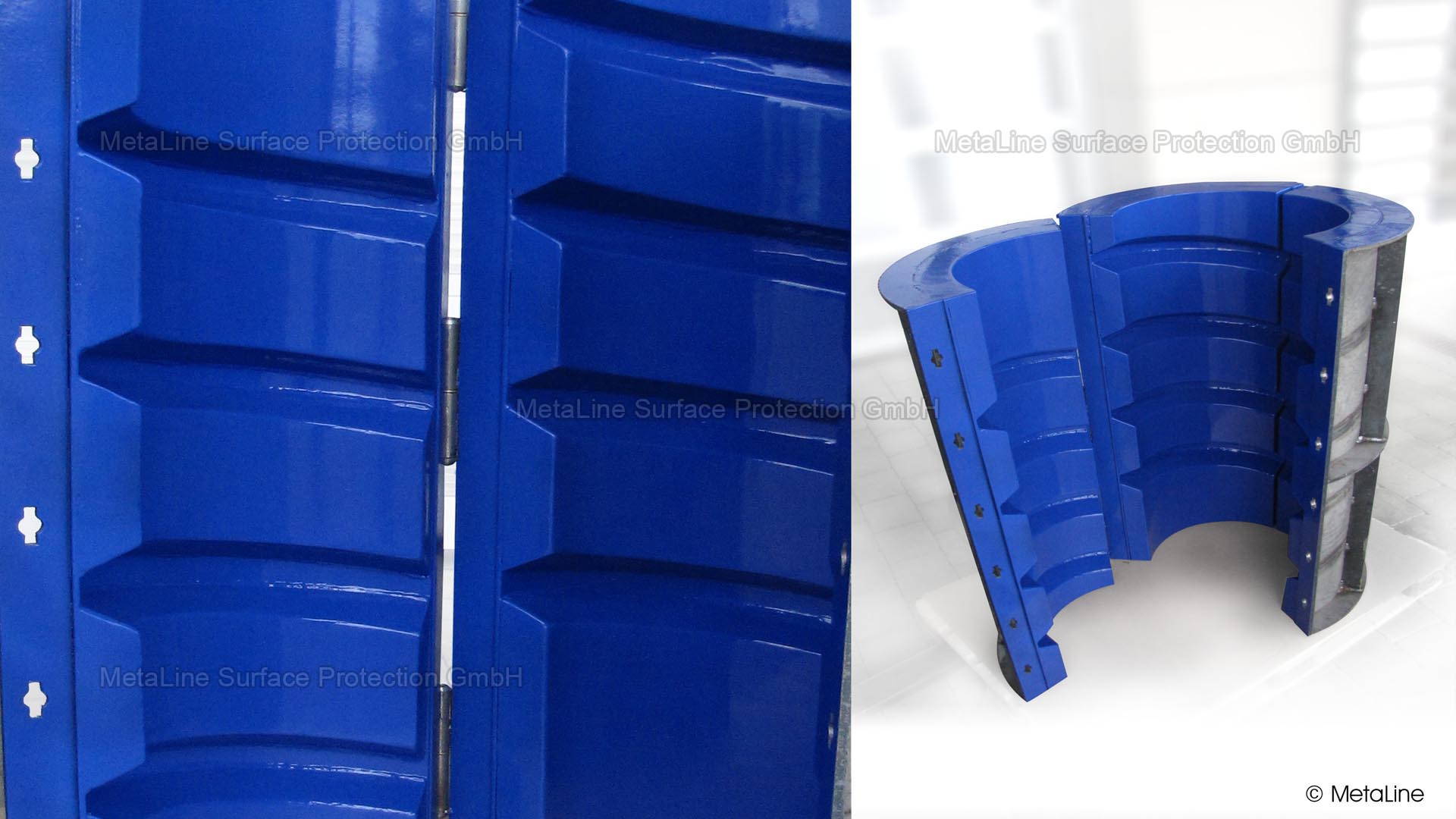

Concrete mold coating – completely seamless, non-stick coating with extremely wear resistant properties. Easy to clean, anti-adhesive towards cement-based materials, repairable. The smooth surface finish improves the quality of the molded articles

Concrete bucket coating - the focus here is on quick and easy cleaning. MetaLine 795 is a combined non-stick and wear-resistant coating. Even dried concrete dissolves on contact with a water jet

Concrete bucket coating - even if everything looks very uniform, these components are coated locally with different layer thicknesses depending on the load. Thicker for higher loads and thinner in areas with lower loads

Coating of concrete formwork - this box formwork for a modular concrete bridge construction system was coated with MetaLine 795. Easier demolding and better surface quality are the result!

Non-stick coating of concrete formwork - this elastomer molded part of an adjustable concrete formwork was partially repaired and professionally repaired with MetaLine 785. The cost of a replacement part was saved

Chute coating - Inlet cone for concrete coated with 8 mm (320 mils) MetaLine 785. More wear-resistant than steel in the long term, easier to clean and also lighter in weight

Trough coating - concrete transport trough coated with 3 mm (120 mils) MetaLine 785. It is a fundamental question of whether or not to protect such parts with a coating. The more expensive the component is, the more reasonable long-term protection is

Bucket elevator coating – MetaLine 795 is not able to solve every problem – but many. Here to prevent adhesion of sticky artificial stone material. The non-stick effect can be re-freshened anytime by a simple wipe over with MetaLine 980

Mixer coating - this small mixing trough has been coated with 6 mm (240 mils) MetaLine 785 to ensure effective wear protection and make cleaning easier

Mould coating - coating with MetaLine Series 795 not only provides lasting protection for the mould, but also makes demoulding much easier. What's easier is more fun!

Wear protection coating - conveyor trough for concrete protective coated with 6 mm (240 mils) MetaLine 785. Applied on site by the customer - after ½ day of training. The result is impressive!

Concrete mixer coating - Ready-mix concrete mixer spout protected with MetaLine 785. Slips better, does not stick, is easy to clean, but above all is much quieter when working in residential areas

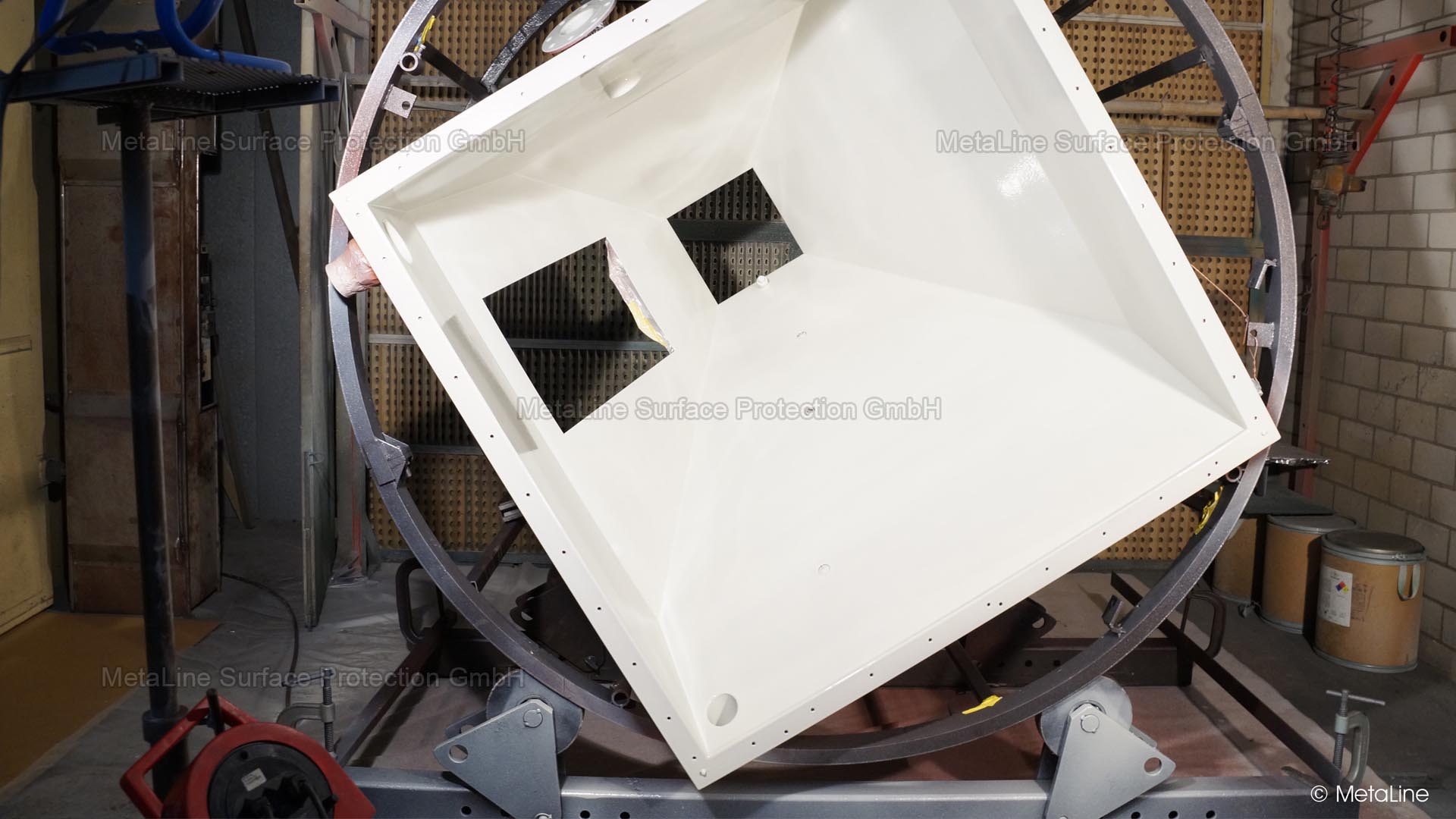

Hopper coating - professional coating work is preferably carried out under rotation. The coating thickness is more even, the surface is smoother, the edges are better covered and, last but not least, quality control is easier

Non-stick coating for concrete processing - it looks easier than it is. But with our training and your skills, you can professionally coat components in your own workshop