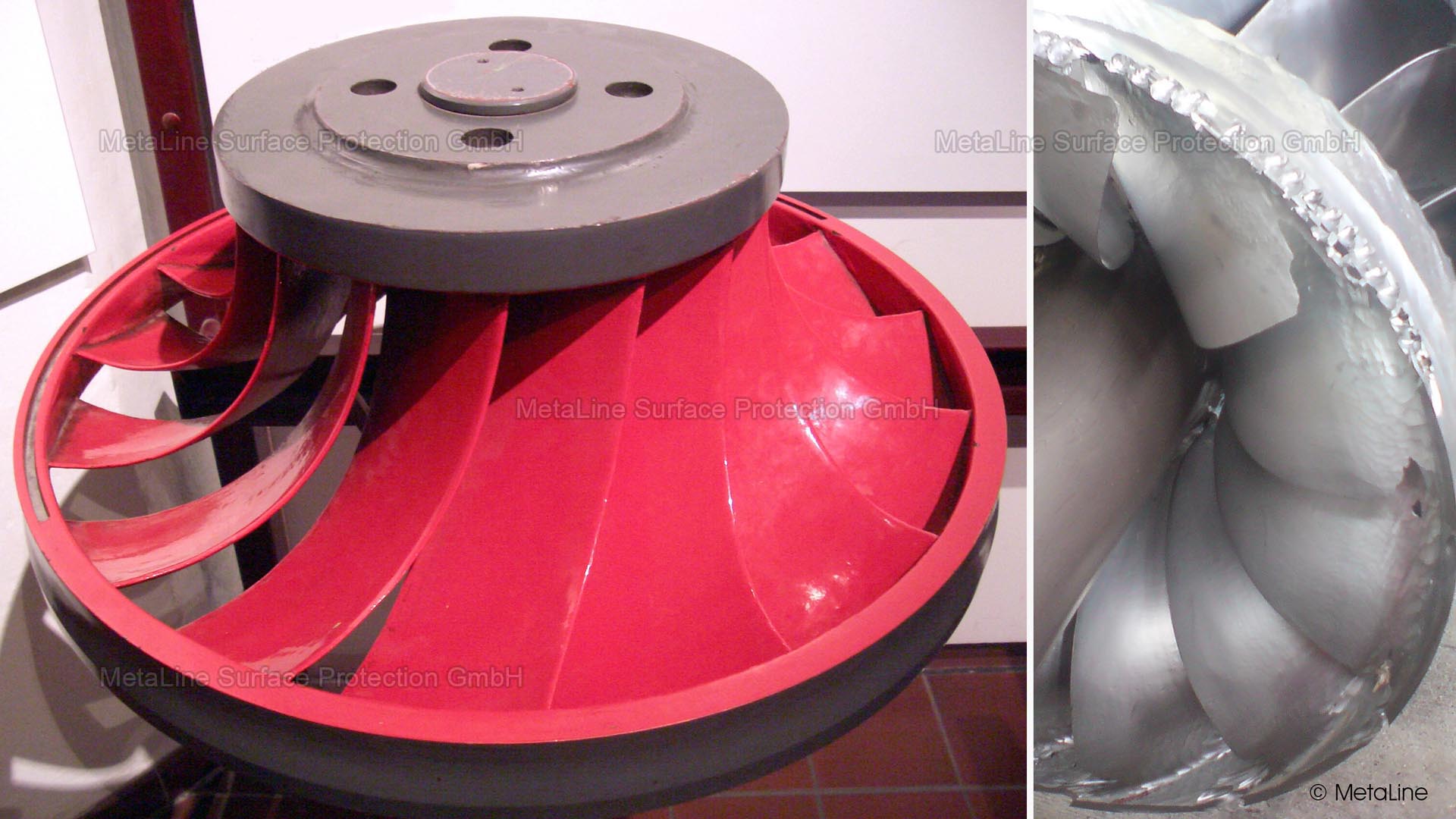

Water turbine coating for small Francis impellers – Spray-applied elastomeric coating on a 600 mm Francis turbine impeller from a small Austrian hydroelectric power plant, suitable for turbine refurbishment and hydropower renovation.

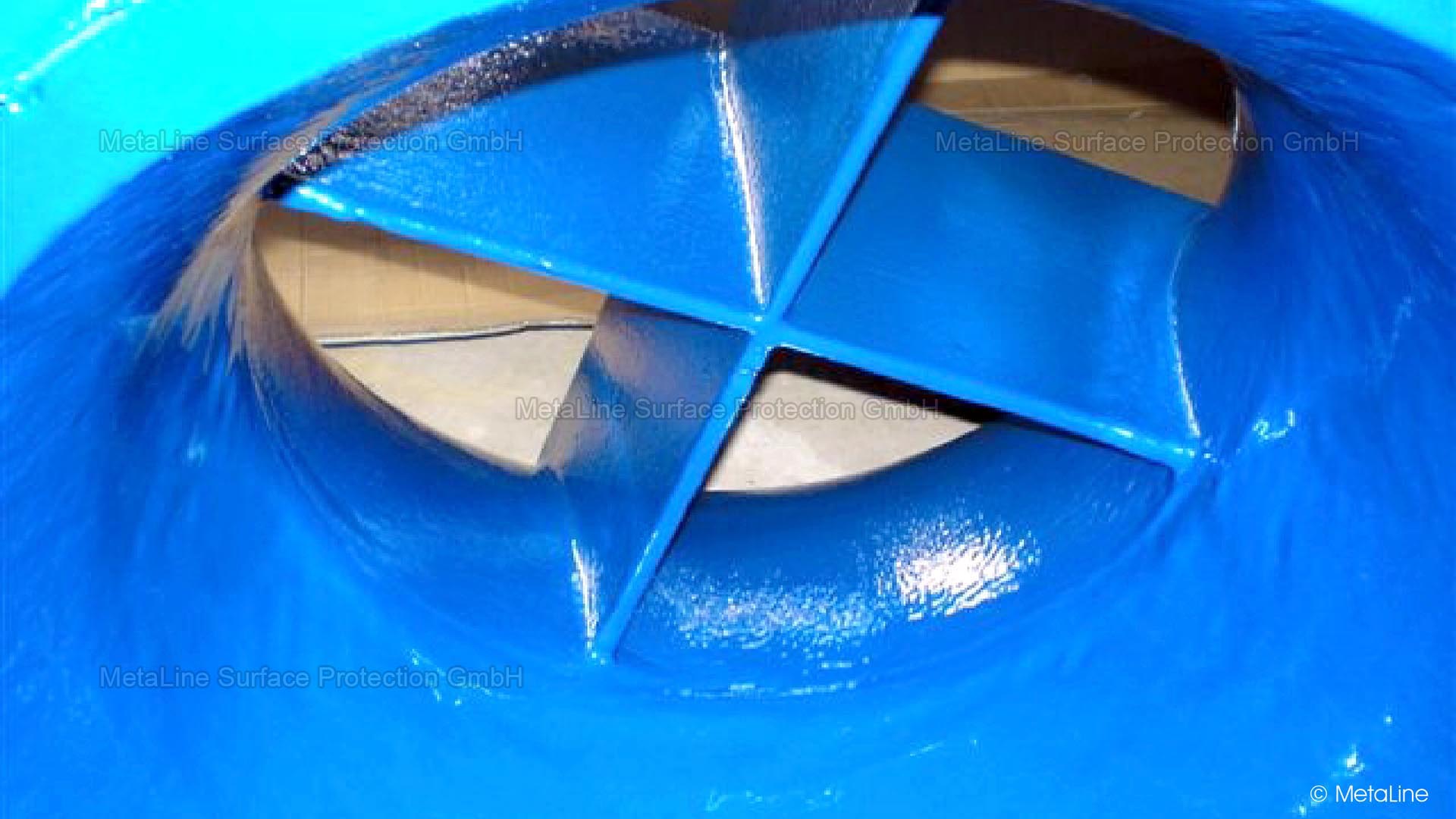

Francis impeller coating for hydroelectric turbines – High-quality spray-applied coating system for Francis impellers, requiring specialized tools and application expertise to achieve maximum durability, efficiency, and service life.

Francis runner coating for hydroelectric turbines – Precision spray-applied coating where substrate preparation, adhesion, blade-edge thickness control, application uniformity, and coating boundary definition determine long-term turbine protection and performance.

Francis impeller lining for hydropower turbines – Elastomeric coating system applied at a hydroelectric power plant in Costa Rica, demonstrating MetaLine’s global expertise and application-driven approach to turbine protection.

Francis turbine protective coating for hydroelectric turbines – Spray-applied elastomeric coating with the impeller vertically mounted and continuously rotated to achieve uniform coverage and consistent coating quality, demonstrating why in-situ turbine coating is avoided.

Turbine runner coating – MetaLine 785 elastomeric coating achieves wear resistance comparable to AISI 316 stainless steel, depending on the impact angle, while being up to eight times lighter in weight. This unique performance advantage is why hydro turbine manufacturers worldwide are increasingly evaluating and adopting the MetaLine soft-coating philosophy for turbine protection.

Francis impeller coated with MetaLine 785 – Spray-applied elastomeric coating performed in a vertical orientation with continuous rotational movement to ensure uniform layer thickness and consistent coating quality.

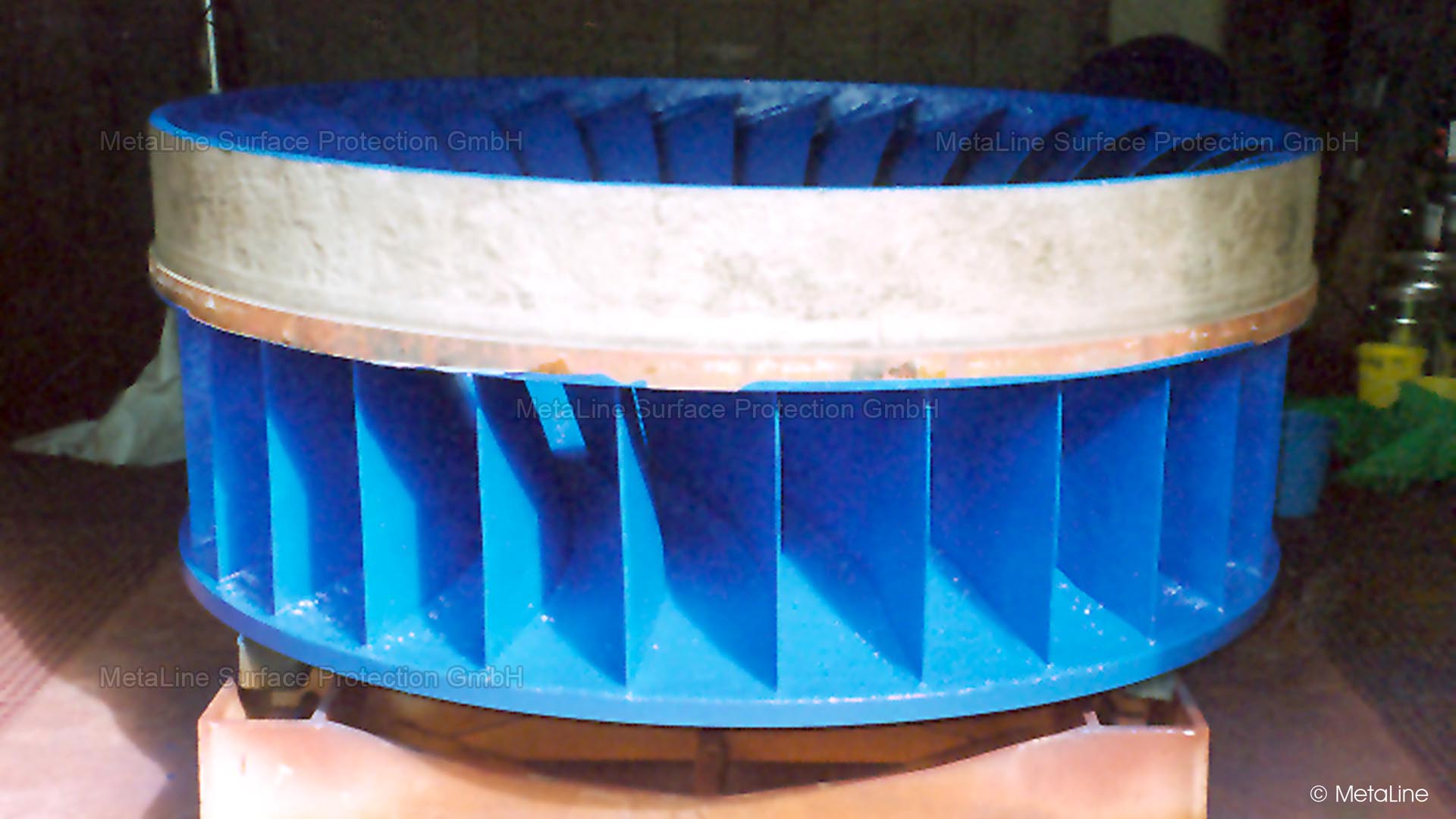

Francis turbine coating – Ultra-smooth, lightweight elastomeric coating with exceptional cavitation resistance for Francis turbines. No alternative coating system combines this level of surface smoothness, cavitation durability, and low weight for high-performance hydropower applications.

Hydro turbine coating with MetaLine elastomeric technology – Cavitation-resistant, ultra-lightweight coating system providing smooth surfaces, vibration resistance, and tension-free performance for hydroelectric turbines.

Francis medium sized impeller coated with MetaLine – the coating thickness amounts to approximately 2 mm

Turbine coating with MetaLine Series 700 – Elastomeric coating system providing a fluid-flow-optimized, ultra-smooth surface finish for improved hydraulic efficiency in hydroelectric turbines.

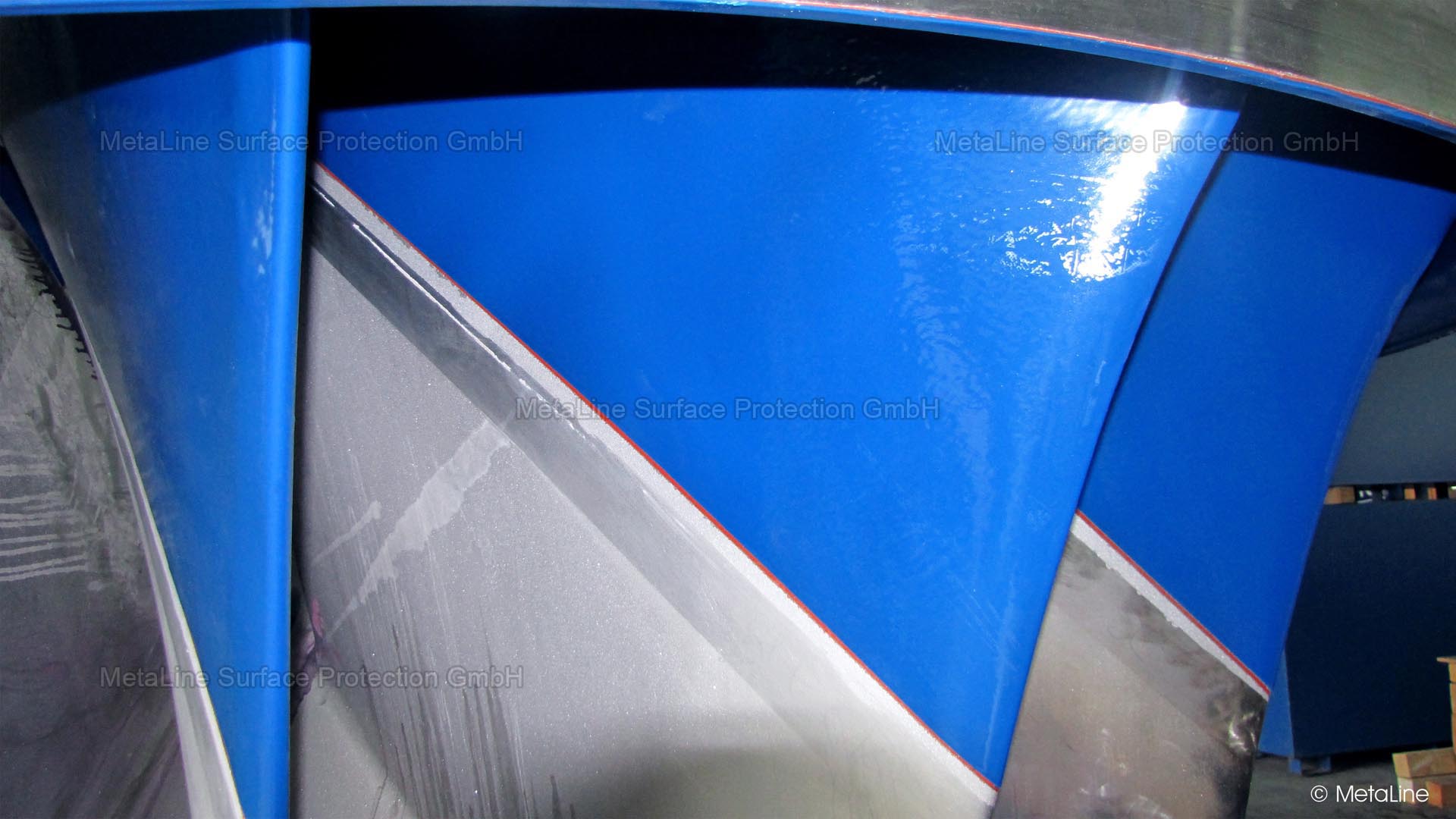

Pelton turbine nozzle hood coating with MetaLine 785 – 4 mm elastomeric coating applied in a two-color system for enhanced wear protection and visual wear indication in hydropower applications.

Hydroelectric turbine coating with MetaLine 785 – 4 mm elastomeric coating applied at a hydroelectric power plant in Portugal to enhance wear resistance, cavitation protection, and operational reliability.

Kaplan impeller coating with MetaLine Series 500 – Elastomeric turbine coating applied at a hydroelectric power plant on the River Rhine in France for enhanced durability and performance.

Francis turbine hub coating with MetaLine 785 – 2.5 mm elastomeric coating providing durable, permanent protection and high-visibility surface quality for hydroelectric turbine hubs.

Kaplan turbine blade coating – Large-scale Kaplan turbine blades coated with MetaLine 785 elastomeric coating in our central workshop, demonstrating the capability to handle and protect large turbine components for hydropower applications.

Francis impeller partial coating – Partially coated Francis turbine impeller with MetaLine 785, applied in situ without removing the impeller. This approach is highly unusual and only used under specific technical conditions.

Turbine frame coating with MetaLine 590 – Elastomeric protective coating applied to turbine frame structures at a pump-storage power station in Luxembourg, demonstrating long-term durability after five years of service.

Turbine coating with MetaLine 785 – 2.5 mm elastomeric protective coating applied to a turbine frame structure during manufacturing to prevent wear and corrosion prior to on-site installation.

Wicket gate coating with MetaLine Series 700 – Elastomeric, impact-absorbing coating system for hydro turbine wicket gates, designed to withstand mechanical impact and outperform rigid epoxy-ceramic coatings.

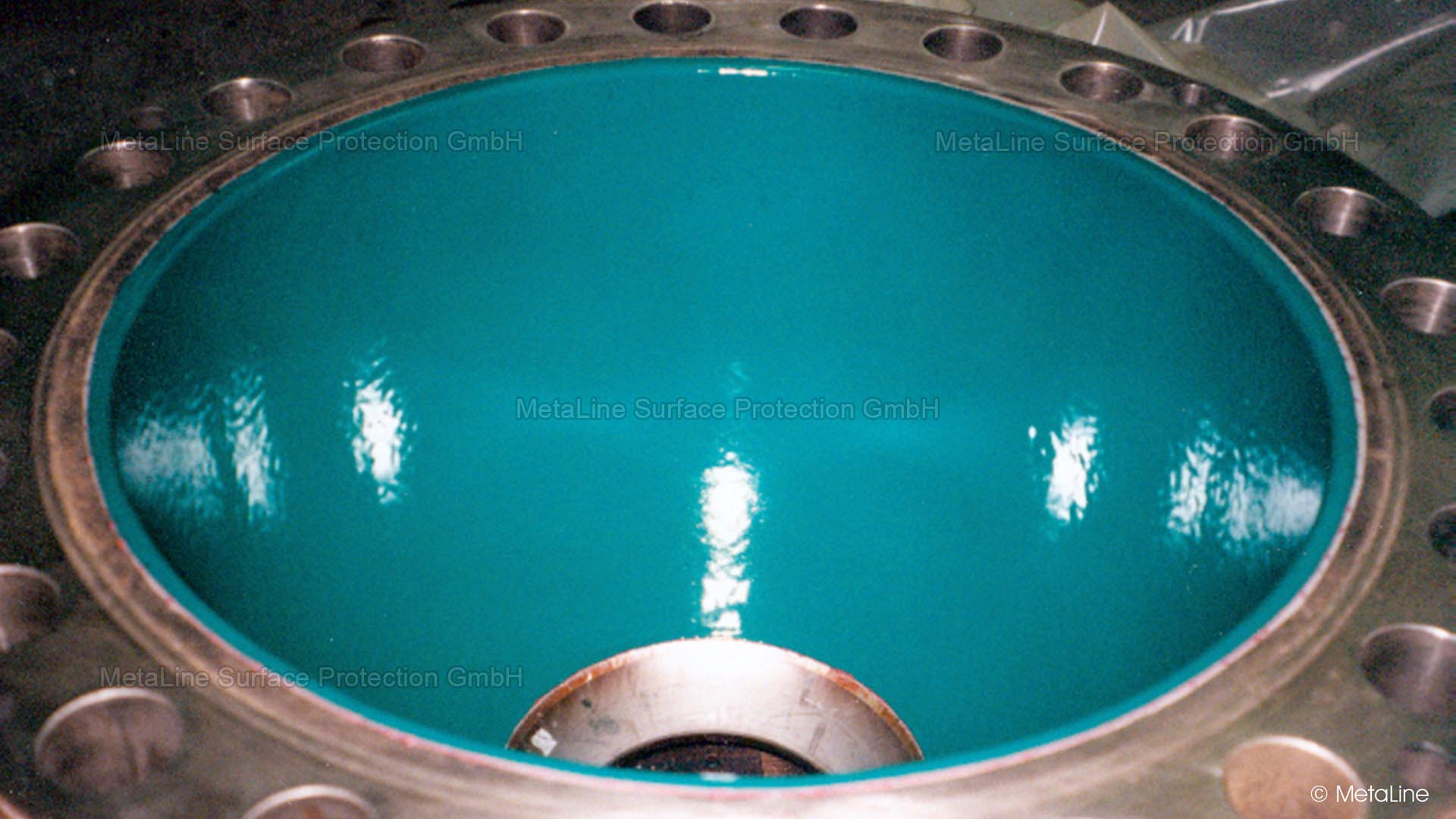

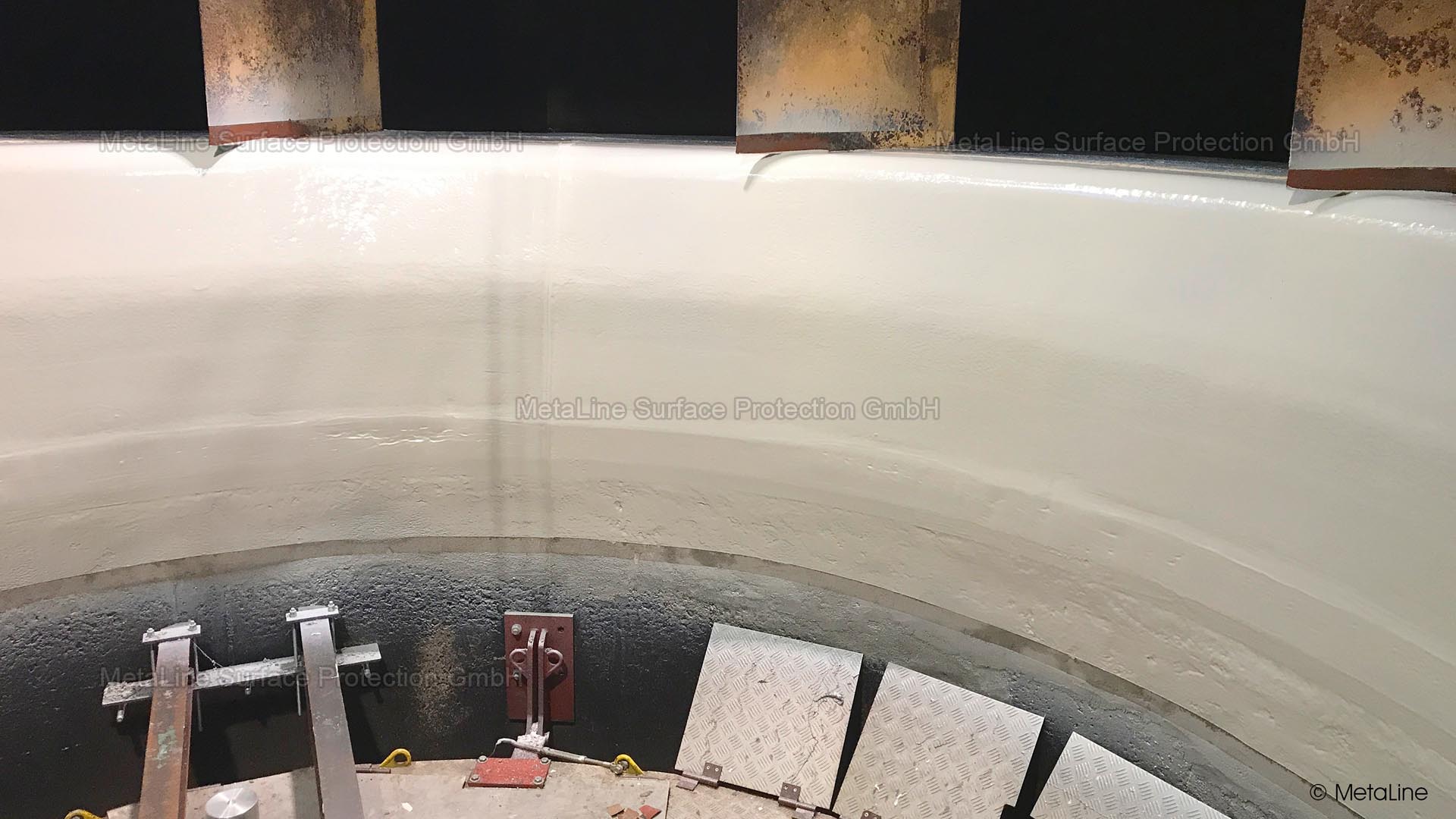

Francis turbine spiral housing coating – Spiral housing of a Francis turbine installed in the Swiss Alps, protected with a 2.5 mm MetaLine 785 elastomeric coating. Latest inspection reports confirm excellent coating condition and long-term performance.

Water brake inlet coating with MetaLine Series 500 – 4 mm elastomeric protective coating applied to a water brake inlet in the Tyrolean Alps for long-term durability and wear resistance.

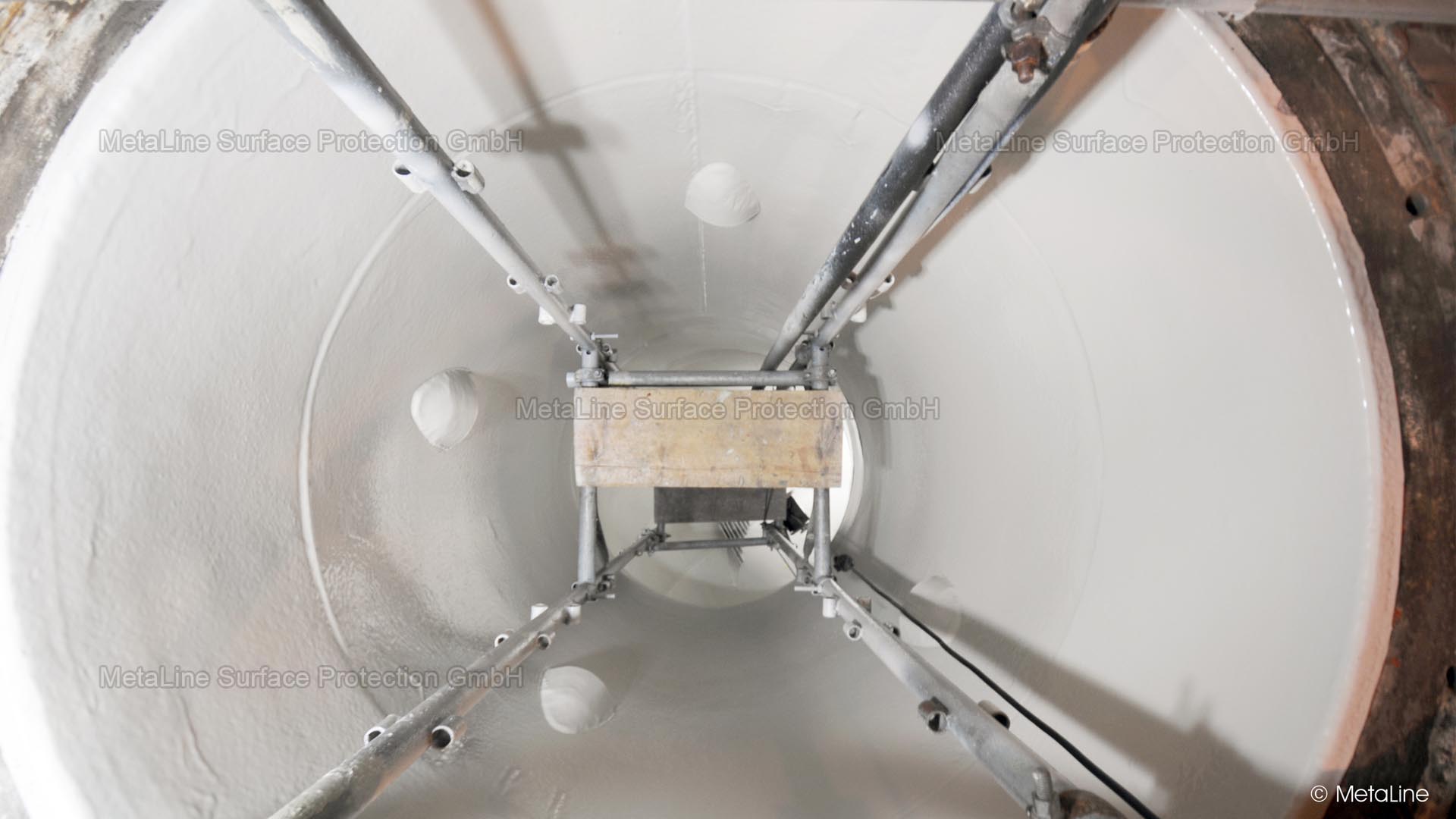

Suction pipe coating with MetaLine 785 – Elastomeric wear- and corrosion-resistant coating applied inside a turbine suction pipe in a Swiss Alpine hydropower installation.