Pharmaceutical coating – dosing device for tablets coated with 1.0 mm (40 mils) MetaLine 795. The precise transition to the electropolished surfaces is particularly noteworthy. Coating precision in perfection!

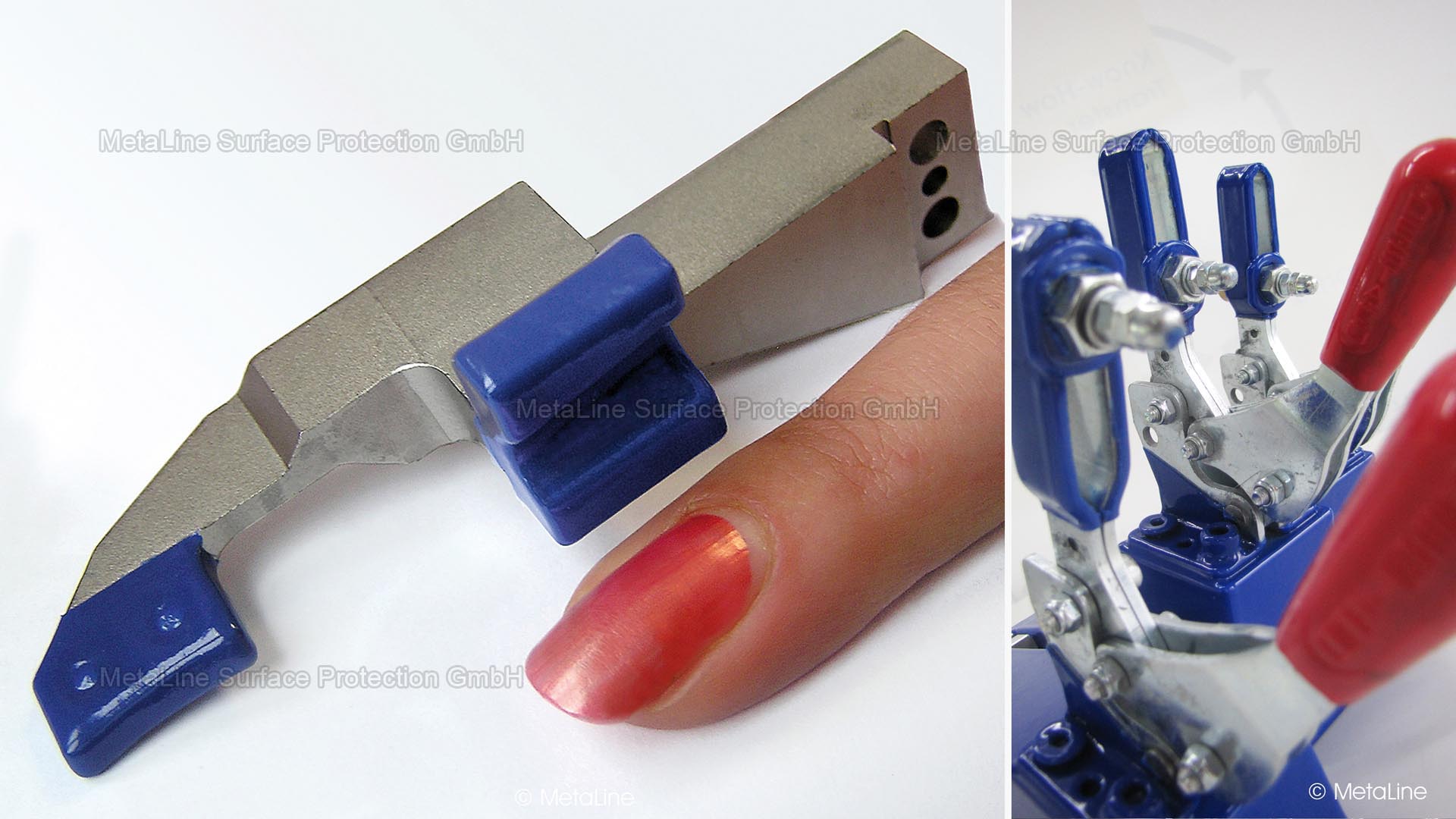

FDA-compliant coating – gripper coated with MetaLine 590 for sealing liquid medication packaging. Size is no limitation for MetaLine in any dimension

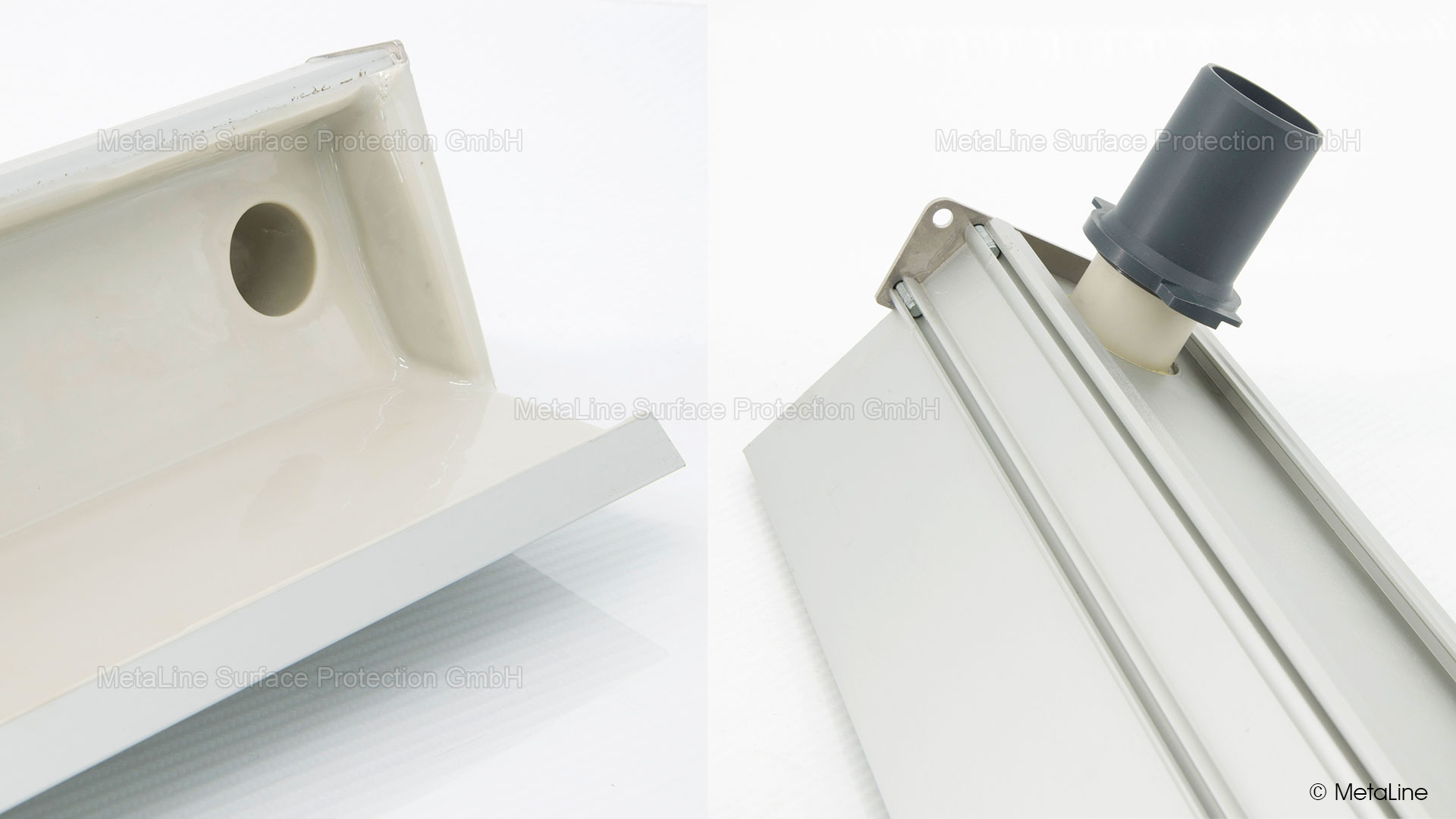

Pharmaceutical-grade coating – this incline conveyor is coated on the inside by the manufacturer for feeding empty cosmetic packaging. A 1 mm (40 mils) thick layer of MetaLine 795 protects the conveyed goods and reduces noise

Pharmaceutical coating – Vibratory feederbowl coated on the inside with 1 mm (40 mils) MetaLine 590. Maximum surface protection for the plastic parts being conveyed. Coating such a geometry is an art – one that MetaLine has mastered!

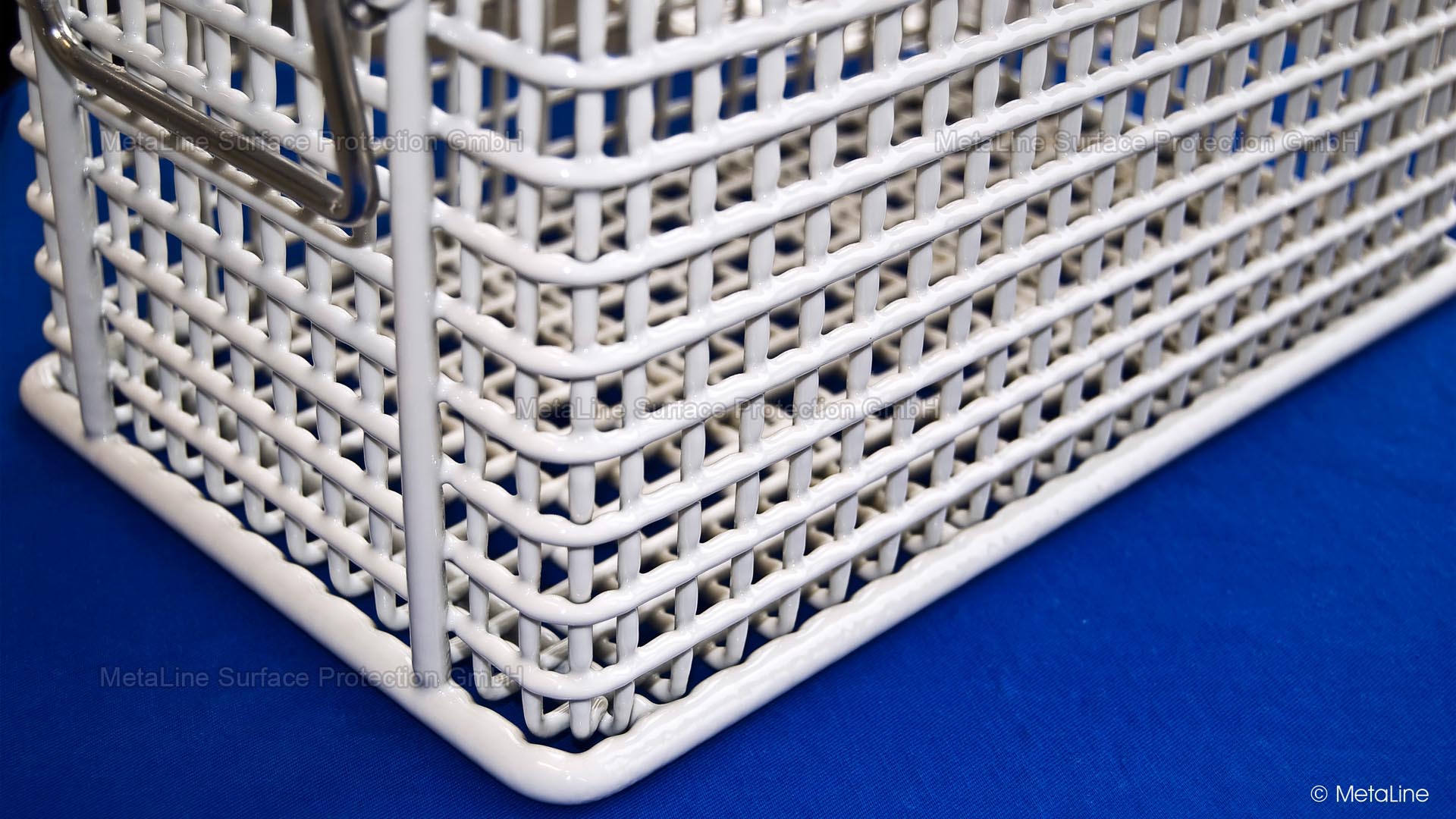

Wire basket coating – Transport and cleaning basket coated with 1.5 mm (60 mils) MetaLine 785. The aim is to prevent scratching of the conveyed goods in the ultrasonic bath. As the items being cleaned are medical devices, FDA compliance is essential!

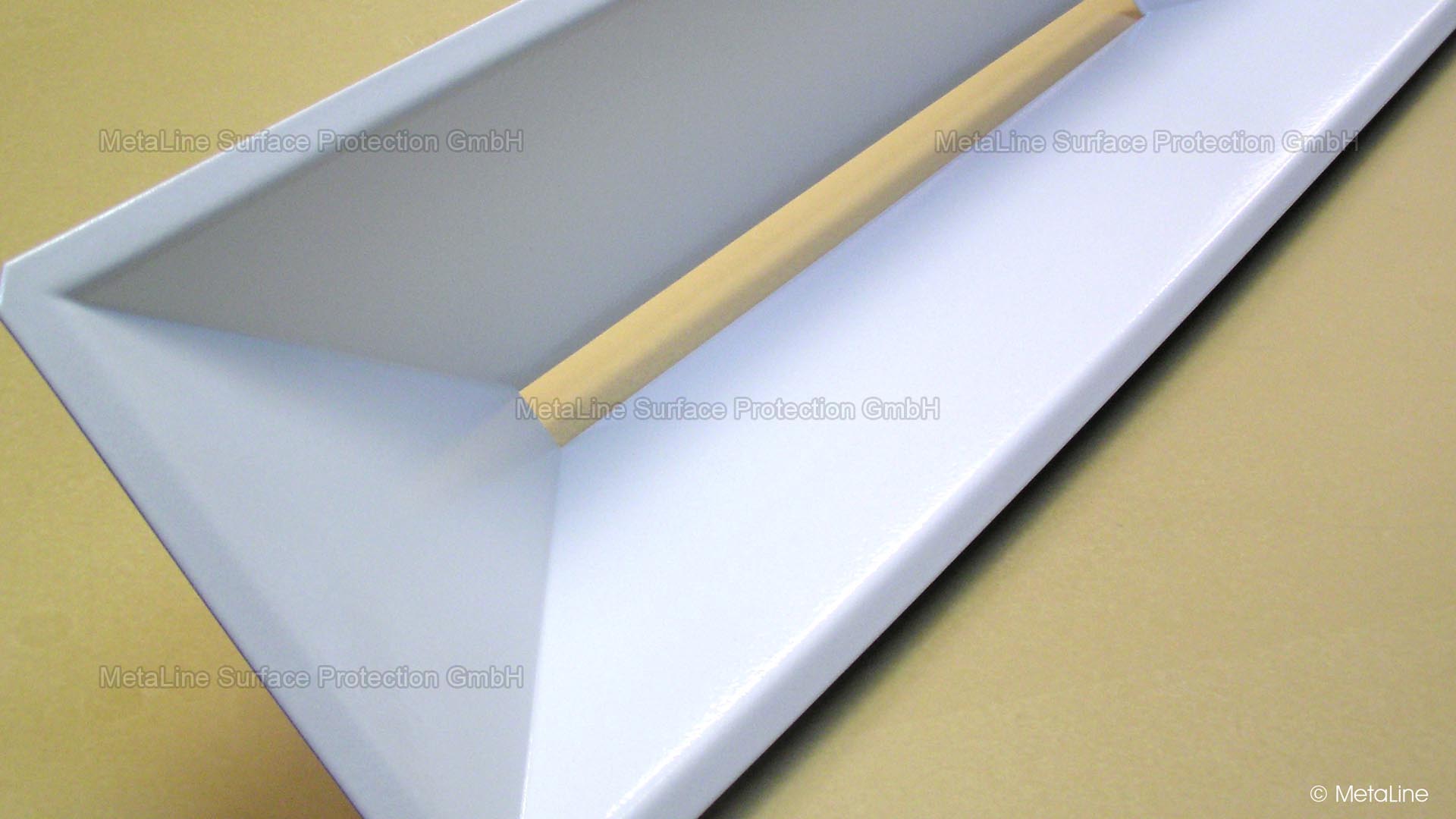

Pharmaceutical coating – a sensible concept for surface protection and noise reduction in the pharmaceutical industry - 2 mm (80 mils) MetaLine 785 on this transfer chute protects against tablet breakage and discoloration

Medicine-compliant coating – feed chute for a tablet packaging system coated with 1.5 mm (60 mils) MetaLine 785. The smooth surface and rounded edges ensure damage-free transport

Hygienic coating – seamless, no contact between the conveyed material and the substrate, metal-free, thermally insulated, FDA-compliant. This is what surfaces need to look like when they have to ensure hygiene and safety at critical points. MetaLine knows what matters to you!

FDA coating – why is a scoop for sampling in pharmaceutical manufacturing coated? To be honest, sometimes we don't know the customer's reasons either . . .

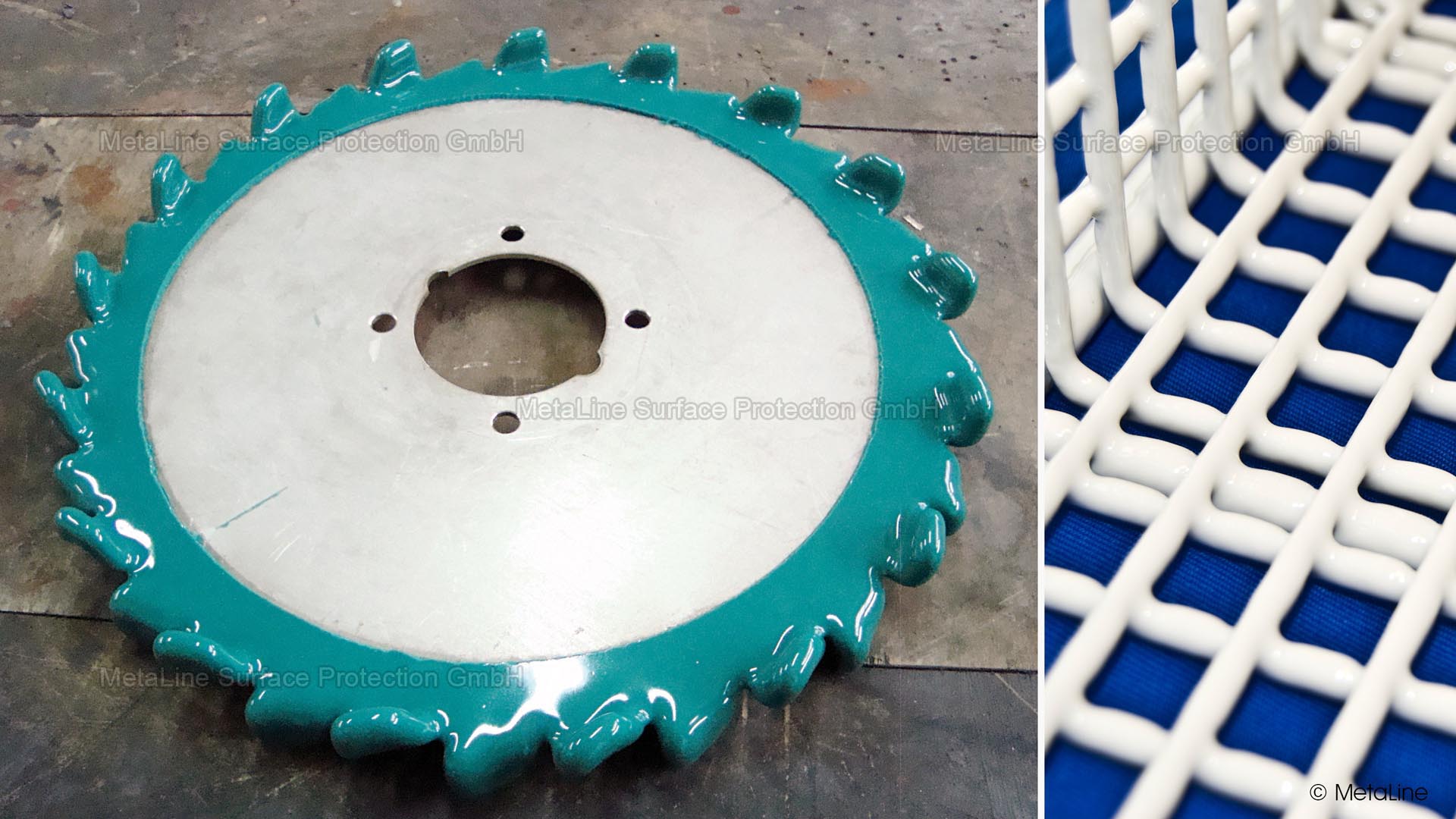

Feeding disk coated with MetaLine 785 due to FDA regulations. The excellent friction assures a safe and constant rotary feeding of the drug packaging

Pharmaceutical-compliant coating – chute of a pharmaceutical packaging system coated with MetaLine 795. Optimal cleanability was a decisive factor in the choice of material . . .

Pharmaceutical-grade coating – 2-jaw gripper coated with 1.0 mm (40 mils) MetaLine 580 to increase static friction against glass objects. This allows for a more secure grip with less clamping force!