Roof tile mold coating - when it comes to protecting steel from mechanical attack, one name should come to mind - MetaLine Germany. Elastomeric coating ideas in surface protection that break new ground . . .

Silo coating - on the one hand, this storage container for color pigments must ensure good flow properties of the sticky powder. On the other hand, there must be no metallic abrasion, which would lead to problems during baking.

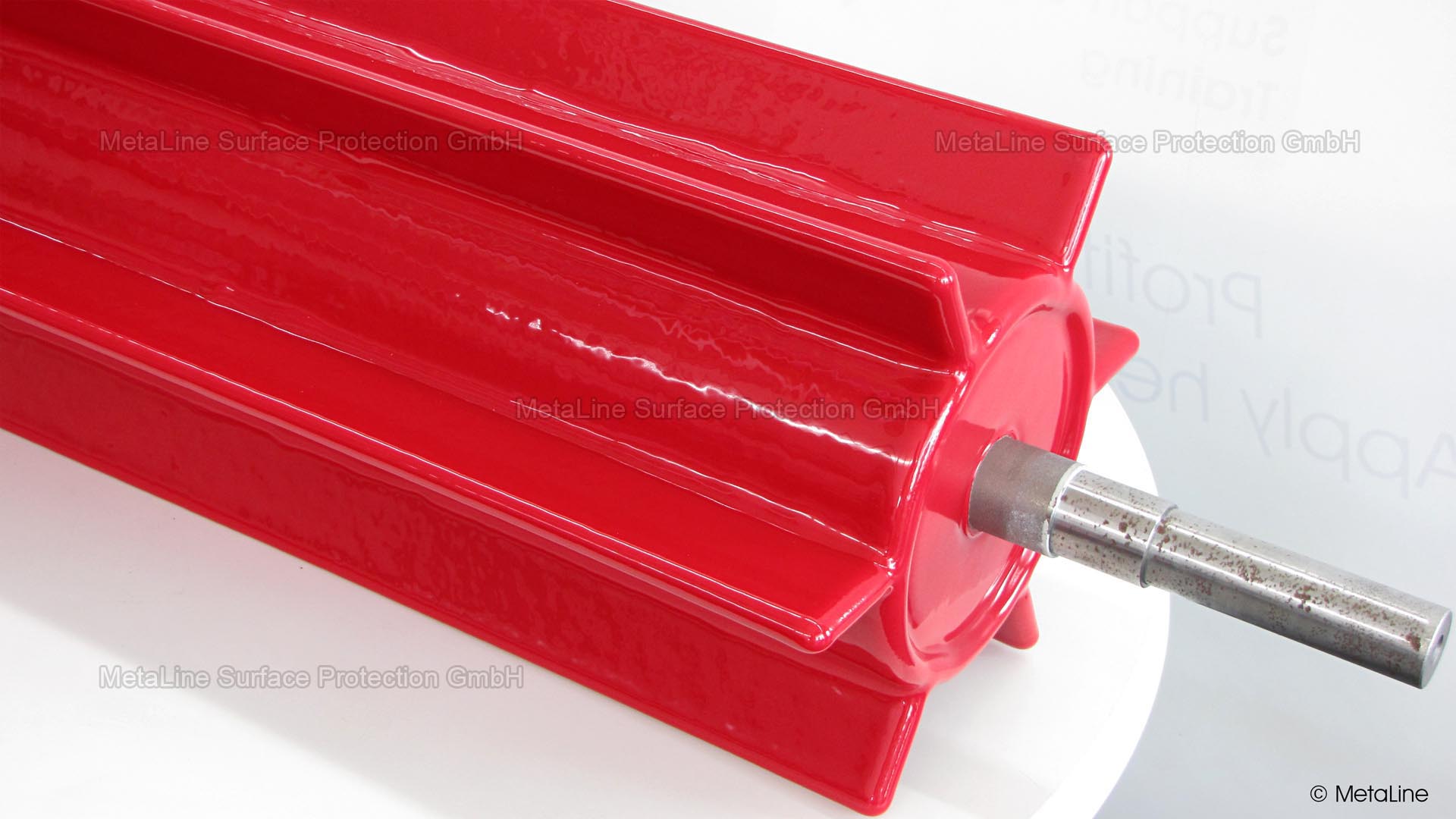

Mixer coating - wear-related system abrasion unfortunately always ends up in the end product. The ingredients of MetaLine Series 700 wear protection do not cause discoloration or other chemical reactions in mineral building materials.

Mould coating - MetaLine 795 develops durable non-stick properties and tends to demould more easily and quickly than hard, inflexible surfaces due to its soft, yielding behavior

Mixer wear protection - all MetaLine Series 700 coatings have one purpose: extended service life, surface protection and optimum cleanability. They are also suitable as a repair material for existing linings

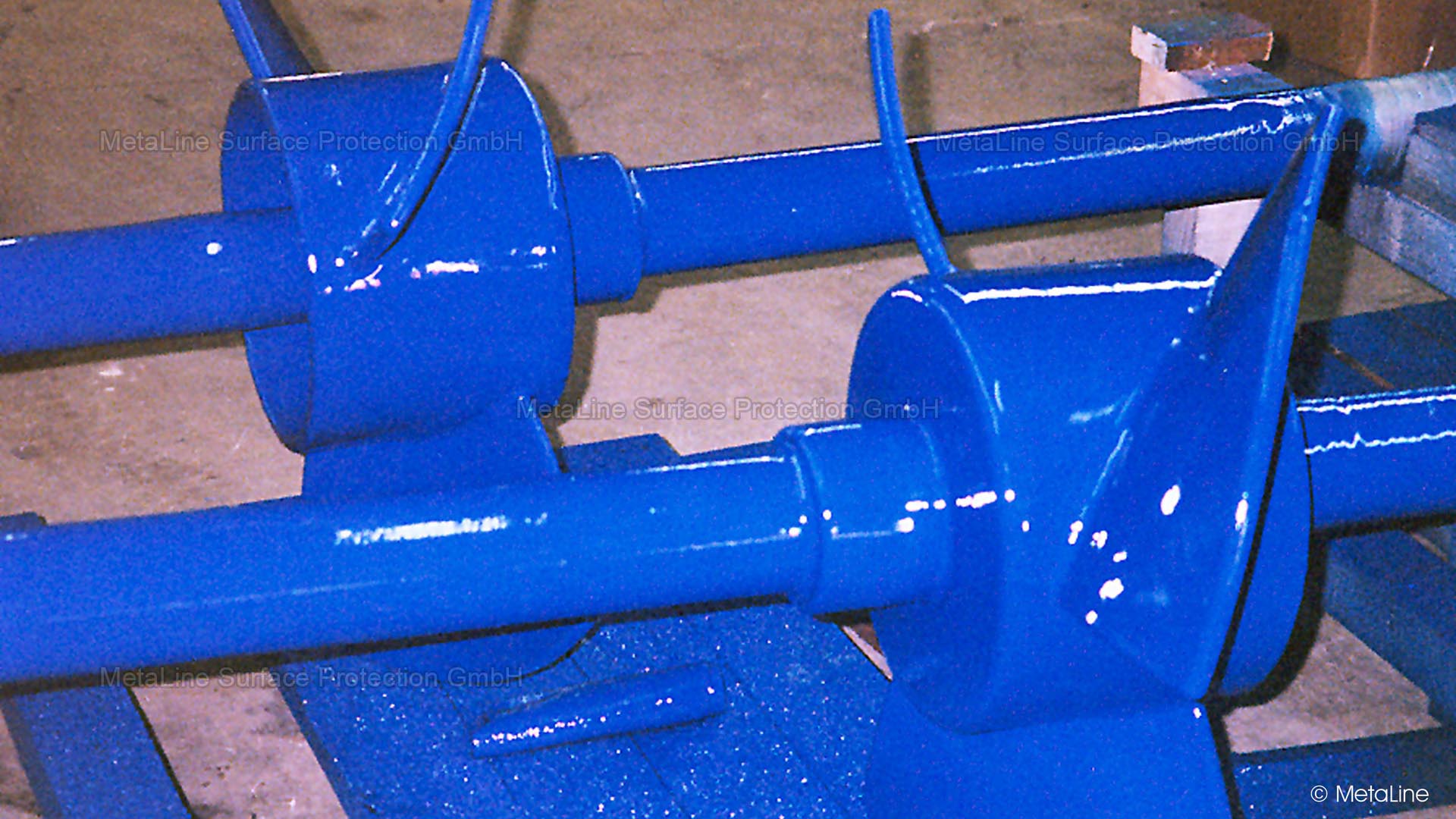

Mixer coating - MetaLine 785 as a professional casting variant on this interchangeable part of a mixer. Impressive in function, durable and, with a little attention to detail, you can even make it yourself

Agitator coating - with 5 mm (200 mils) MetaLine 785 coated bar mixers of a planetary agitator for ceramic compounds. The MetaLine process is sustainable: worn agitators can be repaired or recoated at any time

Pump wear protection - The conveying of all components in the production of ceramic construction materials causes a high level of abrasion. Tough-elastic, rubber-like linings are a proven alternative to metallic armoring in many places

Wear protection in pipes - the perfect solution when enormous service lives are required on pipe bends subject to wear. A screwable outer wall coated with MetaLine 785 - which can be repaired at any time . . .

Non-stick coating - MetaLine 785/795 applied as a sandwich. The softer base (785) allows hard, dried-on coatings to break and fall off, while the non-stick coating (795) on top ensures non-stick gliding

Container protective coating - where a lot falls in, a lot can happen. Reliable impact and wear protection is just as useful as non-stick properties that make cleaning easier = MetaLine 785!

Wear protection coating - MetaLine Series 700 can be applied to the most complicated contours and geometries that can never be protected with rubber

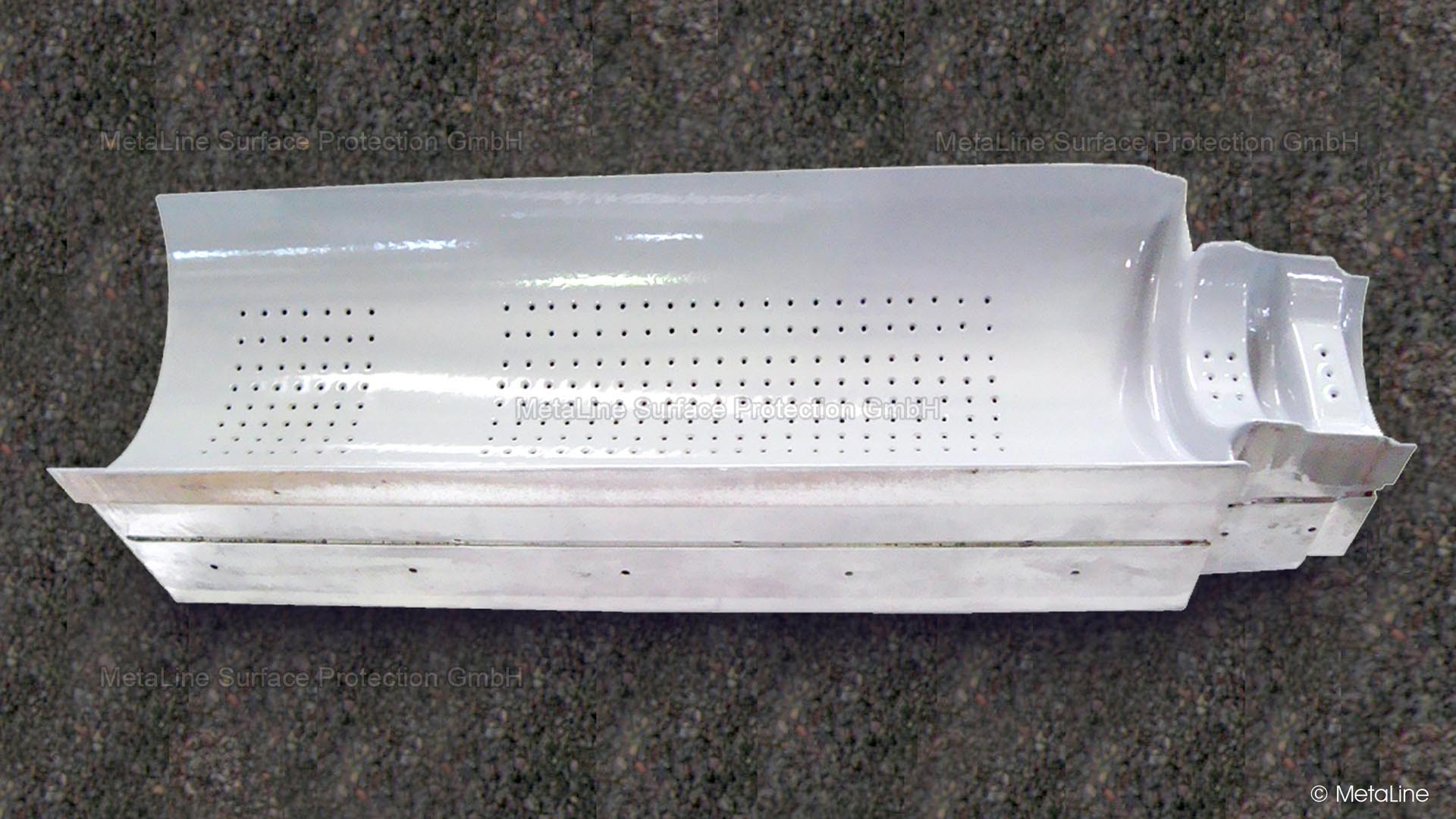

Concrete distributor coating - a coating combination of MetaLine 760/785 protects this distributor against wear and the build-up of unwanted deposits - an entire work shift without intermediate cleaning

Chute coating - not only the production of building materials poses a challenge. The plastic film must slide easily and the labeling on it must not become illegible. MetaLine 795 solves both problems!