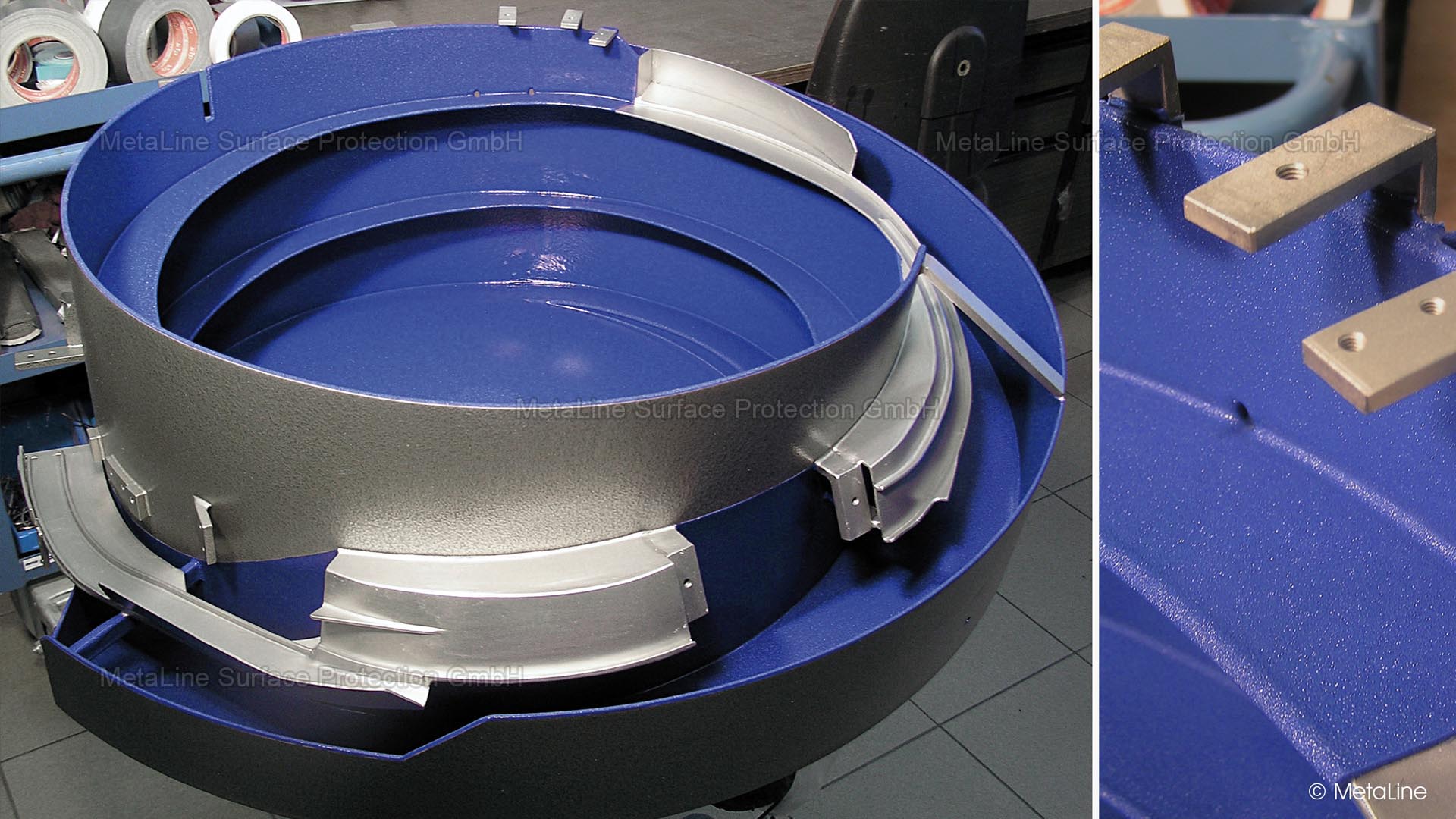

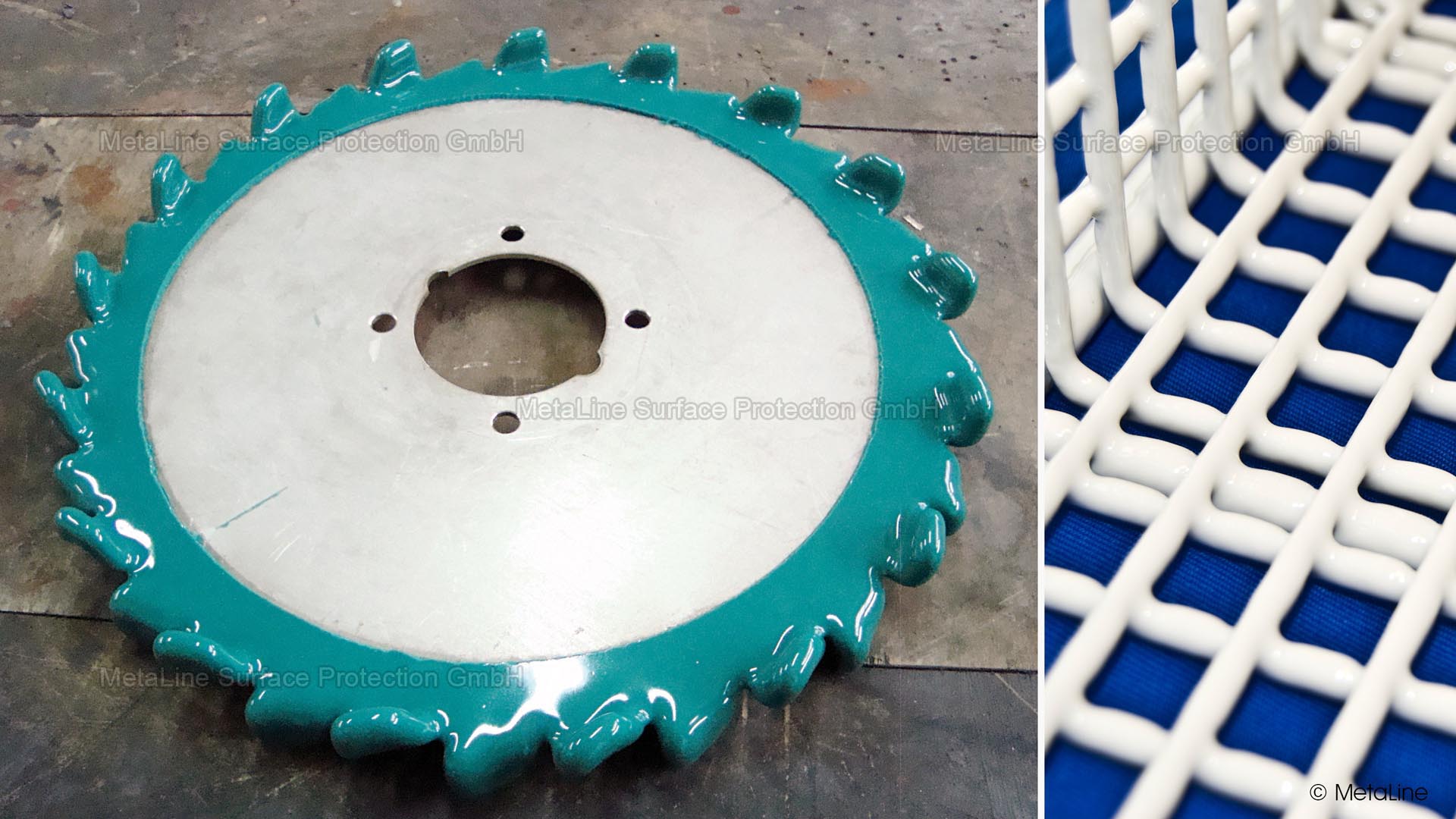

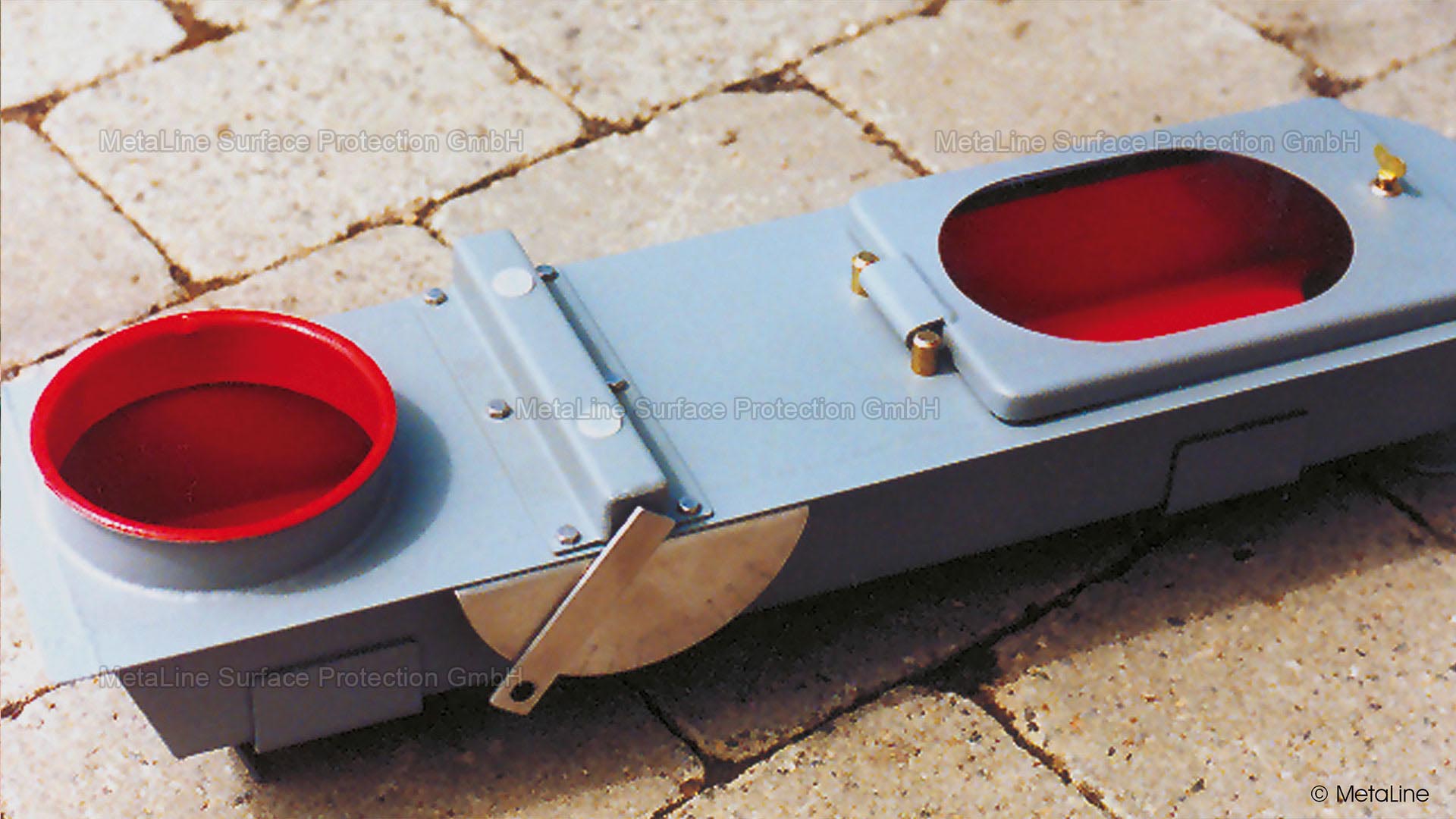

The idea behind the MetaLine Series 500 automation coatings is adapting the most important surface characteristics individually to the parts to be fed!

Only such a professional feeding specialization allows an even, rapid, careful and low-noise parts handling.

The objectives are as follows:

- protecting from scratches

- reducing noise emissions

- increasing feeding rates

- avoiding parts pollution

- preventing electrostatic charge

- fullfilling FDA standards

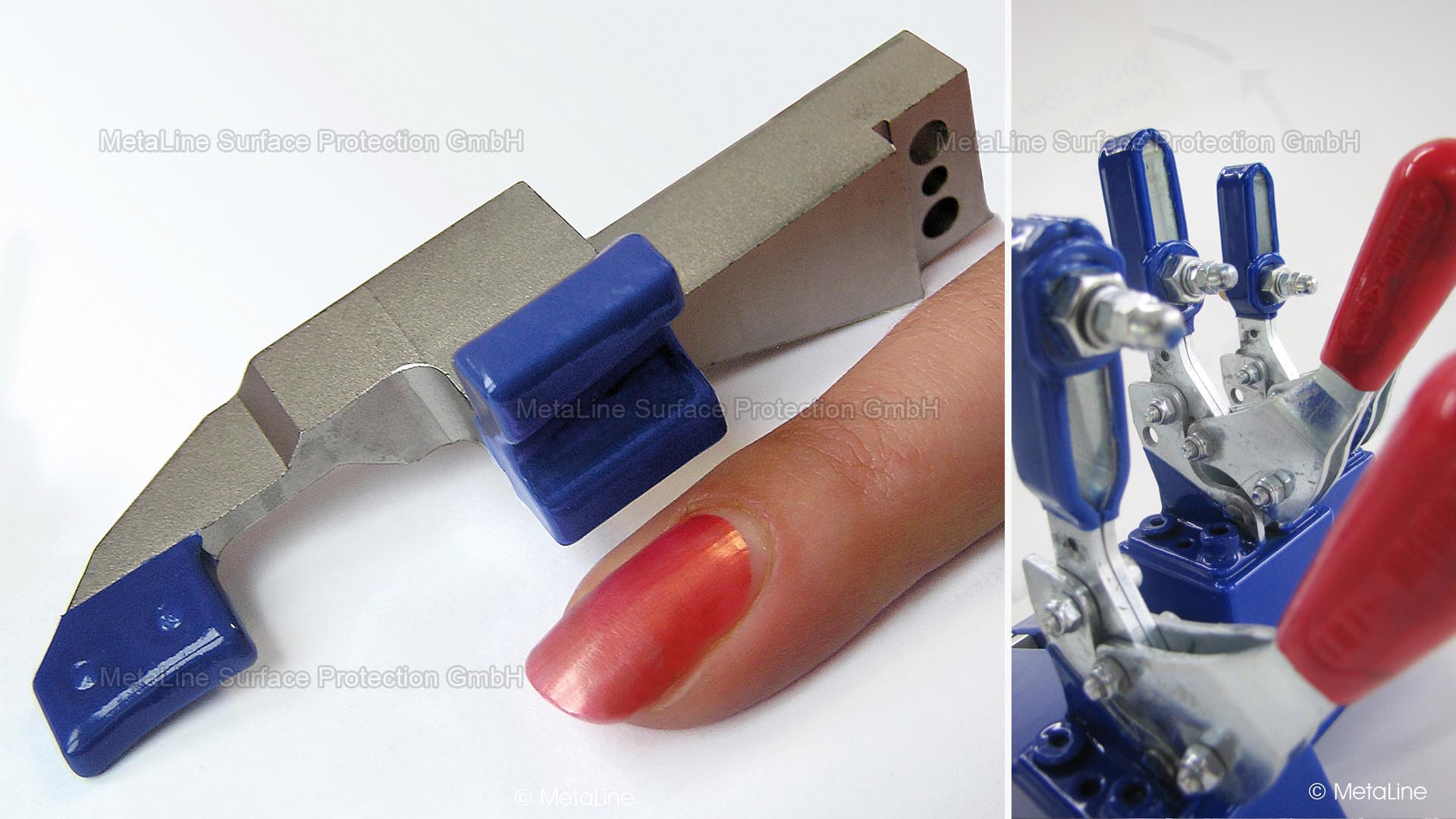

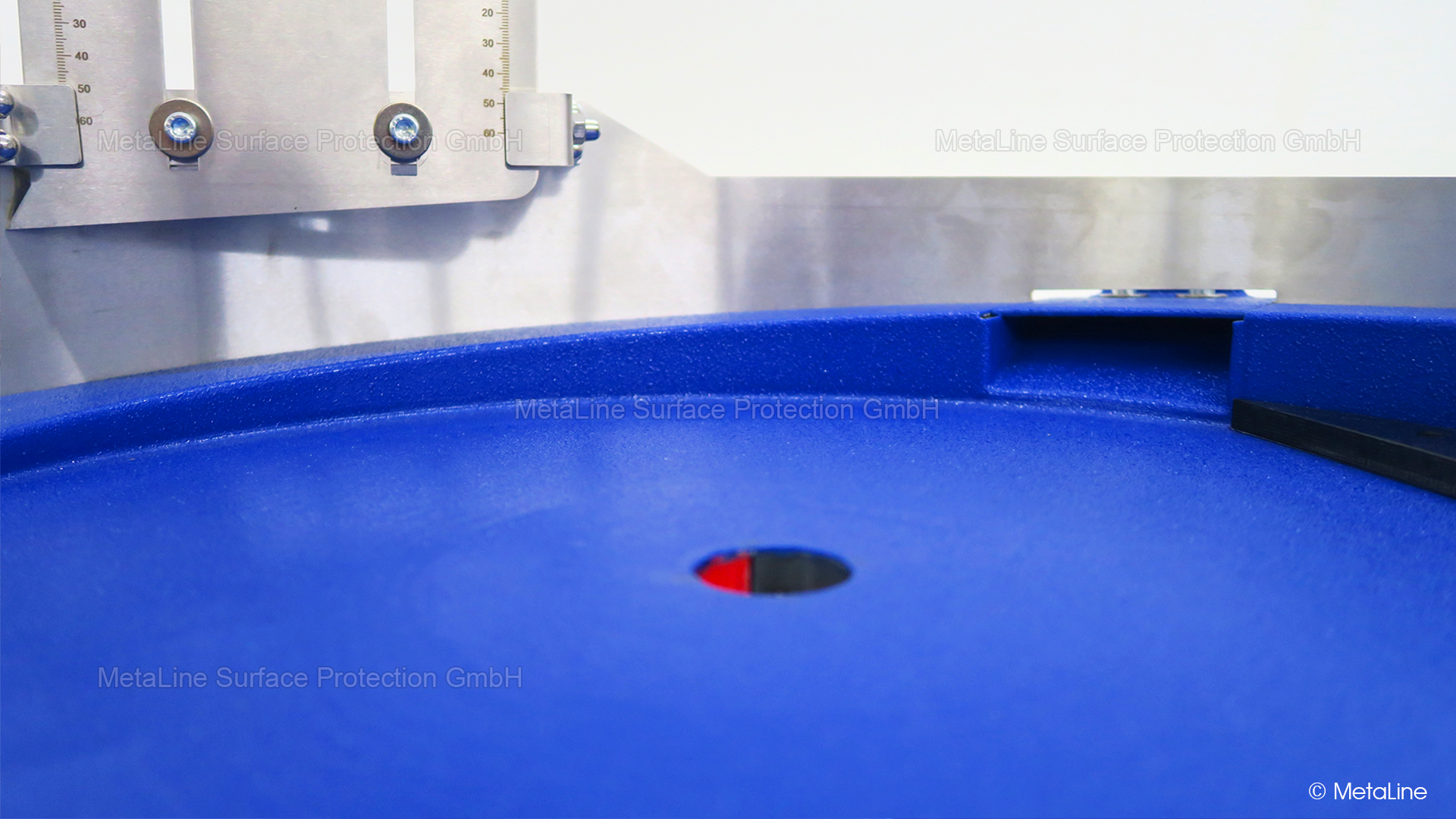

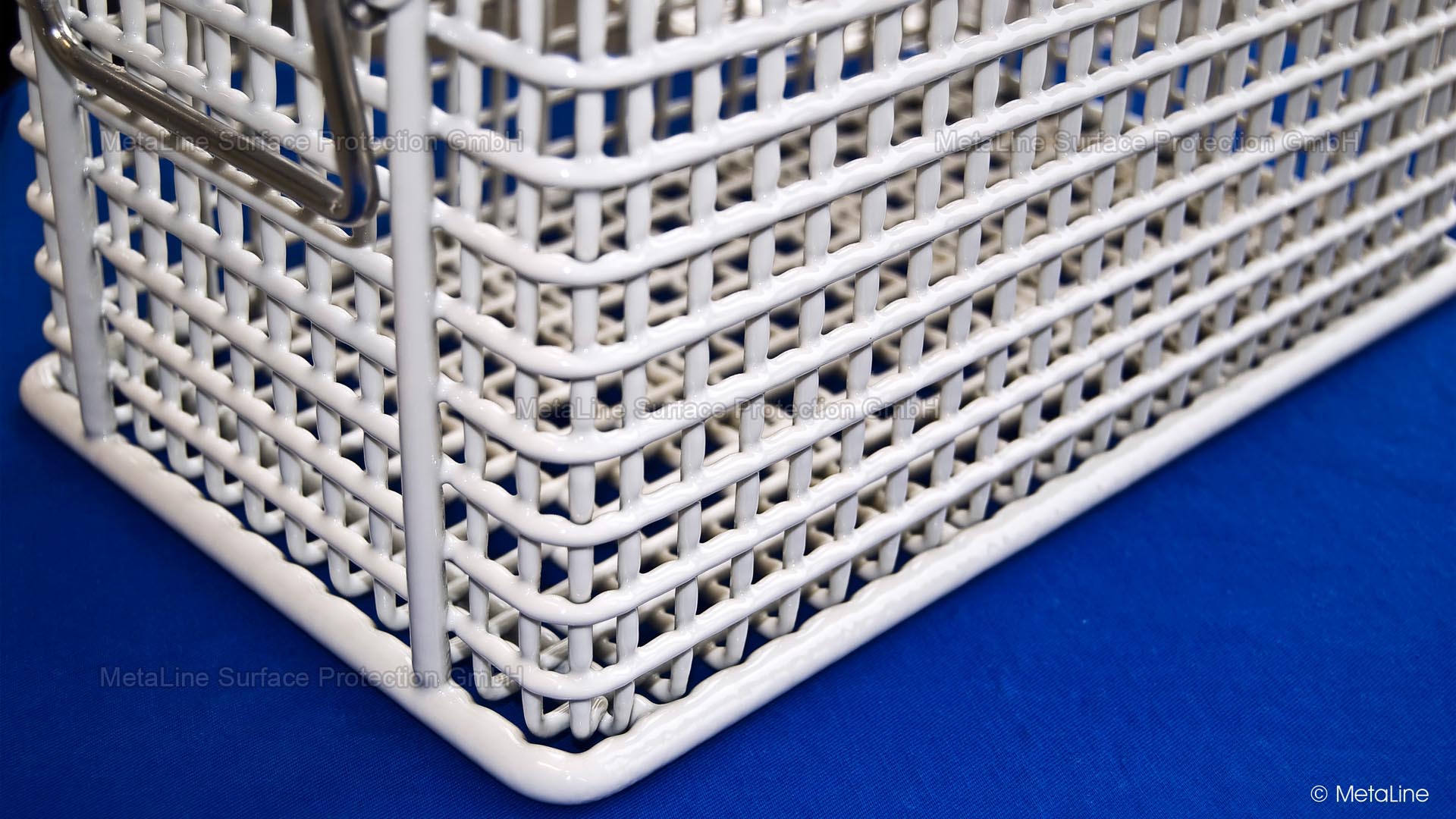

Optimization of automation / conveying - so that everything runs smoothly Process involved The MetaLine Series 500 coating is adapted individually to each component regarding its hardness, static friction, thickness, surface structure and color. Furthermore, the coating sprayed on under high pressure has no seams at all and is thus protected against infiltration of matter (such as oil) and separation. And what about the cost? This aspect, without doubt, will be a pleasant surprise for you, and the same goes for the quality: abrasion-resistant slip-proof / slide-enhancing impact-absorbing ideal for rubber or oily problematic parts precisely contoured / seamless disinfectable / sterilizable In addition to its extraordinary wear resistance, the MetaLine process is most convincing due to its individuality. True pharmaceutics & food characteristics according to FDA standards (CFC 177.1680) and EU 1935/2004 round off the service portfolio. MetaLine has been approved by all leading European Feeding Manufacturers. Lifetime results of up to 280.000 tons output capacity may be cited. MetaLine Series 500 is available throughout Europe. Thanks to its technical versatility, longevity and an optimum cost-benefit ratio, it is ideally suited structurally for new systems and for optimizing already existing feeding systems. Standard coatings can be achieved within 3-4 working days. For a surcharge, 24-hour-express manufacture is also possible depending on availability. Technical solutions in detail MetaLine Series 500 - individually optimize transport processes. Four different materials varying in hardness and static friction are available to achieve this: Soft - high static friction for oily materials - MetaLine 560 Semi-soft - medium static friction for metal materials - MetaLine 580 Semi-hard - medium static friction for plastic materials - MetaLine 590 Hard - low static friction for rubber materials - MetaLine 598

With every mix the MetaLine Series 500 coatings are individually adapted regarding their hardness, stiction, thickness, surface texture, color & electrical conductivity. The high-pressure sprayed-on coating has no seams and is thus protected against infiltration, such as from oil. Typical delamination as with glued on PU-sheets is not likely. Quality made in Germany featuring unique properties as: abrasion-resistant slip-proof / slide-enhancing impact-absorbing suited for problematic rubber or oily parts precisely contoured / seamless disinfectable / sterilizable long-lasting / economical In addition to its extraordinary wear resistance, the MetaLine process is most convincing due to its purity! Pharmaceutical & food conformity according to FDA standards (CFC 177.1680) and EU 1935/2004 is available. MetaLine has been approved by all leading European feederbowl manufacturers. Lifetime results of up to 280.000 tons output capacity may be cited. MetaLine Series 500 is globally available. Thanks to its technical versatility, longevity and cost-benefit ratio, it is either suited for new equipment or already existing feeding systems. Standard coatings can be achieved within 3-4 working days. For a surcharge, 24-hour-express service is possible depending on availability. MetaLine Series 500 – individually optimizing transport processes. 4 different coating types, varying in hardness and static friction, are available: Soft - high static friction for oily materials - MetaLine 560 Semi-soft - medium static friction for metal materials - MetaLine 580 Semi-hard - medium static friction for plastic materials - MetaLine 590 Hard - low static friction for rubber materials - MetaLine 598