Screw armoring - the size is unlimited! Downwards as well as upwards. A typical feature of MetaLine coatings. The right tool for every size. And yet there is still criticism. The customer has not created the required radius on the edge of the screw. Sooner or later, this will take its toll . . .

Screw wear protection - during the coating of a screw conveyor with MetaLine elastomer armoring for the low-wear transport of potatoes in starch production. With food and pharmaceutical conformity. Does that make sense? It is always a case-by-case decision. That's why you should talk to us first!

Screw blade coating - unsurpassed in smoothness and flow harmony. MetaLine 795 on this conveying system for the transportation of sugar with EU 1935/2004 approval. The non-stick properties and good cleanability were the decisive criteria for the customer to use MetaLine

Archimedian screw coating - MetaLine Series 700 coatings are viscoelastic, rubber-like and can also be made non-stick. They absorb destructive energy - and do not deflect it. We would be happy to discuss the technical advantages and disadvantages over the phone. Anyone who asks knows more!

Transport screw liner - wear protection, corrosion protection, non-stick properties and FDA food suitability all in one - MetaLine Series 700. An interesting solution, but one that also has clear technical limits that must be strictly adhered to

Screw coating - transport screws coated with 4 mm (160 mils) MetaLine 785 for the processing of sand in foundries. Every detail counts when it comes to coating! The coating thickness, the edge rounding, the gap dimension to the trough, the speed, the pressure, the incidence height of the conveying medium, . . .

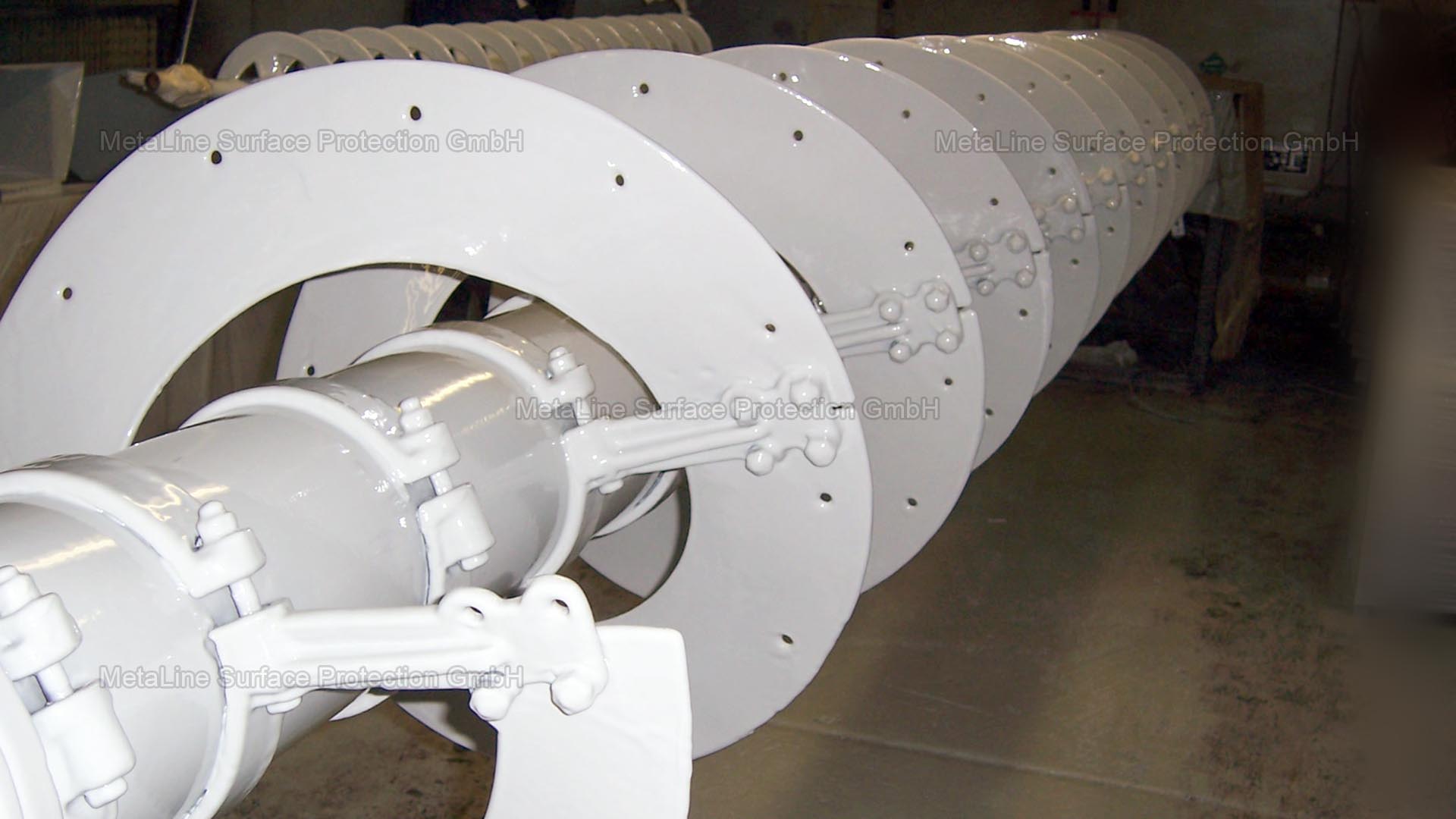

Conveyor screw coating - a conveyor screw over 10 meters long coated with a combination of MetaLine 785 and 795 - a combination for maximum wear protection and the best non-stick effect. Area of application is a municipal organic waste disposal system

Screw conveyor insulation - a protective coating with 8 mm (1/3 #) MetaLine 785 in a drum-shaped screw conveyor. Conveying and mixing in one operation. Whatever is abraded from our coating is non-metallic. Interesting for all those who deal with ultra-pure minerals

Transport screw armouring – Do-it yourself and OEM quality level at the same time is not impossible anymore! MetaLine Series 785 is not only a well-proven repair solution but have entered engineering construction design due to its remarkable wear resistance

Conveyor coating - does our coating change the geometry of the component? Yes, a little more at the beginning and then slowly decreasing. Does wear change the geometry of the component? Yes, a little less at the beginning and then rapidly increasing. Decide which is better!

Mixer coating - admittedly, a slightly different screw shape - but still a case for 3 mm (120 mils) MetaLine 795. Food conformity and non-stick properties were the decisive criteria in the material specification. Unfortunately, simple solutions are not always the BEST way to achieve a goal! MetaLine looks at the entire route and shows you the most promising way - not the quickest!

Extruder coating - stainless steel extruder coated with 3 mm (120 mils) MetaLine 795. The ferrite-free MetaLine coatings meet the highest purity requirements and can even be used for ultra-pure silicon applications (photovoltaics)

Screw coating - this time the other way round - the outer housing rotates! Note the smoothness and optimum flow shape. There is no better way to force a medium in one direction. But without pressure, please! Stuffing screws must not be treated elastomerically!

Screw conveyor coating - Archimedean conveyor for municipal wastewater technology. During the rubber-like coating with MetaLine elastomer armoring. Different component sizes require different application equipment. MetaLine has solutions for all sizes

Screw conveyor repair - another option with MetaLine Series XL - just protect the worm beam and run the blades for wear. But please contact us in good time for such a project. Not everything that is possible makes sense!