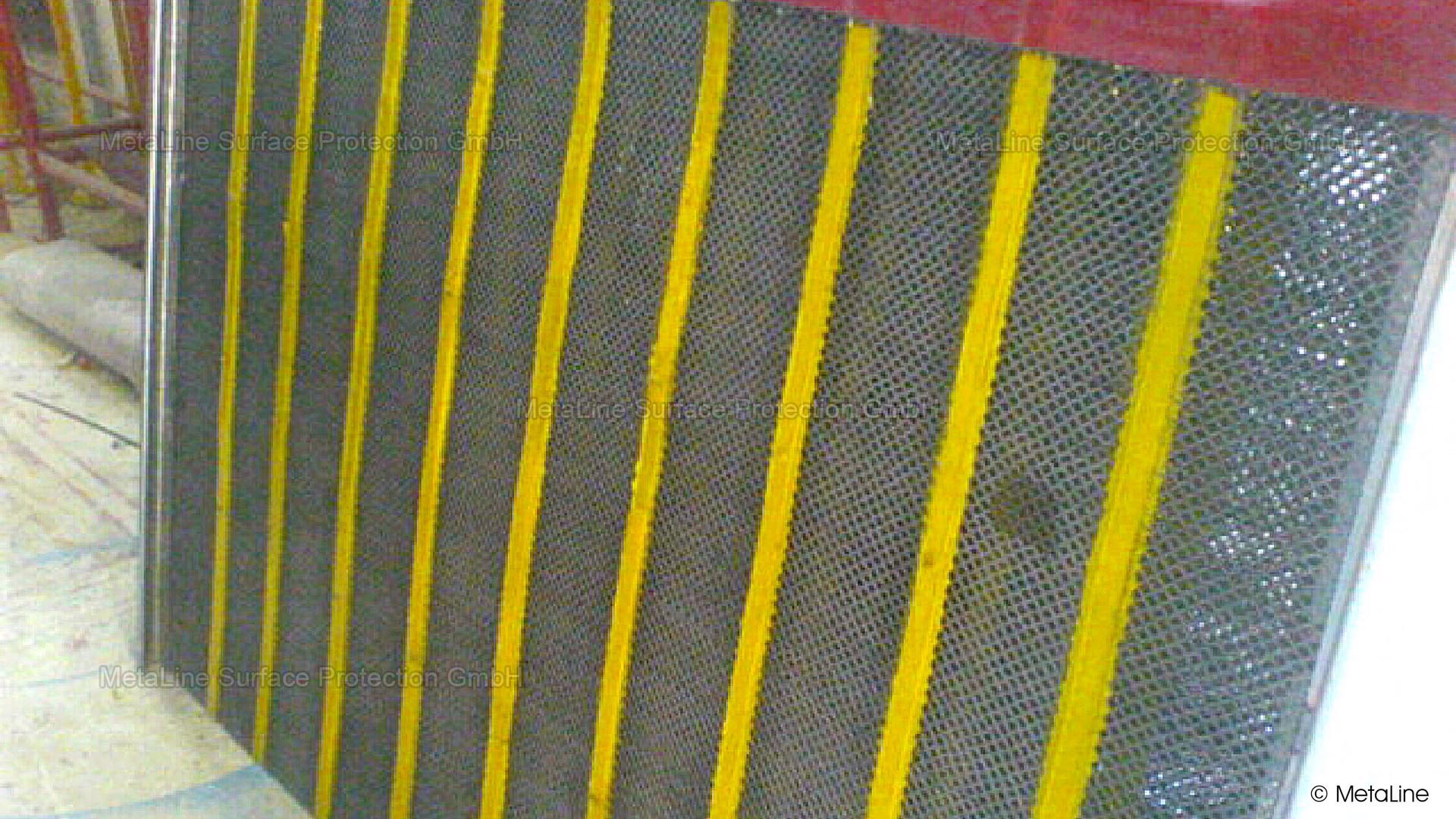

Screen coating - 2-deck system seamlessly coated with 2 to 6 mm (80 to 240 mils) MetaLine 785 on the way to the installation site

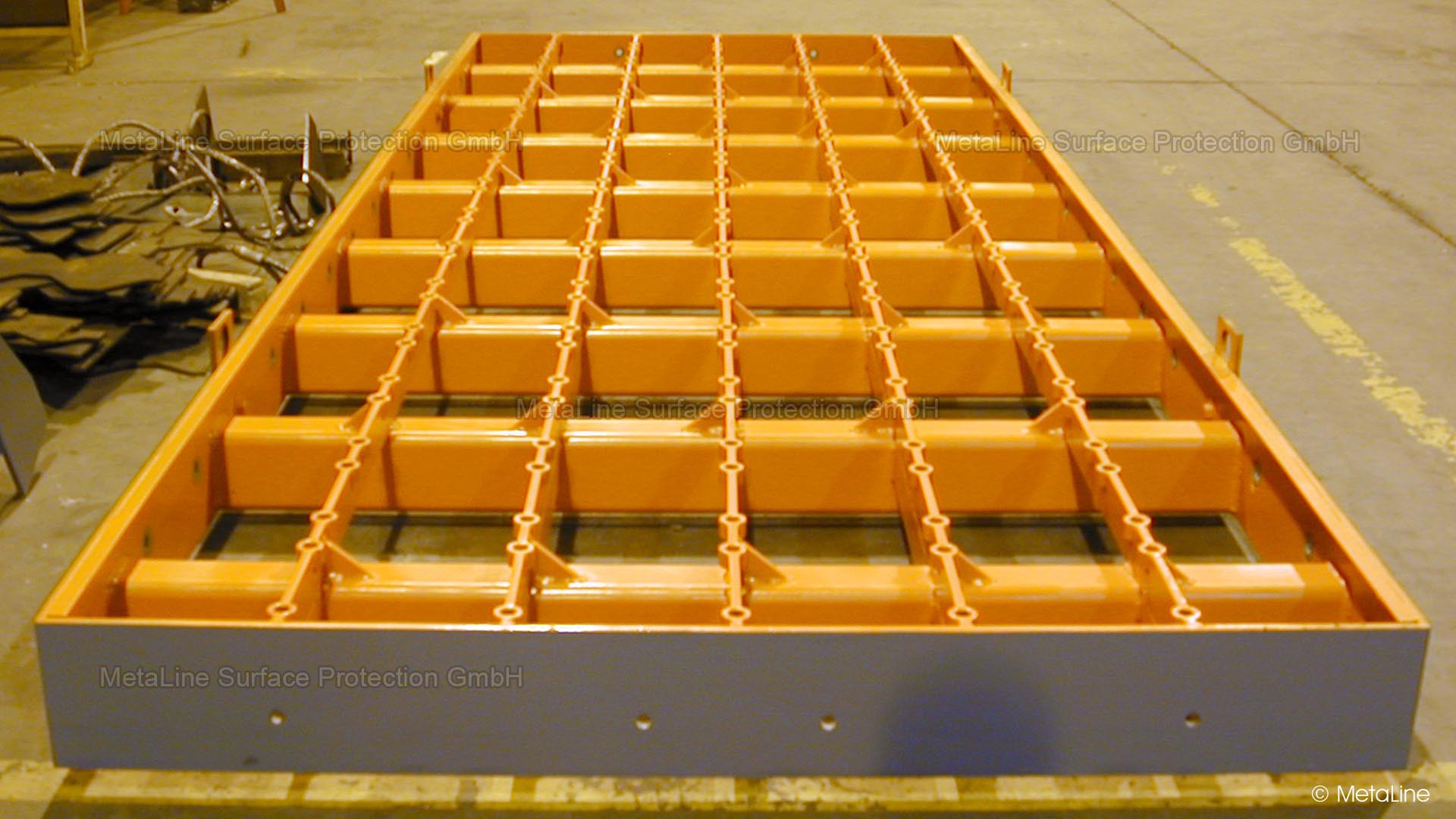

Screening machine lining - partial protective coating with MetaLine 785 in the area above and below the screen beams

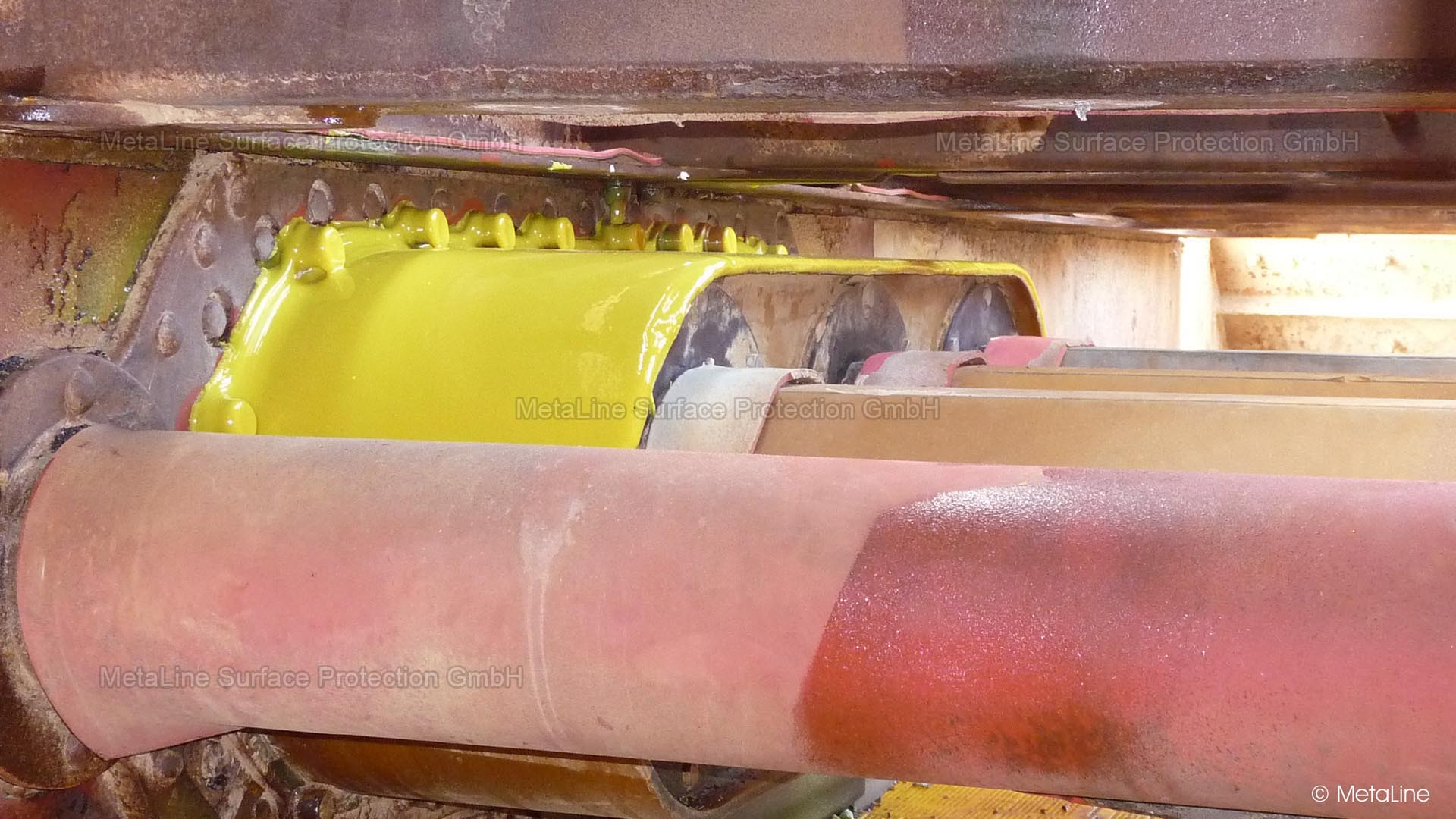

Screening machine repair - a completely seamless wear protection made of 4 mm MetaLine 785 protects this beam from loss of substance on all sides

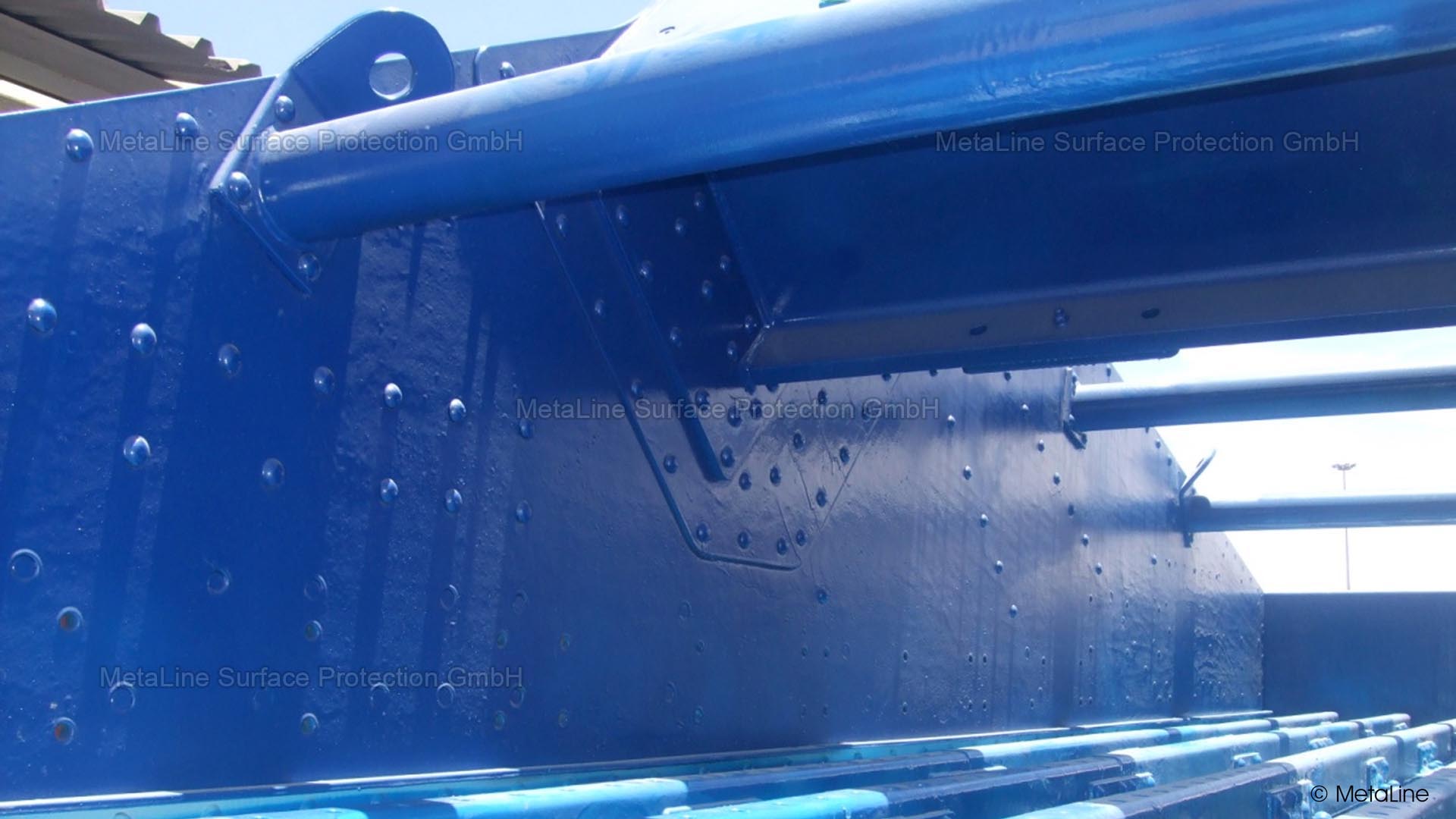

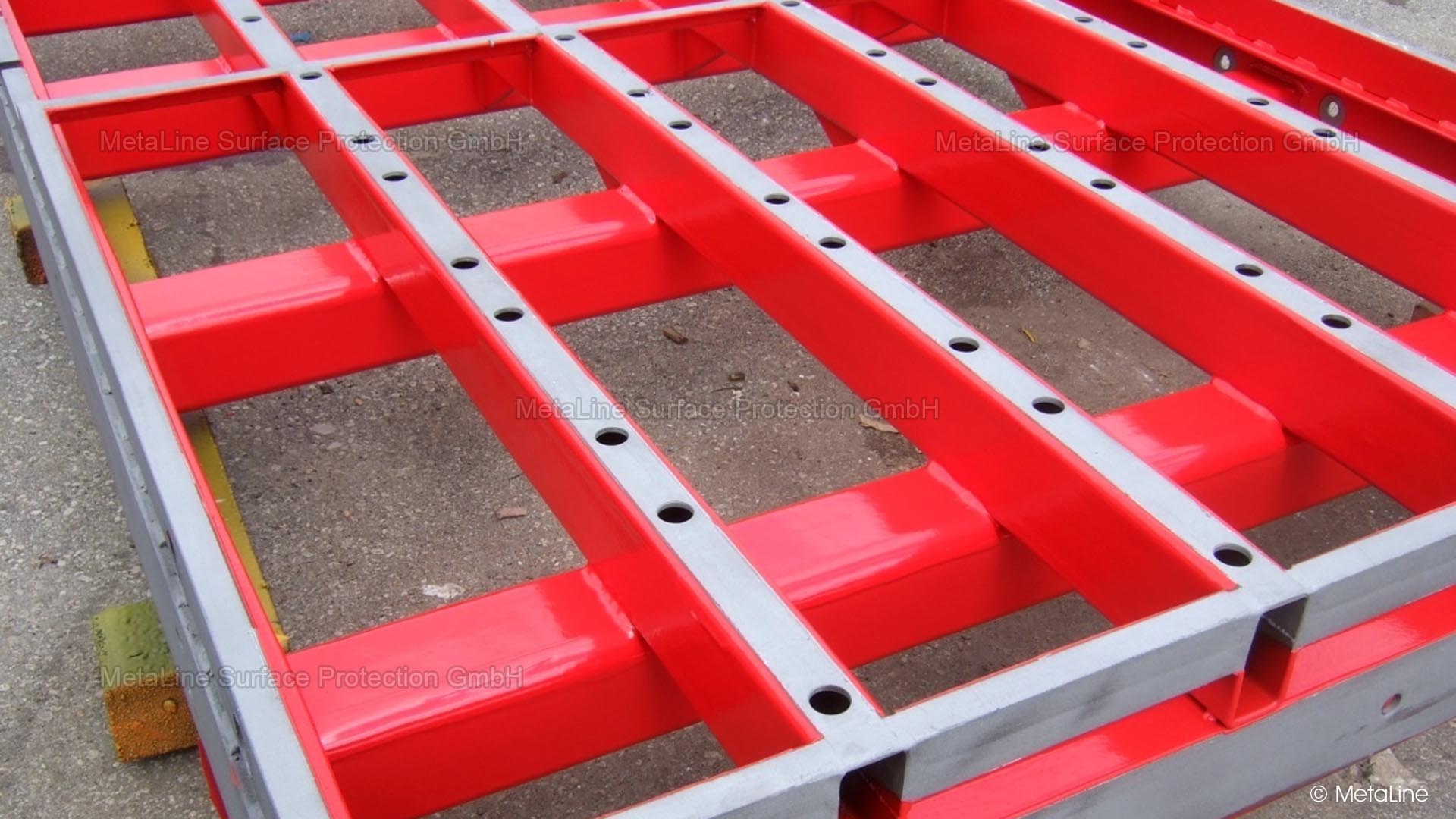

Supporting steel structure for the PUR-screens coated with 4 mm MetaLine 785

Screen coating - parts of the screen have been precisely and permanently sealed with MetaLine 785 to protect the supporting beams underneath

Screen coating - and this is the everyday life of the screening machines and the MetaLine 785 protective coating. Here in a zinc mine in Namibia!

Screening deck repair - complex geometries on the supporting structure. A case for the MetaLine 785 sprayable protective coating. No bolted or bonded coating develops this level of perfection at the crucial points

Multi-deck screening machine - seamlessly sealed was the customer requirement for this wet screening machine. The coating was applied directly at the plant manufacturer in Dülmen (Germany) as an OEM coating

Sizer coating - multi-deck screening machine after complete coating with 3 mm MetaLine 785. Seamlessly closed like with paint - but more durable than rubber!

Screening deck repair – wear protection at hard to reach areas is a particular strength of the MetaLine Series 700 coating system. Where no human hand can reach anymore to properly glue down rubber sheets, the MetaLine Cartridge Spray will cover the surface and secure a proper result

Screen coating - MetaLine 785 seamlessly applied here for a zinc mine in Central Africa. Our more than 60 years of experience is the decisive difference. Nothing gives you more security!

Screen lining - consistent seamless precision. MetaLine offers coating concepts ranging from initial factory coating to local on-site repair technology. The result is not only technically impressive, but also visually satisfies every customer

Screen frame protection - In the beginning, MetaLine simply had the idea of processing wear-resistant "rubber" seamlessly and without vulcanization. Here is the sprayed result - today in many countries THE technical standard for high-performance wear protection in screening technology

Screen frame coating - partially coated with 4 mm MetaLine 785, not easy to apply but technically proven with the famous "Made in Germany" perfection!

MetaLine coatings in continuous wet use. Tried, tested and used by many well-known screening machine manufacturers as an OEM coating. Not because it is cheap - but because it delivers what you expect from it!

Tumbler coating – MetaLine 795 being applied in a thickness of 1,5 mm to the lower bottom part of a tumbler. The application was realized as OEM coating directly in the manufacturing plant of the south German equipment manufacturer