Anti-scratch coating - no one in Europe deals so intensively with wear-resistant coatings that are nevertheless soft and gentle on the counter surface. It depends on different parameters - not only how soft the material is. Ask us, we will gladly explain it to you!

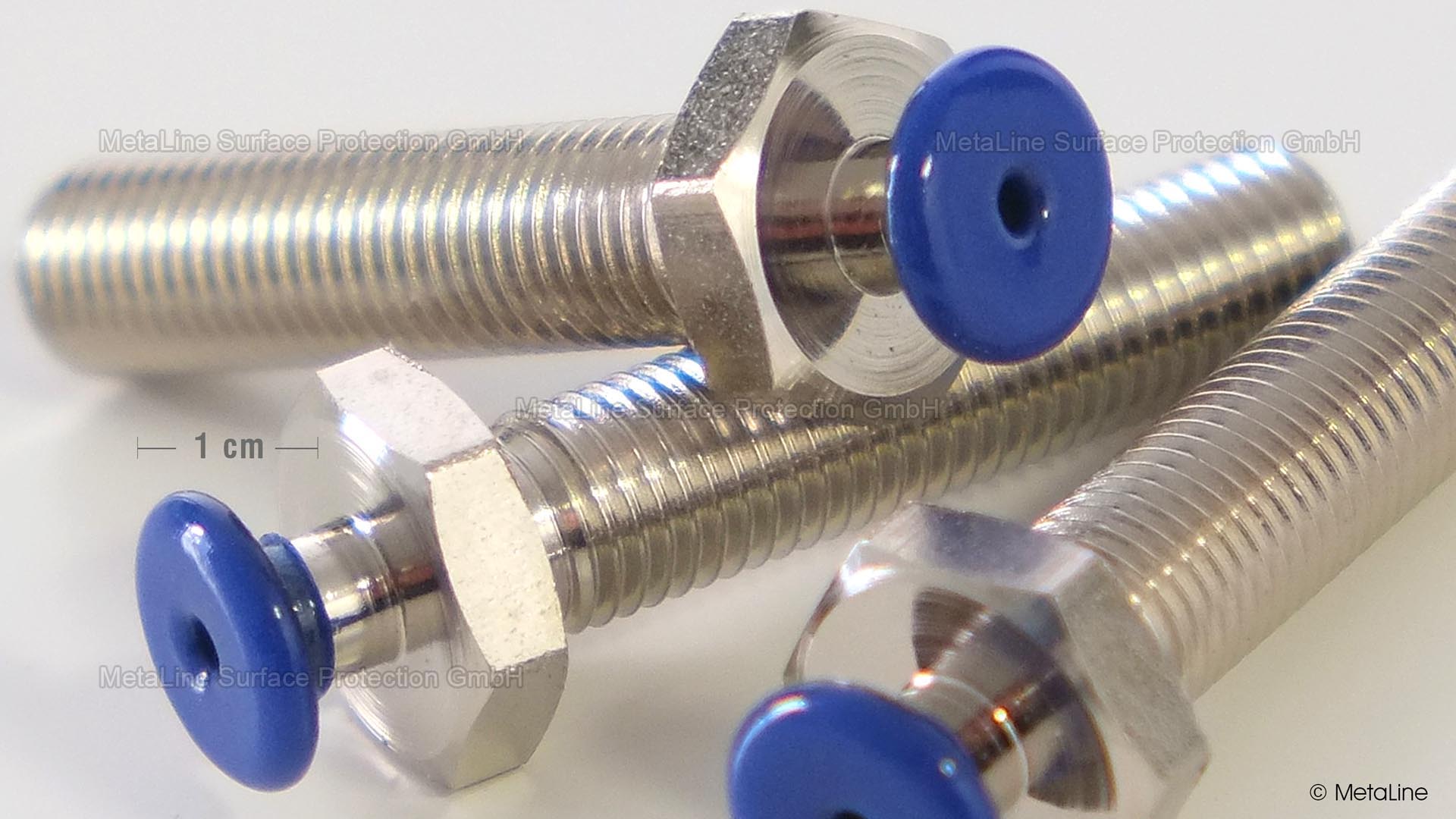

Marker protection coating - the surface is smaller than a fingernail! And yet at MetaLine have been equipped with elastomeric coating. You have only 1 piece of it? Individual and prototypes are our strength!

Anti-scratch coating - Small parts gripper with a precise protective coating made of MetaLine 590 for parts protection. Variable static friction values can also grip problem parts securely

rollercoating - MetaLine 785 applied in a precise, 3 mm thick coat to this diaboloroller

Removable coating - what an idea! The coating can be slid on as a "shoe" at any time, can be peeled off or replaced in case of damage! That is MetaLine - always one idea ahead!

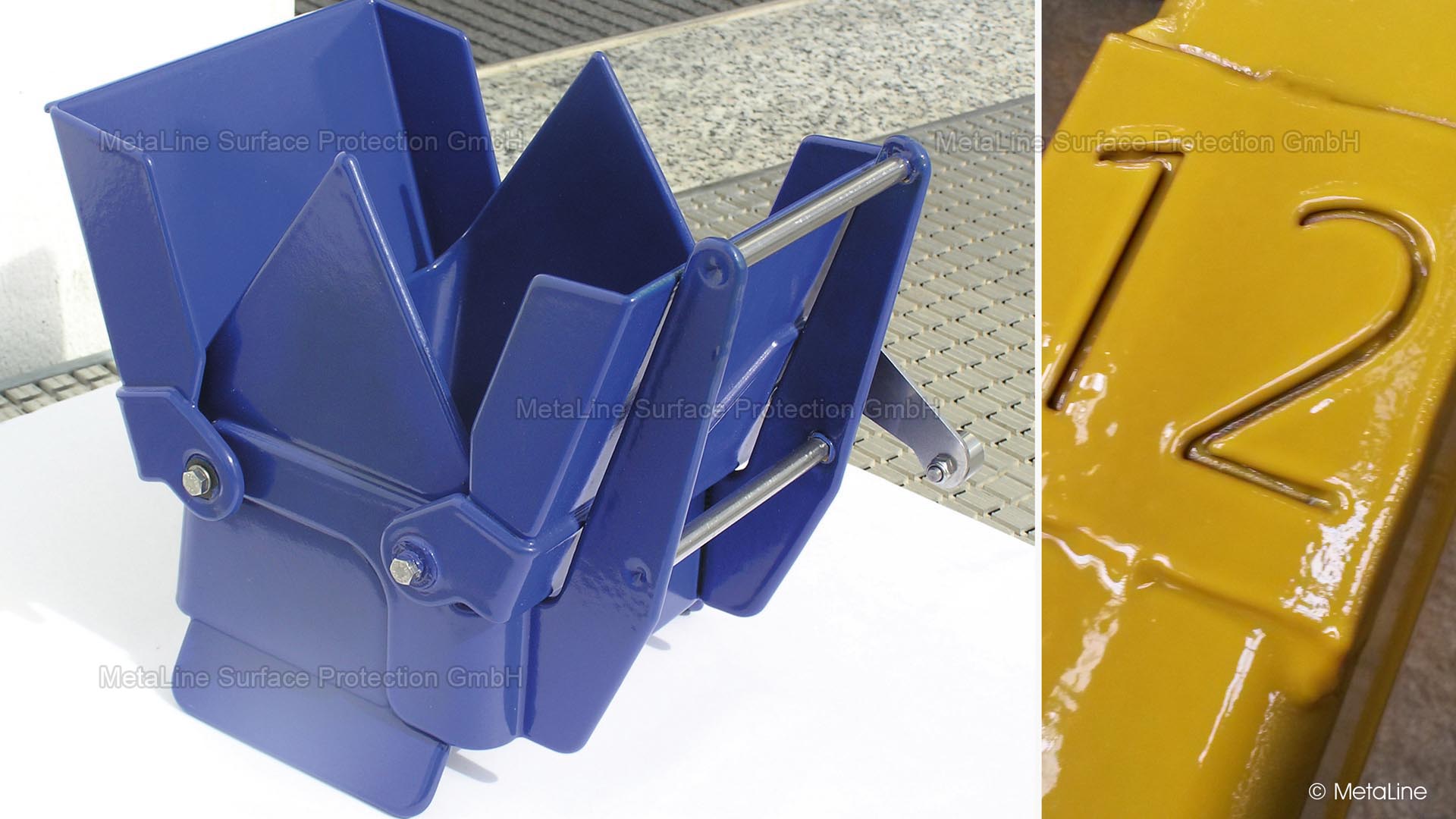

Pharmaceutical coating - feeders for pharmaceutical technology electropolished and coated with 1 mm MetaLine 590 elastomer to minimize tablet breakage

Weighing pan coating - weighing unit of an Ishida multihead weigher coated with 1.5 mm MetaLine 590. Breakage protection and noise reduction in perfection

Load hook coating - scratch protection coating with 3 mm MetaLine 785 on these heavy load hooks. The coating thickness is freely selectable and depends on weight and load

Truck bed coating in perfection - no rhinoceros skin but a variable MetaLine multifunctional coating. Ask us...

Non scratch coating - an individually sprayed elastomeric covering out of 2 mm MetaLine 785 protects the front part during the assembly procedures in the engine room

Tool coating - small tools coated with 1 mm MetaLine 590 for use in car manufacturing. Different colors stand for different models

Testing device protection - car test plug (Mercedes) coated with 1 mm MetaLine 590 for paint protection. When plugging or unplugging in the engine compartment, nothing more can therefore happen

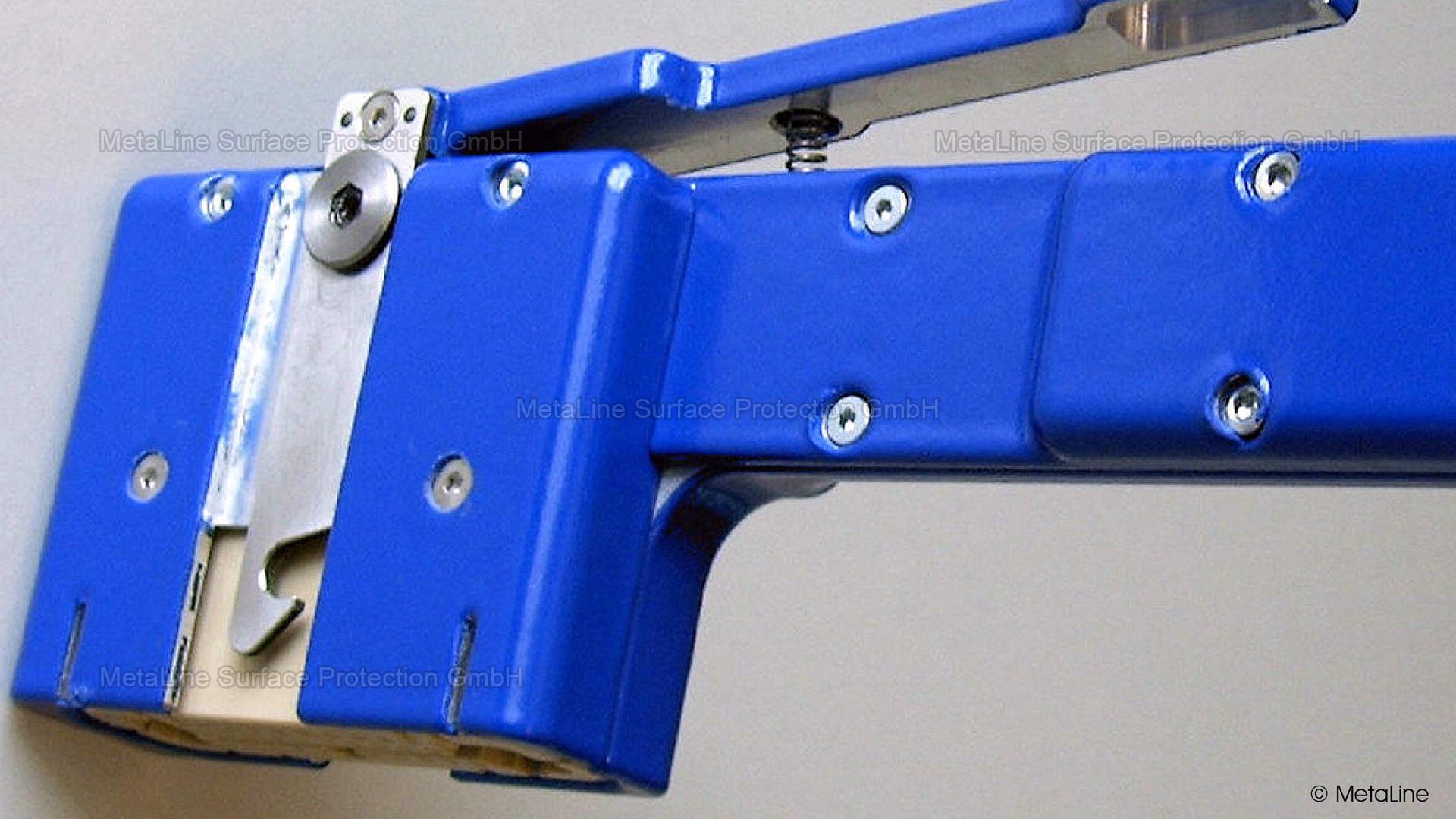

Clamping jaw coating - coated blank holders in body-in-white production prevent marks and scratches during welding work. Rework before cathodic dip painting treatment can be omitted

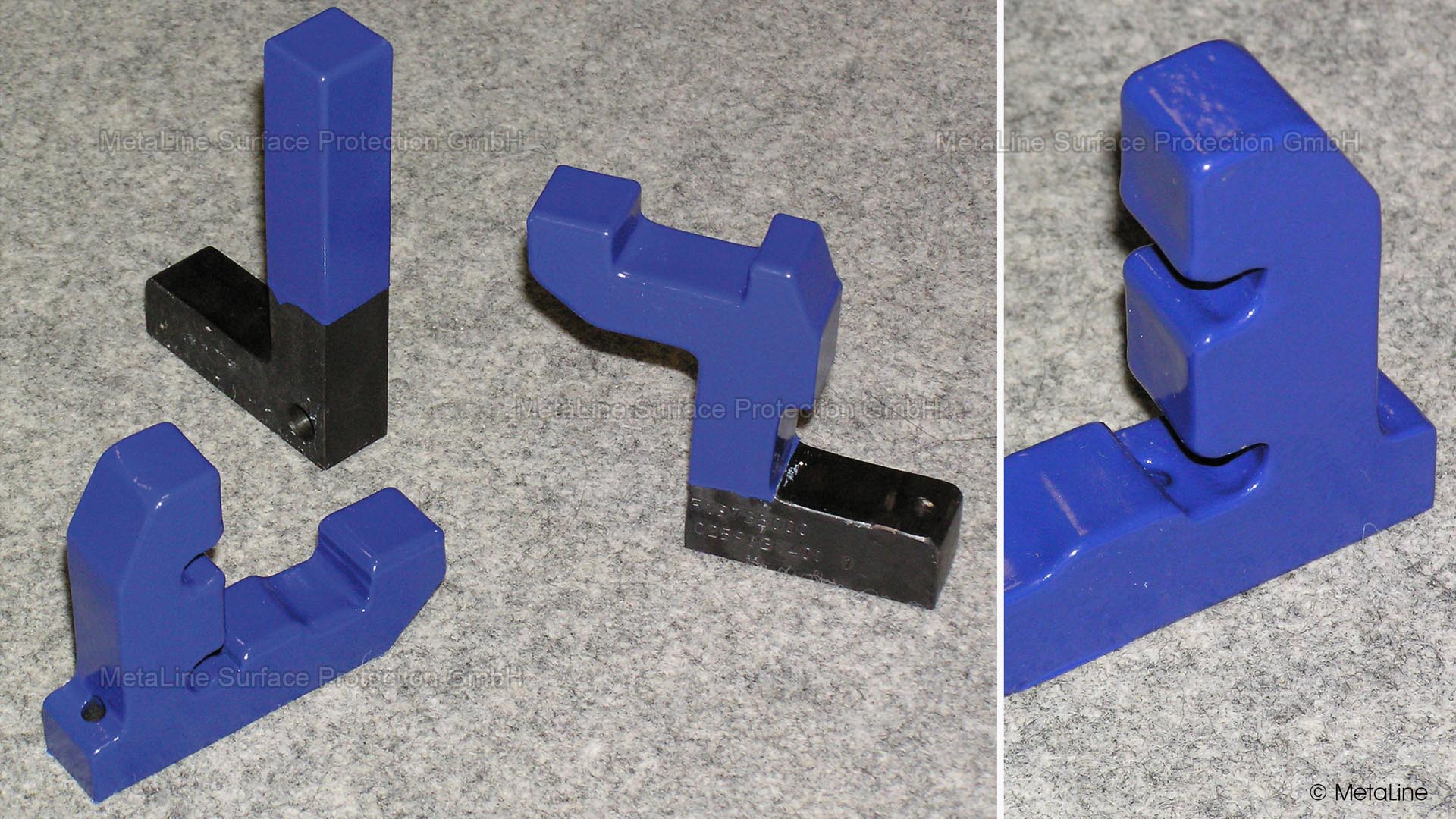

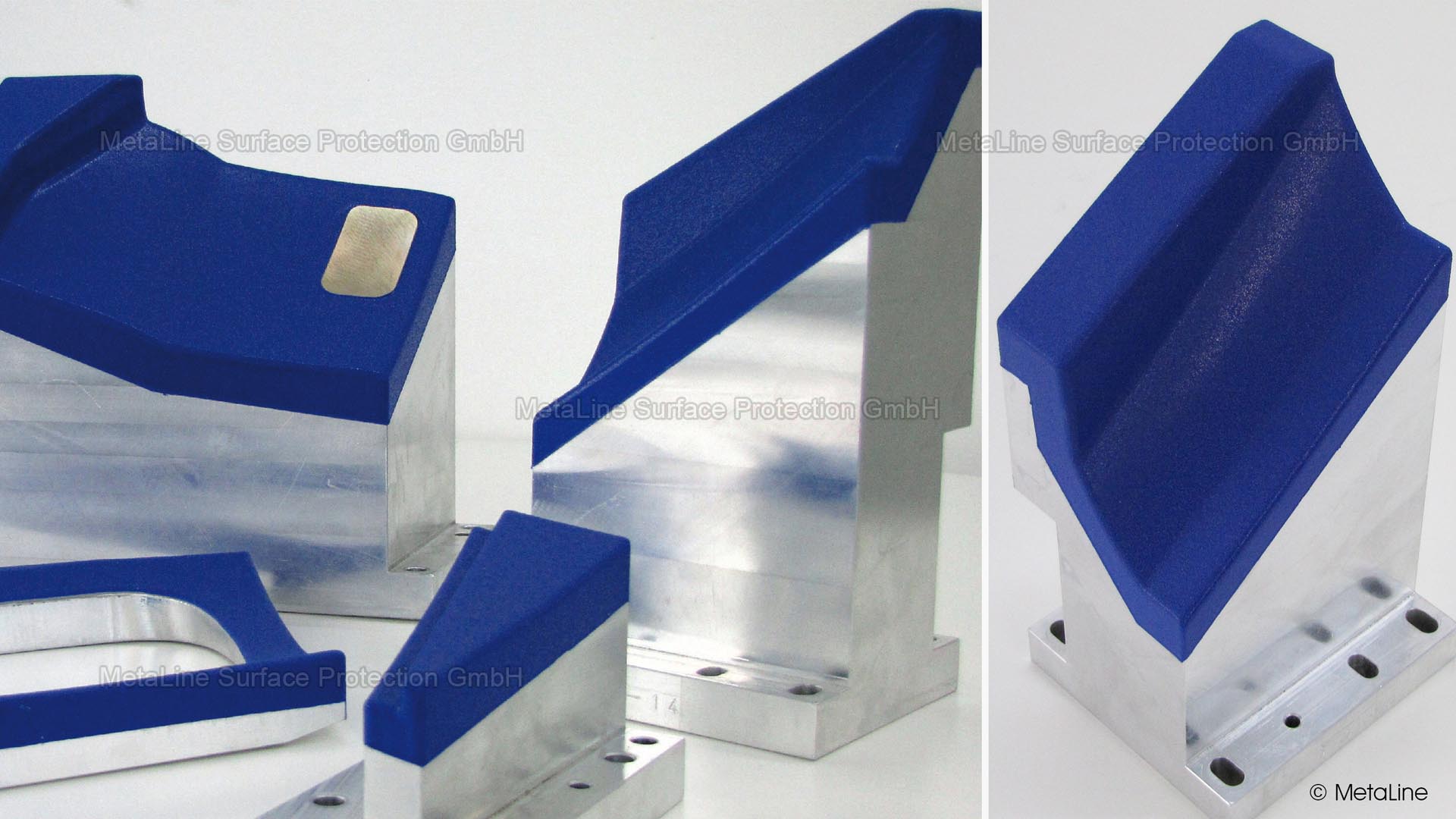

Forging dies coating - tool dies coated with MetaLine 560 structure. The finely textured coating reduces the actual bearing surface and prevents direct contact between any contamination and the workpiece

Overlay coating - even wooden sinks can be coated with textured MetaLine 590. It's not what's underneath that counts, but what's on top ...

Welding tool coating - ultrasonic welding tool for a car cockpit protective coated with 1.0 mm MetaLine 580. Accuracy +/- 0.2 mm. MetaLine coatings are recommended by the leading ultrasonic and friction welding equipment manufacturers

Workpiece support coating - Workpiece supports for the mounting of orbital sanders coated on all sides with 1.0 mm MetaLine 590 velvet. Even very sensitive types of plastic can be fixed without damage with MetaLine

Load suspension device coated with MetaLine Series 700 for damage protection of stored brake lines

Impact protection coating - mechanical feeding by means of sizing - protected by a 1.5 mm thick protective coating with MetaLine 795

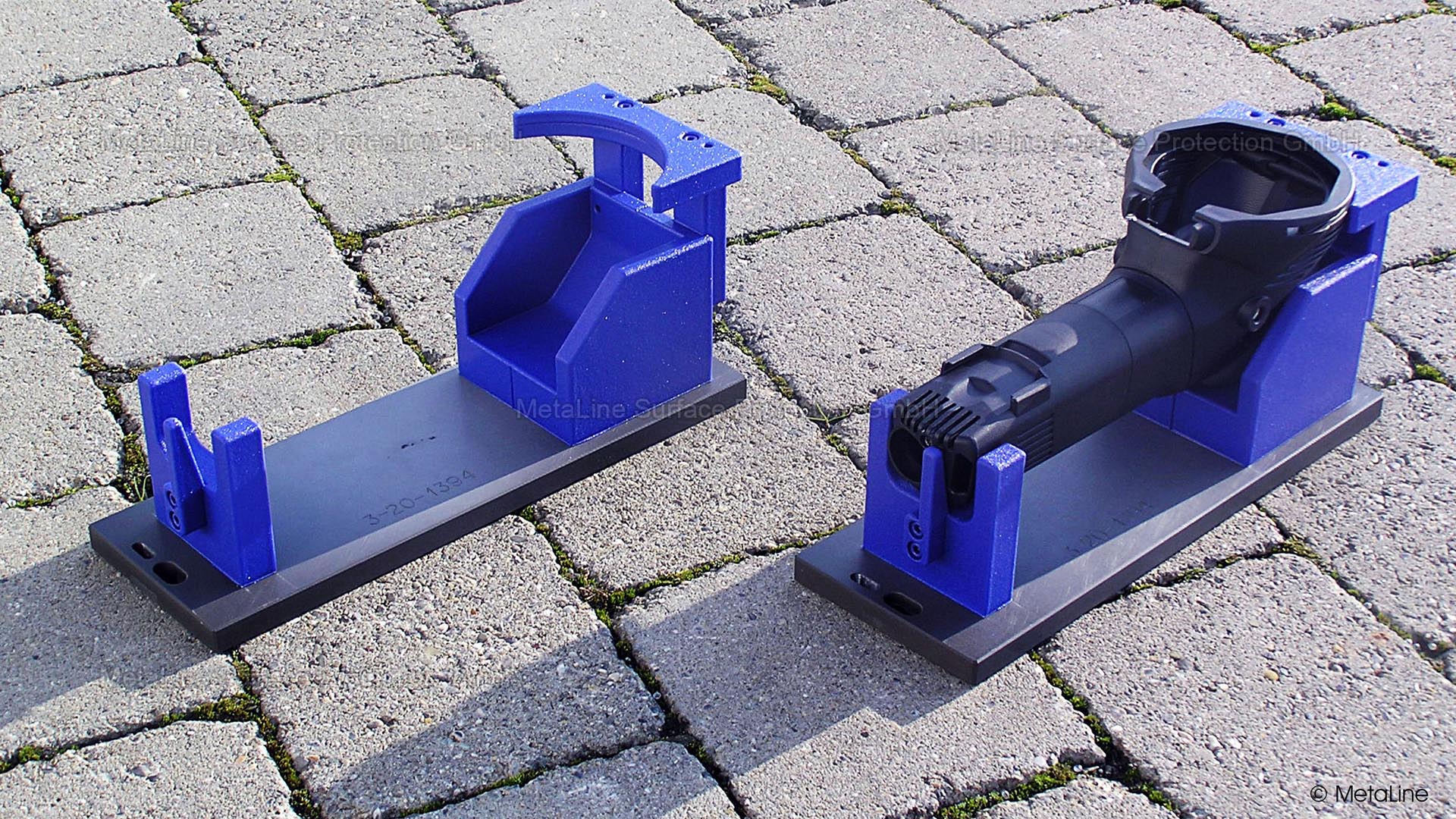

Fixture coating - Fixture with protective coating MetaLine 785 for gentle storage of special tools. The application was made by casting by means of a simple blank

Impact protection coating - injury and impact protection for people and production goods. A soft coating with MetaLine 760 makes it possible