MetaLine SXL had been used to rebuild the huge shaft and to calibrate the missing structure

Pipe bend sealed with MetaLine Ceramic Repair Compound SXL and metal reinforcement fabric

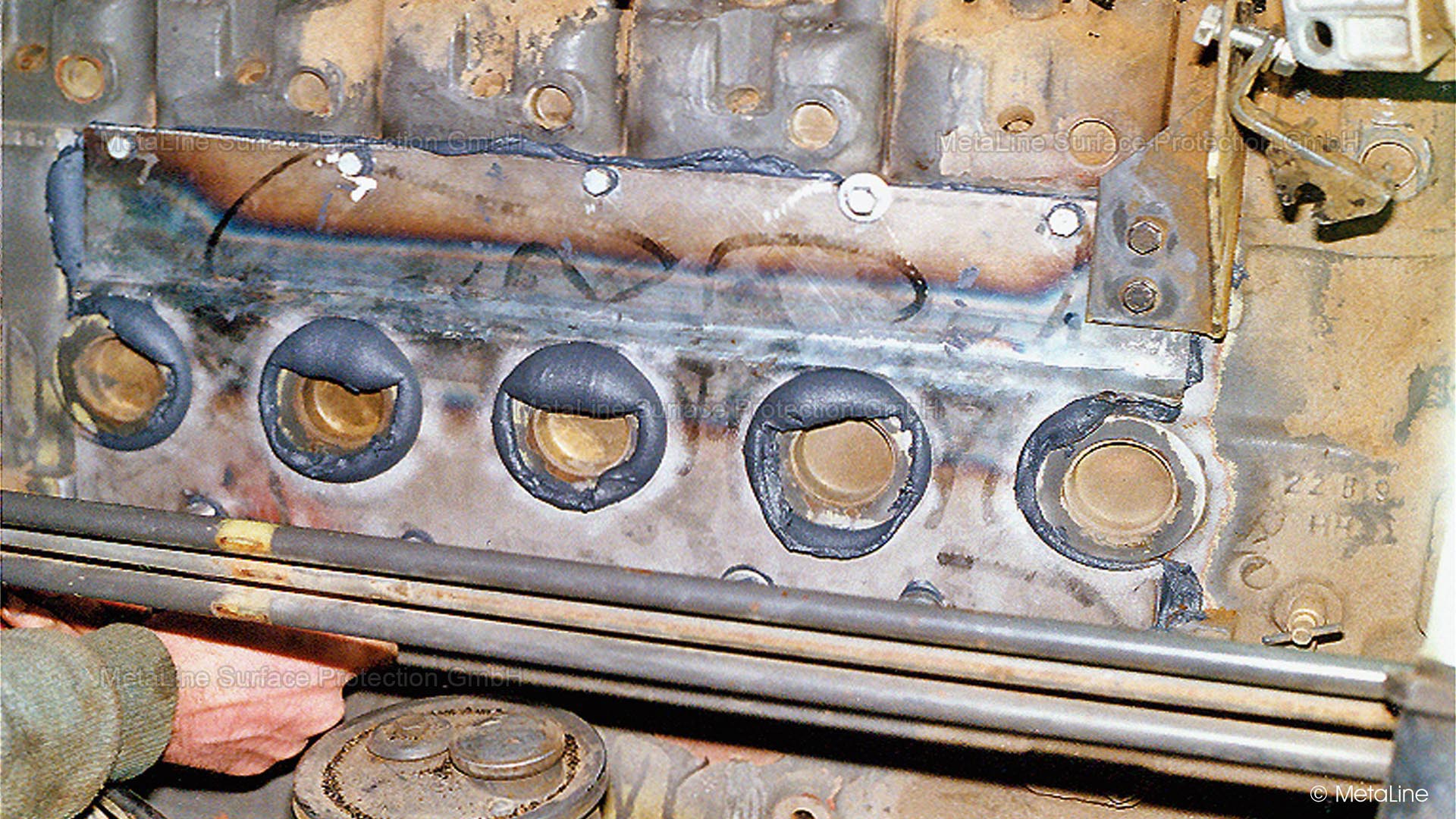

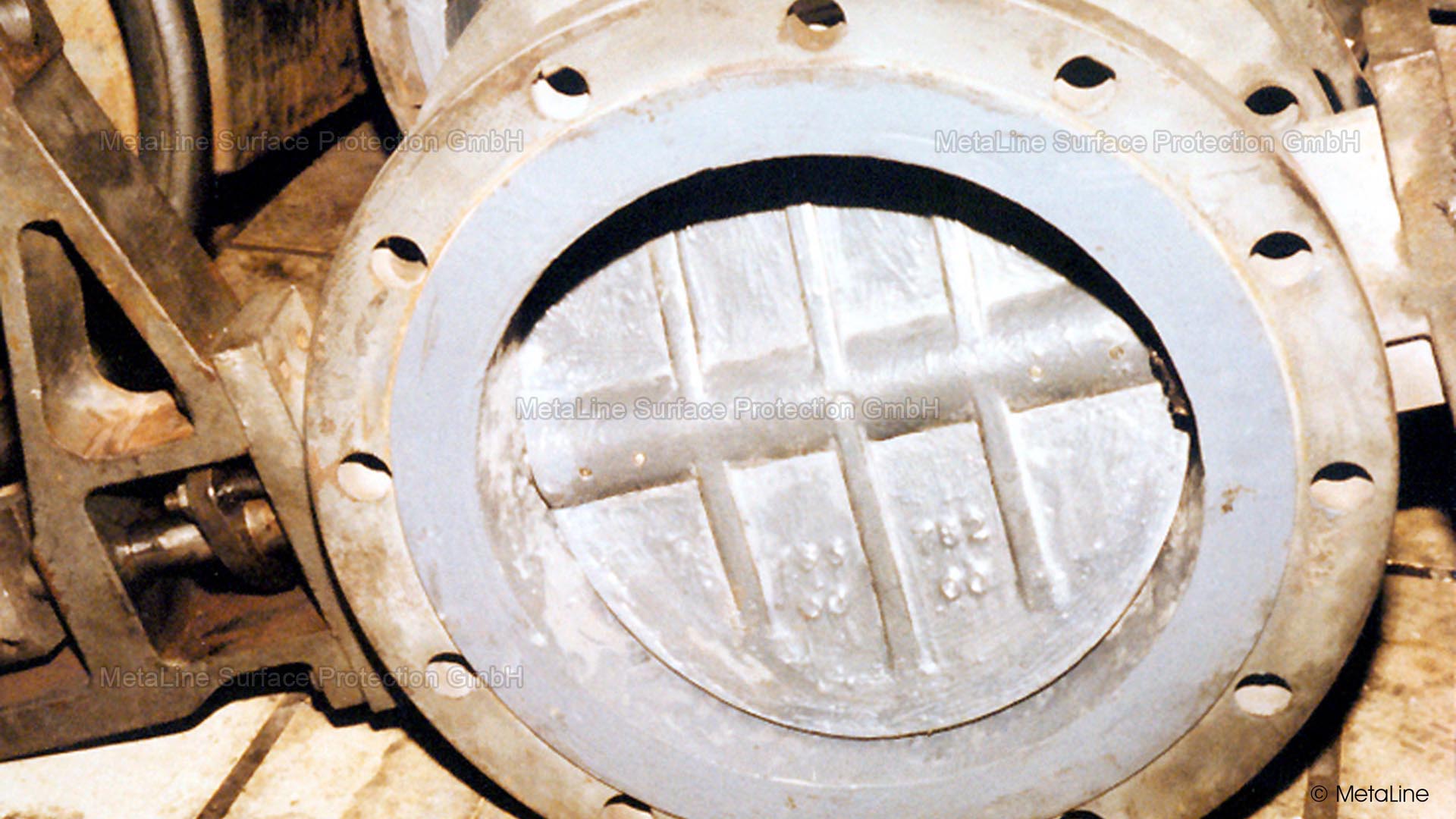

Crack in a bigger diesel engine stabilized with a massive steel plate and MetaLine SXL

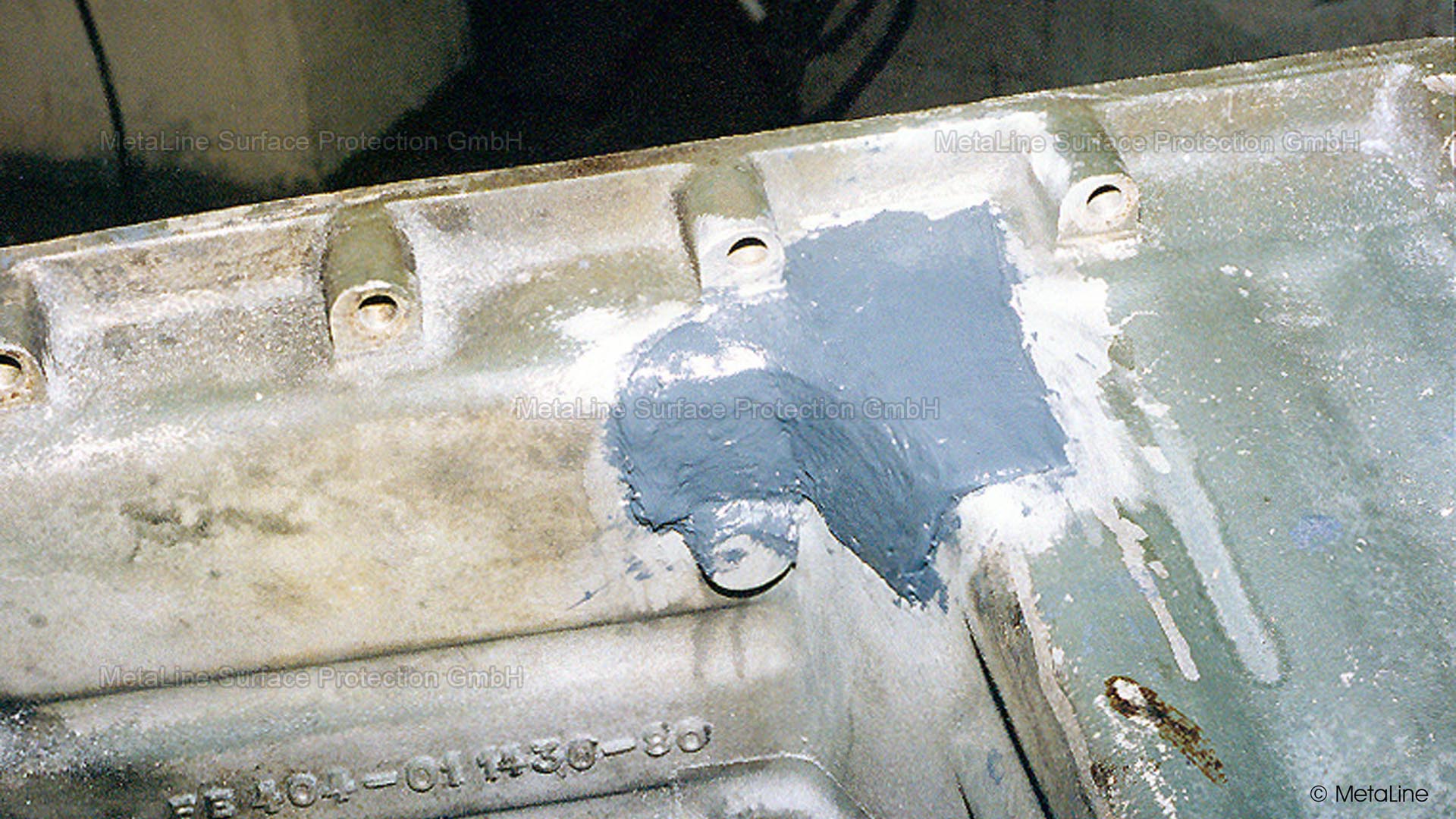

Oil sump successfully sealed with MetaLine Ceramic Repair Compound SXL and metal reinforcement fabric

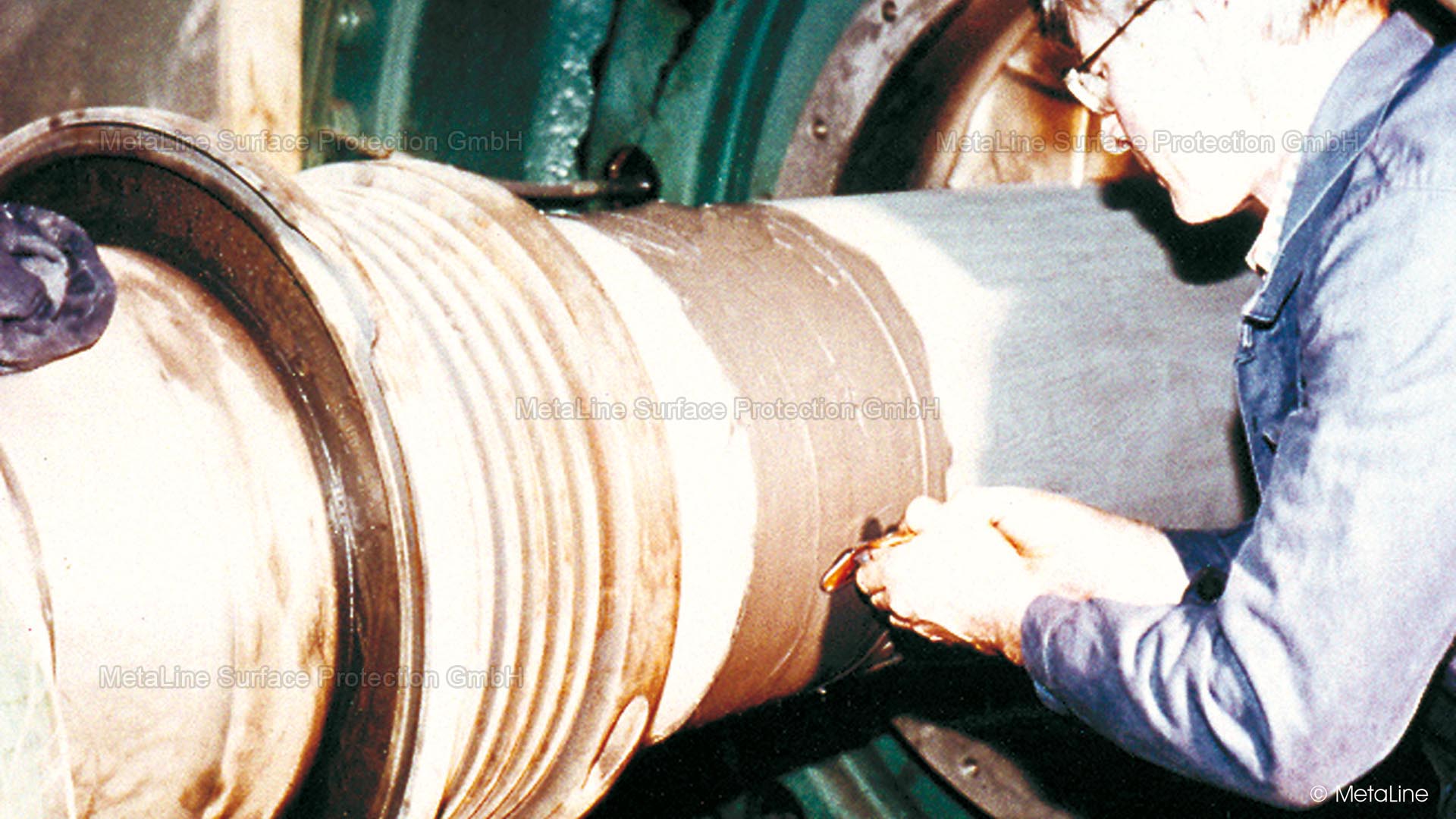

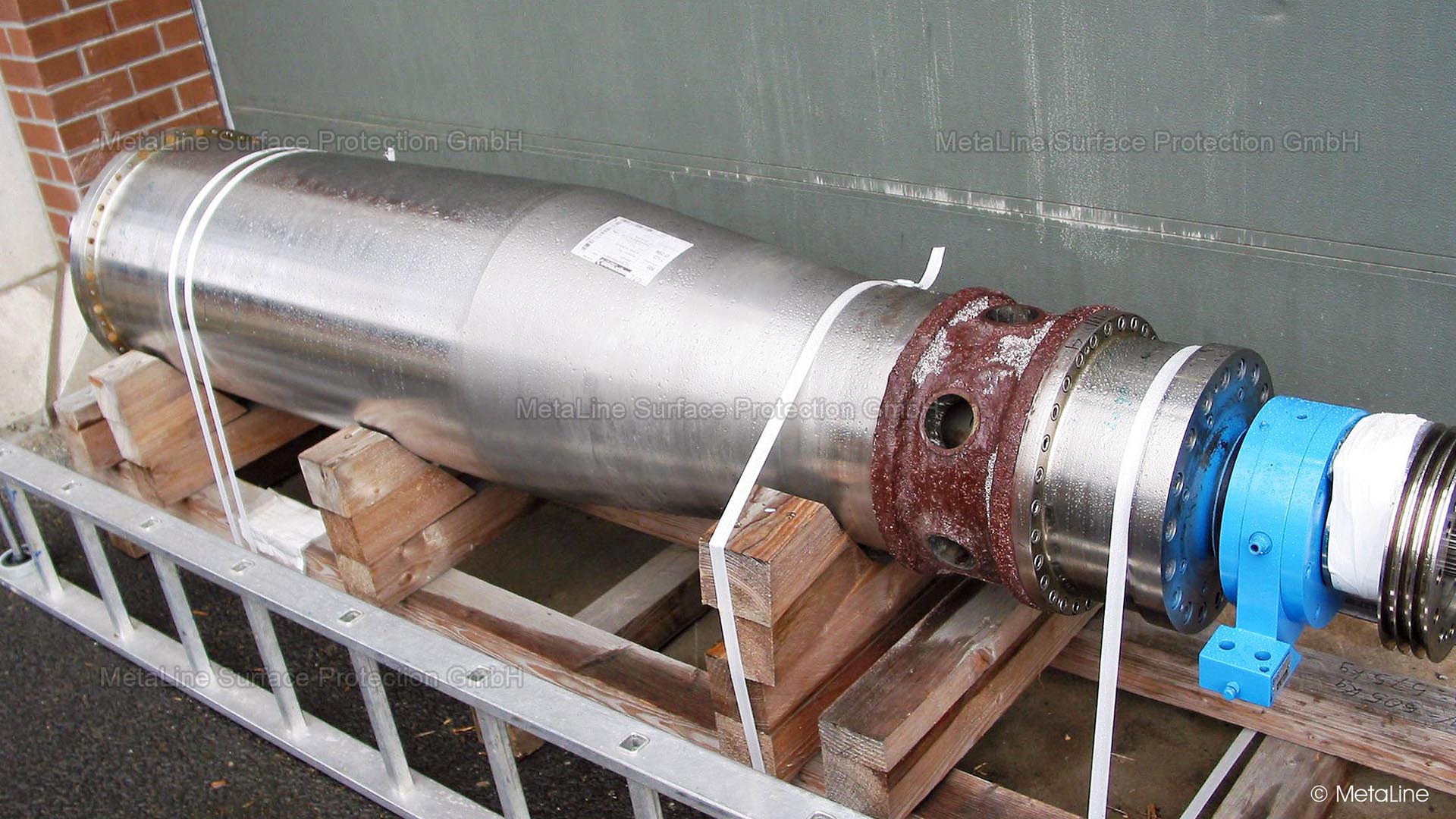

Ship shaft repair - a local damage on this shaft was reconditioned with the MetaLine SXL under rotation and then ground down to the nominal dimension. The repair was permissible because the shaft stability was sufficient and the damage resulted from a bearing problem and not from a fundamentally insufficient mechanical resistance.

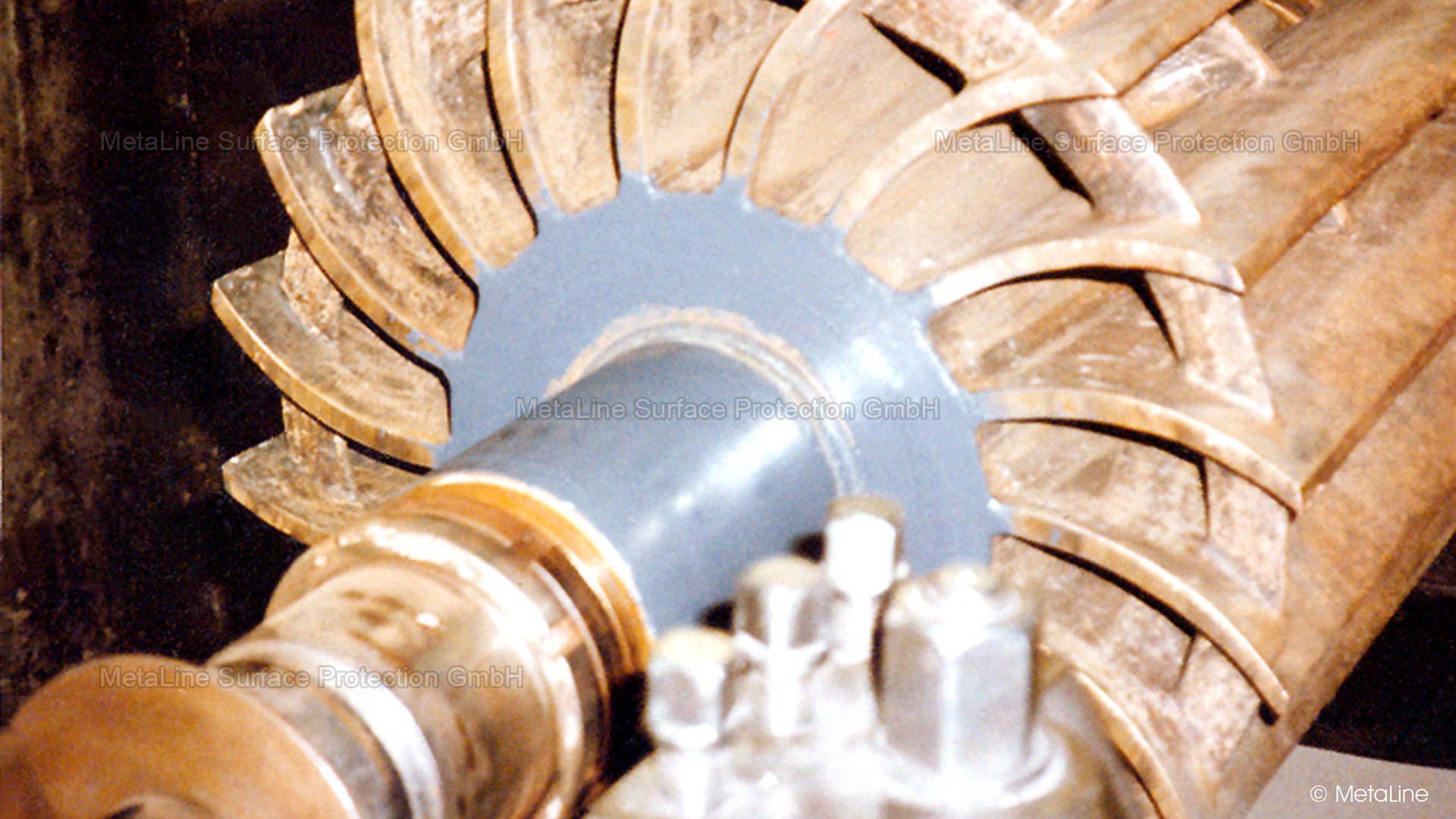

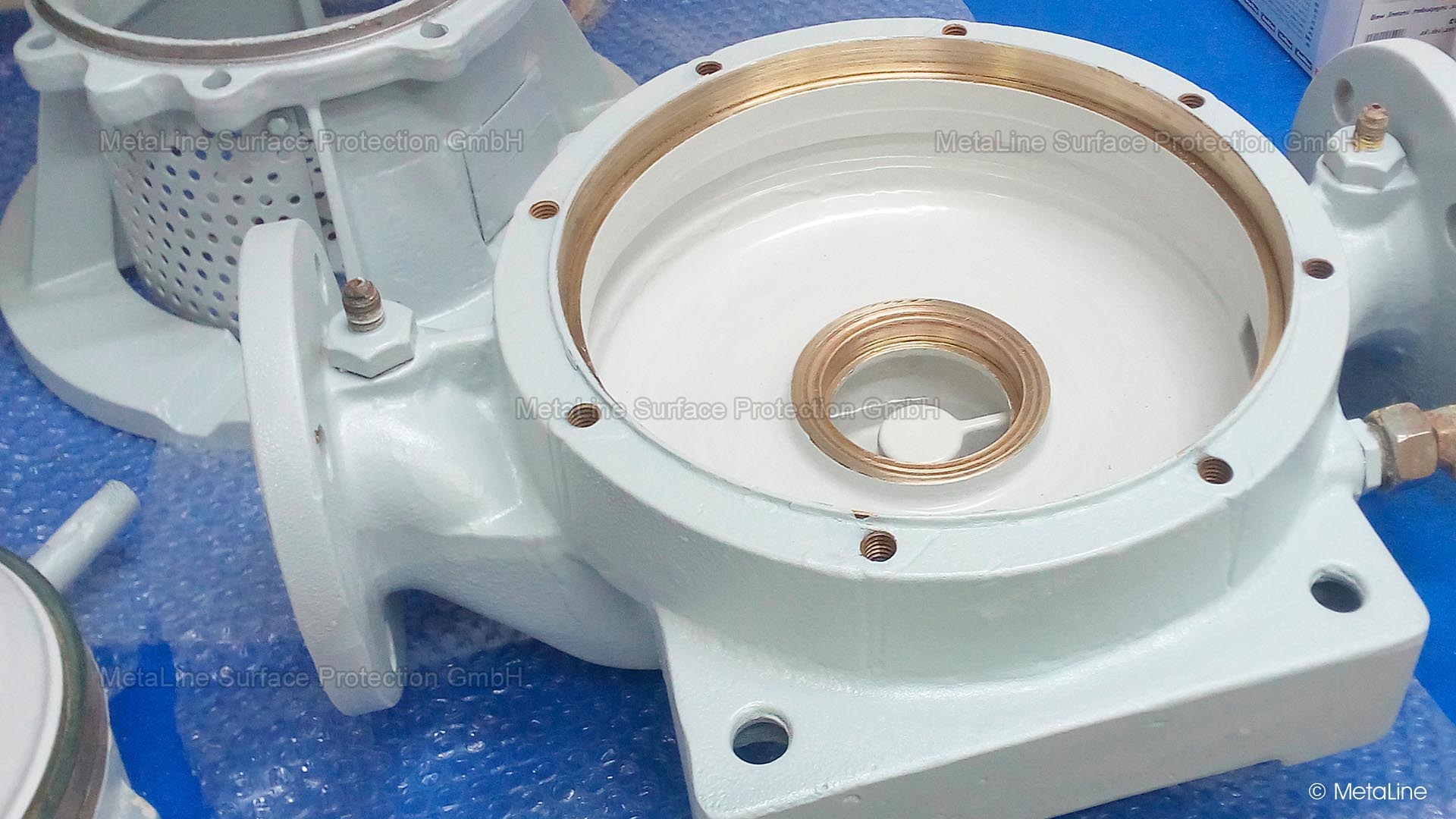

Installation of the bearing bushing on the prepared axle stub by means of MetaLine ceramic repair compound SXL

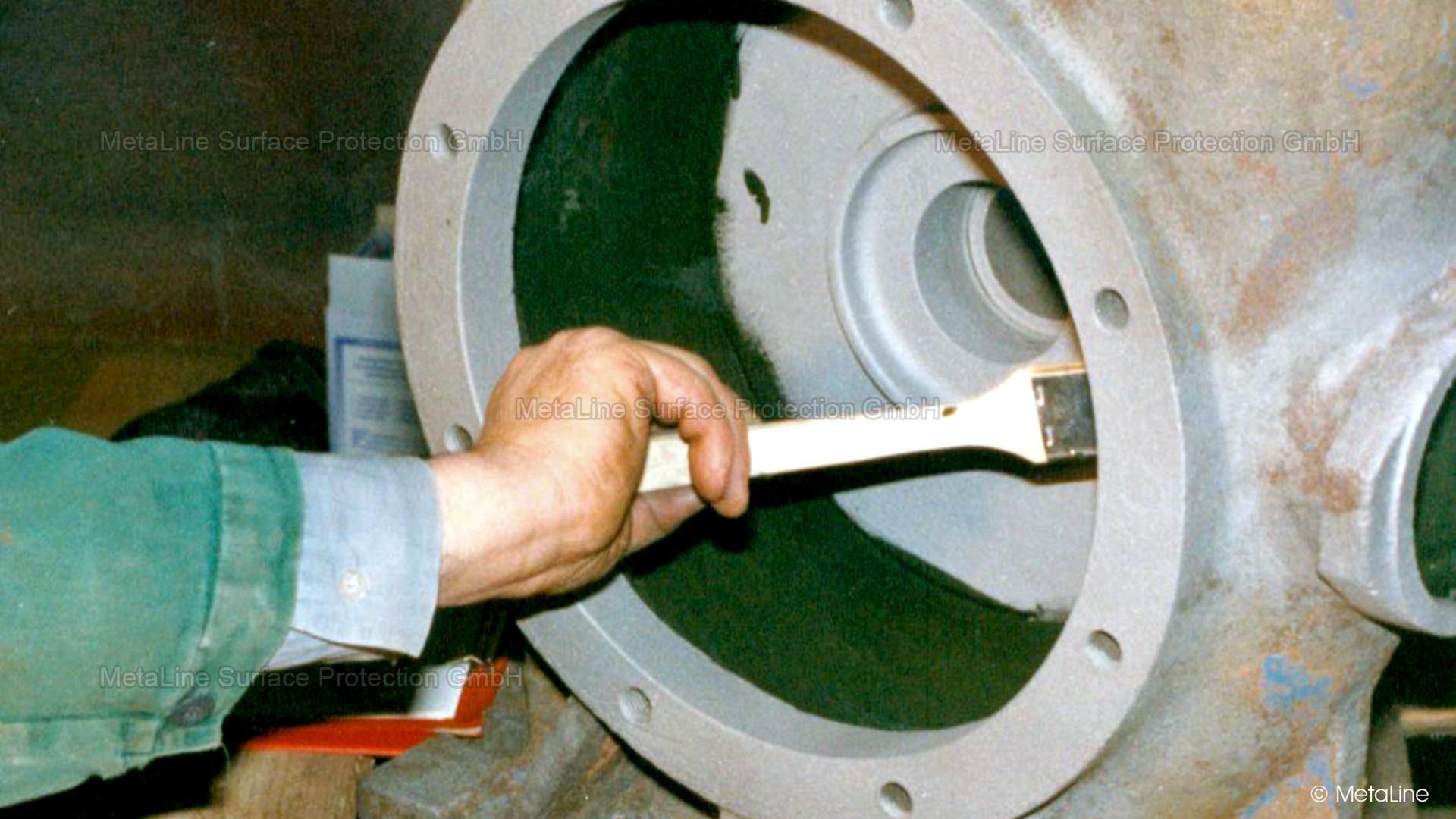

MetaLine Ceramic Repair Compound SXL is being applied overhead to this flange for sealing purposes

New ceramic bearing area finished with MetaLine Ceramic Repair Compound SXL

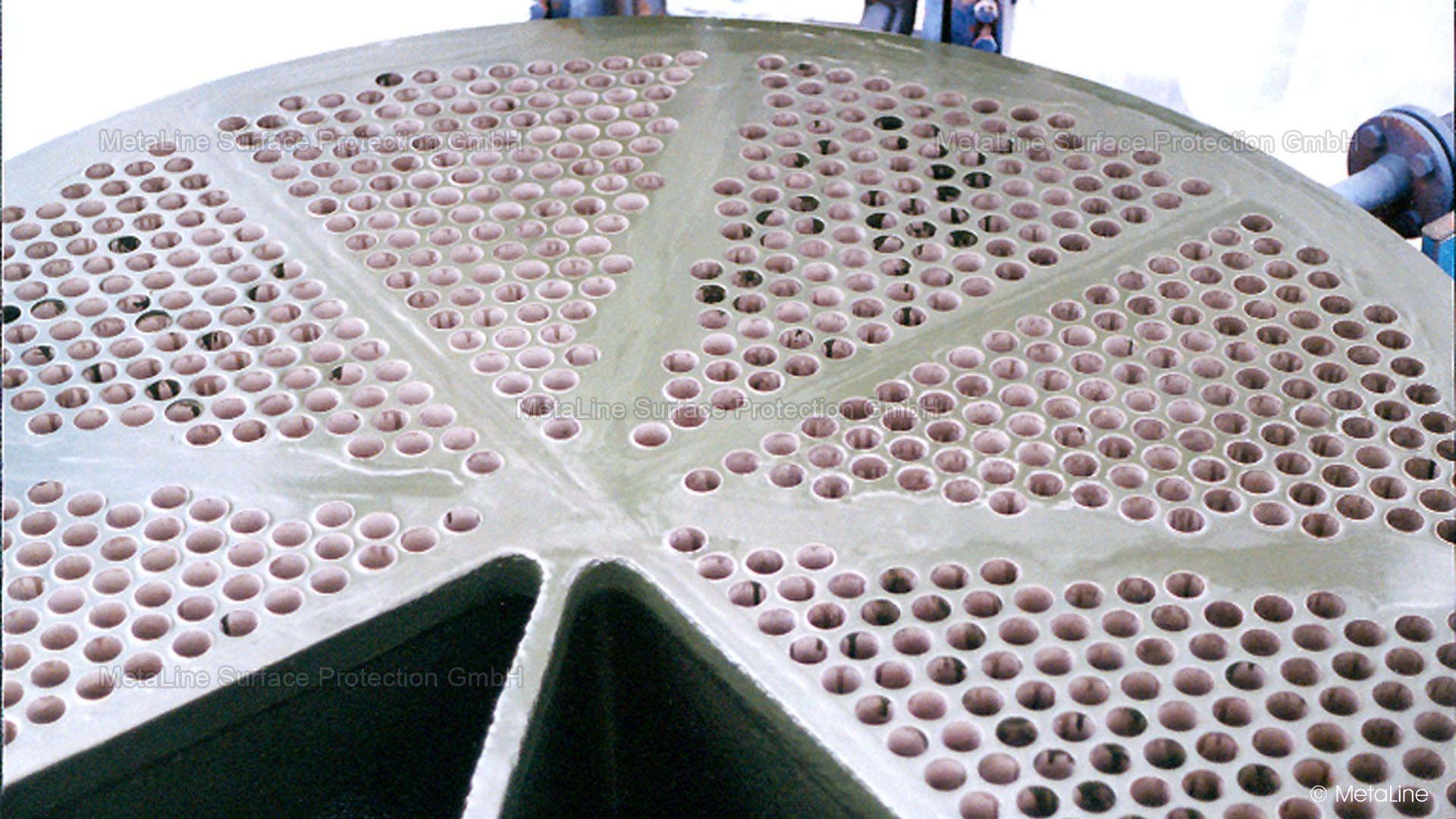

Electrically insulating ceramic protective coating on this heat exchanger inside a German sugar manufacturing plant

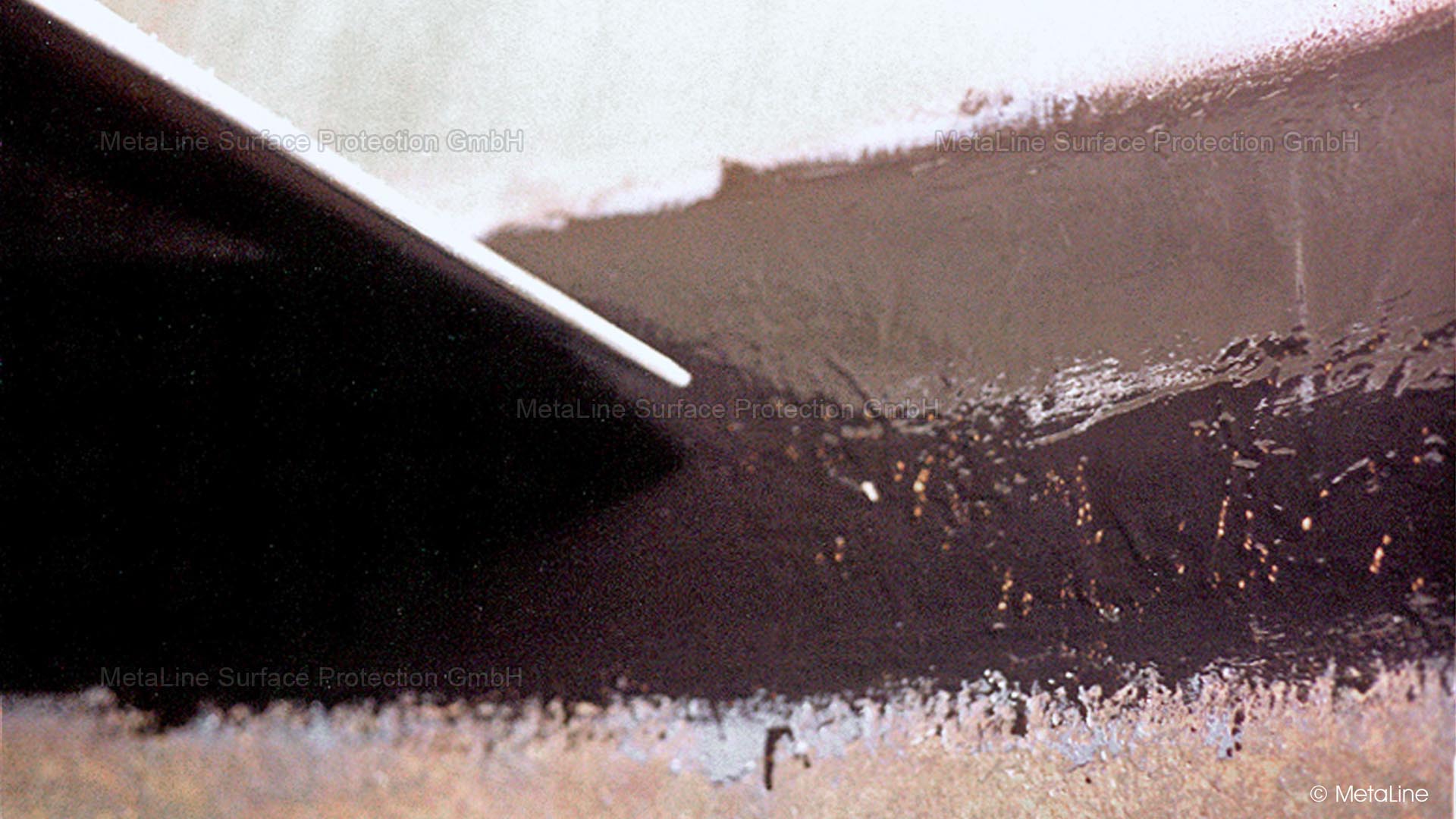

During the repair with MetaLine Ceramic Repair Compound KXL – we do not really like to use a brush as a coating tool. Have a look at the MetaLine Series 700 cartridge spraying process which presents a good alternative including an advanced performance and an unbelievable smoothness

During application of the MetaLine ceramic repair compound – manually installed and afterwards brought to shape by a simple template

Insertion of the steel reinforcement by means of MetaLine SXL - a durable crack sealing technology using a high-performance polymer

Pump service - corrosion-resistant, wear-resistant, professional - MetaLine Series XL has restored the pump contour in this case and, with its corrosion-free properties, pose a high hurdle for renewed attack.

MetaLine's cavitation protective coat has been applied by the customer himself - technically welldone, optically not the first choice

Throttle coating - coated flap & housing. Further corrosion is inhibited and the good erosion resistance of MetaLine promises a significantly extended lifetime

Seawater pump - a coating is purposeful because practically all metallic surfaces are synthetically encapsulated. Salt water can no longer attack as long as the protective film is intact. Professional surface preparation is always a prerequisite. Sandpaper is NOT sufficient for this!

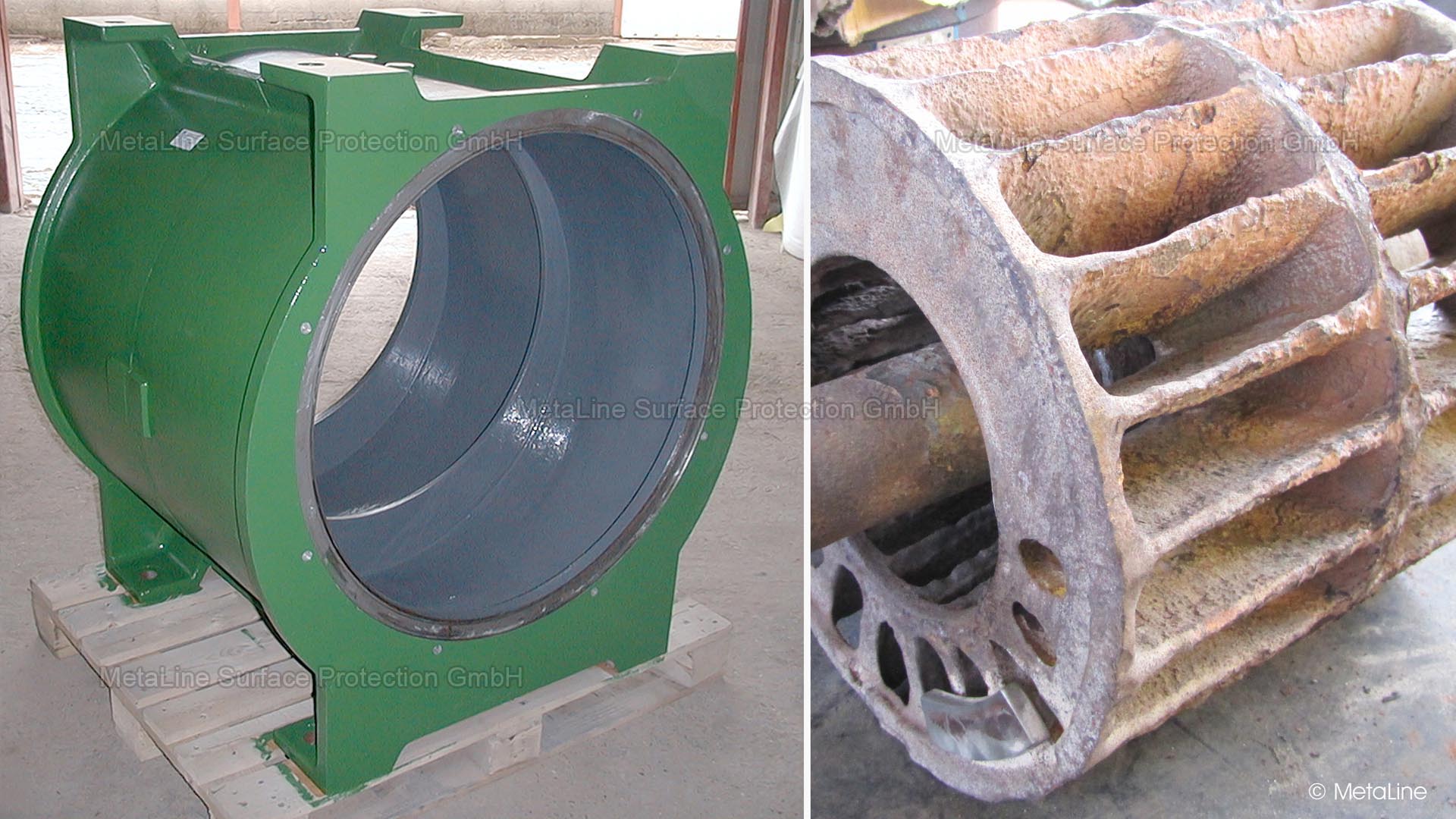

Brought back to life, internally and externally – with MetaLine surface technologies

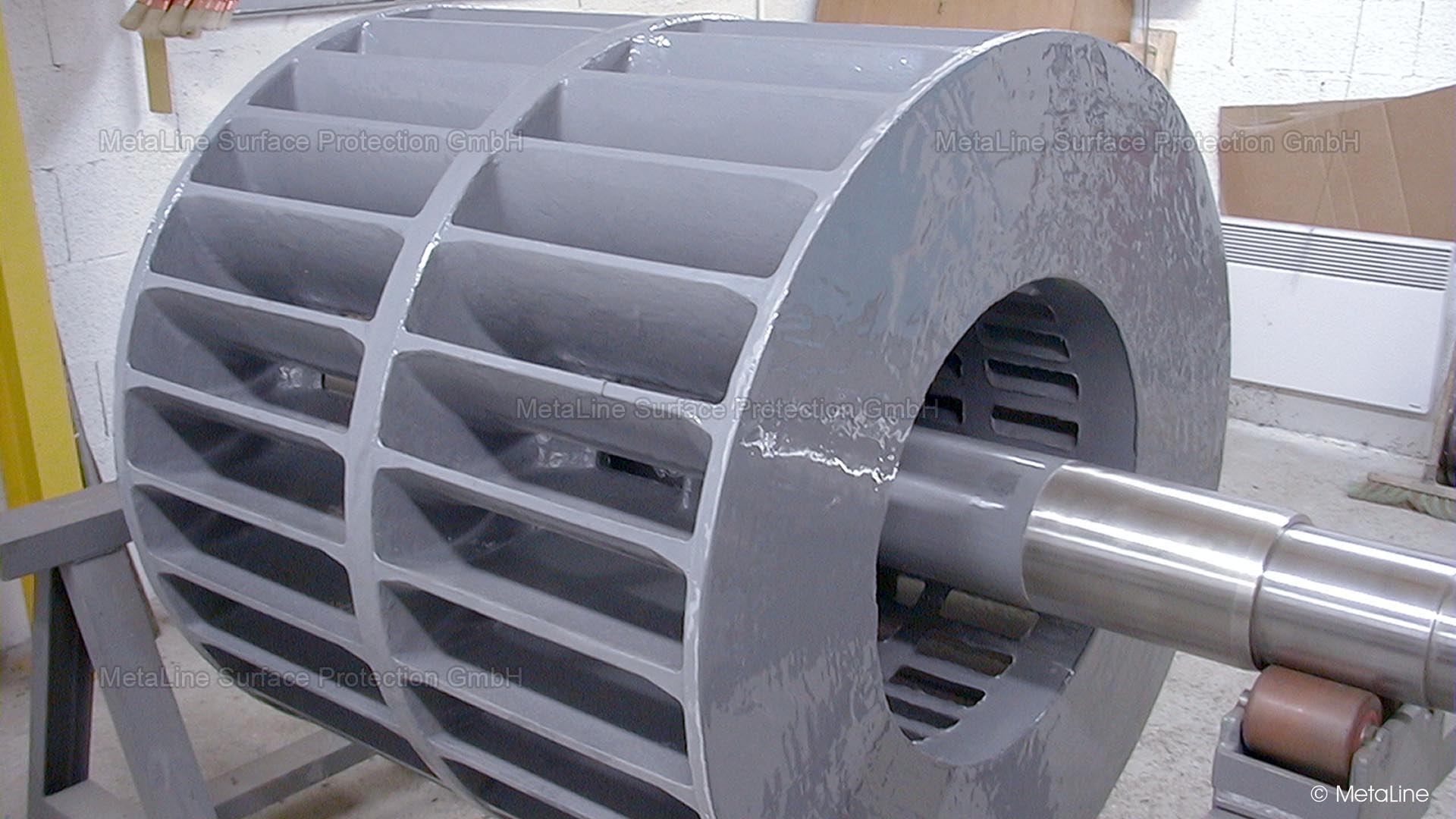

Vacuumpump rotor coating - revised and overcoated with MetaLine repair ceramic KXL. Ready for use - the result is more than impressive

After the relining had been completed. Due to the high costs of the spare-part casings - MetaLine technology is a thrustfull alternative to optimize the maintenance costs

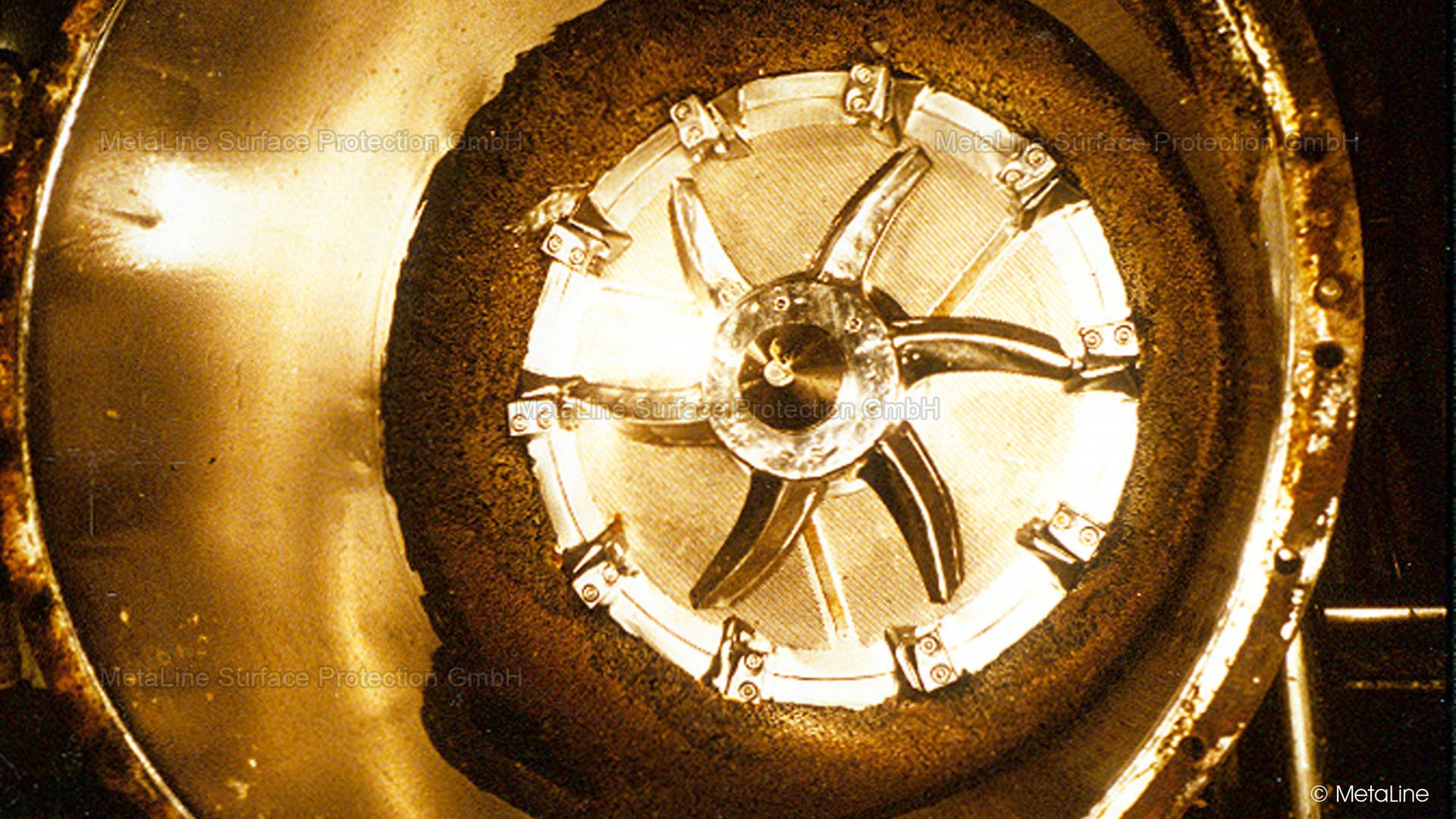

Francis impeller repaired with MetaLine Ceramic Repair Compound KXL – a spray coating was not possible due to the limiited clearance between the blades

During application of MetaLine Ceramic Repair Compound SXL – the cap tells you something about the application temperature – which was quite low

The shaft of this feeding screw had been subjected to corrosion and wear. A treatment with MetaLine KXL encapsulated the surface against moisture & chemicals

Recontoured with MetaLine Ceramic Repair Compound SXL / KXL and protected against further substantial attacks

Turbine protective coating - subsequently, the entire repair area was additionally coated with brushable MetaLine repair ceramic KXL

Preparations for sealing measures with MetaLine Ceramic Repair Compound SXL applicable by trowel

Pulper coating – MetaLine Ceramic Repaircompound CXL had been used to repair and protect this stainless steel pulper

Feeding distributor during protective coating with MetaLine Ceramic Repair Compound CXL

Completely protected decanter – a thick coat of approximately 8 mm MetaLine Ceramic Repair Compound CXL