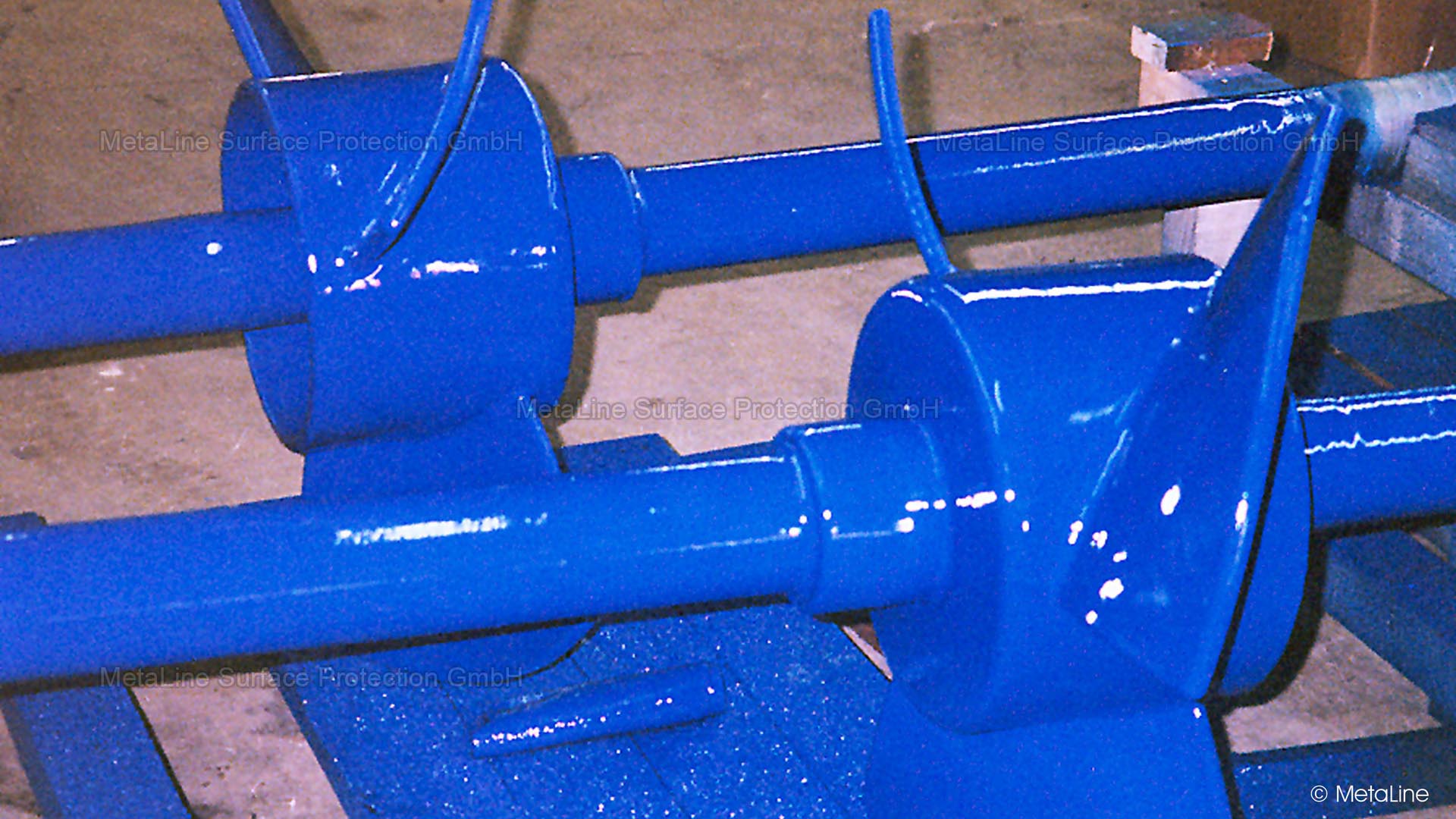

Archimedean screw – special dimensions require special protection – MetaLine is you on-site partner

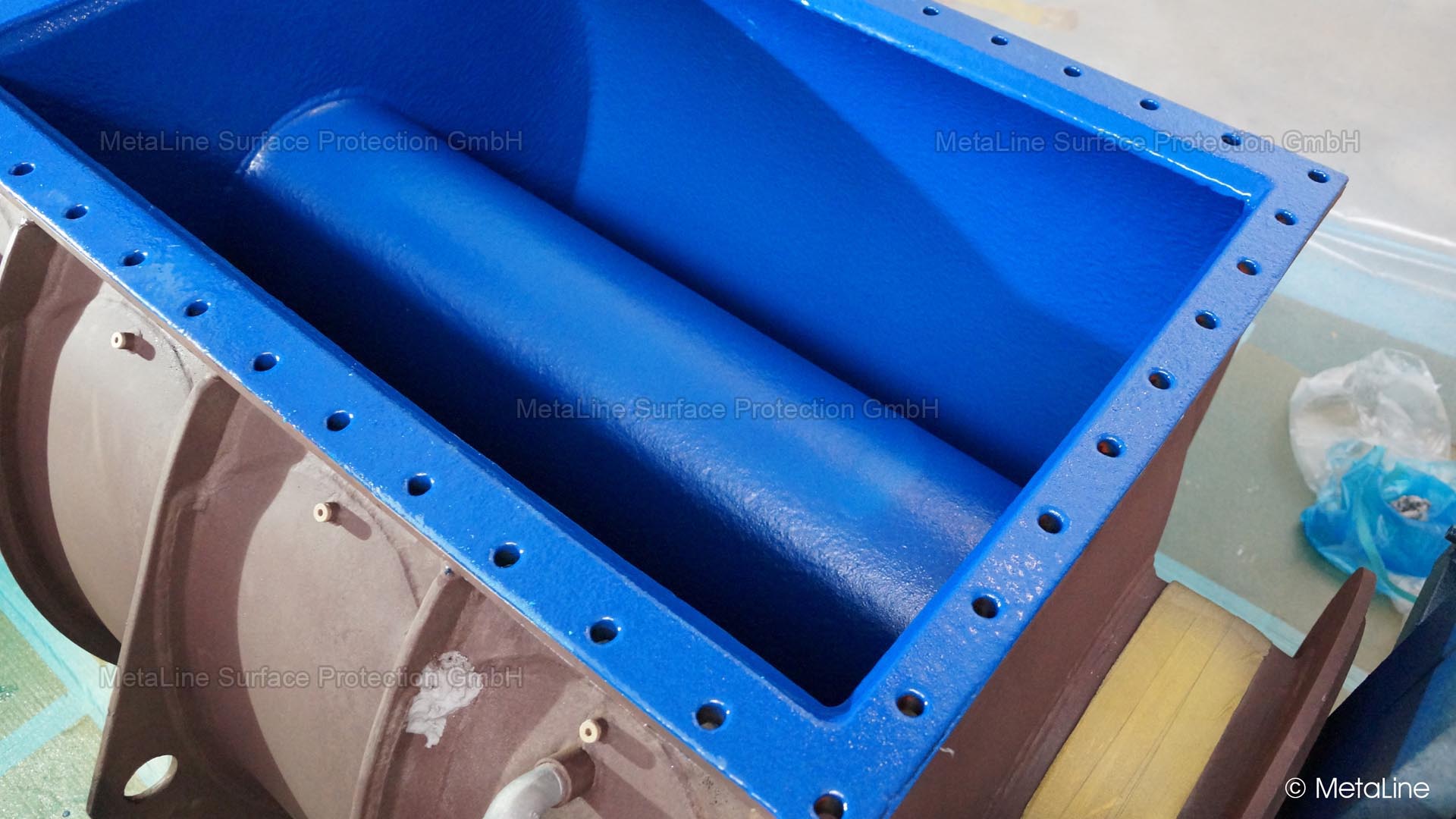

Mixercoating – a good coat of 3 mm MetaLine 785 is used to protect this alumina-mixer from wear and chemical attack

Feeding in a sewage plant – no problem at all with MetaLine Coating Systems

Dissolver coating – MetaLine Series 700 coatings are also available in a pigment-free version (natural) and are thus suitable for pure mixing processes as in silicon manufacturing

Mixer lining – Wear prevention, non-stick properties, metal free character, low investment costs – many different demands to a single coating. MetaLine covers all...

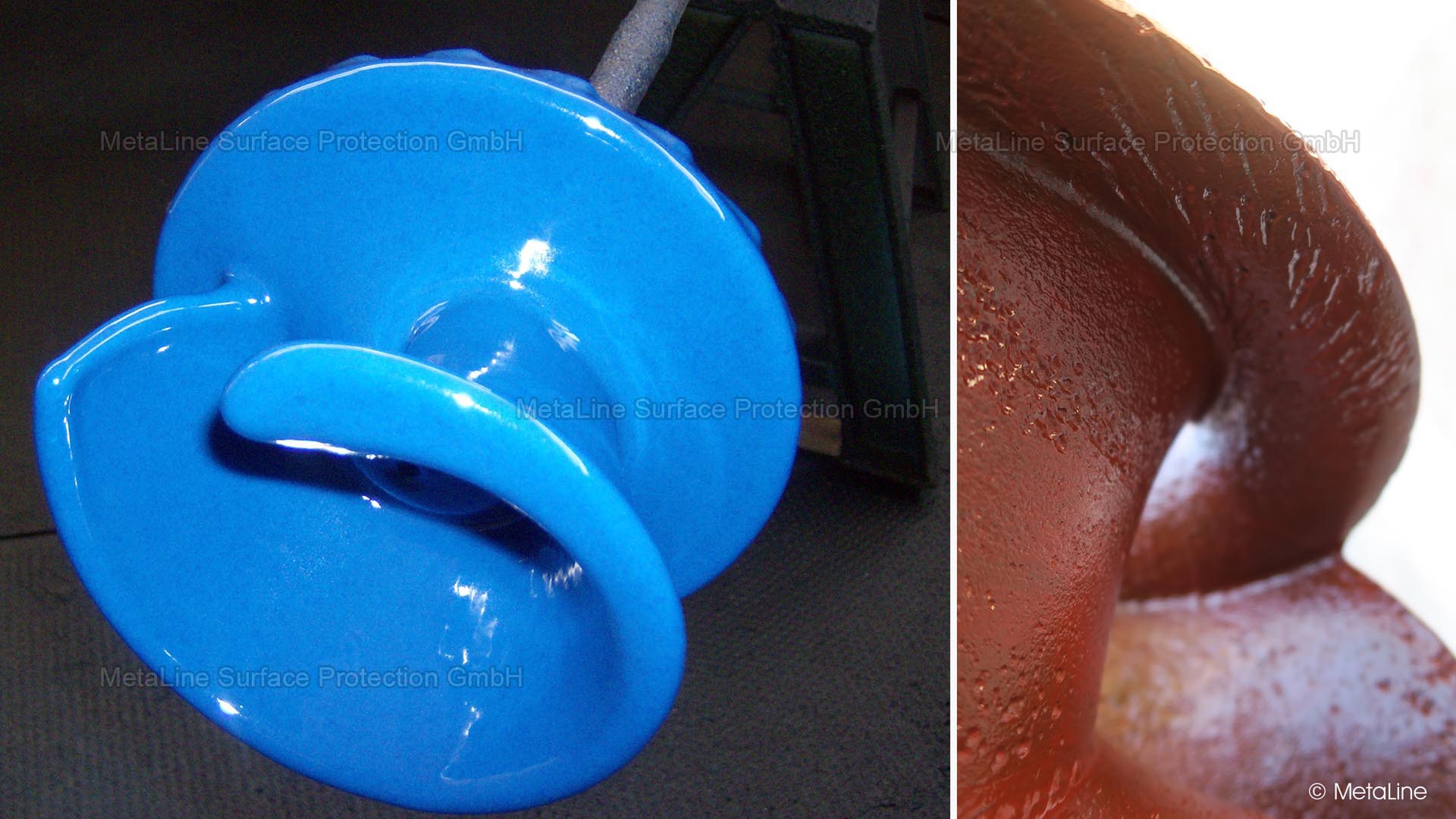

Mixer coating – an elastomeric coating with MetaLine 785 protects this mixer from wear and improves its cleanability

Mixer protective coating – MetaLine 785 protects this massive mining mixershaft from fast mechanical attack

Edge protective coating – a project work from South Africa. The threatened edges of mixers coated with MetaLine 785 up to a thickness of 10 mm

GFRP agitator for use in sewage plants – MetaLine coating protects against mechanical damage, chemical attacks and infiltration of GFRP

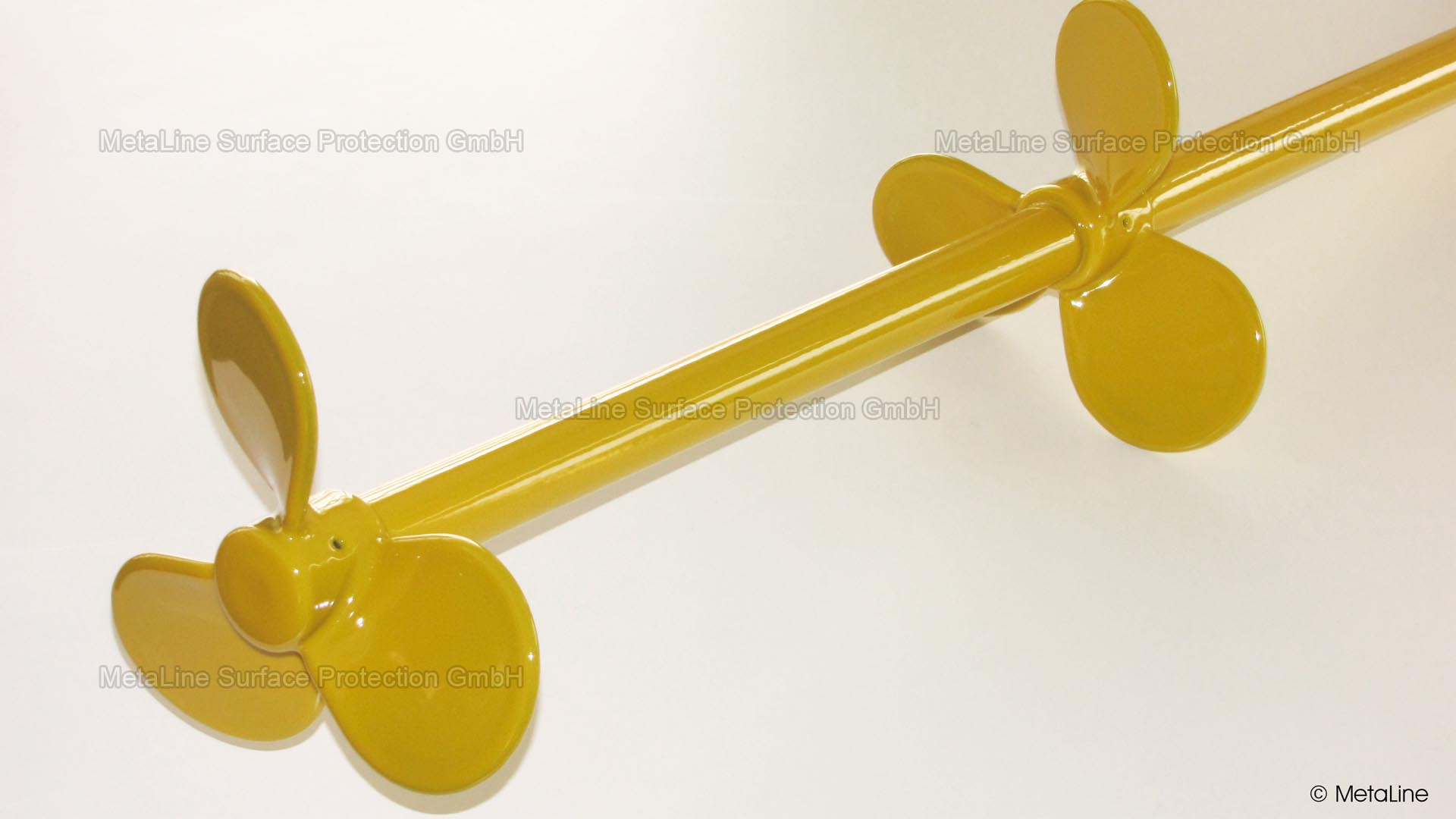

Stainless steel agitator coated with MetaLine 795 in order to assure there is absolutely no metal contact with the mix (ceramic color powder)

Blademixer coating – a coating of 2 mm MetaLine 795 protects against build up of residues and forms an effective non-stick surface character. Wear and abrasion of the equipment is minimized

Mixer protection – MetaLine 795 as a combination of anti-wear coating and functional non-stick cover being free of silicone

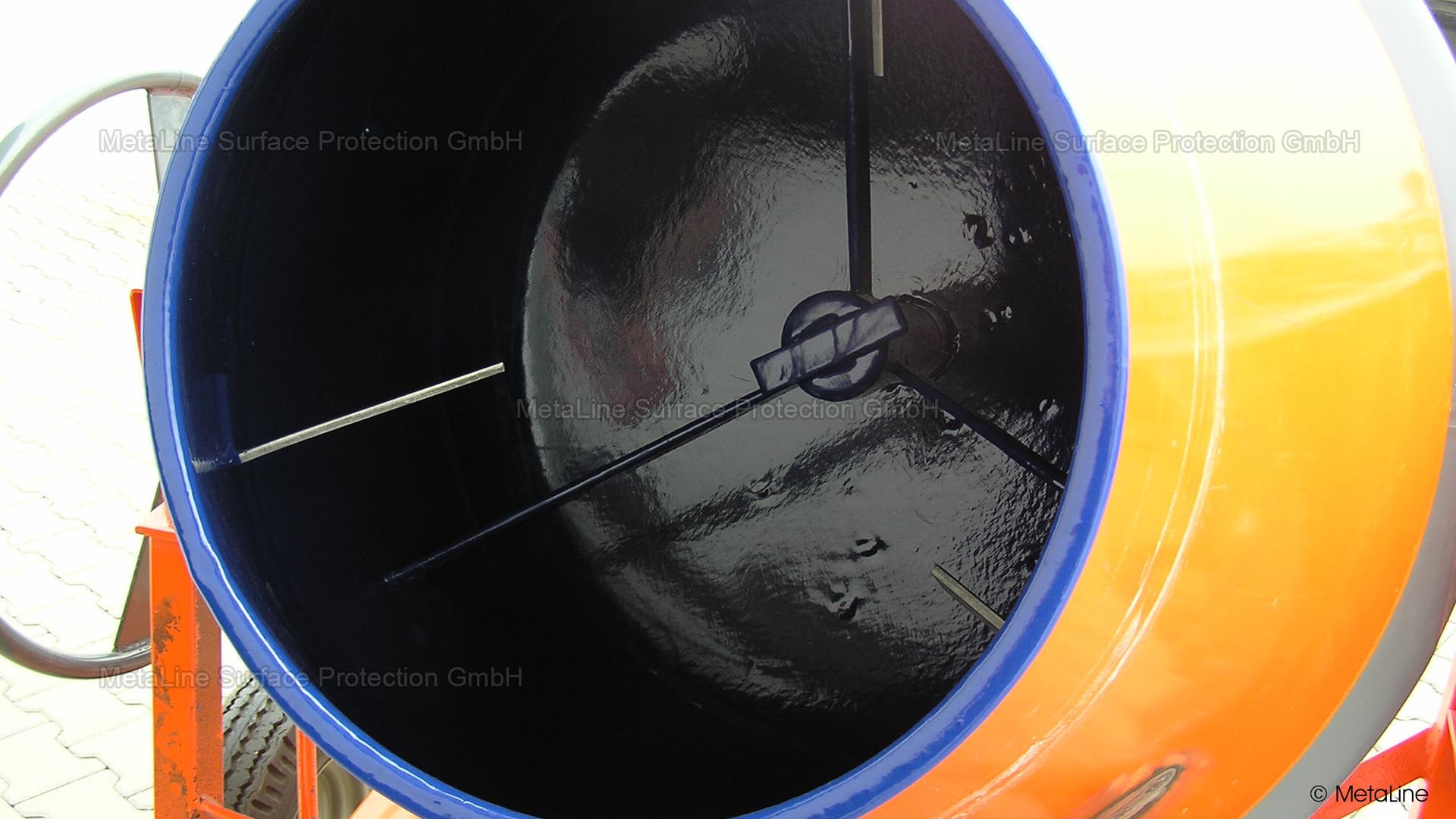

One of the most popular items to mix – with MetaLine there is no corrosion and less sticking

Mixer tray coating – who would have the idea to do a rubber lining inside such a complex geometry? All those who miss the knowledge that a sprayable elastomer can be implemented more durable – the special topic of MetaLine

Mixer lining – a complex geometry which is impossible to protect by common rubber linings. However a seamless sprayed MetaLine 785 elastomer can do so...

Blade mixer in a pipe conveyor – coated with MetaLine 795

Stirrer coating – elastomeric surfaces develop a tremendous resistance against impacting and scratching forces. MetaLine Series 700 elastomeric spraycoatings optimize this by its seamless character further enhancing the operation life