Features

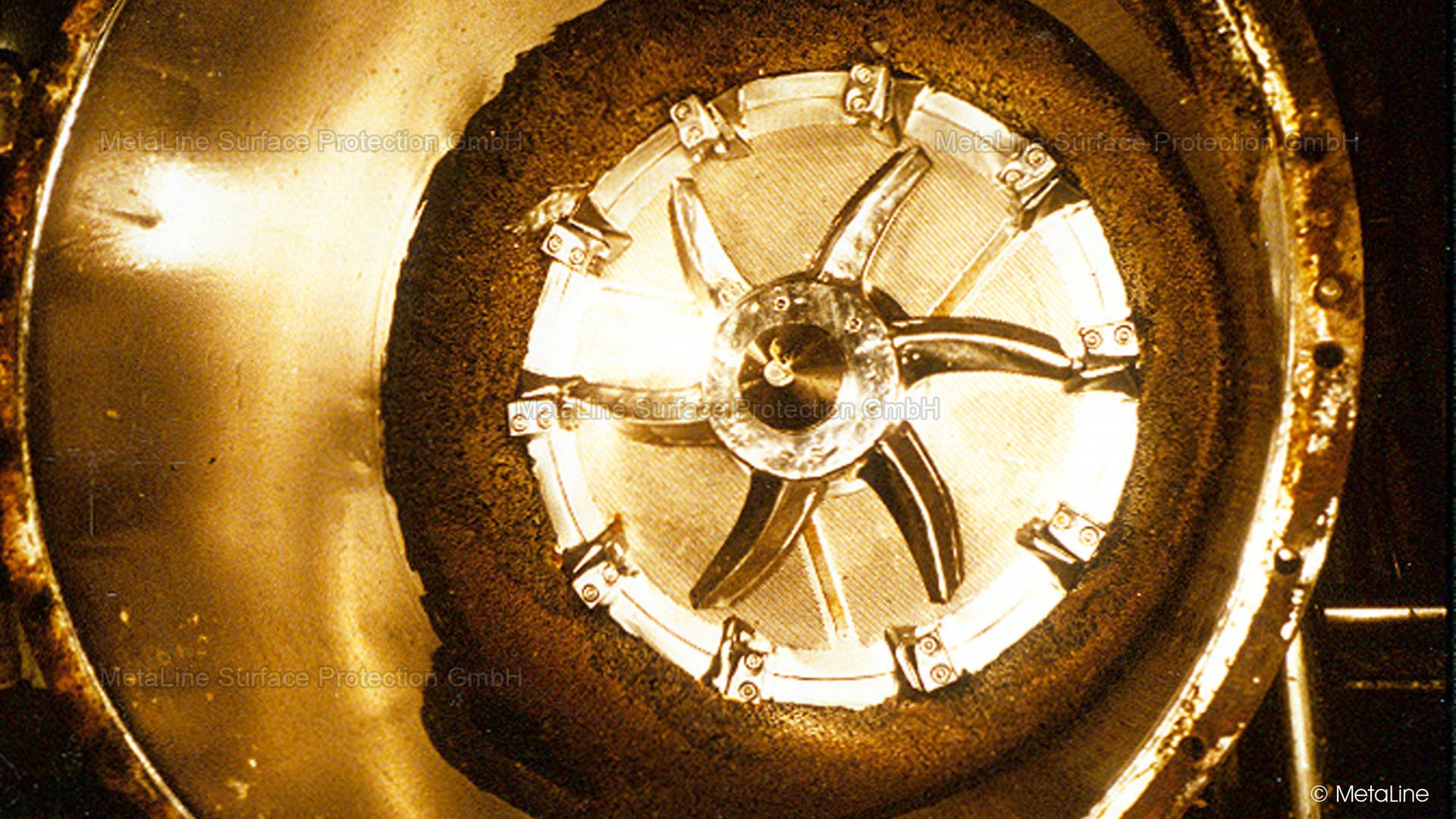

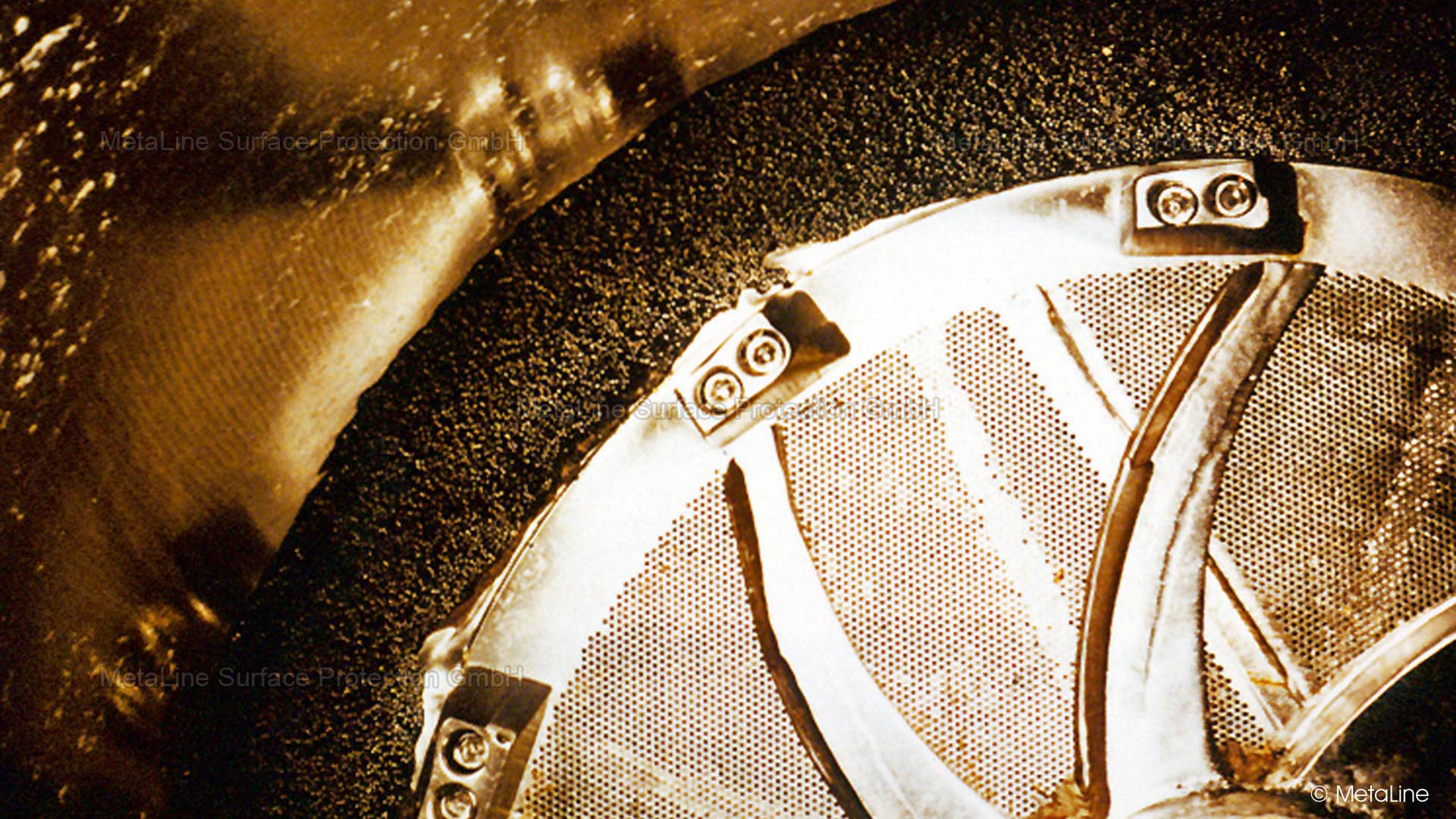

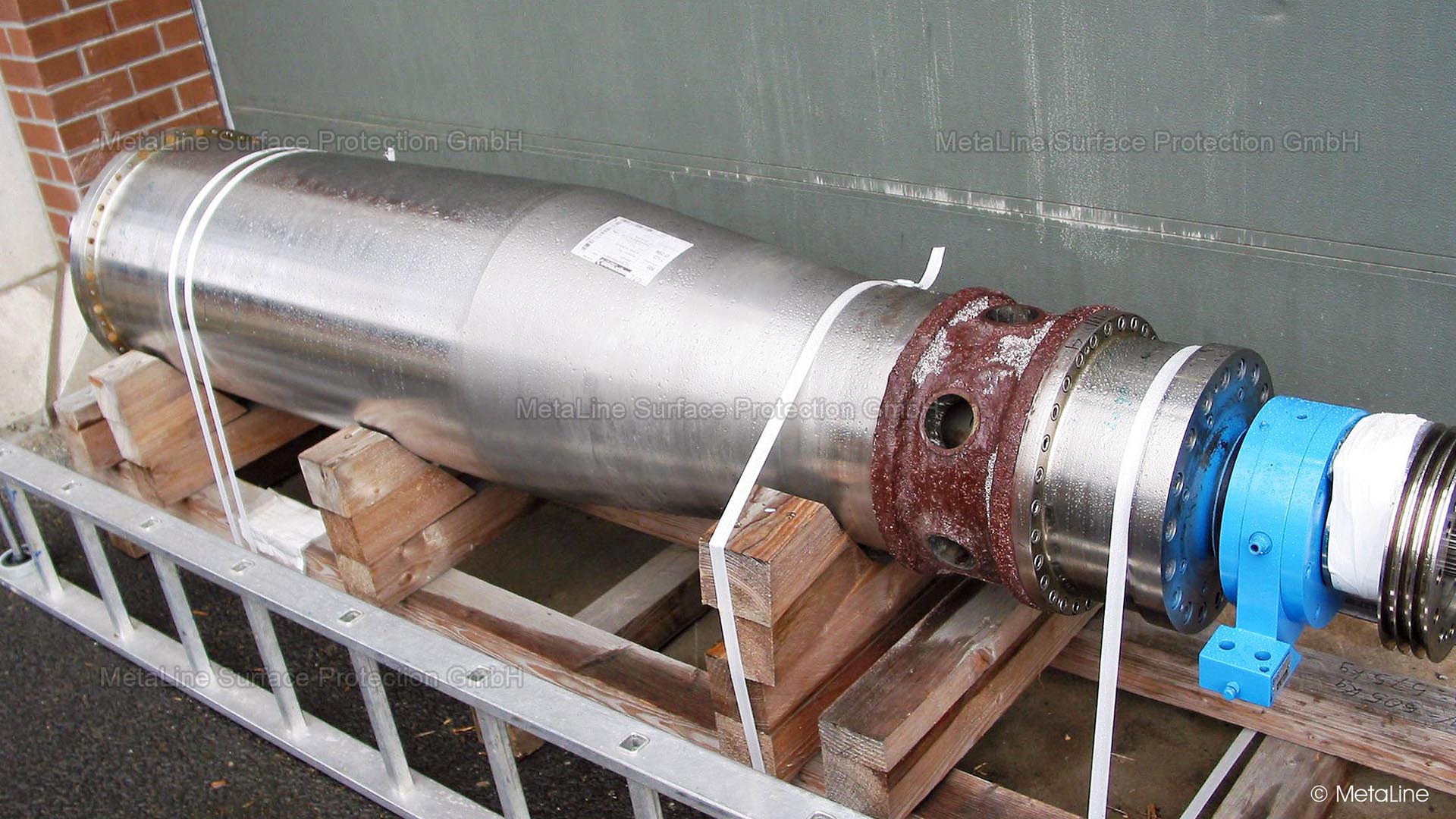

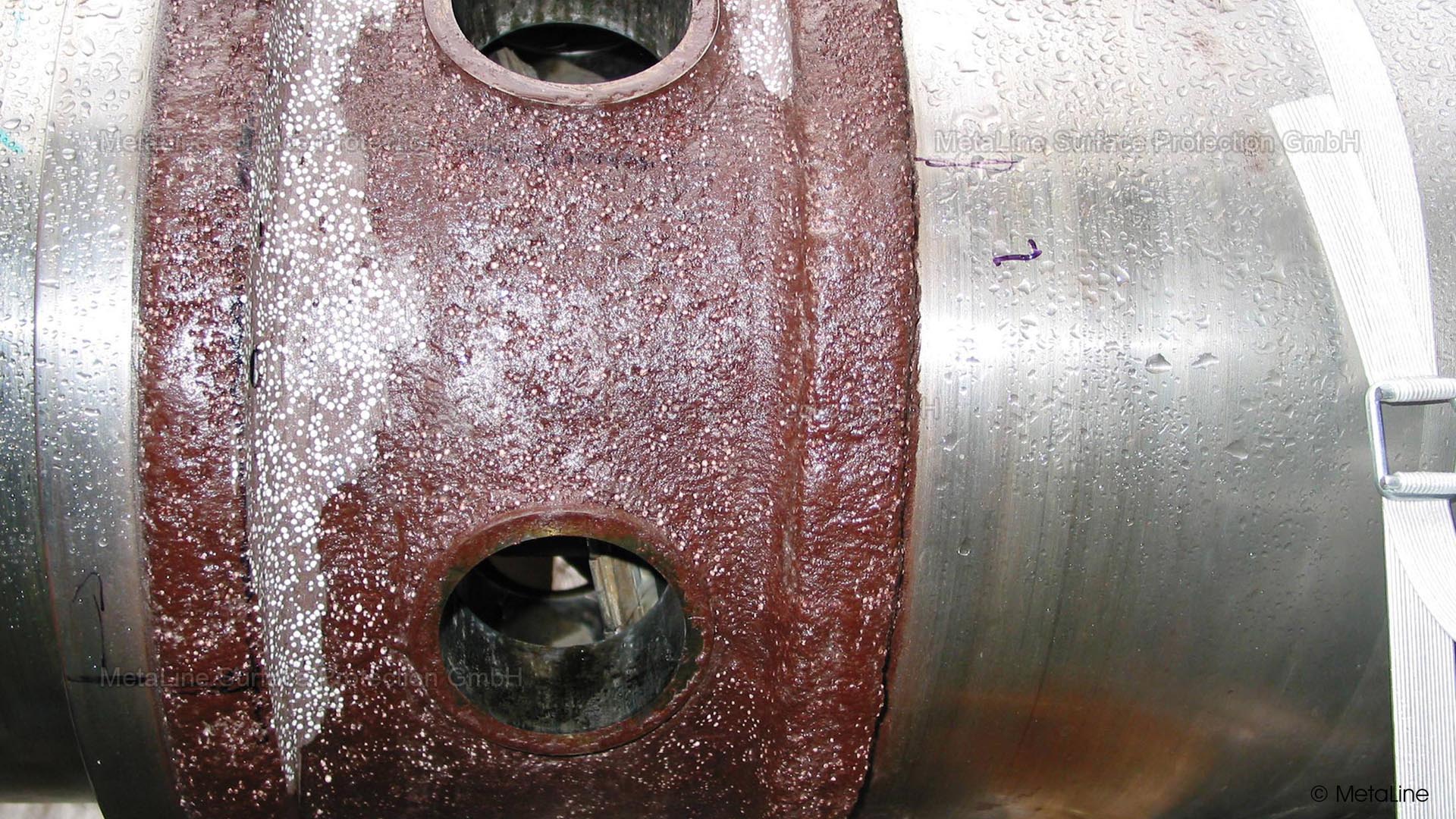

MetaLine's ceramic repair compound CXL is a self-processing ferrite-free, 2-component carbide material for the structural protection of metallic components against impact.

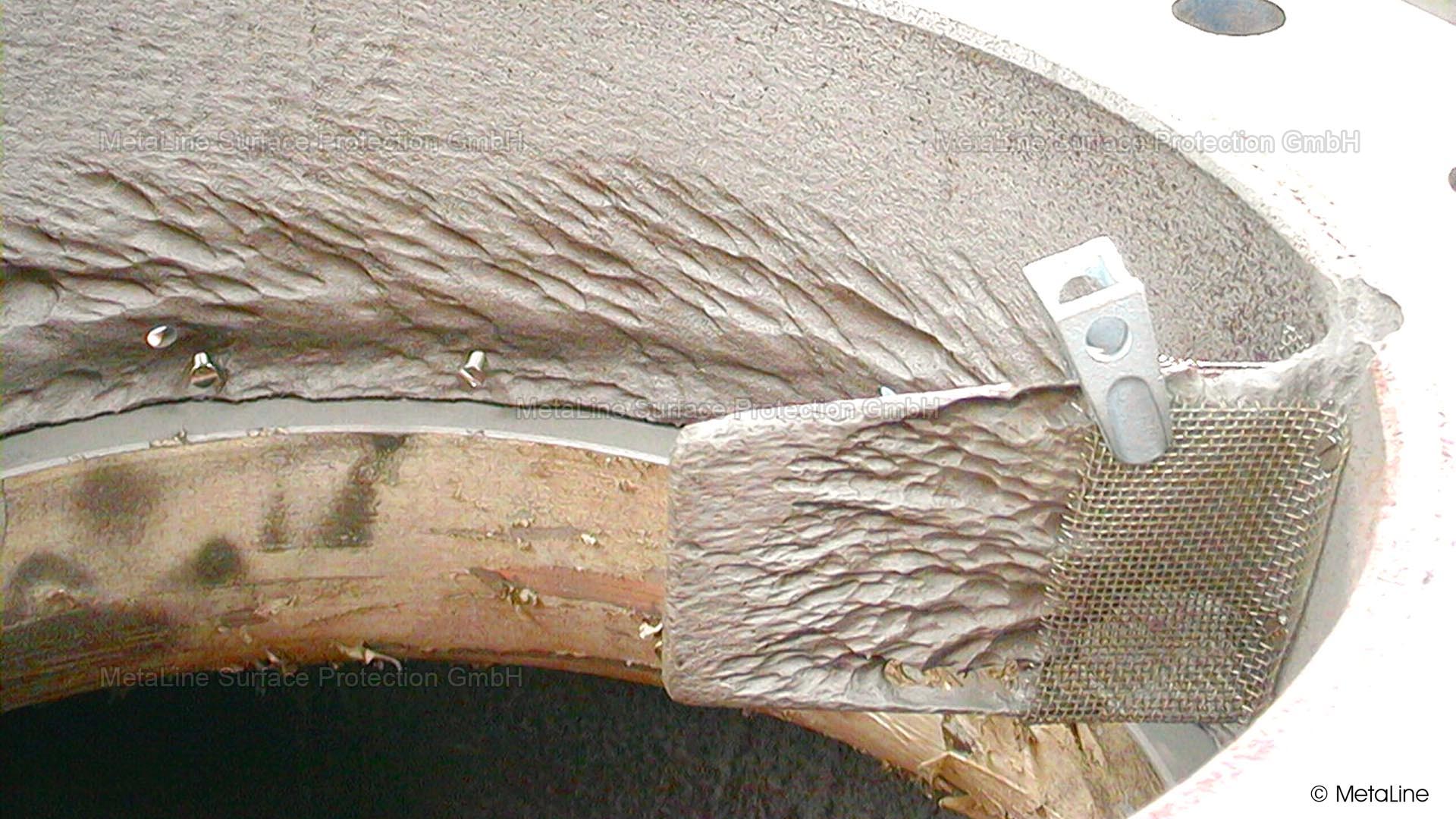

The product is based on ceramic components, aramid-fibers and carbide particles of various dimensions. The structured surface in itself causes the pumped medium to adhere to the coating. An effective protective layer is formed by the medium itself, thus giving the substrate a longer service life. In surface technology, this "self-protection process" is referred to as autogenous wear protection.

Material properties: Pasty / High-Coat Trowelable / Ceramic-Carbide

- Trowelable at room temperature (minimum thickness 3 mm / 120 mils)

- Solvent-free & non-toxic

- Cold curing without heat transfer into the substrate

- No special tools or expertise required

- Adheres to steel, stainless steel, soft-/non-ferrous metals, alloys (casted / forged / rolled)

- Replaces lost metallic structures but without equivalent static stability

- Completely corrosion resistant

- High dynamical wear resistance

- No shrinkage or expansion

- Non-magnetic

- Good thermal and electrical insulation properties

- Heat resistant under dry conditions up to 200 °C (400 °F)

- Extreme chemical resistance

- Superior cathodic disbonding resistance

- Not machinable anymore (except grinding)

Technical data

| Material basis | solvent-free polymer ceramics with carbide particles |

| Type of reaction | 2-component material for manual self-mixing |

| Type of application | application by trowel |

| Thermal treatment | not required |

| Properties | residual elasticity, ceramic |

| Characteristics | resistant against dynamic wear, corrosion |

| Layer thickness | 3 mm (120 mils) up to infinite |

| Number of coats | processable in one single layer |

| Shrinking / swelling | not measurable |

| Chemical resistance | usually ph 2-13 |

| Mechanical processability | only processable by non-cutting processes, eg. grinding |

| Coverage / area weight | 2.05 kg per m²/mm (0.42 lb per 40 mils/sqft) layer thickness |

| Ready for use | as from 12 hours |

| Color | dark brown |

| Substrate preparation | mechanical roughing or gritblasting / degreasing |

| Food compatibility | incidental, according to USDA standards |

| Container size | 2 kg (4.4 lbs) package including cleaner, trowel, processing instructions |

| Shelf-life | 4 years |

| Availability | immediately ex warehouse |

Brochures

Pack sizes

The delivery includes:

- 1 x 2.0 kg (4.4 lbs) MetaLine CXL (Base and Solidifier)

- 1 x 0,25 Liter (0.06 gal) MetaLine 990 Degreaser/Thinner

- 1 x plastic applicator

- 1 x latex gloves (pair)

- 1 x application leaflet

- 1 x re-closeable module box

Availability: Immediately ex stock

Order

Order:

MetaLine CXL Repair System:

380.- Euro (net) excl. shipping costs

The delivery includes:

- 1 x 2.0 kg (2.2 lbs) MetaLine SXL (Base and Solidifier)

- 1 x 0.25 Liter (0.06 gal) MetaLine 990 Degreaser/Thinner

- 1 x plastic applicator

- 1 x latex gloves (pair)

- 1 x application leaflet

- 1 x re-closeable modulebox

Availability: Immediately ex stock

Here you can find our Notice of Withdrawal and Privacy Policy