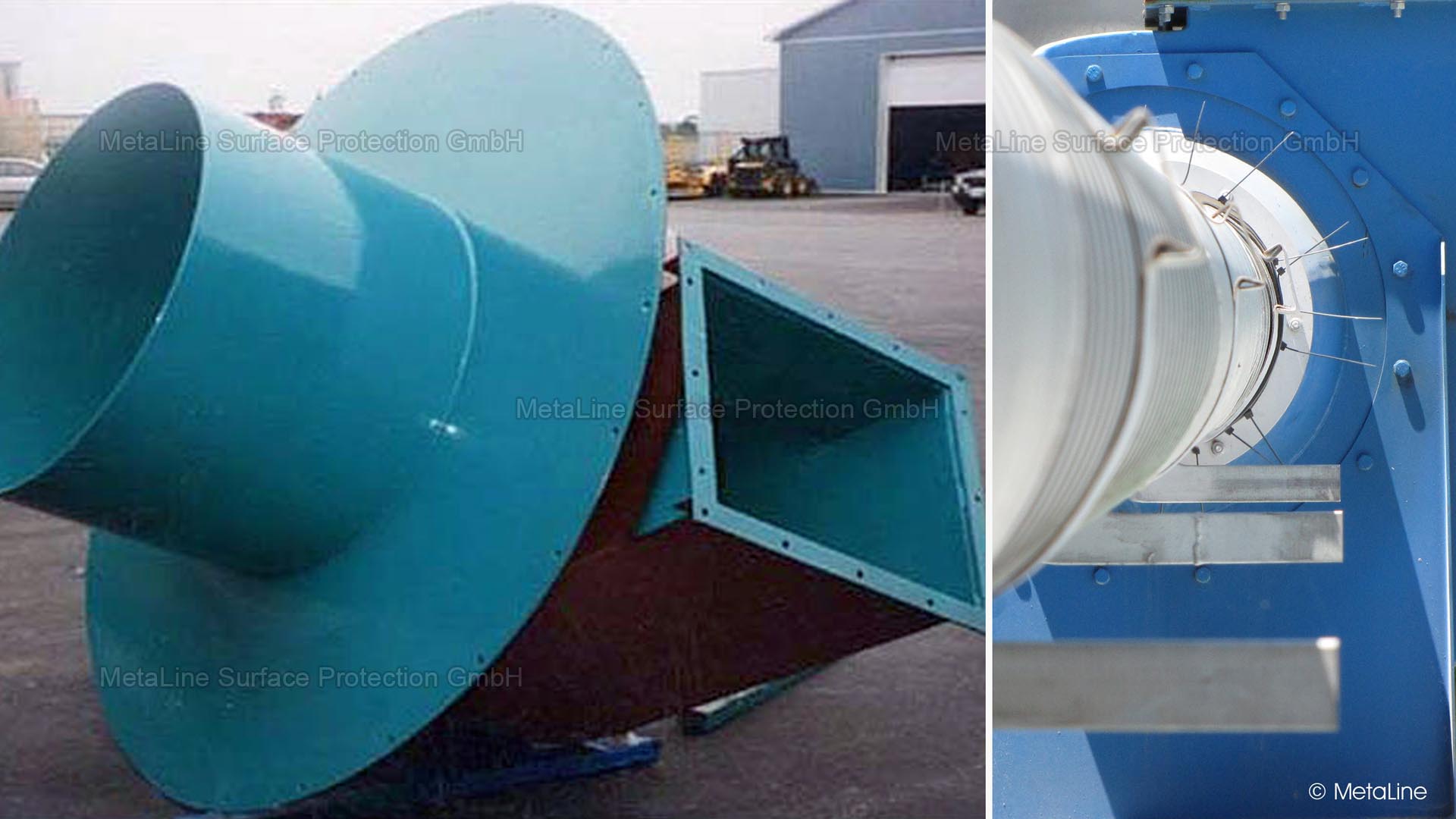

Cyclone coating - a 4 mm (160 mils) layer of MetaLine 785 gives this cyclone a second life for blast media recycling. Elastomeric wear protection in a completely seamless and therefore technically perfect form. Including the flange areas: No more infiltration and no more detachment!

Centrifuge lining - solids extraction system of a metal goods factory protected with MetaLine 785. Coating thickness is always a question of load: mechanical, thermal and chemical - in this case it was 8 mm (1/3 #) due to the increased temperatures

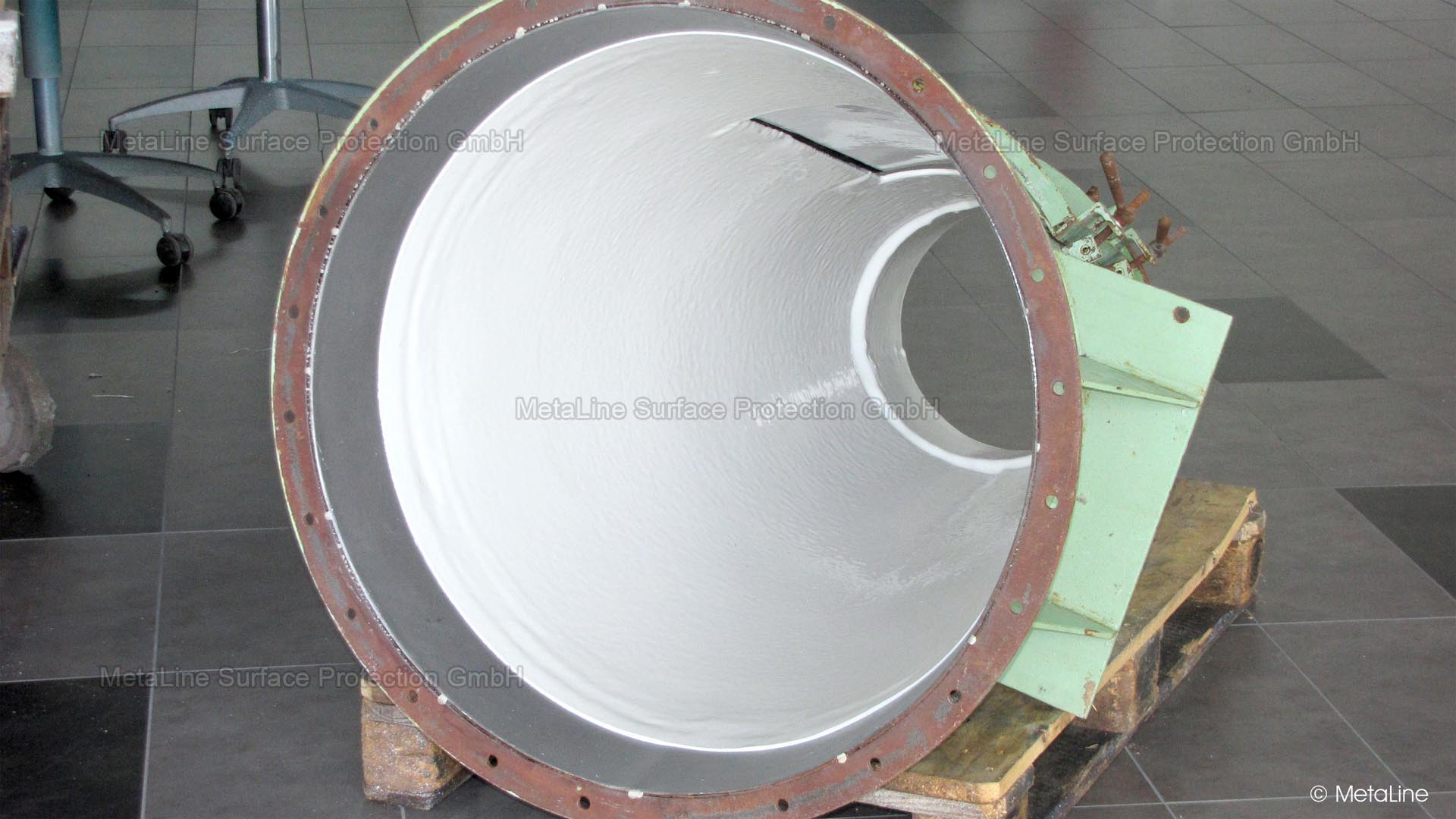

Cyclone lining - MetaLine 700 series wear protection elastomers are extremely resistant. But above 80°C (175 °F) air or solids temperature we advise against them due to the thermal load. You have to know your limits and talk about them - that's what makes a good supplier!

Hydrocyclone lining - actually looks simple, but unfortunately it is not. The different diameters, the length and the cone at the end make coating this component considerably more difficult. A job that requires experience in dealing with sprayable wear protection coatings!

Separator lining – corrosion-resistant, abrasion-resistant protection with MetaLine 785. The coating thickness is individually adapted to the different load areas in the cyclone. Depending on the equipment, this can be anything between 2 and 10 mm (80 to 400 mils) . . .

Cyclone repair - due to the geometry, various components can only be treated effectively using a spray process. Where the hand and arm no longer fit, liquid coating is the last - but definitely not the worst - solution!

Sifter coating - reliably protected even at high flow velocities. MetaLine Series 700 elastomer linings can be used up to 70 m/s (230 ft/s) flow velocity. Above this, wear increases disproportionately - everything has its limits!

Separator coating - MetaLine 785 in a thickness of 3 to 5 mm (120 to 200 mils) as a wear-resistant and noise-reducing lining. And what makes it special? In contrast to any rubber coating, it is completely stress and seam-free. Coating detachment can actually no longer occur . . .

Sifter coating - in the end, it's almost all about the quality of the wear protection, a certain degree of noise reduction and, last but not least, manageable costs! You will be pleasantly surprised by all three! Otherwise this website would not look the way it does!

Centrifuge lining - dividing, separating, precipitating, filtering. MetaLine Series 700 adapts to the requirements in terms of material hardness, coating thickness, sliding friction, electrical conductivity and coating thickness profile for the respective task. You need a “friend” like this in engineering!