Pump impeller coating – the largest pump impeller ever coated with MetaLine 785. 10 tons of steel being protected by our leading elastomeric spray technology

Impeller protection with MetaLine 785 - 2 mm (80 mils) coating thickness in a geometry that NO brush or brushable coating can fit into. Not only does it look impressive - it also lasts just as long!

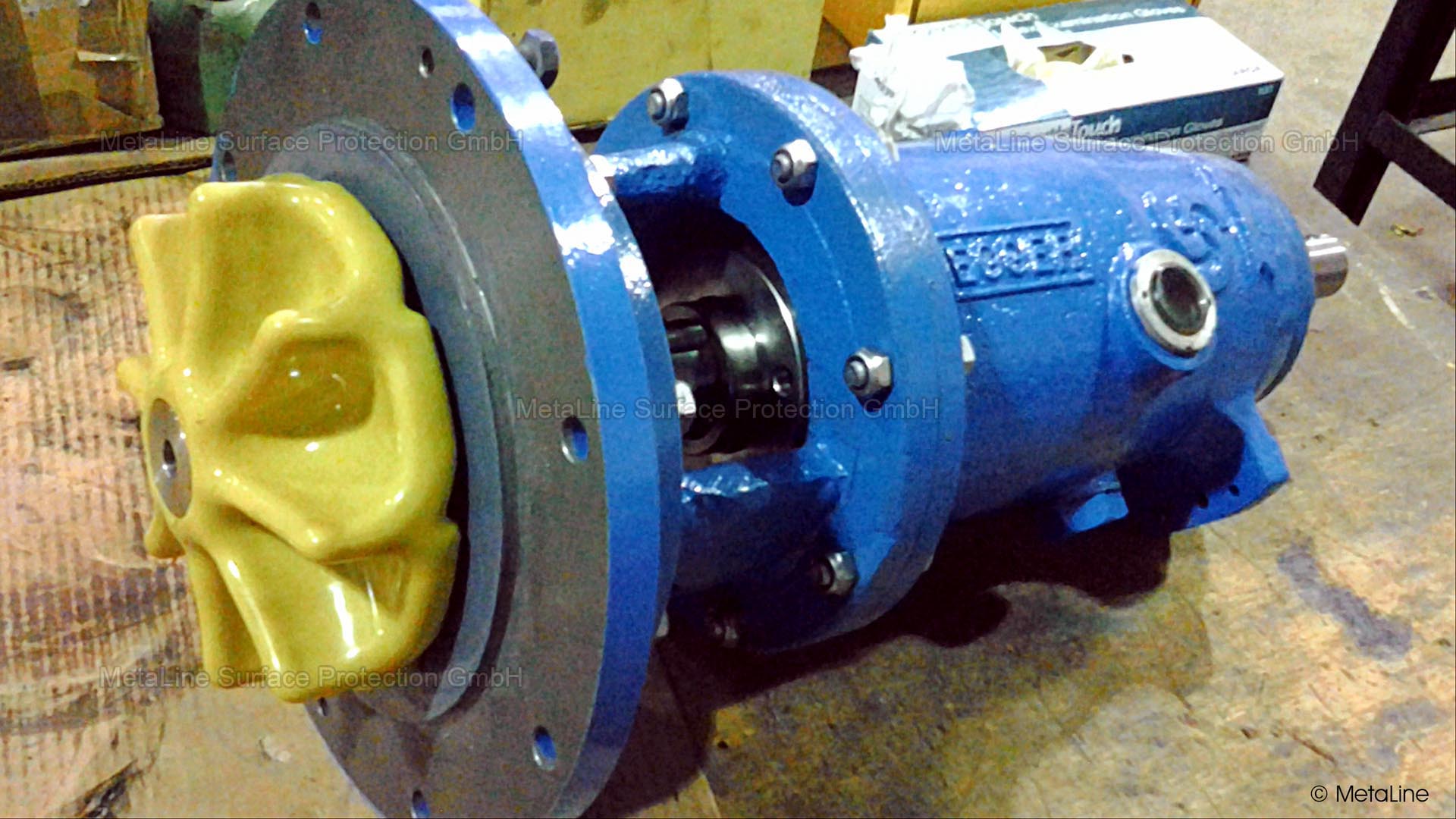

Pump impeller coating - MetaLine elastomer armoring - a large impeller coating even on the smallest diameter (45 mm impeller)

Pump service life improvement - here with 4 mm (160 mils) MetaLine 785 for a classic waste water pump in a sewage treatment plant. What can you expect? Approximately 4 times the service life compared to a conventional cast steel impeller

Pump lifetime improvement - MetaLine 785 in a uniform coating thickness of 1.5 mm (60 mils) on the impellers of cooling water pumps. The uniformity on the edges is remarkable. This quality can only be achieved by spraying

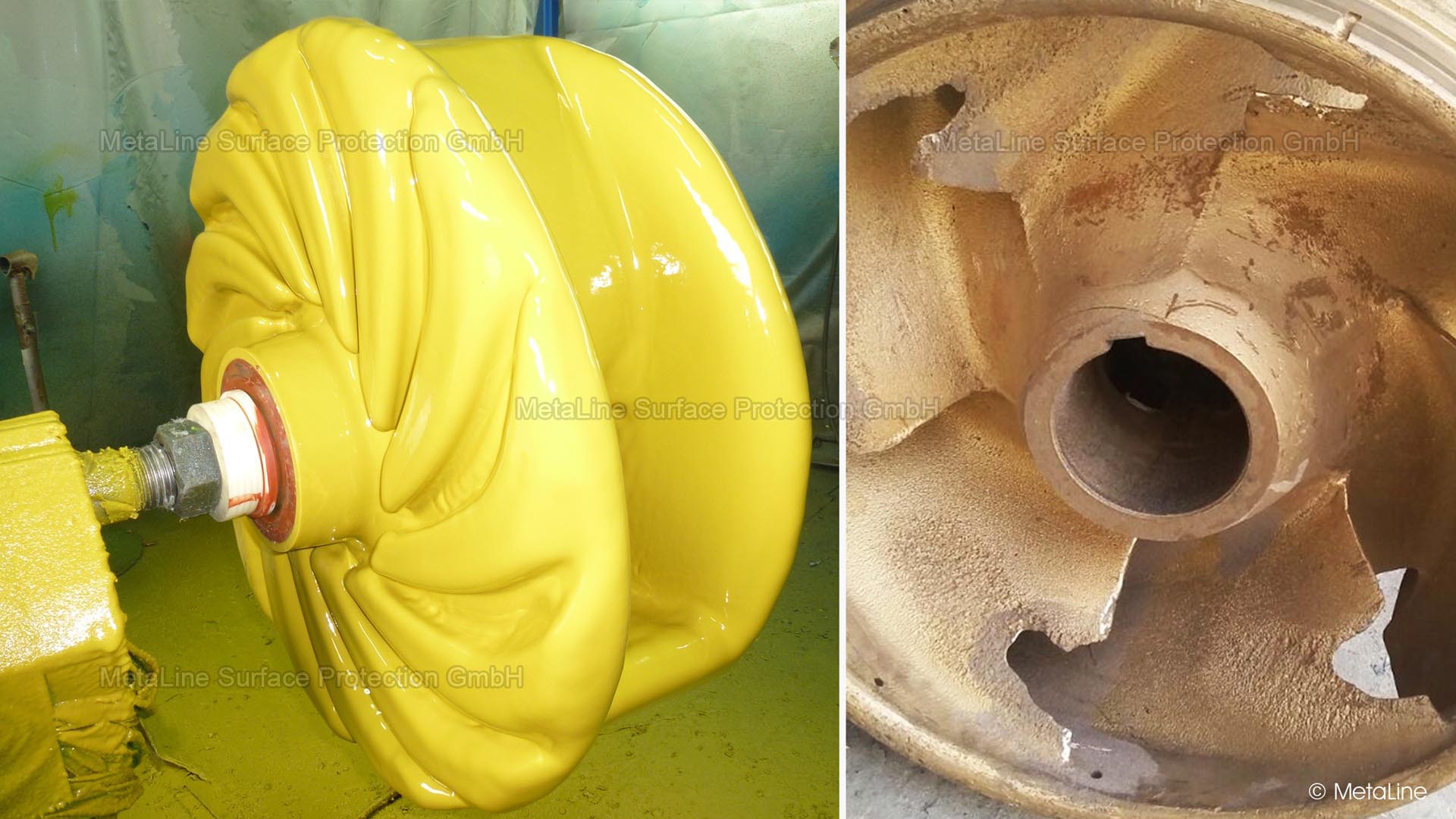

Impeller repair - MetaLine 785 in the before/after view - Substance degradation and static weakening of the original material is prevented by a protective coating that can be repaired at any time

Impeller coating with MetaLine 795 - 2 mm (80 mils) layer thickness on a plastic impeller in chemical engineering. Please contact us for specific chemical resistances

Pump impeller optimization - the pump operator has certified that our MetaLine 785 coating has a 3 times longer service life compared to the original stainless steel impeller - a protective coating cannot do more than this

Pump impeller protective coating - a masterpiece in surface smoothness and efficiency improvement. This three-channel impeller was coated in Malaysia outdoors at 100 % humidity with 3 mm (120 mils) MetaLine 785

Rotor coating with MetaLine 795 - 4 mm (160 mils) coating thickness protects this KSB chopper pump from coarse stresses. The slightly harder MetaLine 795 (95 Shore A) has been given preference over the slightly softer MetaLine 785 (85 Shore A)

Pump lining - 1.5 mm MetaLine 795 sprayed on evenly, smoothly and harmoniously. It looks like a paint, but is a synthetic rubber-like skin that is more durable than natural rubber

Rubber coating – a damaged rubber impeller was restored by use of the MetaLine Series 700 elastomeric repair technology. Finally a full protective coating with MetaLine 785 was put on top

Impeller protective coating - a 2 mm (80 mils) elastomer coating with MetaLine 785 on this closed pump impeller changes the situation. Longer service life and lower repair costs!

Impeller coating with MetaLine 795 - 1.0 mm (40 mils) as high-performance corrosion protection on these closed water pump impellers. Of course, balancing is required after coating. This is done by applying more coating locally instead of metallic weights

Wear protection coating - if only everything were as easy as Internet providers would have you believe! No, coatings are for specialists - whenever it is possible to apply them yourself, we will support you. But we also say a clear "stop" if the level of difficulty is too high. A visit to our coating center in southern Germany will clarify many questions

Impeller improvement – what epoxy-ceramic brush coats, vulcanized rubber, hardfaced welding or special alloys in total cannot combine stands for MetaLine – perfect geometries, fluid-flow optimized surface structures, seamless character, low weight, impact resistance, homogenous and in the end being very economical

Waste water pump lining - the size of the component is not decisive for the coating success - but the precise procedure. This includes sandblasting, desalting, degreasing and many other small steps that make all the difference

Impeller improvement – an extremely smooth coating with 3 mm (120 mils) MetaLine 785 optimizes the surface characteristics and increases the grade of efficiency

Salt water protection - MetaLine 795 as heavy-duty corrosion protection for this impeller. Whether you are pumping salt water, fresh water or diluted chemical media - it's worth talking to us. Then you will know more!

Cooling water pump coating - MetaLine 785 in a coating thickness of 2 mm (80 mils) protects these cooling water pump impellers of large marine engines. The material is bronze and yet not sufficiently resistant to cavitation! Guess how many thousand EURO a single new impeller costs? A repair and coating are more than worthwhile!

Pump protection coating with MetaLine 785 - 2 mm (80 mils) thickness. Admittedly, such results are no longer achieved by amateurs. However, the subsequent balancing was carried out incorrectly by the customer. Instead of milling off the coating, further MetaLine had to be applied on the opposite side

Pump impeller repair - MetaLine 785 in a coating thickness of 5 mm (200 mils) on this Warman™ brand pump impeller. Can MetaLine extend the service life of this cast material with over 30 % chromium? No - we can reduce the costs compared to these ultra-hard materials - but no more!

Dredging pump coating - one of MetaLine's fundamental ideas is to conserve resources. Here is a worn suction dredger impeller that has been given a new lease of life with 18 mm (3/4#) MetaLine 785. Works - as long as the filtration is in order and no large stones are sucked in

Pump impeller coating - if you have any doubts about the solution shown, please contact us! We will not persuade you, but will explain our technical approach. We are technicians, not salesmen!

Pump protective coating - MetaLine 785 in a layer thickness of 25 mm (1#) was applied to this pump on a suction dredger in the Portuguese Algarve. The minimum layer thicknesses of elastomeric coatings must be calculated - these are load-dependent. Failure to do so may result in total failure

Impeller protection coating - what distinguishes our coatings from other repair materials on the market is the fact that we also process these materials for you or at least provide you with practical support in their application. A good approach for a good solution!

Pump wear protection - does our coating change the geometry of the component? Yes, a little more at the beginning and then slowly decreasing. Does wear change the geometry of the component - yes, a little less at the beginning but then increasing very quickly. Decide which is better!

Pump regeneration - a highly wear-resistant pump impeller from the manufacturer Warman™ after regeneration and coating with MetaLine 785. The customer opted for MetaLine elastomerization because the original material is no longer weldable or repairable due to its hardness

Pump repair - The coating can come to the component - or the component can come to the coating! MetaLine has a portfolio that covers almost all technical requirements!

Impeller coating - the geometries of impellers present us coaters with major challenges on an almost daily basis. Like here for a 2 mm (80 mils) elastomeric lining for a standard pump from the Danish brand Grundfos™

Pump protection - no matter how you feel about our elastomeric coatings - you have to admit one thing: you have never seen a smoother and more even coating on a used pump impeller. Our coating technology is also absolutely advanced in this respect!

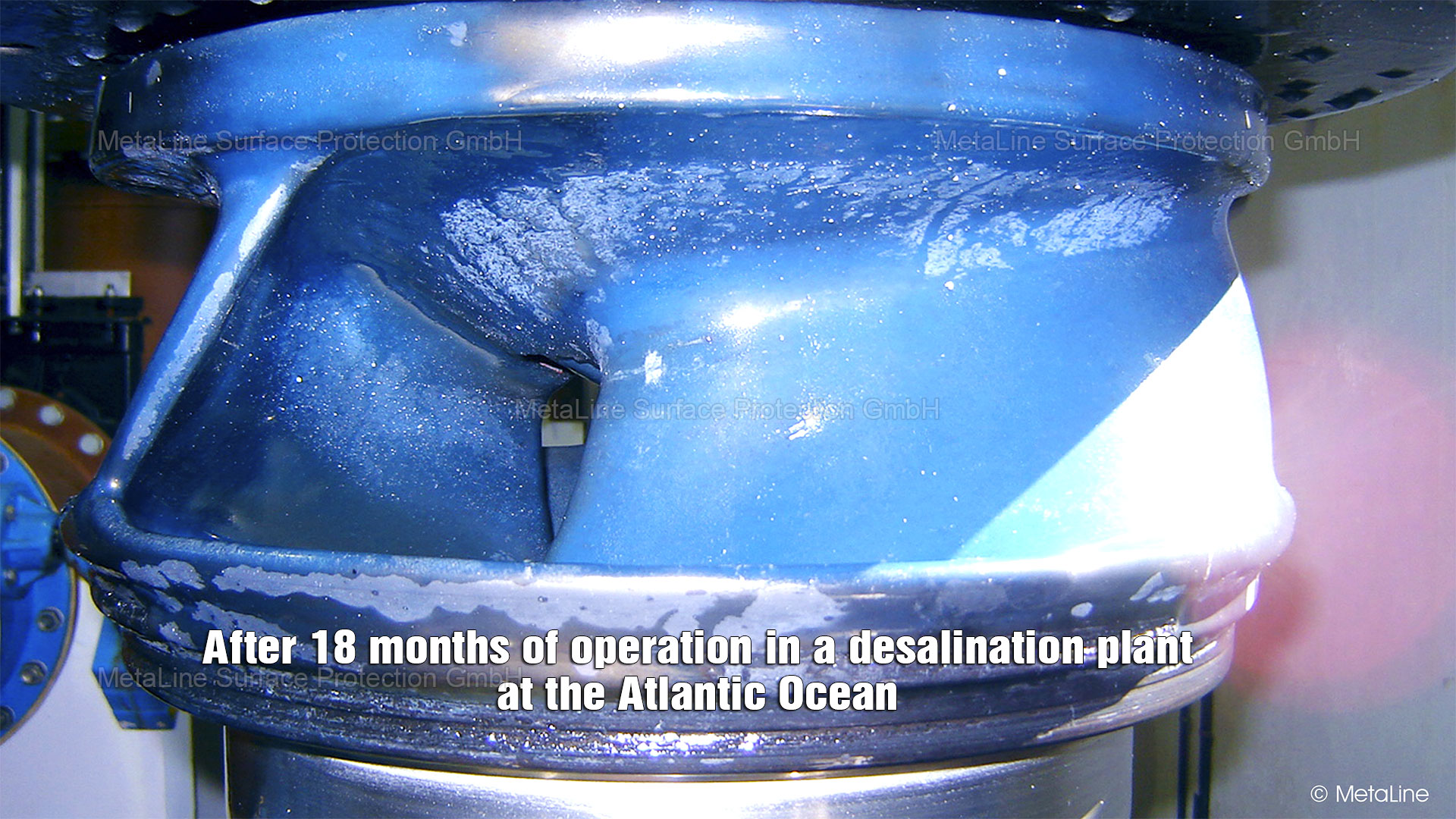

Saltwater-resistant coating - MetaLine 785 after 12 months of continuous operation in a seawater desalination plant on the Portuguese Atlantic coast. More corrosion protection is not possible . . .

Volute impeller coating – what do you expect of a first-class pump impeller? A smooth surface for optimum efficiency? A low weight for minimum energy consumption? An extreme wear resistance to obtain maximum lifetime? Low investment costs to take care of your budget? Congratulations – you found it!

Impeller coating - Any questions about the possible improvement in efficiency after a MetaLine coating? A smoothness and flow harmony that speak for themselves . . . you can expect up to 3.5 % improvement in efficiency!