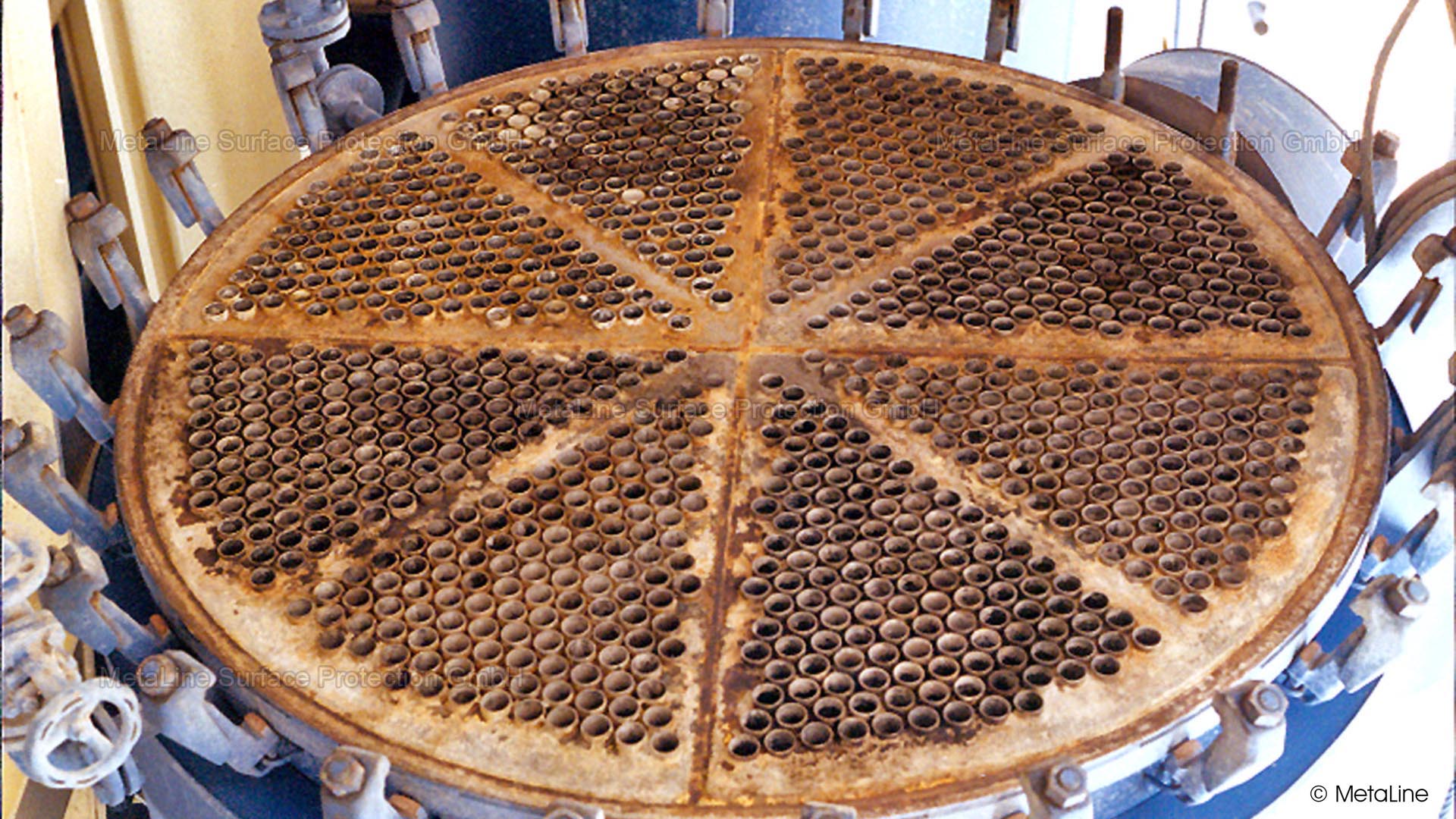

Heat exchanger repair - extreme galvanic corrosion on the heat exchanger base of a German sugar factory. If action is not taken promptly, this can lead to the complete loss of the heat exchanger

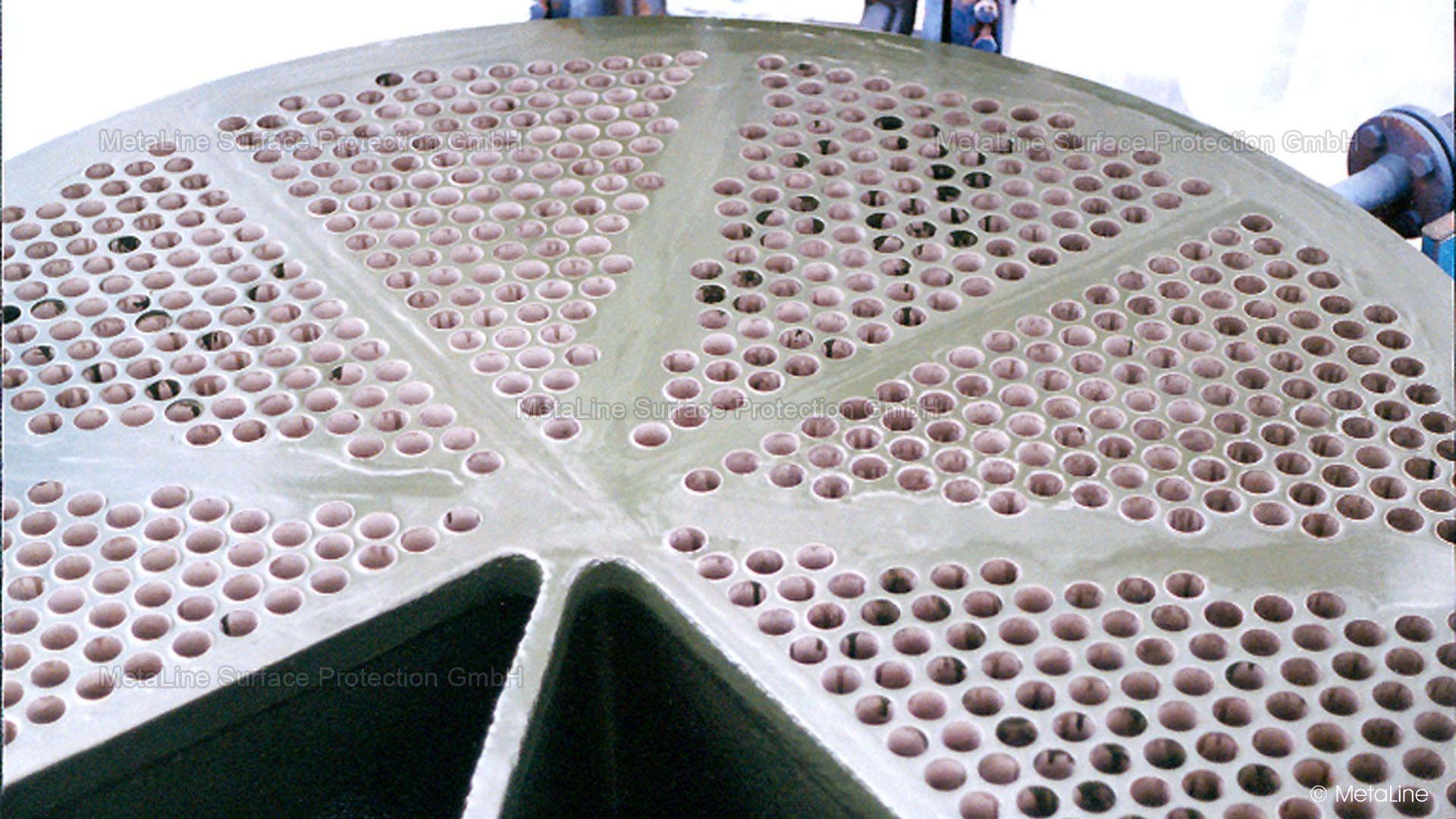

Heat exchanger sealing - professional corundum blasting is essential for surface preparation. No other form of rust removal provides a reliable basis for subsequent operational loads. Necessary repairs to the tube ends are carried out at the same time

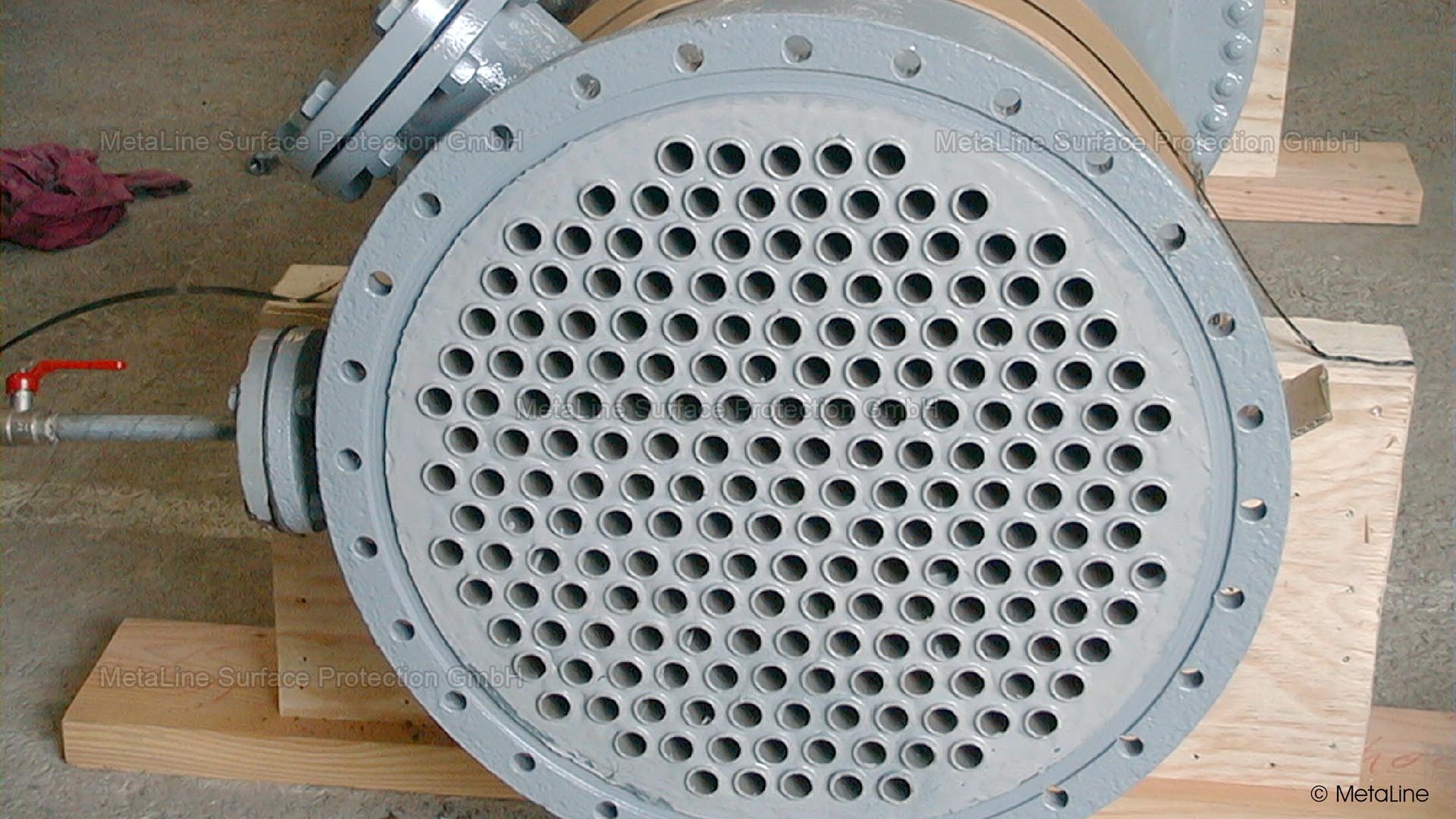

Heat exchanger coating - electrically insulating, ceramic corrosion protection coating with the pourable/brushable MetaLine KXL. Wear-resistant, temperature-resistant, can be used on site and is cost-efficient!

Galvanic corrosion protection - an enormous loss of substance due to permanent electro-chemical corrosion. As long as the perforated plate is still structurally stable, it can be safely repaired and electrically insulated . . .

Electrochemical corrosion protection - clogging of the pipe ends and synthetic re-contouring of the heat exchanger bottom plate using the liquid repair ceramic KXL. The layer thickness depends on the pipe protrusion and can be several millimeters!

Heat exchanger bottom plate protective coating - the highly efficient MetaLine KXL corrosion protection in a seamless design. The coating also protects against abrasion and reduces operational build-up

Heat exchanger tube sheet repair - not always easy to carry out on site, but a proven solution with MetaLine Series XL. But be careful with “do-it-yourself”. These are not applications that can be completed quickly and easily!

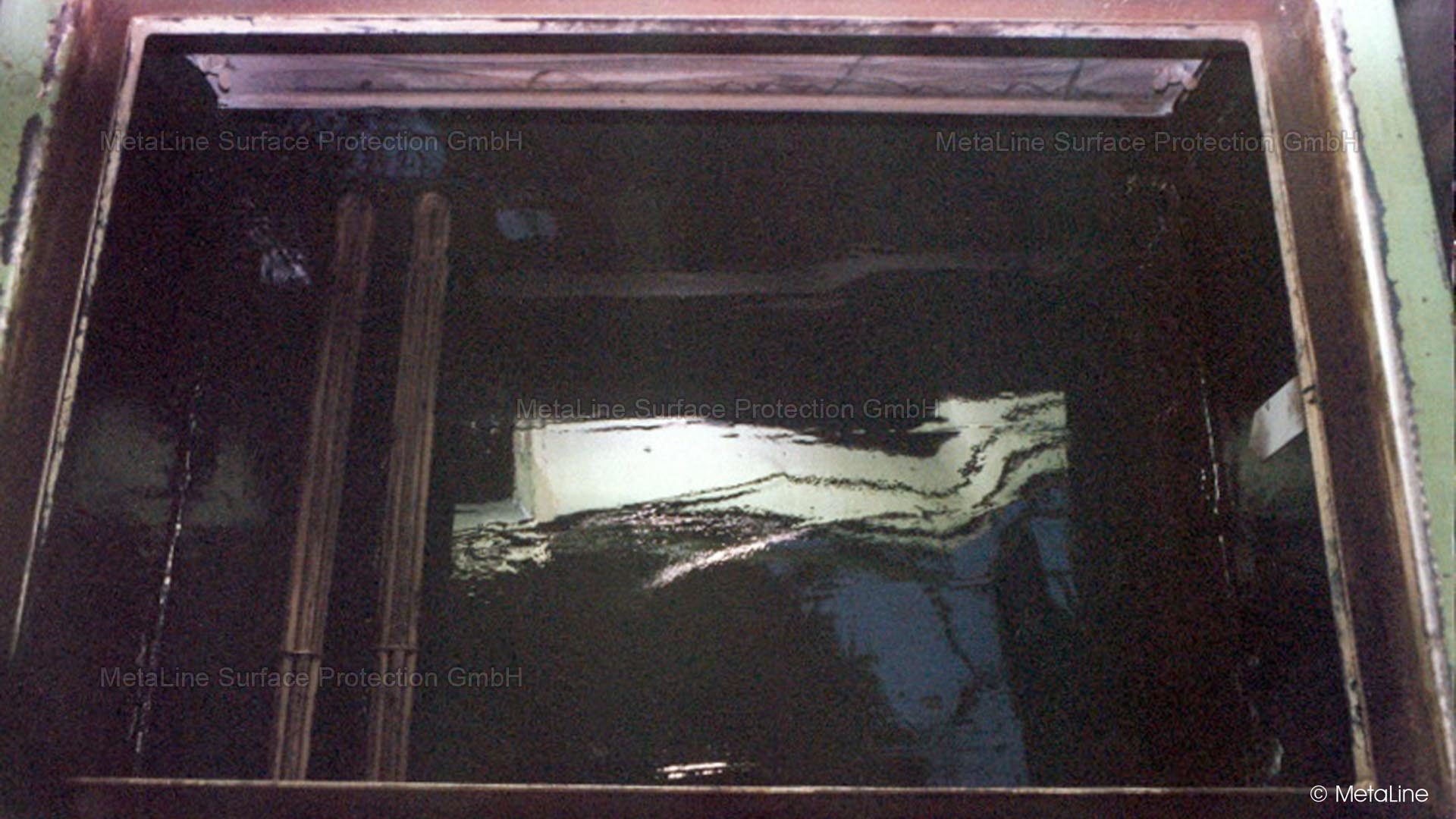

Bi-metal corrosion - a typical scenario in a metal collection tray of a machining center. Chips of various metals are deposited and the electrochemical voltage series takes care of the rest: corrosion, pitting and leakage!

Electrochemical corrosion protection - fully electrically insulating, extremely chemical-resistant protective lining with MetaLine 100XTM. Brushable, rollable or professionally sprayable with our cartridge spraying process!

Electrochemical insulation - mild steel guideway on a highly stressed underwater rail system that had to be sheathed in stainless steel for technical reasons. Actually an impossible requirement . . .

Bi-metallic corrosion protection - the existing steel guides were completely coated and the new stainless steel guides were bonded and screwed onto the existing construction using MetaLine repair ceramic KXL. Even the screws were insulated against the substrate with the ceramic compound!

Heat exchanger cover protective lining - a series application with MetaLine 785. An elastomeric protective coating for heat exchanger covers for long-term corrosion protection - also against galvanic corrosion

Heat exchanger sealing - maximum protection for this heat exchanger in a French nuclear power plant. The joint at the transition to the cover must be protected against thermal expansion and (galvanic) corrosion. MetaLine 785 in the special color orange was entrusted with this task by the operator!