MetaLine – first choice irrespective of dimensions

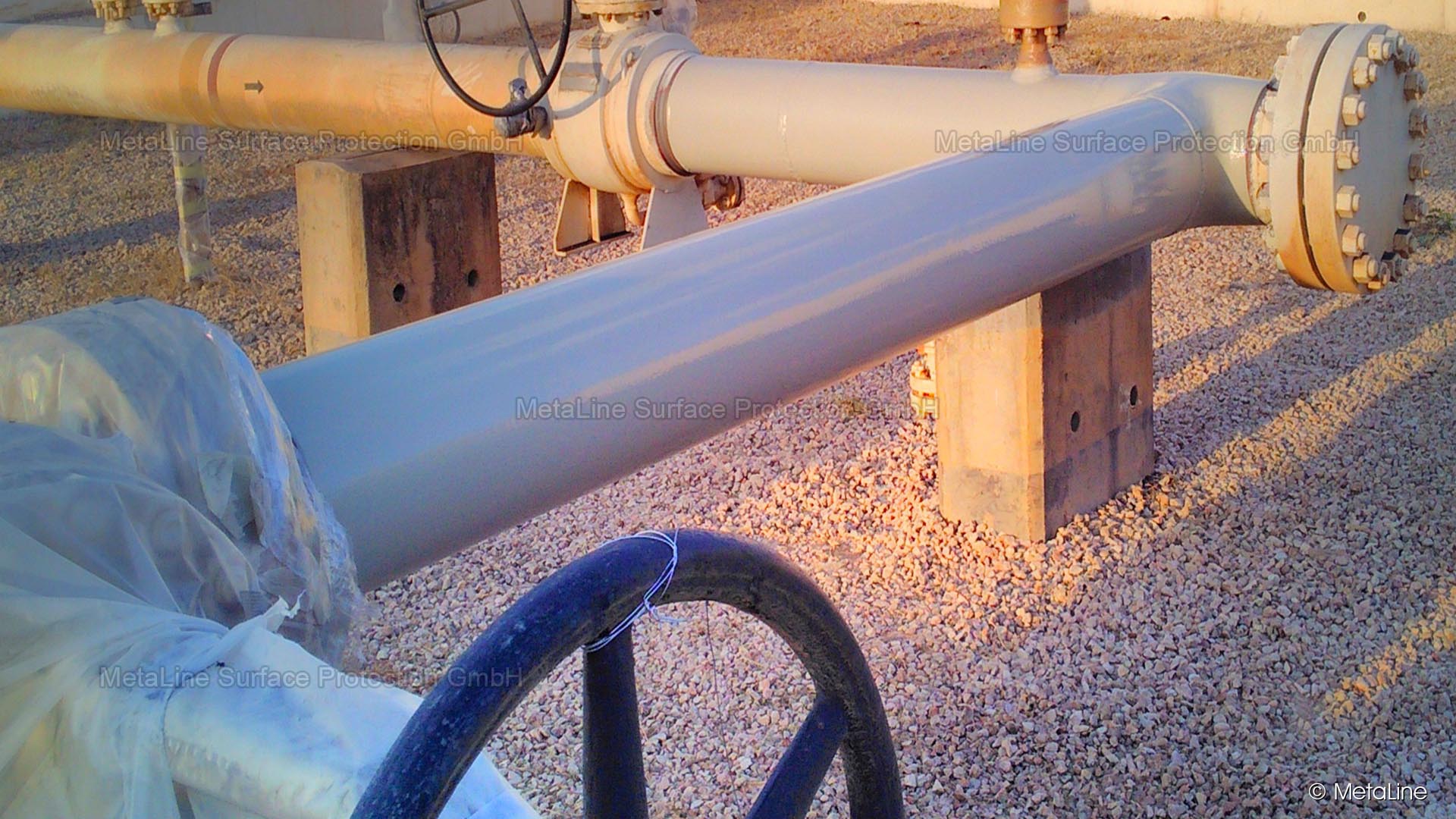

Outside pipe coating – nevertheless if pipes are buried in the earth or exposed to atmospheric conditions – permanent elastomeric MetaLine Series 700 coatings come into the game, when unusal high performance requirements do exist...

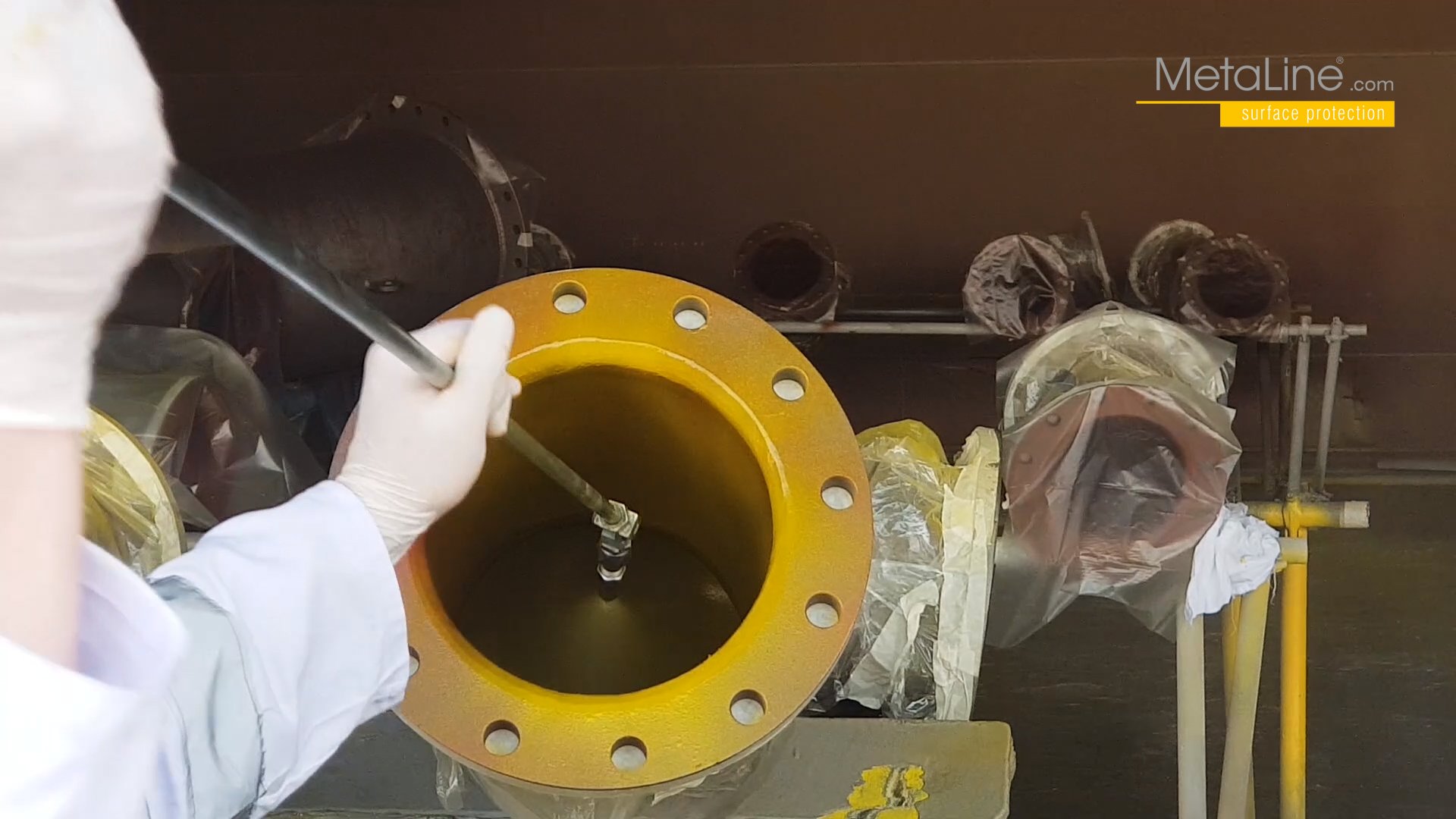

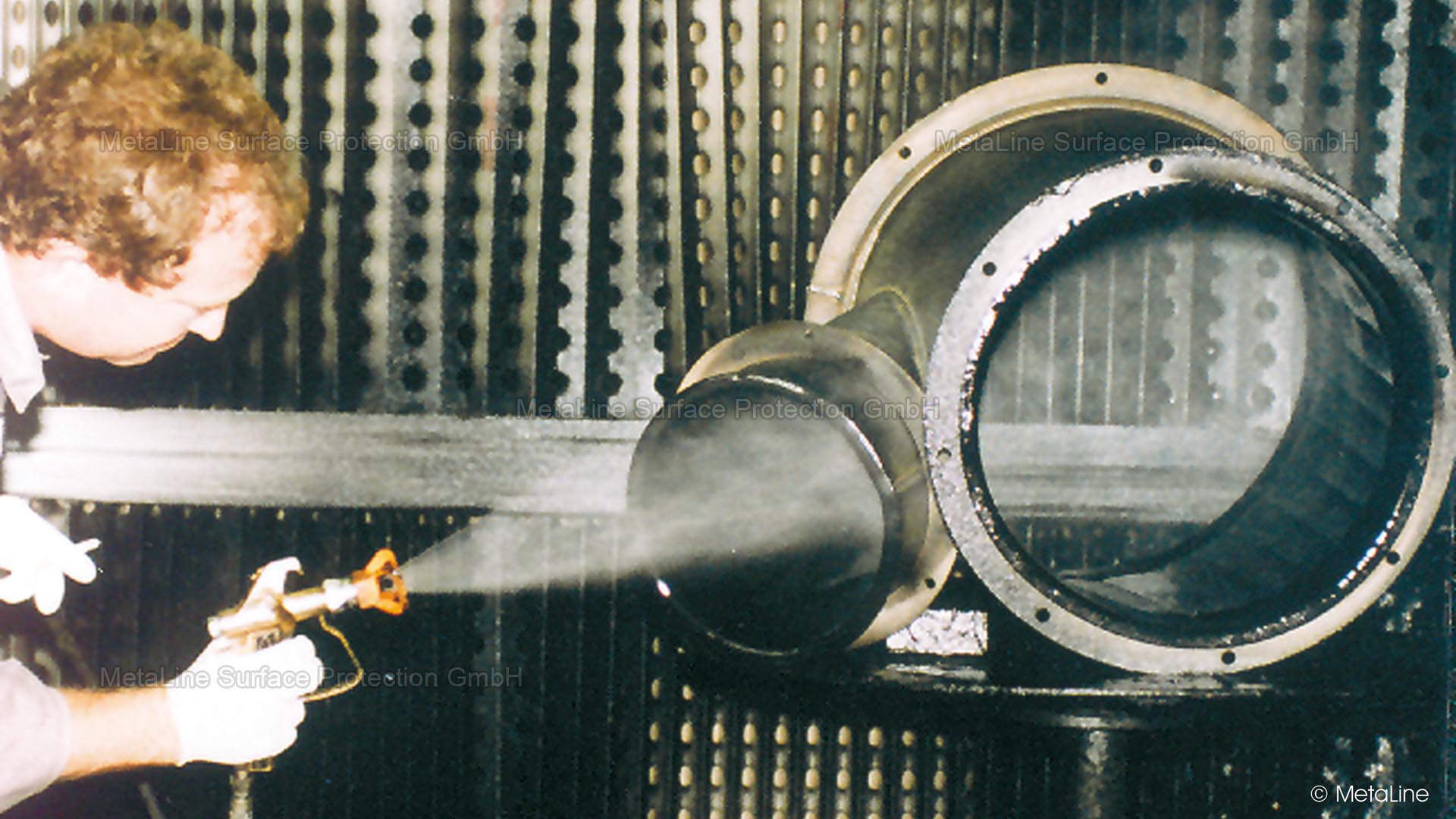

Coating Gun – The MetaLine Applicator S700 is a fascinatingly safe and easy application tool. Except compressed air with about 5 bar nothing is needed. And the best? NO cleaning! The coating material is NOT passed through the applicator, so no cleaning work is required after the end of work. The mixing nozzle is a disposable item and is easily exchanged for the next use.

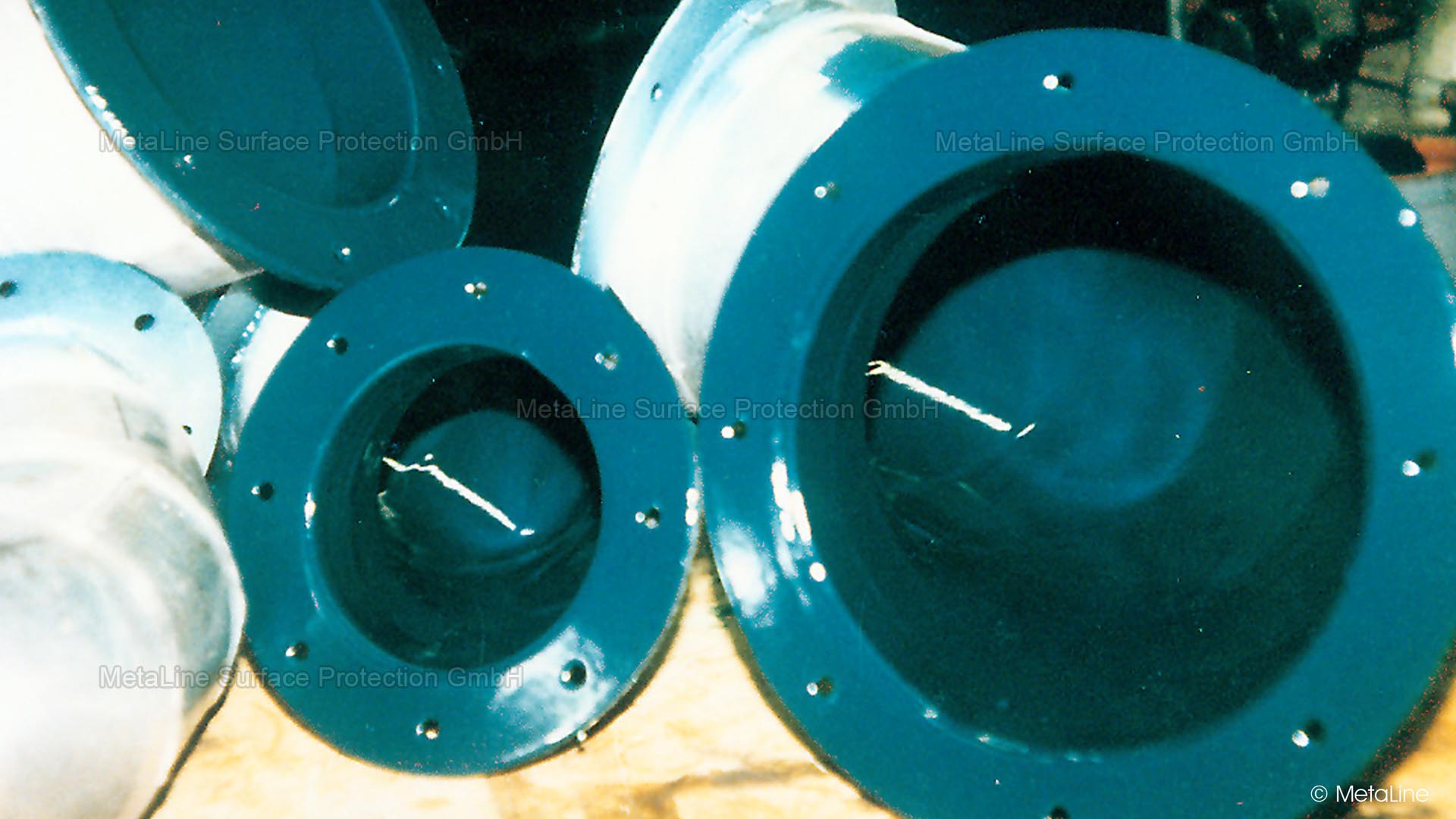

Pipe coating – when paints and varnishes are not effective anymore. MetaLine’s elastomeric coatings solve various corrosion protective und wear preventive duties

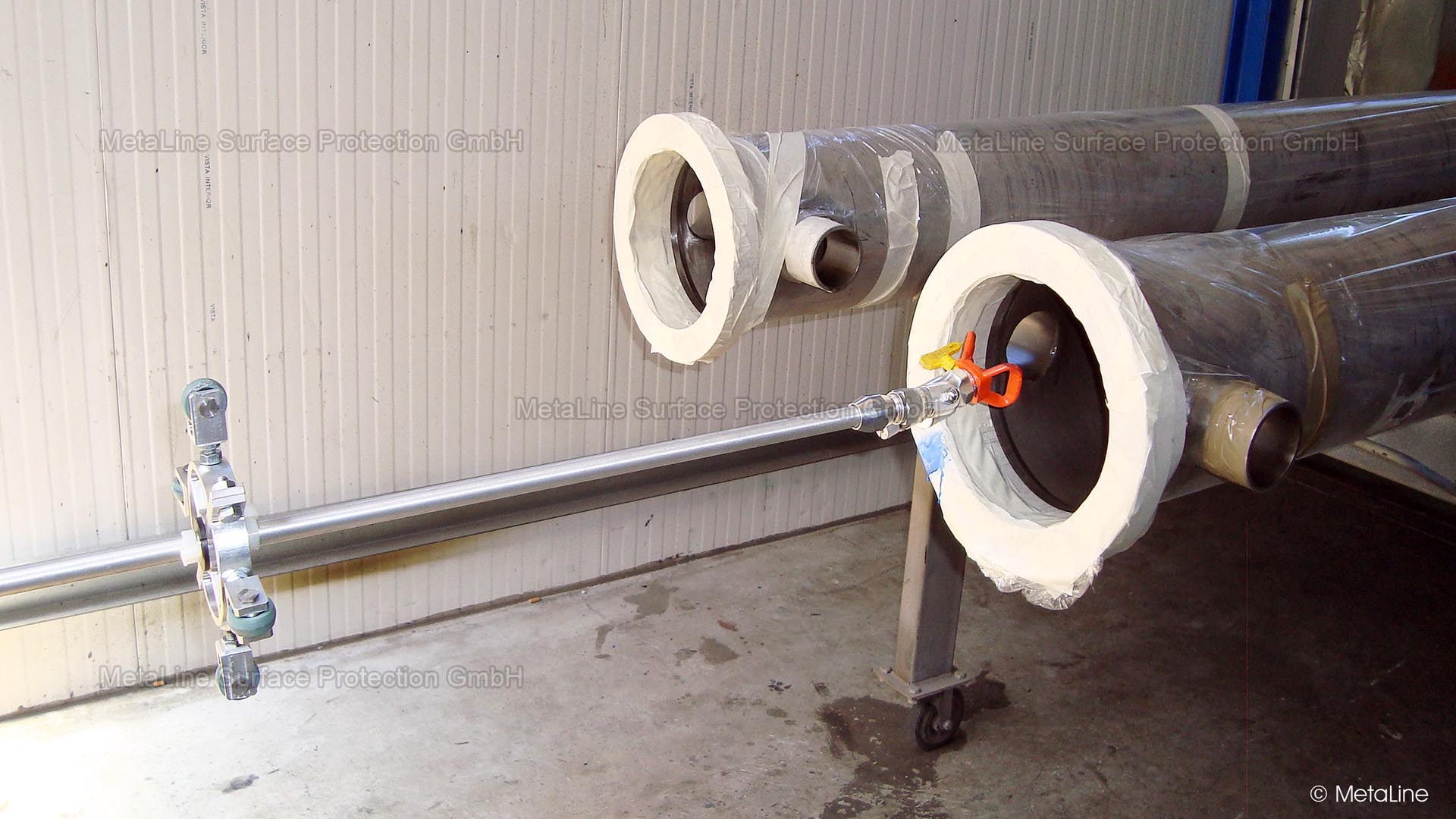

Pipe protective coating – MetaLine 795 as saltwater resistant, rubberlike inside coating of these fire fighting water pipes on board of a ship

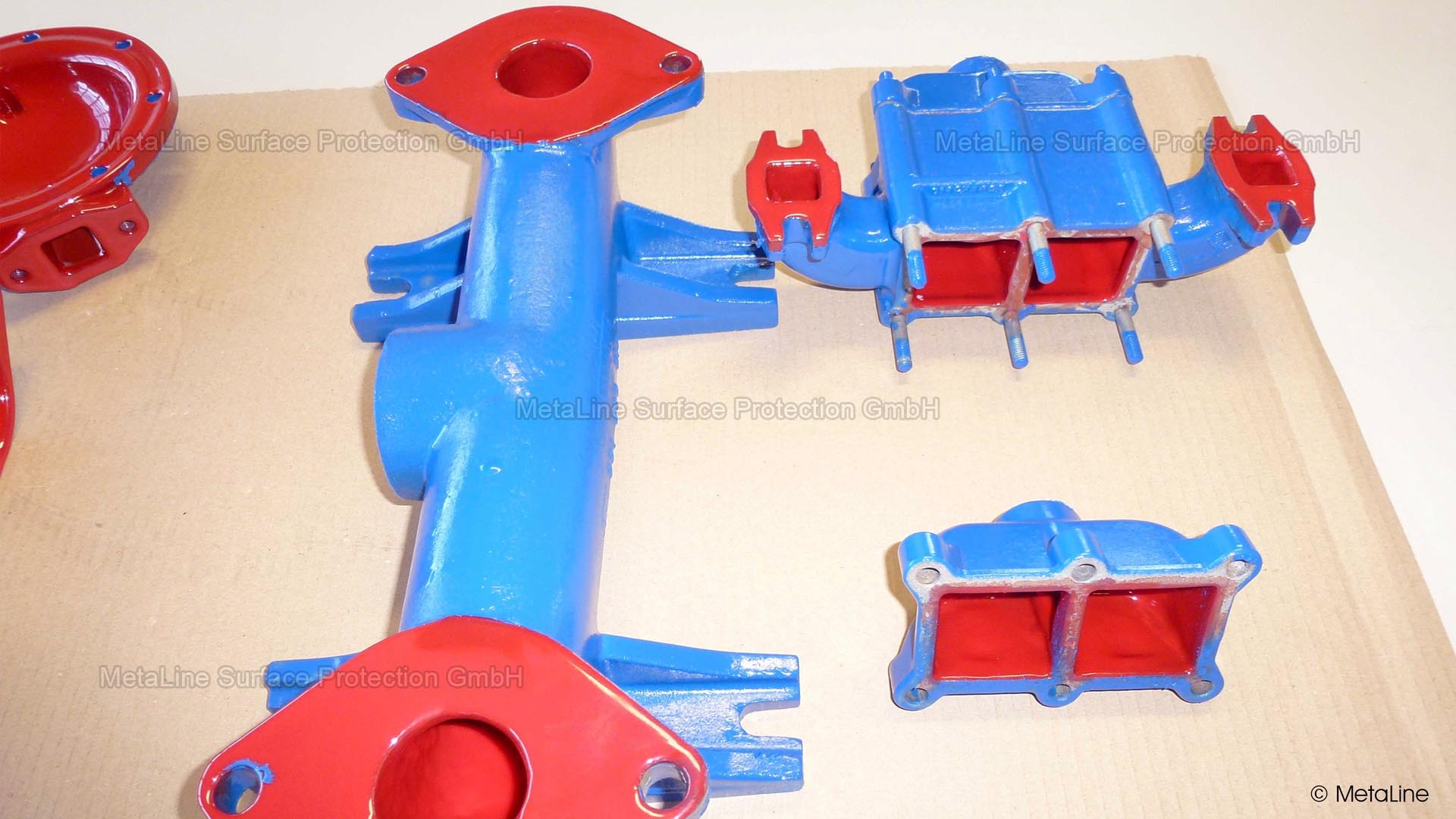

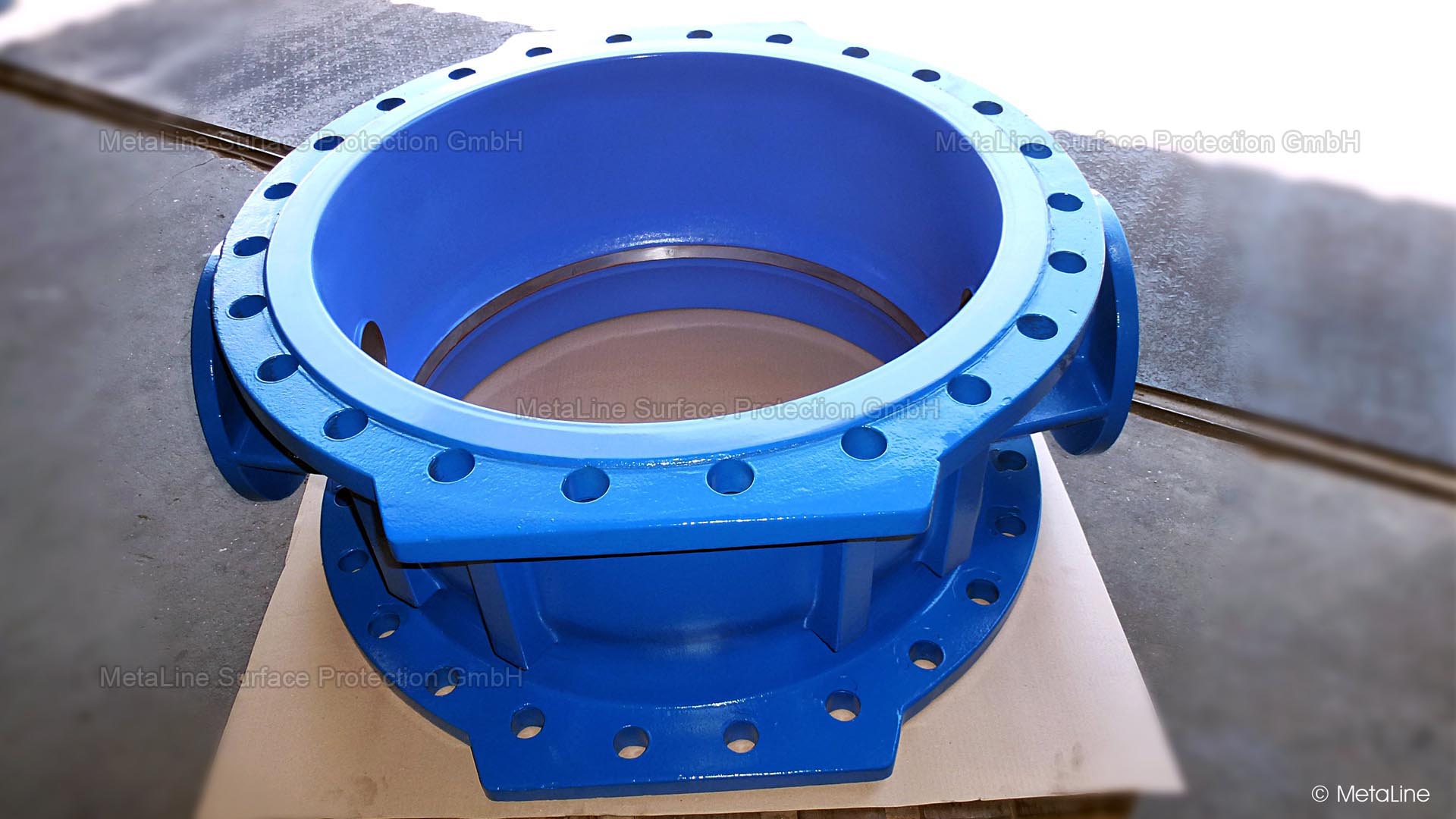

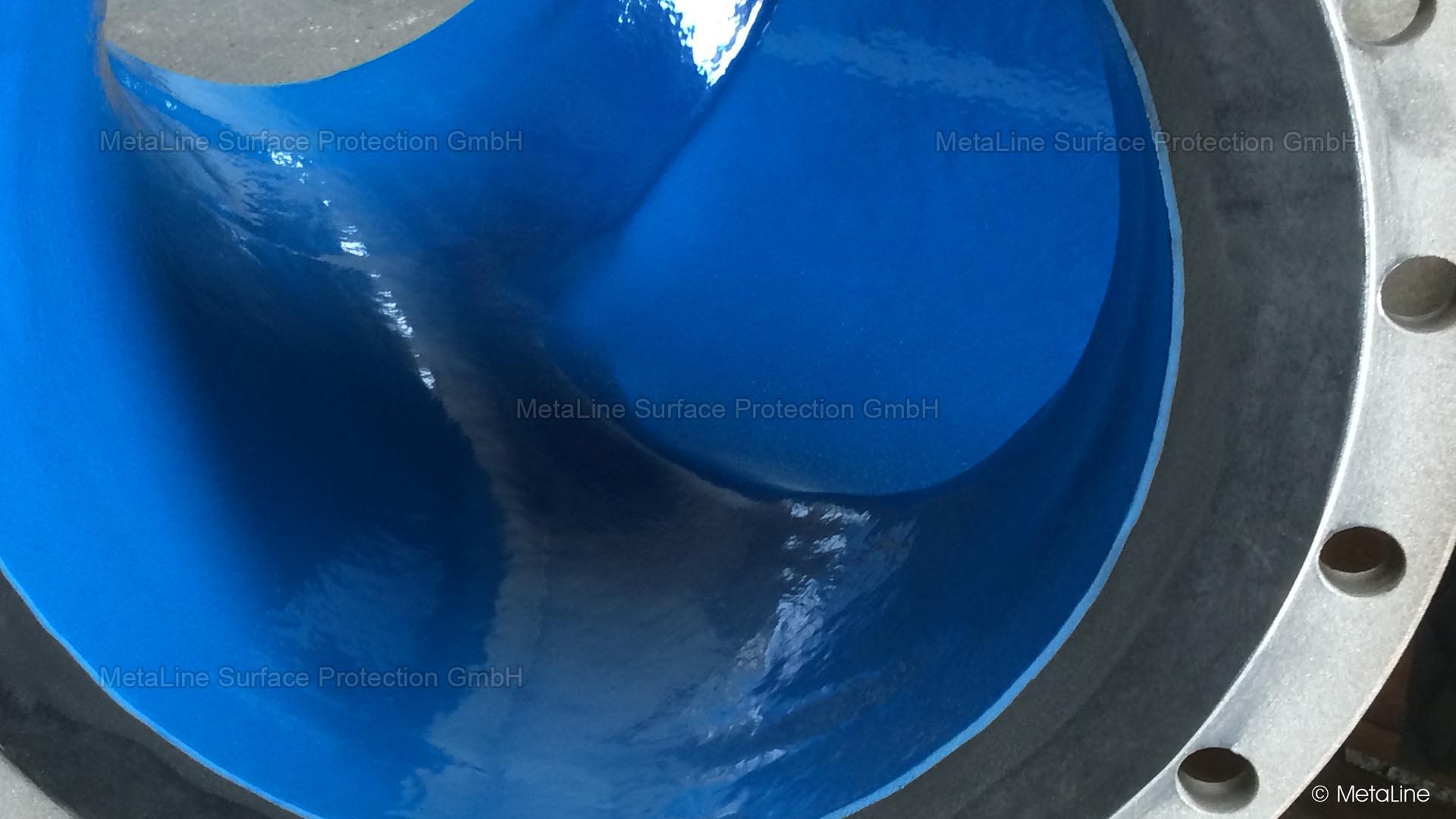

Valve coating – MetaLine 795 in a thickness of 1,5 mm protects this part of a valve gate construction against aggressive mechanical and chemical influences

Typical for MetaLine & clever for the user – thicker, where needed, thinner, where cost can be reduced

Sleeve coating – MetaLine 100 XTM as extremely chemical resistant coating to protect theses stainless couplings

Heavy duty pipe protection – 15 mm MetaLine 785 represents an elastomeric armouring which will withstand enormous load

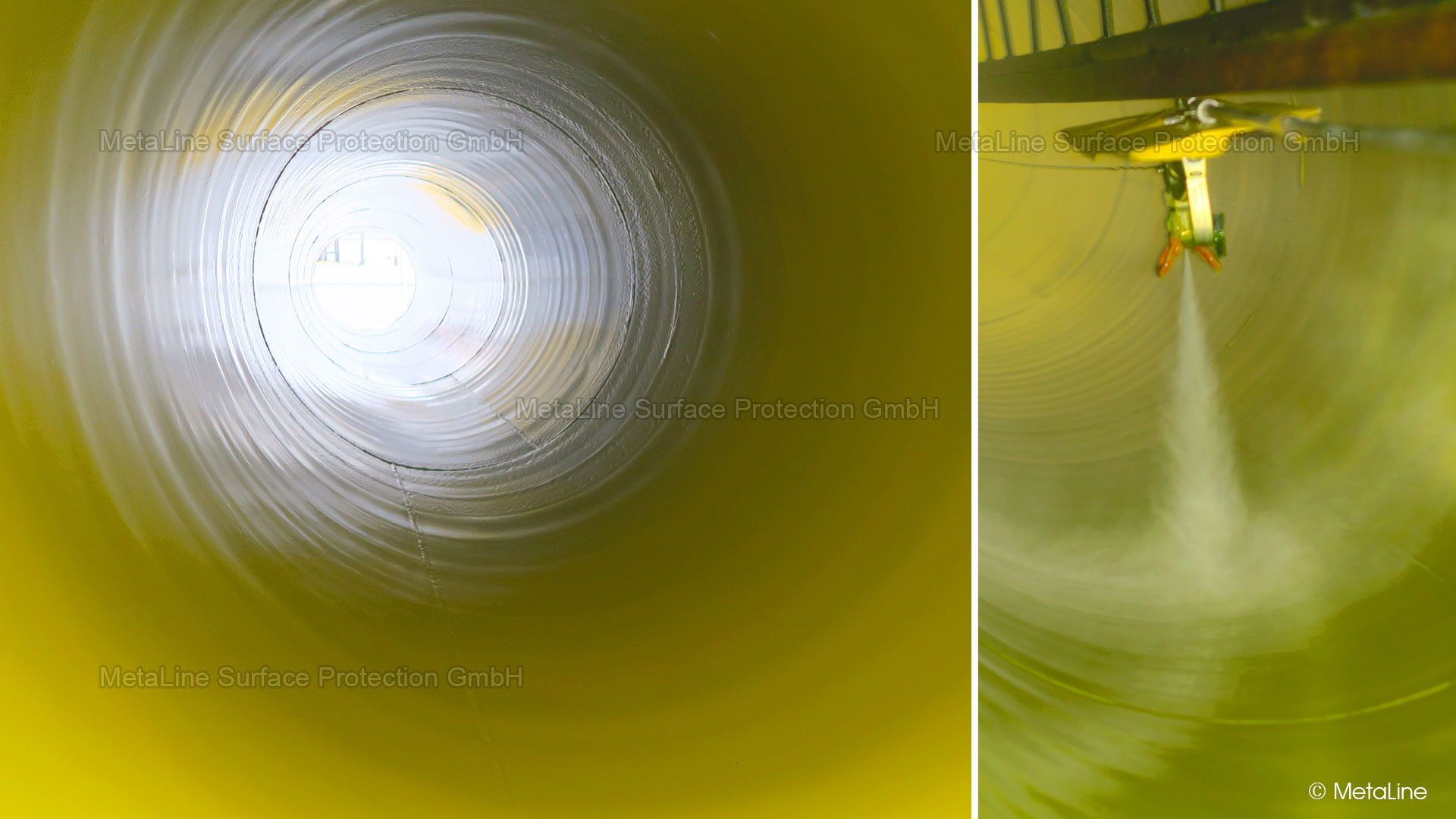

A completely different concept for interior pipe coating – longitudinal division for rapid and cost-effective coating & relining if needed

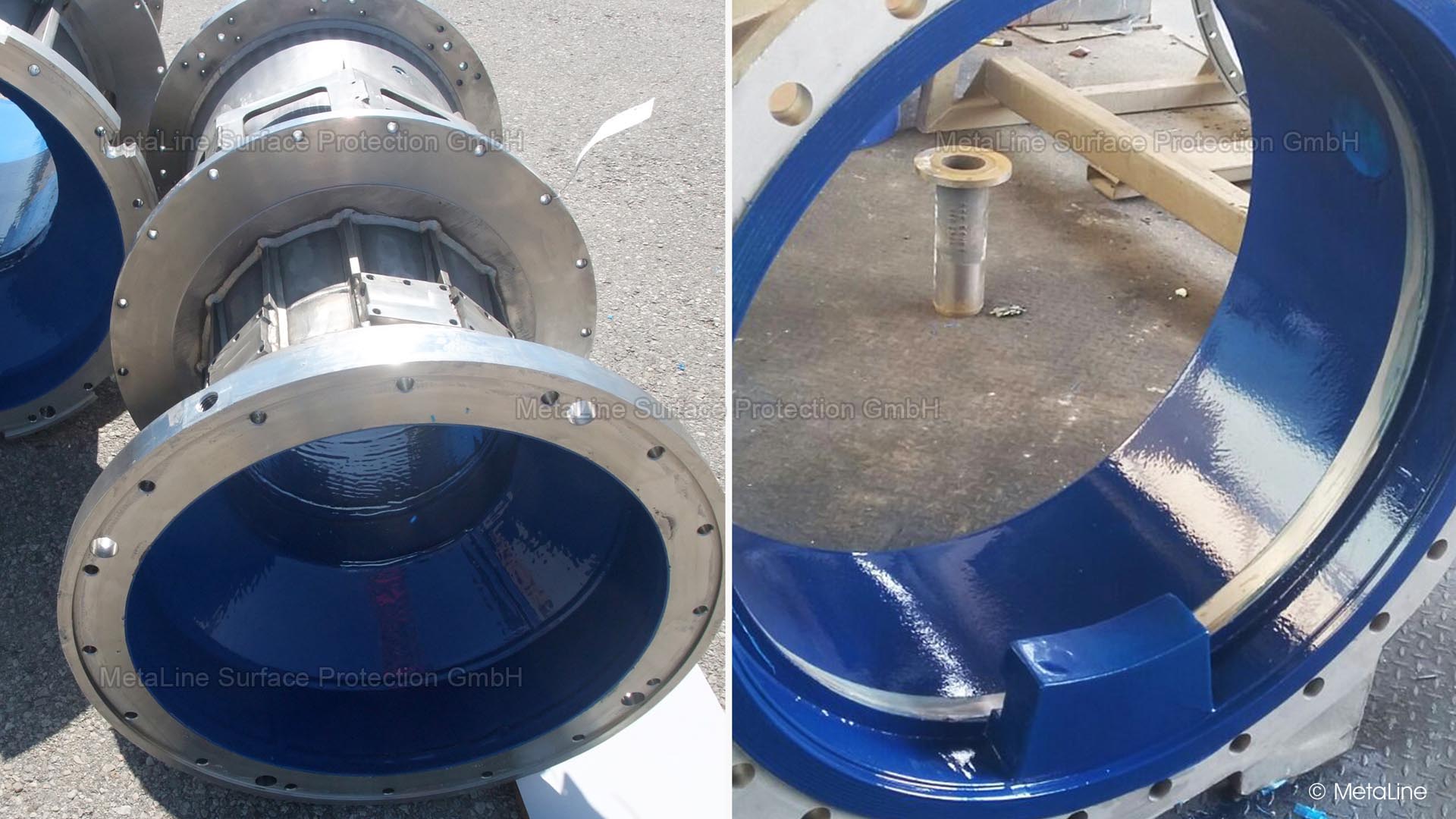

Pipeline coating - MetaLine 785 protects these pipe segments against abrasion and corrosion. Due to its on-site applicability, the flange areas can be additionaly sealed after installation

Pipe spool coating – especially in danger for rapid wear: distributing guides, tapers, Y-pieces

Protected stop valve. MetaLine is in duty – it was developd for nothing else!

Saltwater resistant coatings – MetaLine 785 as seamless in-situ elastomerification for seawater piping in all diameters

What is good on the inside, offers even better protection on the outside – MetaLine Series 700

Tube coating – MetaLine 685 as seamless inside rubberlike lining of this 2 inch pipe. Applied on-site by use of a combined pouring / tumbling procedure. MetaLine not only offers superb coating products but even unusual application procedures and field problem solutions

Cleaning pig coating – wherever pipes do exist, cleaning is a fundamental issue. MetaLine 785 is used as soft coating on cleaning pigs made out of foam. This is a simple construction but becomes an effective tool with the right MetaLine coating

Pipe bend coating – in a different way. The cathodic borderline corrosion protection MetaLine 924 is being applied. This is followed by the elastomeric encapsulation MetaLine Series 700. No epoxyceramic brand can offer such a duplex protection. A must when it comes to harsh circumstances...

Internal pipe lining - MetaLine internal pipe coatings are feasible with the “Series 500” starting from a pipe diameter of 50 mm (2 inch). But please do NOT think about trying to realize this yourself with on-board equipment - that would be naive!

Pipe coating – the on-site coating of single pipes is typically a remarkable challenge. However with the MetaLine Applicator S700 and its nozzle extension, the inside lining with the elastomeric MetaLine protective coating becomes a routine procedure

Coating satellite in use – it's not the easist operation but a very professional one!

MetaLine coating thickness is exclusively dependent on stress potential – the more aggressive the stress occurring, the ticker the protective coat applied

Pipe coating – even severely abraded or corroded surfaces could be re-vitalized by use of the MetaLine Series 700 coating system. A professional surface preparation is mandatory in each case. Simply contact us...

You look for a professional pipeline coating, corrosion resistant lining, pipe coating, salt water resistant lining? Simply ask MetaLine!

Slurry coating – typically rubber lined parts in slurry installations. Due to various seams however limited in its durability and performance. MetaLine offers a superior lifetime by using a seamless, tension-free installed, homogenous spray-coating...

Rubber lining – to overcoat existing rubber? For what? To receive an improved abrasion resistance, to change the coefficient of friction, to improve the surface smoothness, to get rid of seams. You require something else? Simply dial +4970343111!