MetaLine 785 as 2.5 mm (100 mils) heavy underwater corrosion & erosion protection on these blades of a French Kaplan turbine. Rubber-like surfaces can simply withstand impact stresses better than brittle-hard coatings!

Francis turbine coating - Inlet spiral of a Francis turbine in the area of the Swiss Gotthard Massif coated with 2.5 mm (100 mils) MetaLine 785. One of the most complicated geometries to professionally install a high-performance coating system like MetaLine!

Filler coating - Coatings are usually applied evenly in a constant layer thickness! But what if the substrate looks like this? MetaLine 785 is available in sprayable, liquid form and in identical but trowelable form as MetaLine 680. One application, no overcoating time, no layer separation!

Steel protection - MetaLine 795 is a tough elastic protective skin with excellent impact resistance and good non-stick properties. A real rubber-like coating - not paint - that thickly covers all corners and edges. When steel needs to be permanently preserved under water . . .

Dredging coating - the rubber-coated pipes of suction dredger installations are subject to wear, bending stresses and UV exposure. Wear and cracking in the rubber coating are a permanent problem. Repairs with MetaLine 785 preserve, protect and are economical!

Ship fender repair - the repair of elastomer components has always been problematic and associated with considerable financial and technical vulcanization costs. MetaLine replaces, repairs and reinforces rubber parts in their entirety

Anti-fouling coating - MetaLine 795 is a “passive” anti-fouling coating. No toxic or volatile substances, but the biocompatibility has a price: fouling occurs, but can be removed relatively easily. If you don't want that, you have to fall back on conventional products . . .

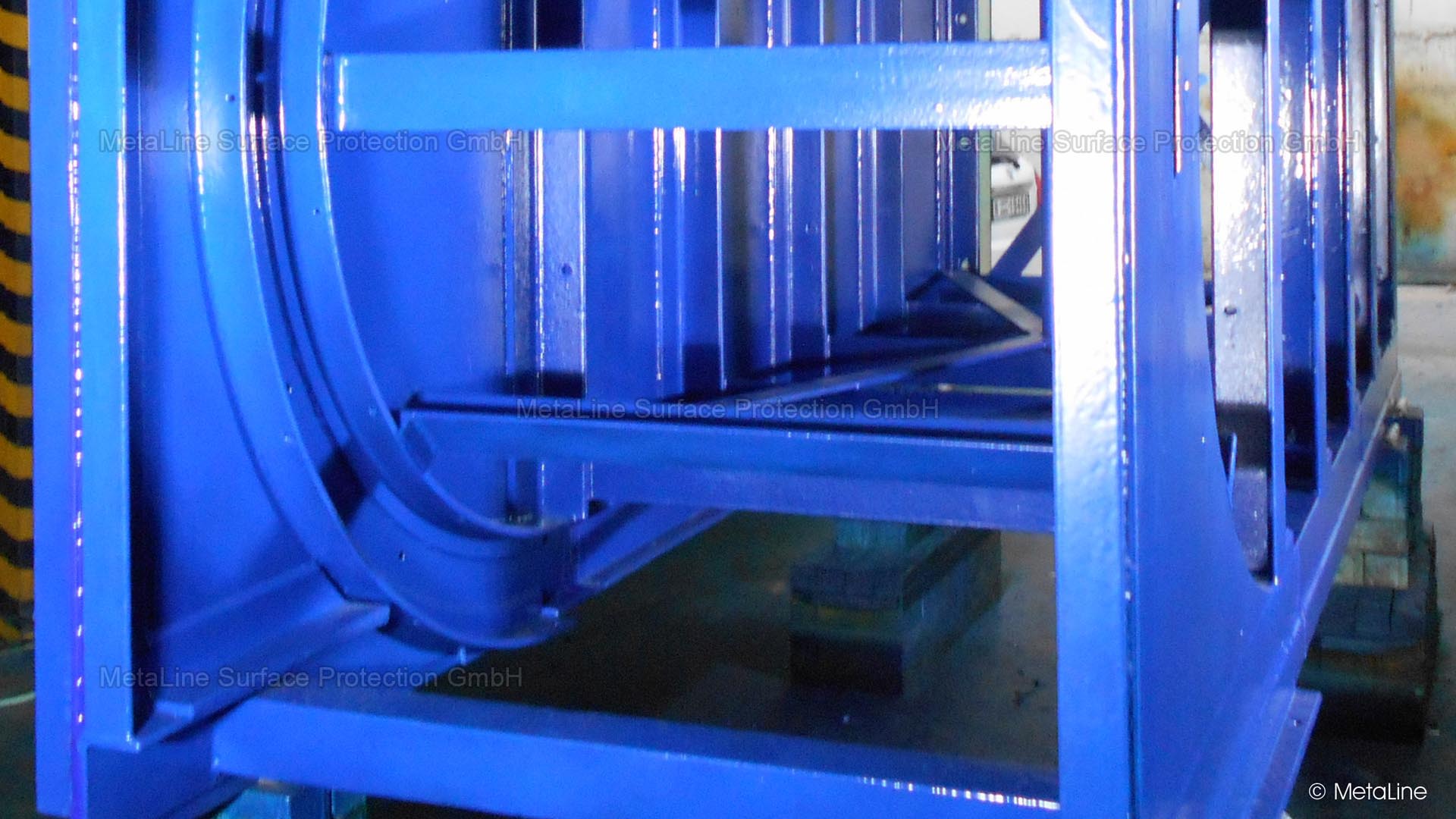

Corrosion protection coating - an underwater steel frame from the mining sector during on-site coating with 2 mm (80 mils) MetaLine. Unfortunately, a certain loss of spray mist cannot be avoided with such a small-area construction. Nevertheless, we would not brush it - the uniformity and absence of pores would suffer!

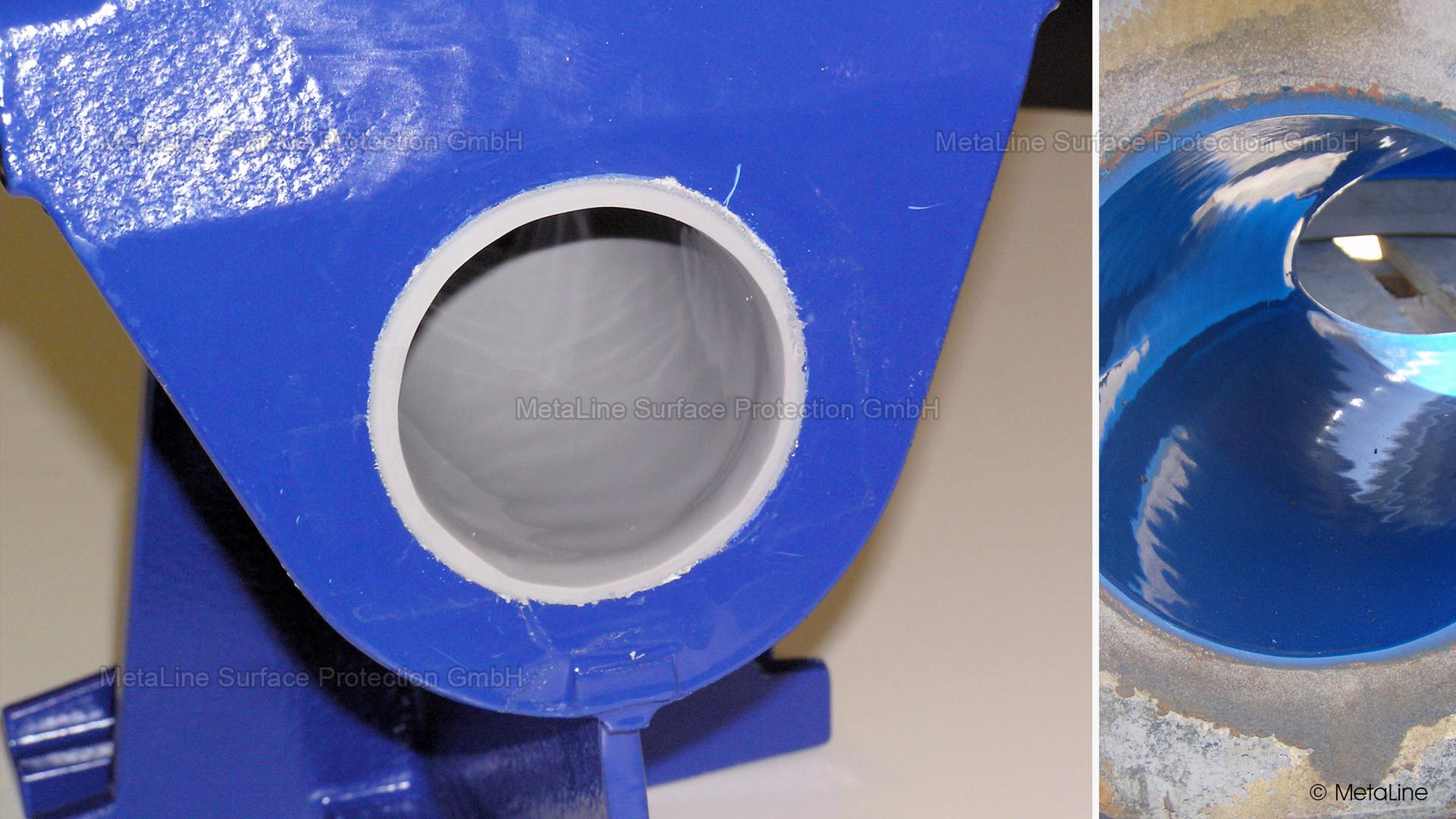

Hydrowater turbine coating - inlet area for a water brake of an Austrian hydropower supplier. The 3 mm MetaLine 785 elastomer coating was preferred to thermal welded armoring due to its higher cavitation resistance

Floodgate coating – MetaLine 785 is being applied to the weir trap of a Swiss spillway gate. The high resistance to impacting solids such as stones and floating debris were reason enough for the customer to choose MetaLine . . .

Non-stick coating - seamlessly lined with MetaLine 760 in the salt water section of a pump system. Limescale build-up and fouling of the narrow pipe diameter no longer stand a chance

Turbine protective coating - a 2 mm MetaLine 785 coated hollow jet valve of a pumped storage power plant in Luxembourg. The explosive mixture of fast-flowing water, abrasive suspended particles and impacting foreign debris such as wood speaks for the use of rubber-like protection!

Coating repair - not our bread and butter, but nevertheless an important product property for high-performance linings: The ability to repair or recoat when age has left too many traces. MetaLine Series 700 coatings can be repaired and recoated at any time!

Cooling water pipe coating - Inlet area of a power station cooling water pipe coated with 3 mm MetaLine 785. Salt water and foreign debris can practically no longer destroy this coating

Offshore coating - an impressive example of greatness. On-site coating of a pipe section with MetaLine 795 in OEM quality. MetaLine is not a supplier of industrial internal pipe coatings - but only when parts of it need to be coated directly on site . . .

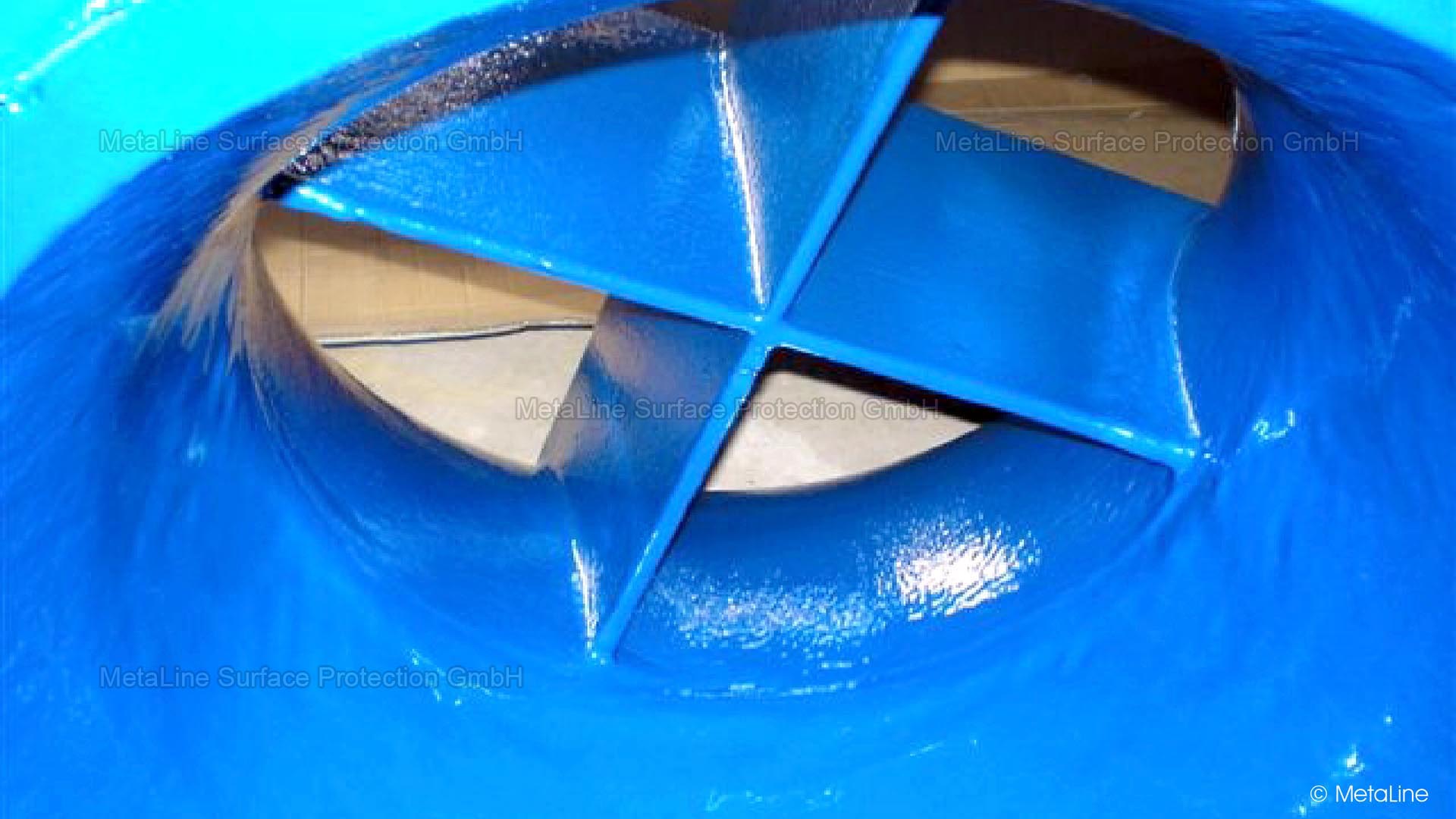

Flotation cell coating - MetaLine stands for professional material quality and a professional finish. Here during the application of MetaLine 785 in a flotation tank

Drum washing systems coating - fresh water, salt water, de-mineralized water, sewage water - a domain of MetaLine. Here on a large washing drum for potato starch production in northern Germany. The system was coated inside and outside at the same time when installed!

Steel sealing - not in the water - but on the water! Here, hundreds of windows on an offshore residential platform were sealed. The steel window frames showed cracks which were bridged and sealed with MetaLine 785!