Features

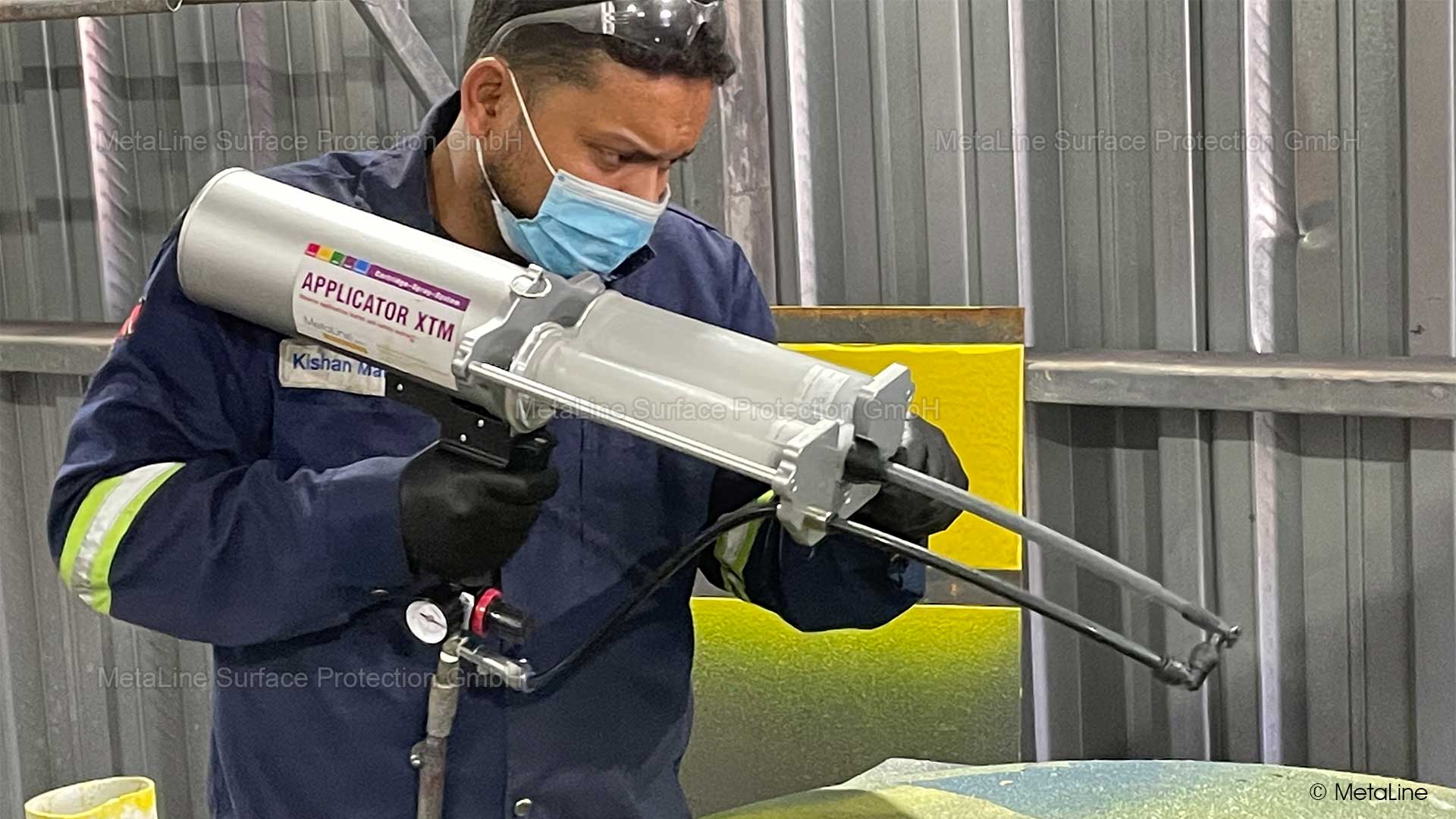

MetaLine 100 XTM is a rest-elastic novolac coating System developed for customer-specific self-processing by brush, roller or airless spraying. Alternatively, the MetaLine cartridge spray APPLICATOR XTM may also be used for application.

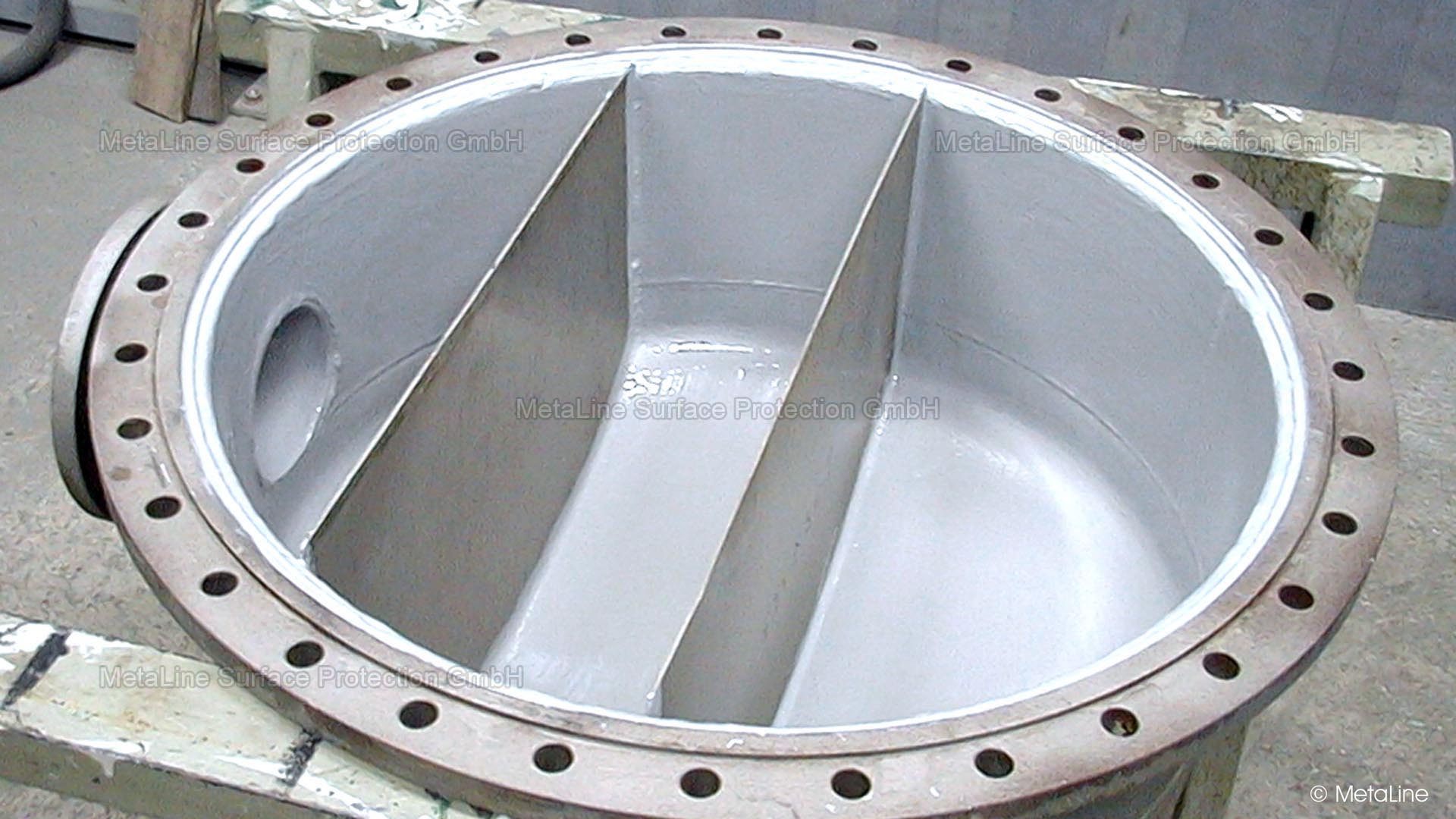

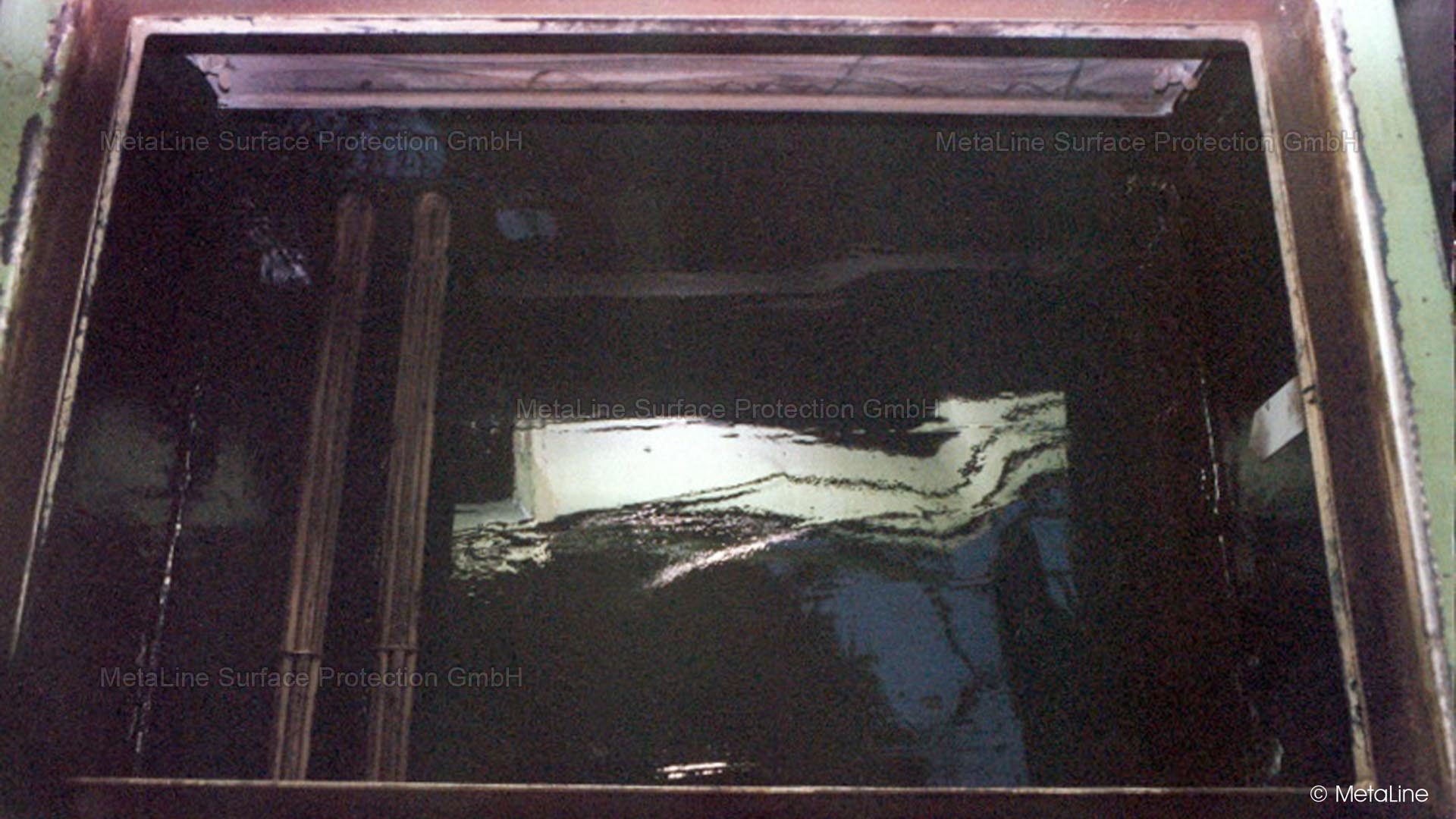

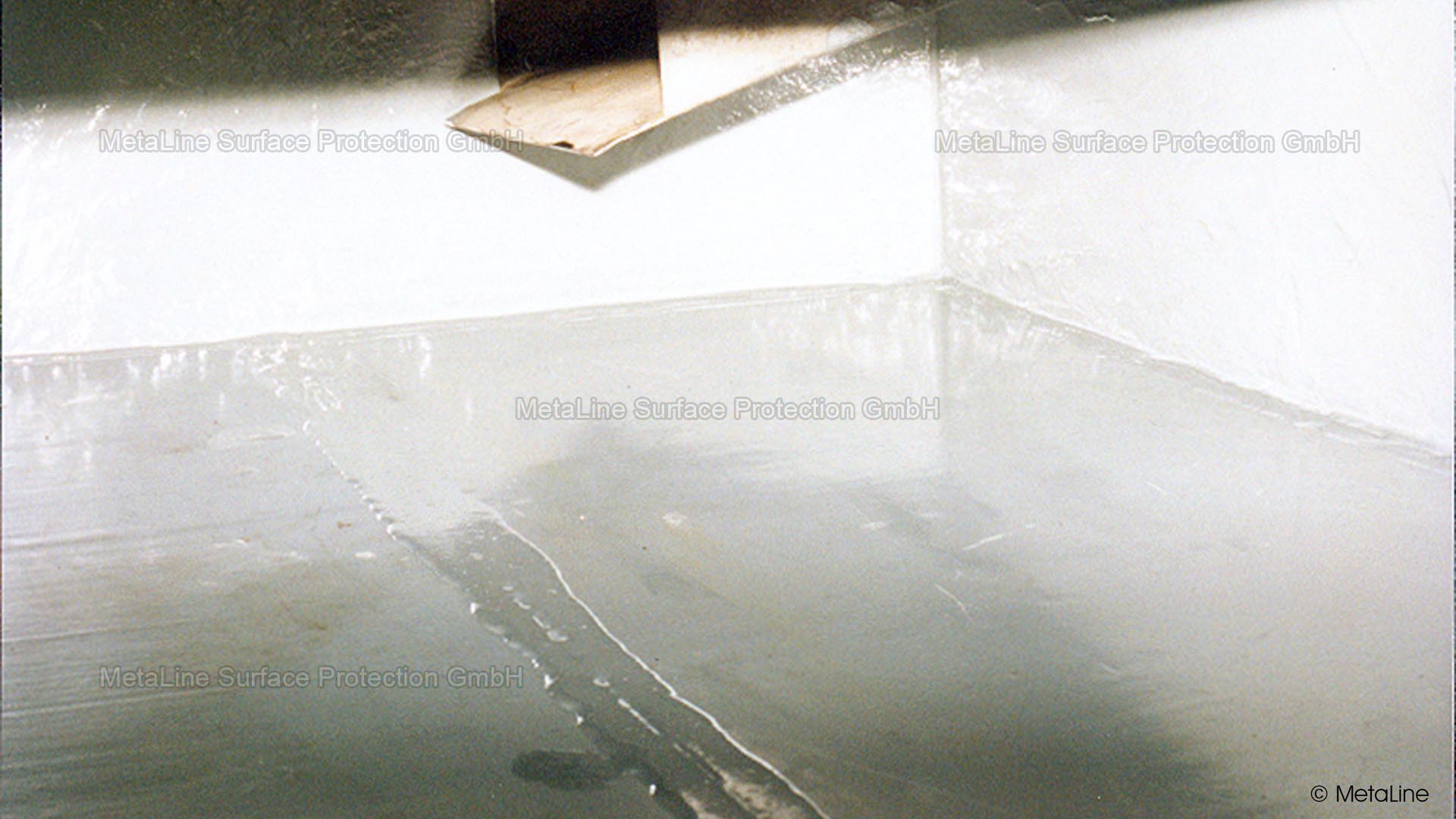

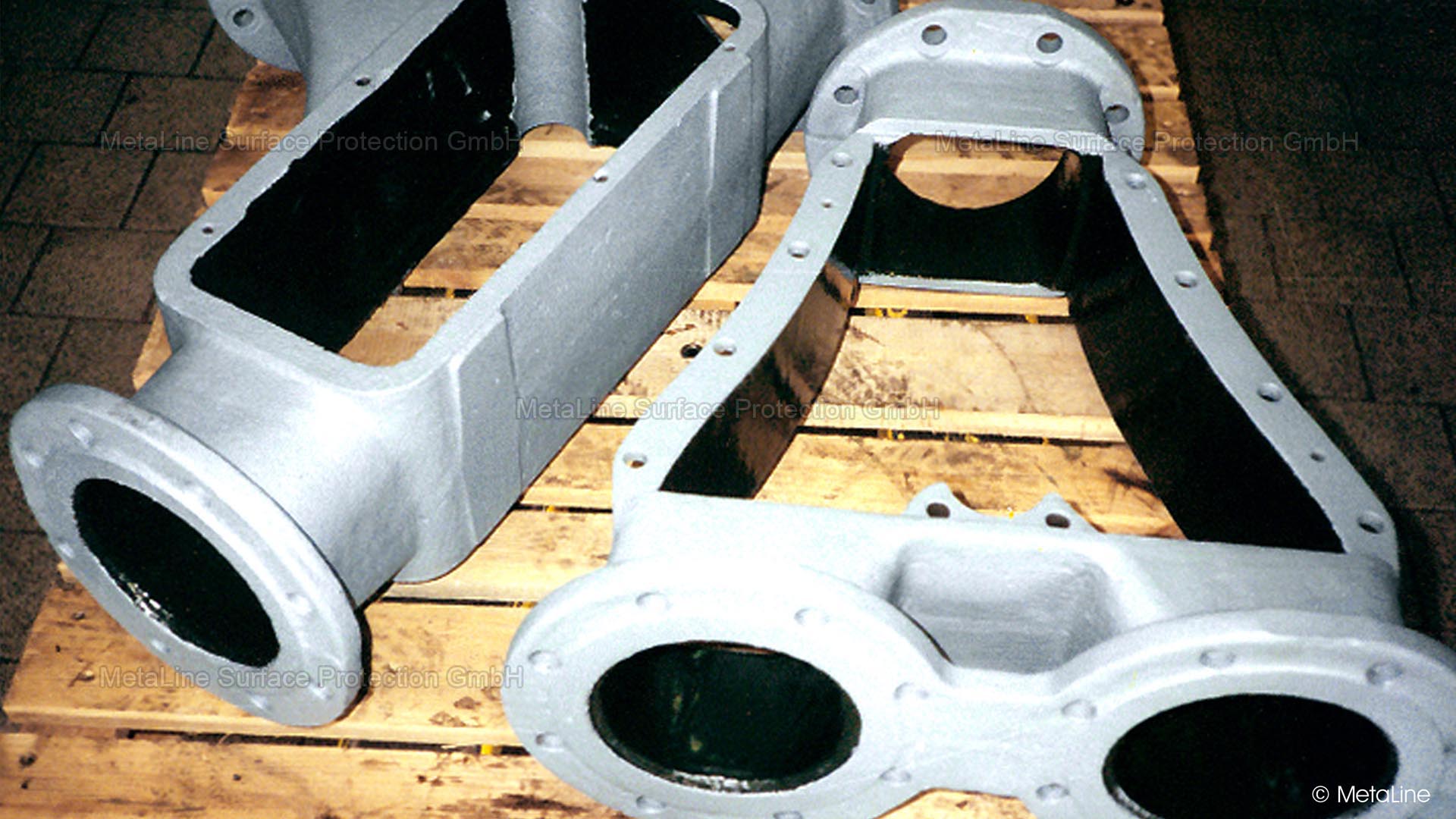

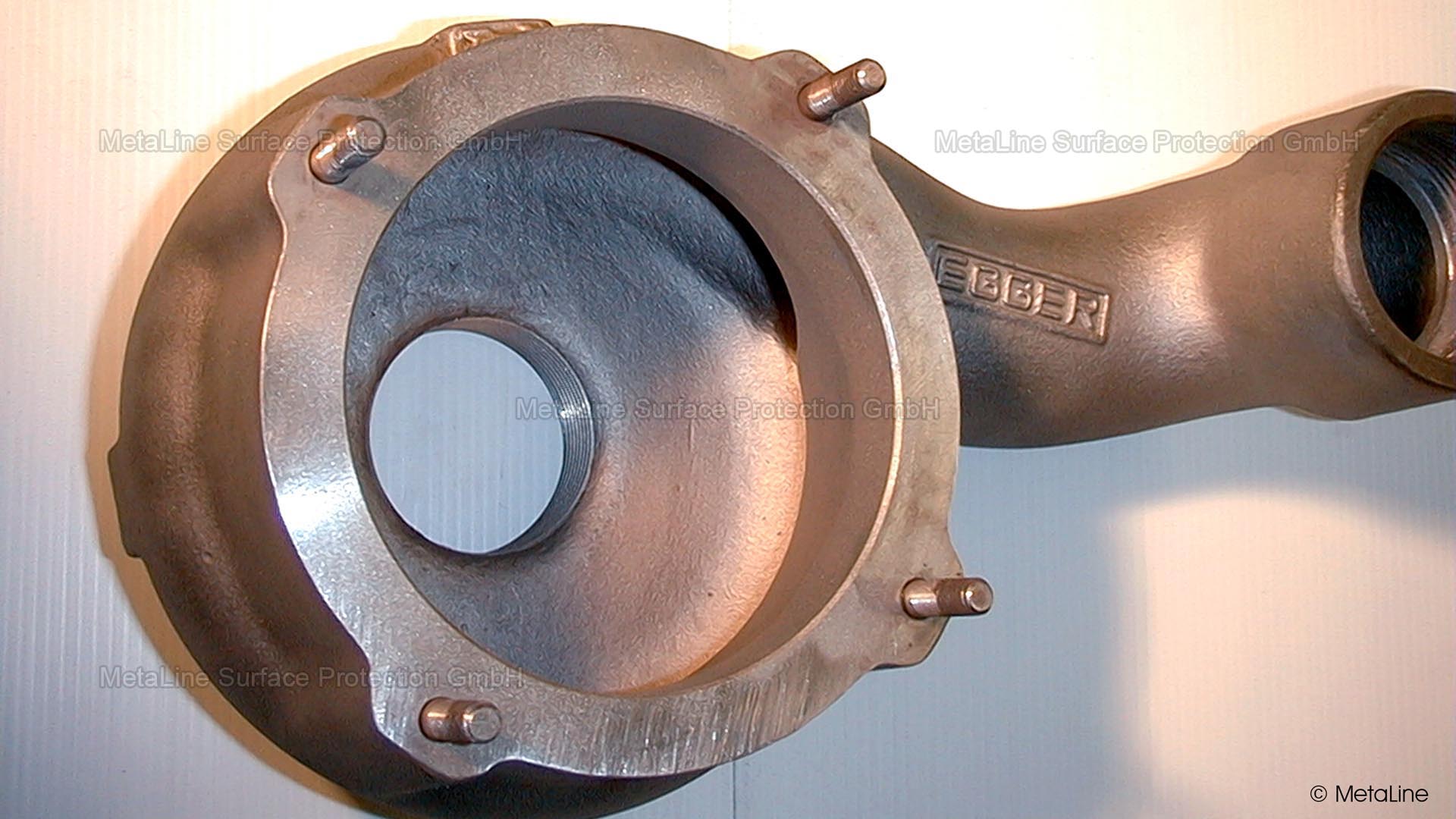

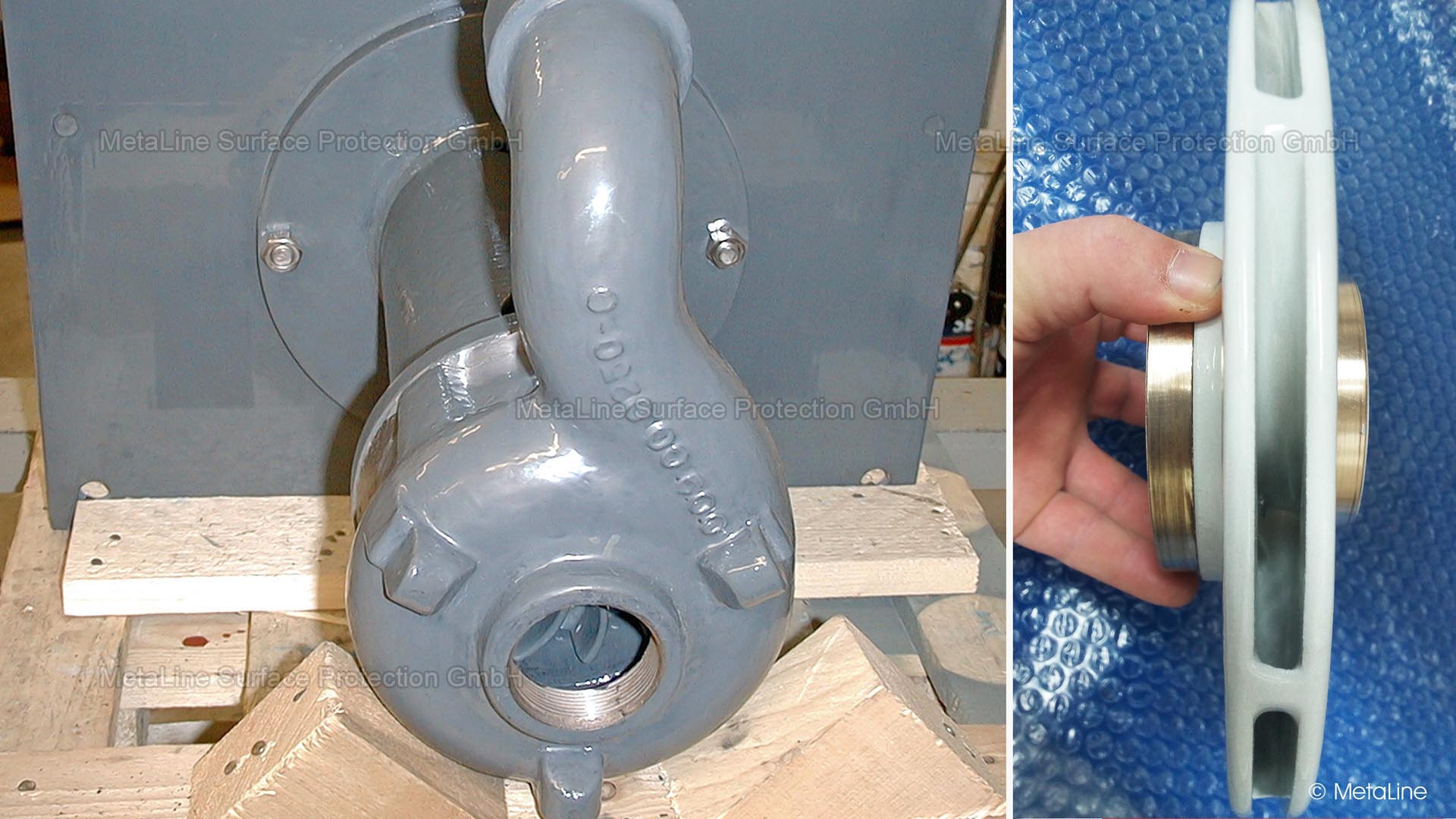

The main area of application is the permanent protection of metal or cement-bound surfaces against aggressive chemical liquid substances, such as acids, dyes or solvents – even under elevated temperatures.

The non-toxic material is applied in several layers under ambient conditions and adheres durably and absolutely corrosion-resistant to nearly all hard surfaces. An extremely impermeable glassflake compound with good chemical resistance forms after solidification. The protective function covers a remarkable spectrum of organic and inorganic pure chemicals, mixed products and production waste on water and solvent base. Temperature resistance amounts under immersed conditions to approximately 130°C (270 °F). The coating admits pressures of up to 100 bar (1,450 psi). Good thermal and electrical insulation characteristics are obtained.

MetaLine 100 XTM with a protective layer of 1.5 mm (60 mils) fulfill heavy-duty corrosion protection requirements of a 10,000 hours salt mist spray test.

Technical data

| Material basis | Novolac / ceramic / glassflake |

| Type of reaction | 2-component material for manual mixing |

| Type of application | application by brush, roller, airless or cartridge spraying |

| Thermal treatment | not required |

| Properties | residual elasticity, glass-tight |

| Characteristic | extremely resistant against chemical attack up to 130°C (270 °F) |

| Layer thickness | 0.5 mm (20 mils) up to 1.5 mm (60 mils) |

| Number of layers | 1 - 3 depending on load |

| Chemical resistance | usually pH 1-14 |

| Mechanical processability | machinable with common tools |

| Consumption | 1.25 kg per m²/mm layer thickness (0.25 lb/sqft per 40 mils coat) |

| Ready for use | as from 48 hours |

| Color | blue grey (similar RAL 7031) |

| Substrate preparation | mechanical roughing or gritblasting / degreasing |

| Food compatibility | none |

| Container size | 0.5 kg (1.1 lbs), 5 kg (11 lbs) and 200 kg (440 lbs) container including processing instructions |

| Cartridge size | 1.25 kg (2.75 lbs) including processing instructions |

| Shelf-life | at least 12 months |

| Availability | immediately ex warehouse |

Brochures

Pack sizes

The webshop delivery includes:

- 1 x 0.5 kg (1.1 lbs) plastic jar MetaLine 100 XTM (Base and Solidifier)

- 1 x Processing Instructions

Availability: Immediately ex stock

Order

Order:

MetaLine 100 XTM – Chemical Protection:

90.- Euro (net) excl. shipping costs

The delivery includes:

- 1 x 0.5 kg (1.1 lbs) plastic jar MetaLine 100 XTM (Base and Solidifier)

- 1 x Processing Instructions

Availability: Immediately ex stock

Here you can find our Notice of Withdrawal and Privacy Policy