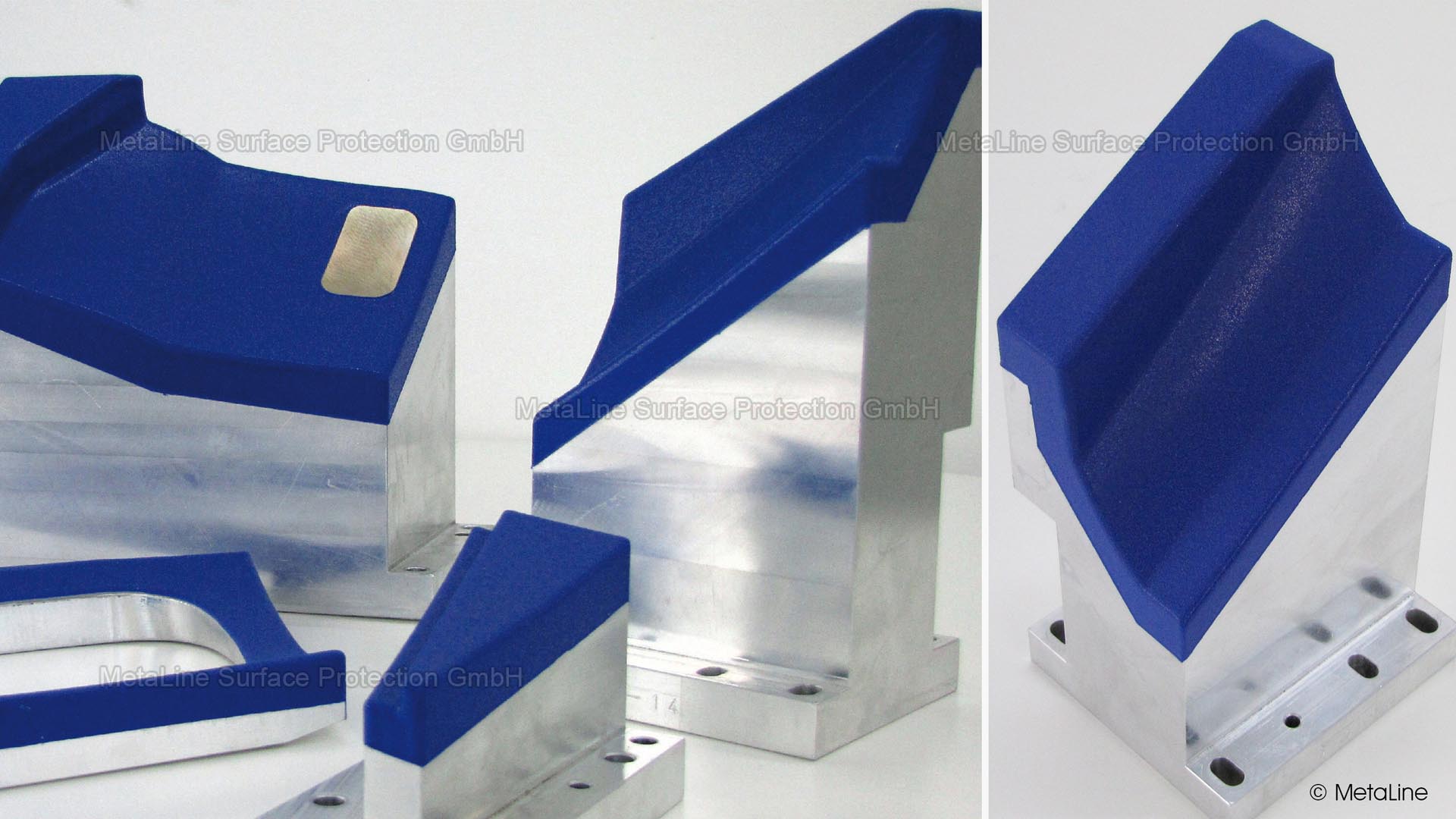

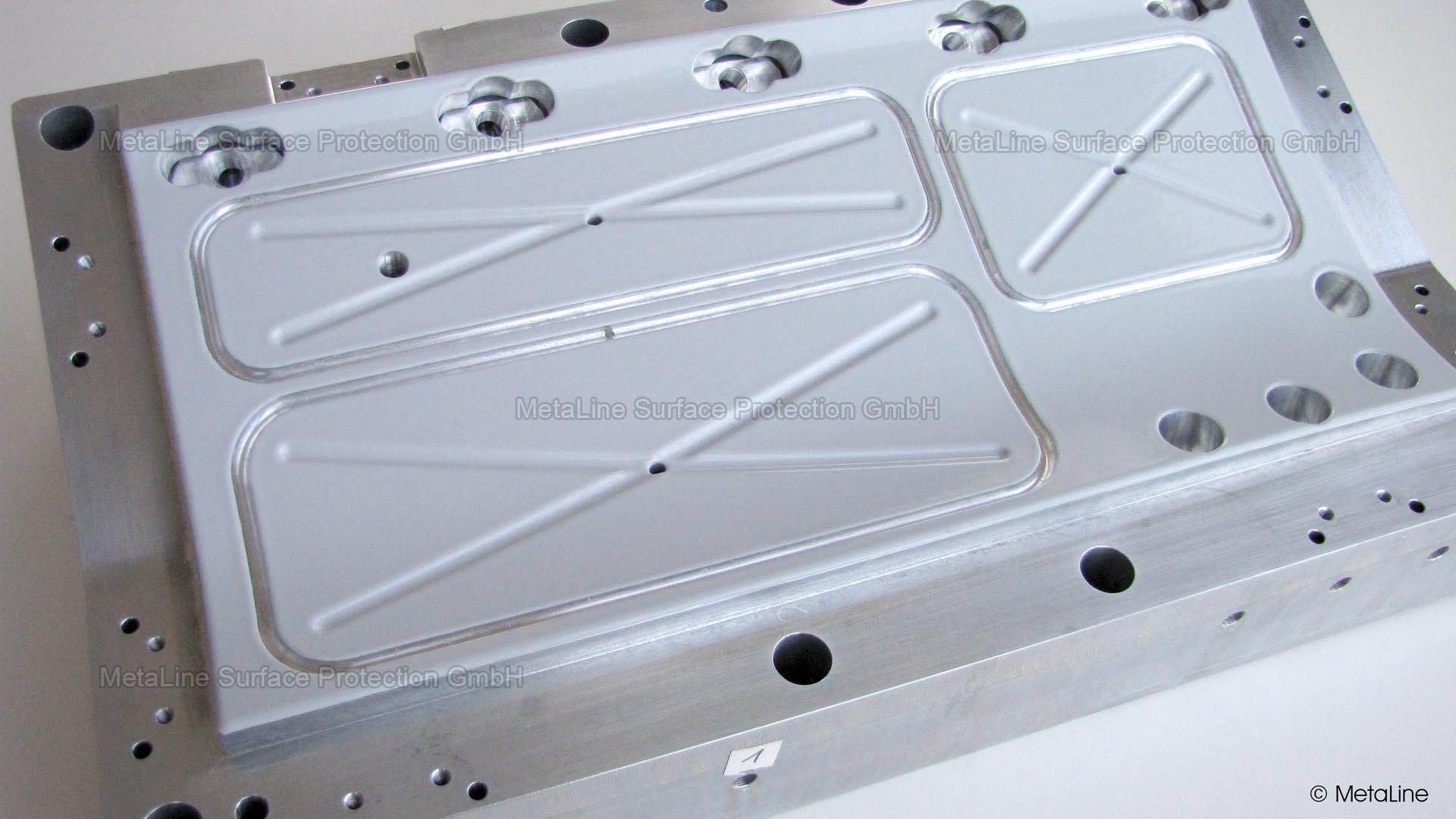

Workpiece carrier coating - tool dies coated with MetaLine 580. The finely structured coating reduces the actual contact surface and prevents direct contact between any dirt and the workpiece - there is no better scratch protection!

Contour stone coating - MetaLine Series 500 elastomer coatings adapt perfectly to the geometry and give any hard surface a soft, gentle yet wear-resistant surface characteristic

Scratch protection coating - MetaLine 580 protects these chrome-plated vehicle parts of the radiator grille from scratches and damage during pre-assembly. Precisely fitting, anti-static, silicon-free!

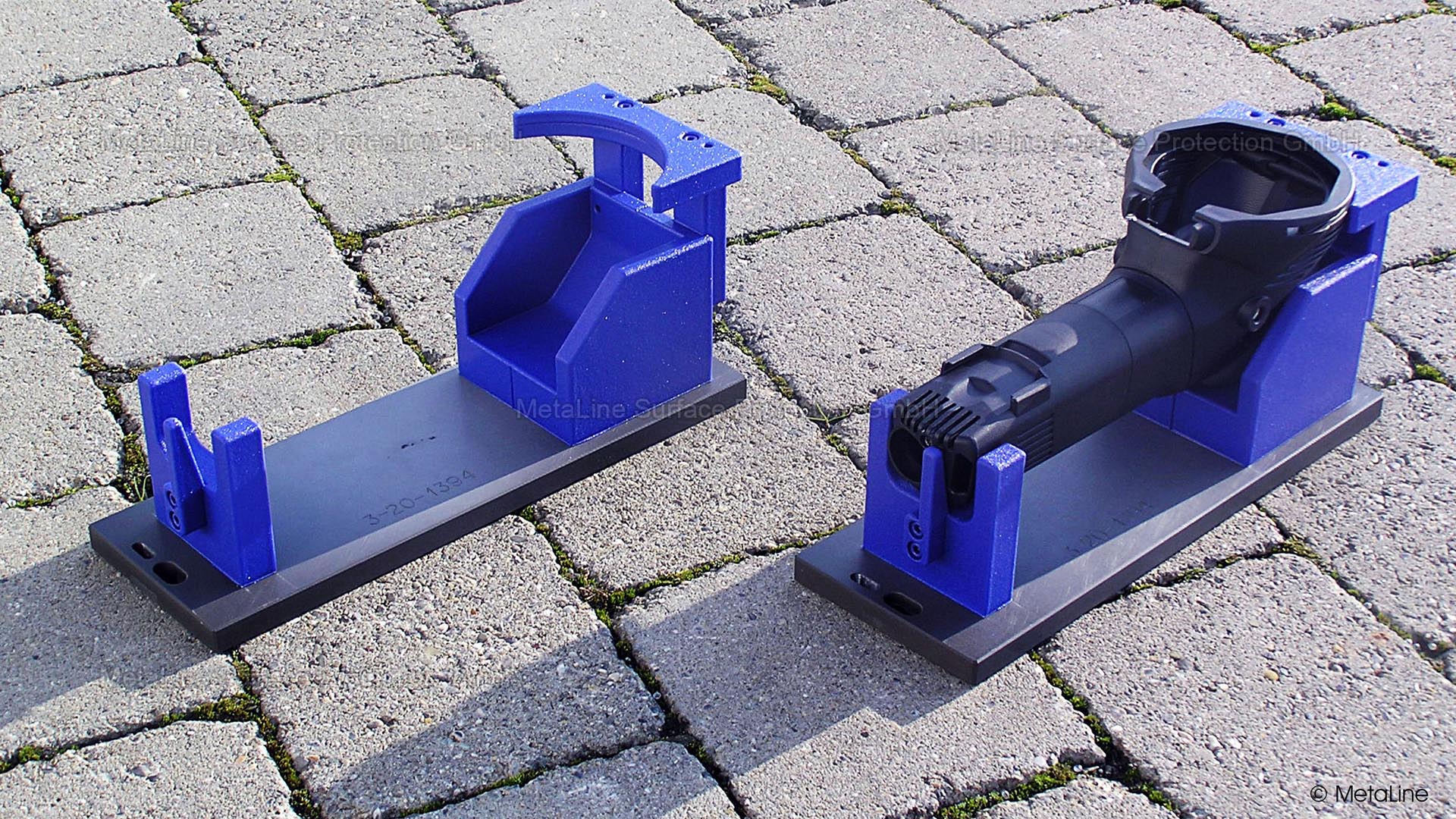

Assembly support coating – Manufacturing tools as perfectly coated as the luxury cars produced on. MetaLine – a more convincing argument for scratch protection in the automotive industry is hard to find

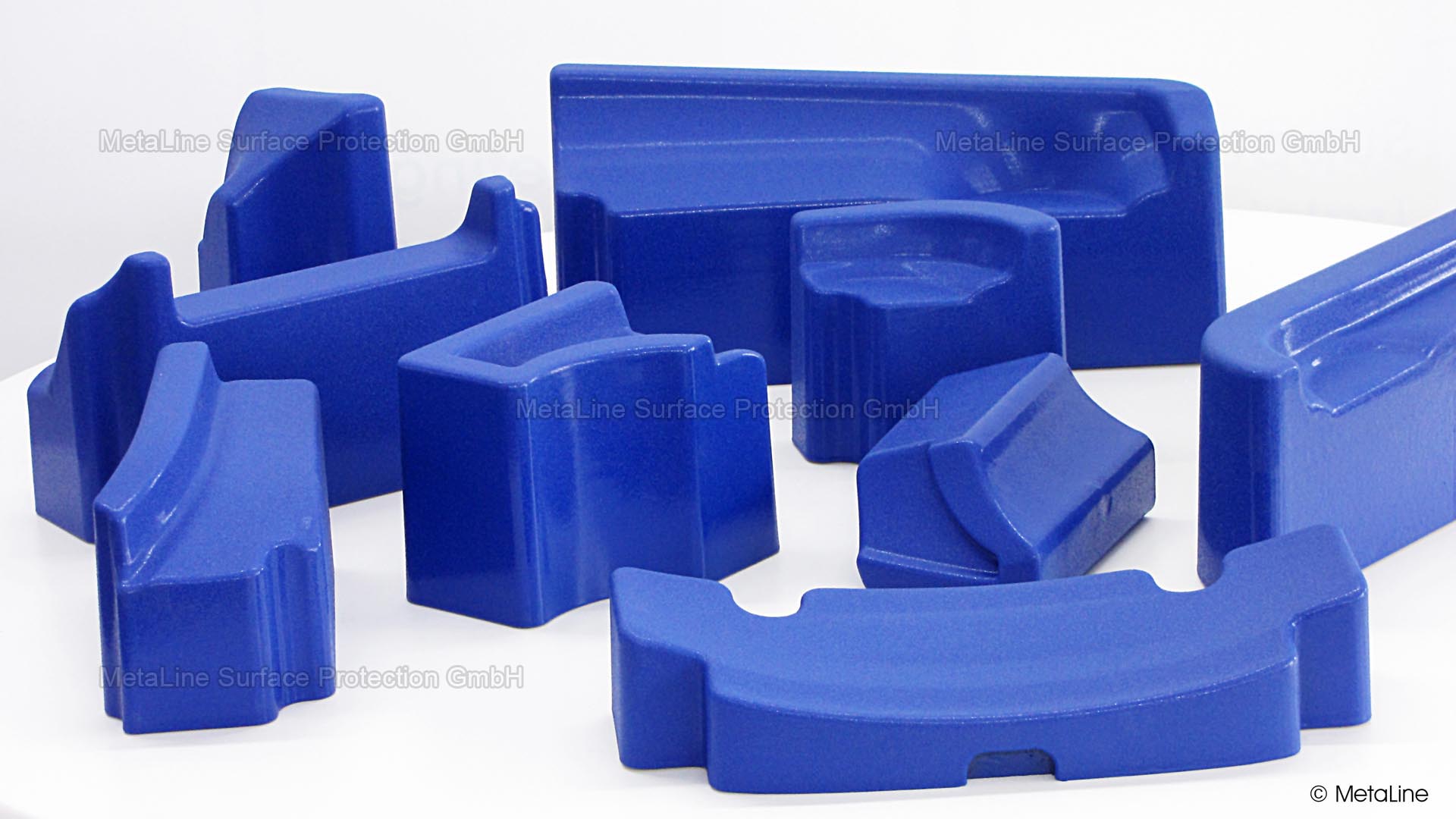

Scratch protection mounting pads - MetaLine is synonymous with scratch protection during assembly. Approved by all European vehicle manufacturers! Questions? Simply dial +49703431000

Jig coating - why does it work so well? It's not just the softness, it's also the surface structure, the conductive behavior, the surface tension and . . . we won't reveal all the tricks on the Internet!

Product carrier coating - workpiece carrier for polished ball joints of car axles elastomer coated with 1.0 mm (40 mils) MetaLine 590. The equipped carriers are used in an ultrasonic washing system, whereby the ball joints must not scratch in the mold. Task accomplished . . . and the product carriers are also protected against corrosion

Mounting supports coating - Workpiece holders for mounting random orbit sanders coated on all sides with 1.0 mm (40 mils) MetaLine 590 velvet. Even sensitive types of plastic can be fixed with MetaLine without damage

Forklift fork coating - this is also a type of “workpiece pick-up”! At MetaLine, it's always about gripping, lifting, transporting, storing or assembling something gently. That's what we are specialized in!

Jig coating - even wooden dies can be coated with textured MetaLine 590. It's not what's underneath that counts, but how good what's on top is ...

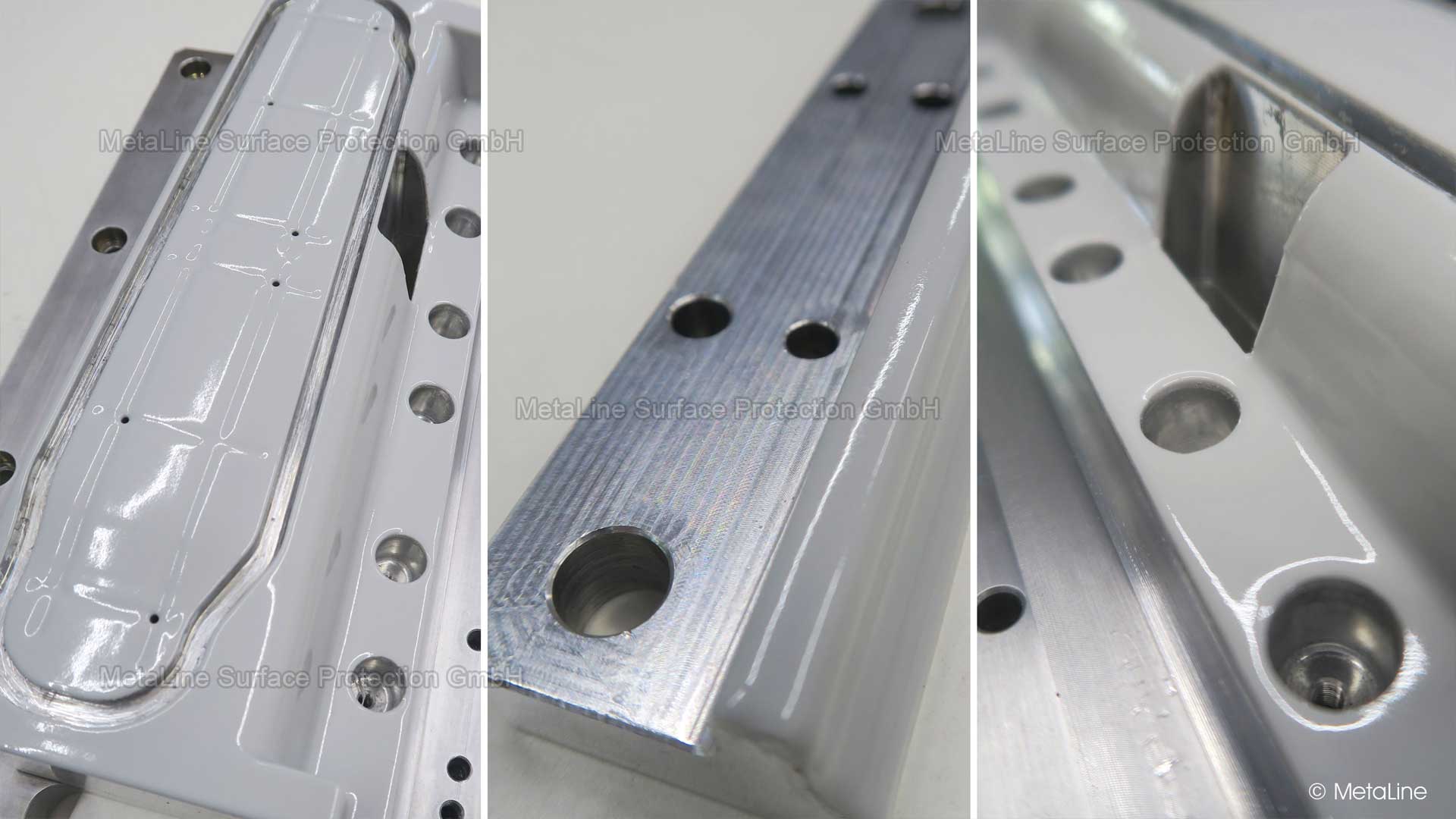

Friction welding tool coating - MetaLine Series 500 with a layer thickness of 1 mm (40 mils) prevents marks and scratches on the plastic parts to be welded. Contour-accurate, seamless & soft!

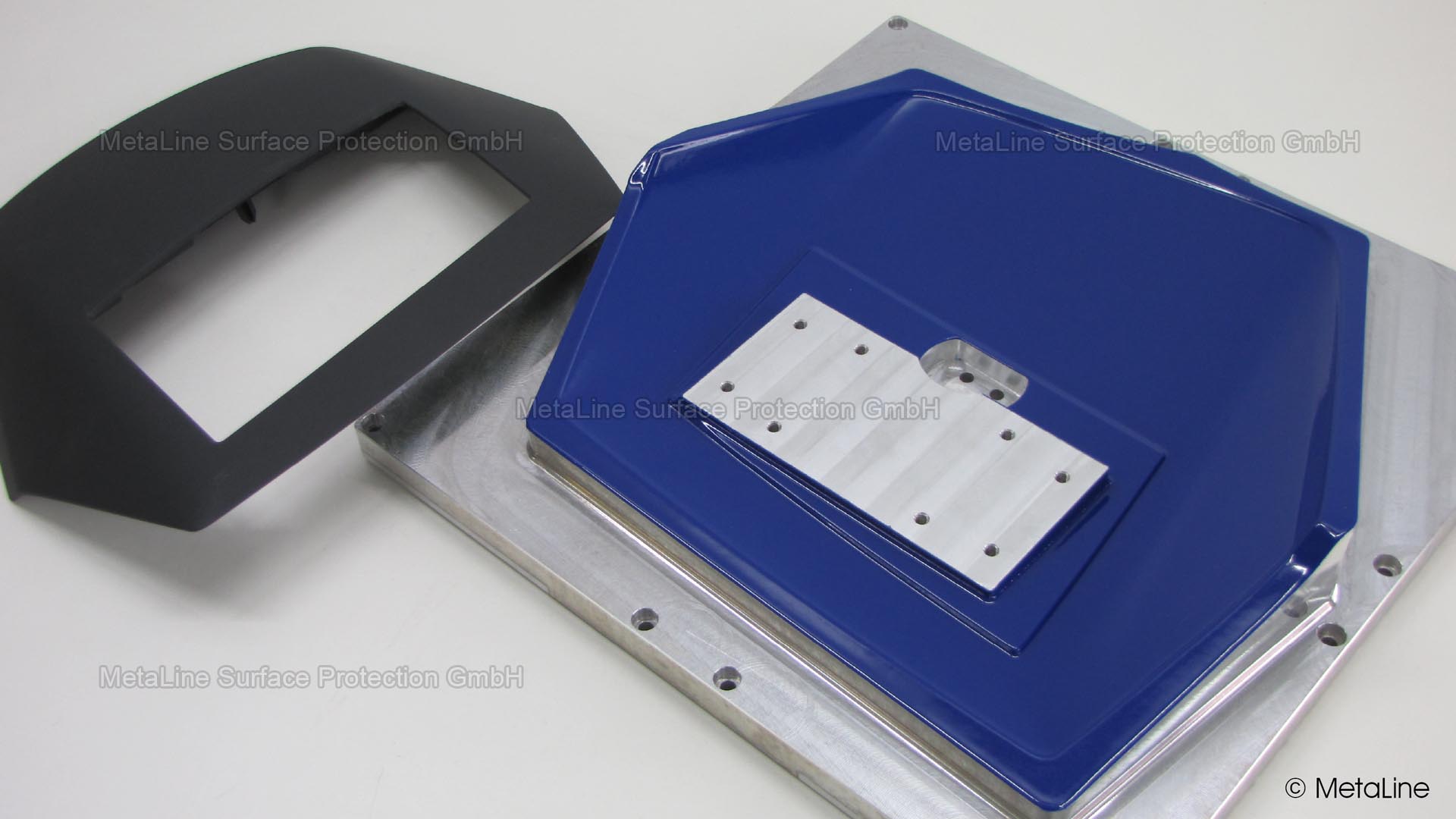

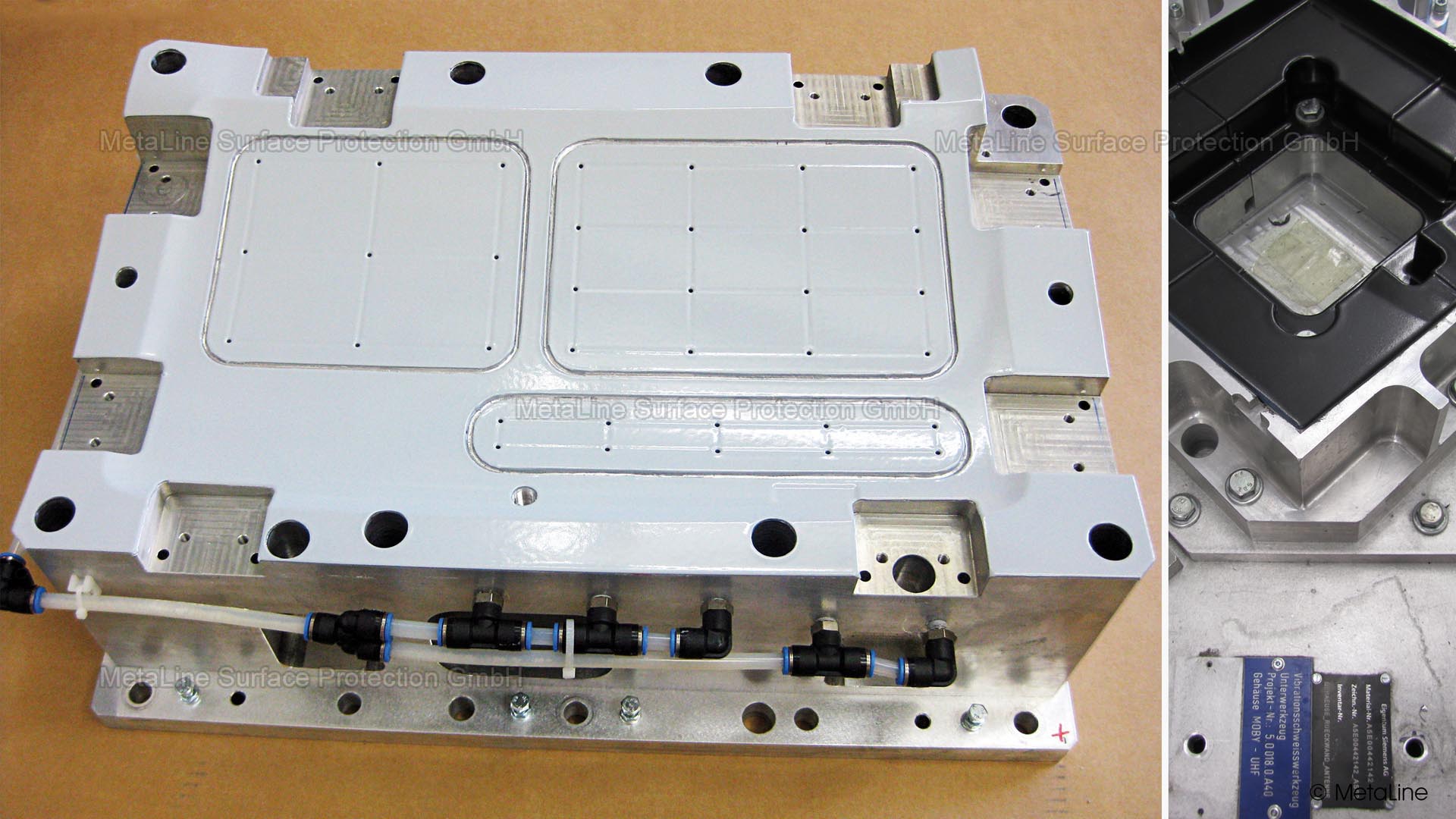

Ultrasonic welding - a tool coating with MetaLine Series 500 enables secure fixing of the parts to be welded without leaving marks or damage

Welding tool coating - Ultrasonic welding tool for a car cockpit protective coated with 1.0 mm (40 mils) MetaLine 580. Accuracy +/- 0.2 mm (8 mils). MetaLine coatings are recommended by the leading ultrasonic and friction welding system manufacturers

Ultrasonic welding jig – MetaLine protects by use of a precise, homogenously seamless sprayed rubberlike coating against marking to the parts to be welded

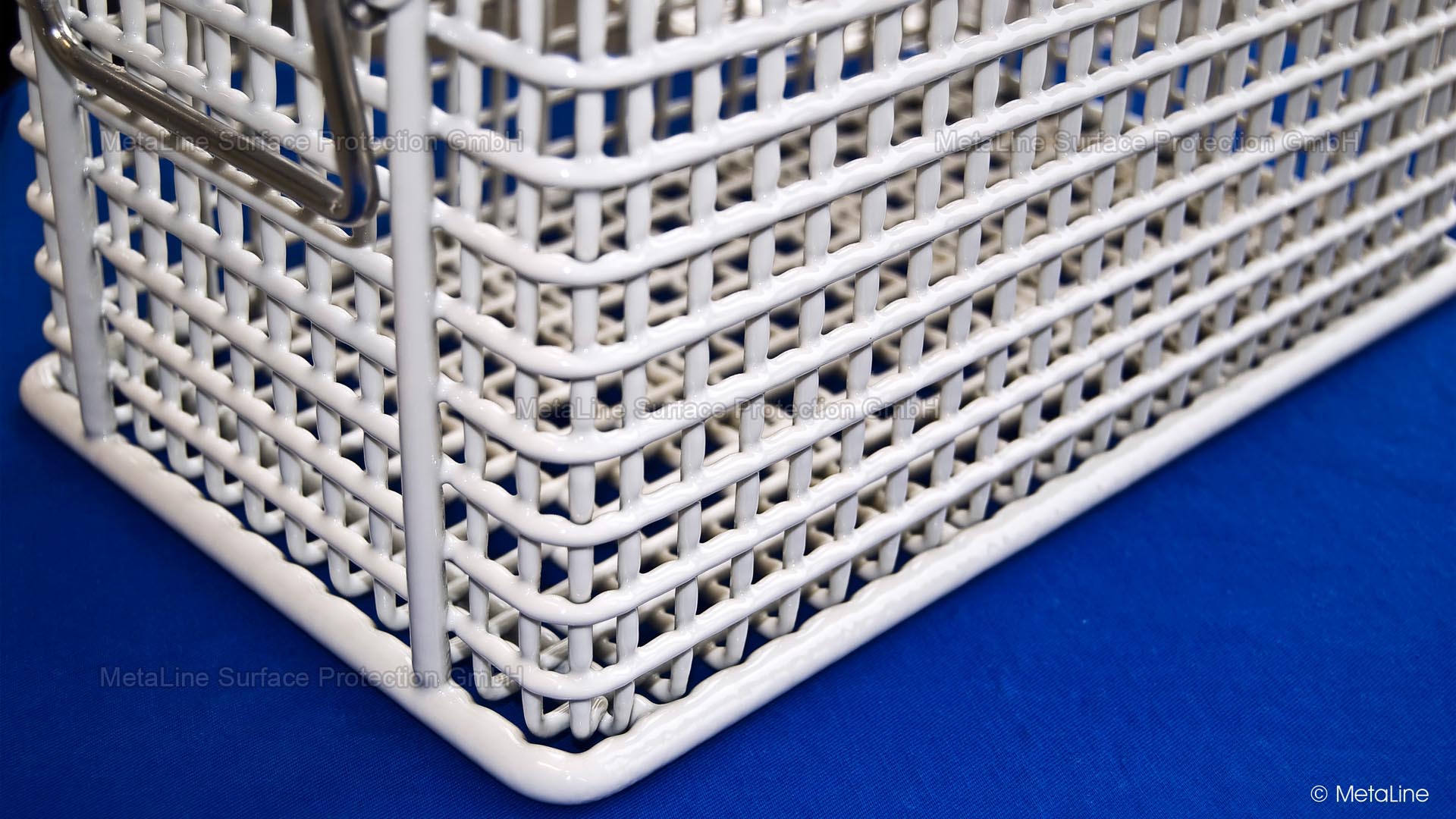

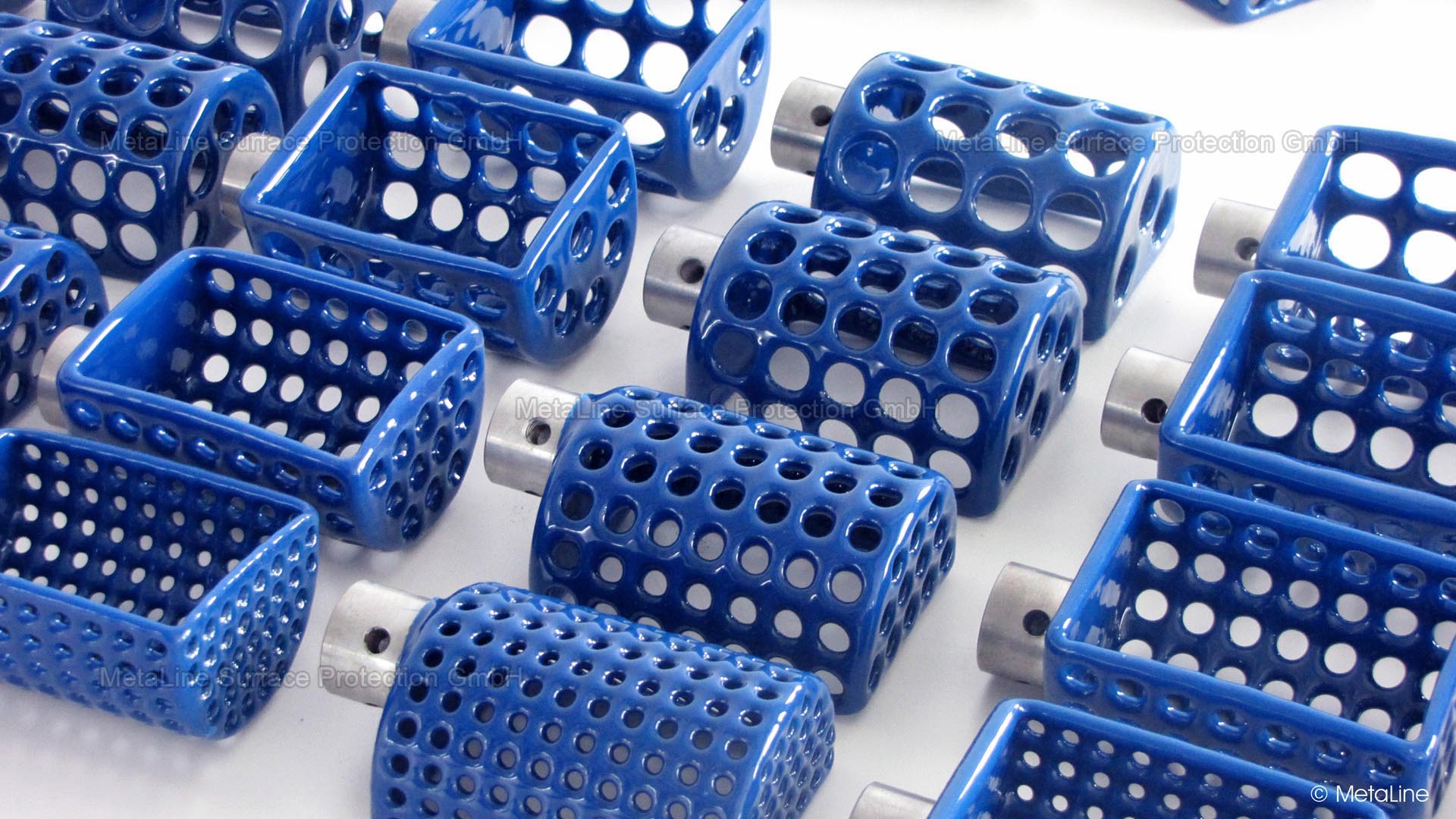

Wash basket coating - Wash basket for an ultrasonic washing system coated with 1.5 mm (60 mils) MetaLine 785 to protect scratch-sensitive parts during washin

Grid basket coating - seamless, soft and anti-slip surface properties protect the parts in the basket from marks and annoying marks. Only suitable for aqueous washing solutions, not for solvents

Anti-scratch coating - an elastic coating made from MetaLine 785 protects sensitive metal parts from scratches and marks in these workpiece carriers. Oil and chips can drip off without damaging the coating

Tool nest coating - mounting support for car lamps coated with 1.0 mm (40 mils) MetaLine 590. This coating is available in anti-static and even electrically dissipative (ESD)!

KTL coating – MetaLine 795 in a thickness of about 1.5 mm (60 mils) protects this car frame holder (satellite) from paint sticking to it during the KTL treatment. The impact resistance as well as good non-stick characteristics convinced the car manufacturer to prefer MetaLine instead of the common GFRP products

Magazine coating - gently washing, transporting, feeding or storing sensitive parts is often associated with a risk of damage. MetaLine's rubber-like coatings reduce this risk and minimize downtime

Would you like to use MetaLine coating technology yourself? This is ONLY conceivable after appropriate training and certain investments. But not for a few parts or only occasionally during the year. The learning effort and equipment costs are far too high for that!