Coated on site with temperatures amounting to 40°C and more than 90% humidity with MetaLine Series 700 cartridge spray system

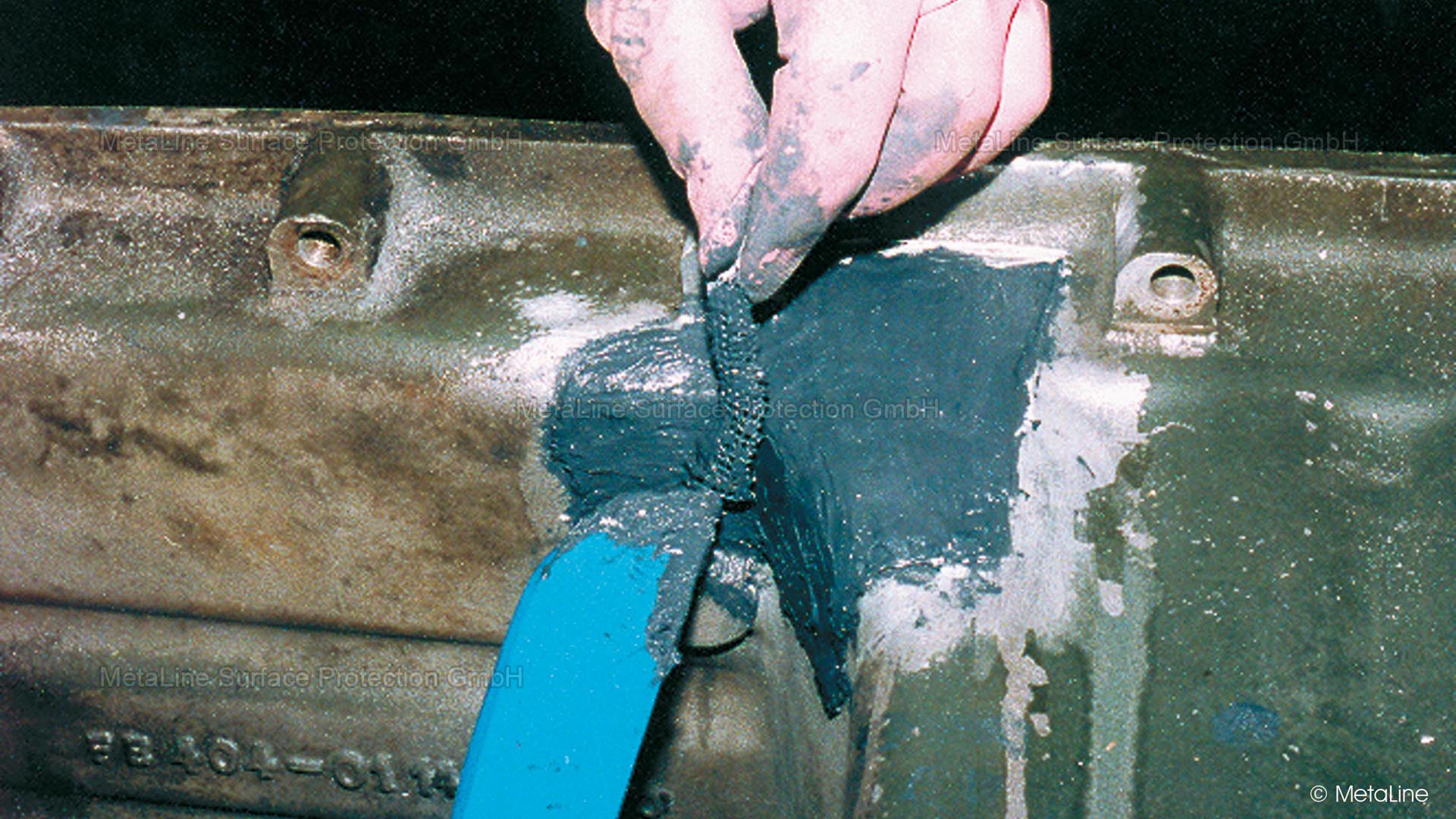

Leaking oil pan during repair preparation – the crack is widened in V form

During oil pan sealing with MetaLine Ceramic Repair Compound SXL

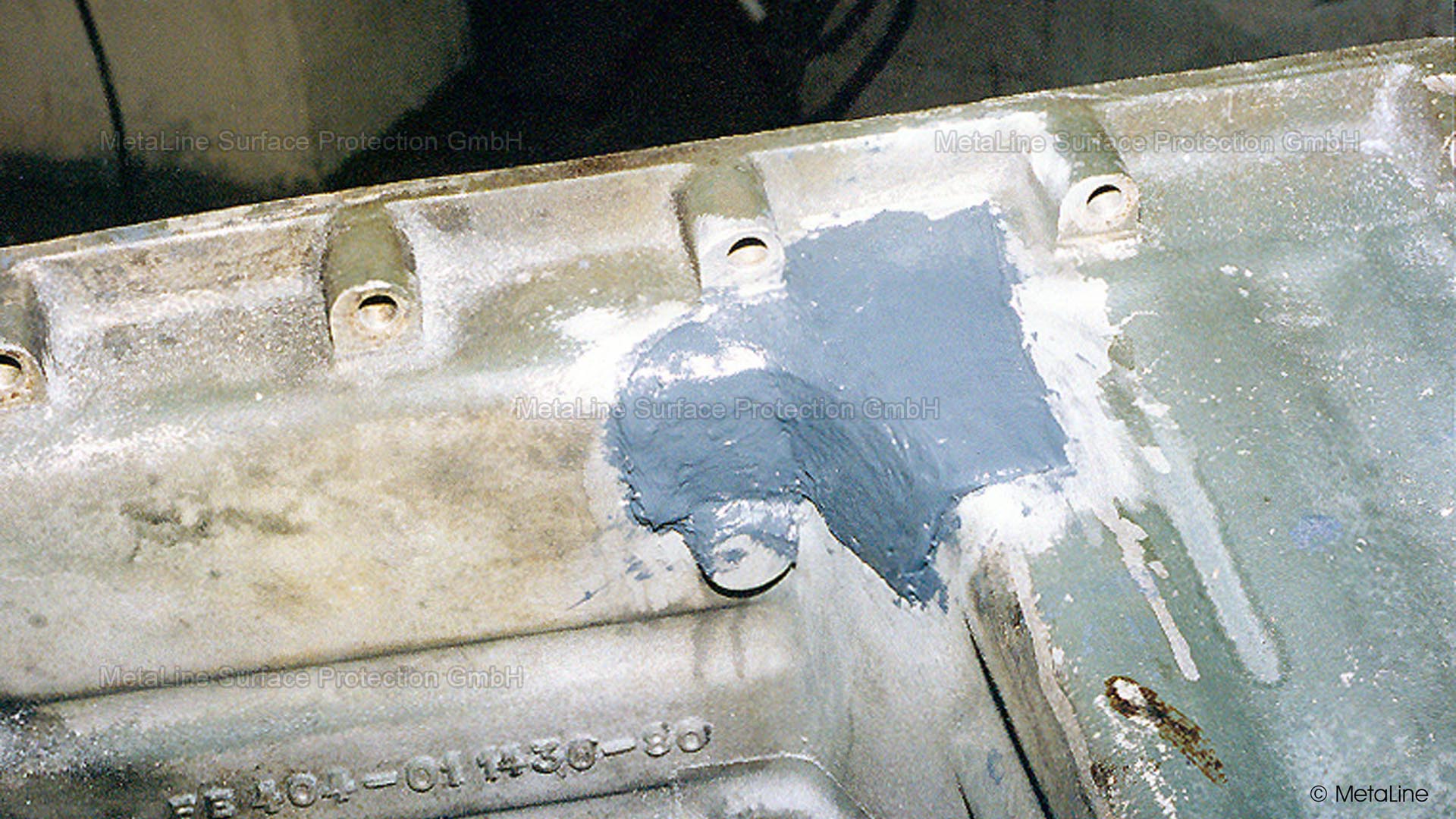

Oil pan successfully sealed with MetaLine Ceramic Repair Compound SXL and metal reinforcement fabric

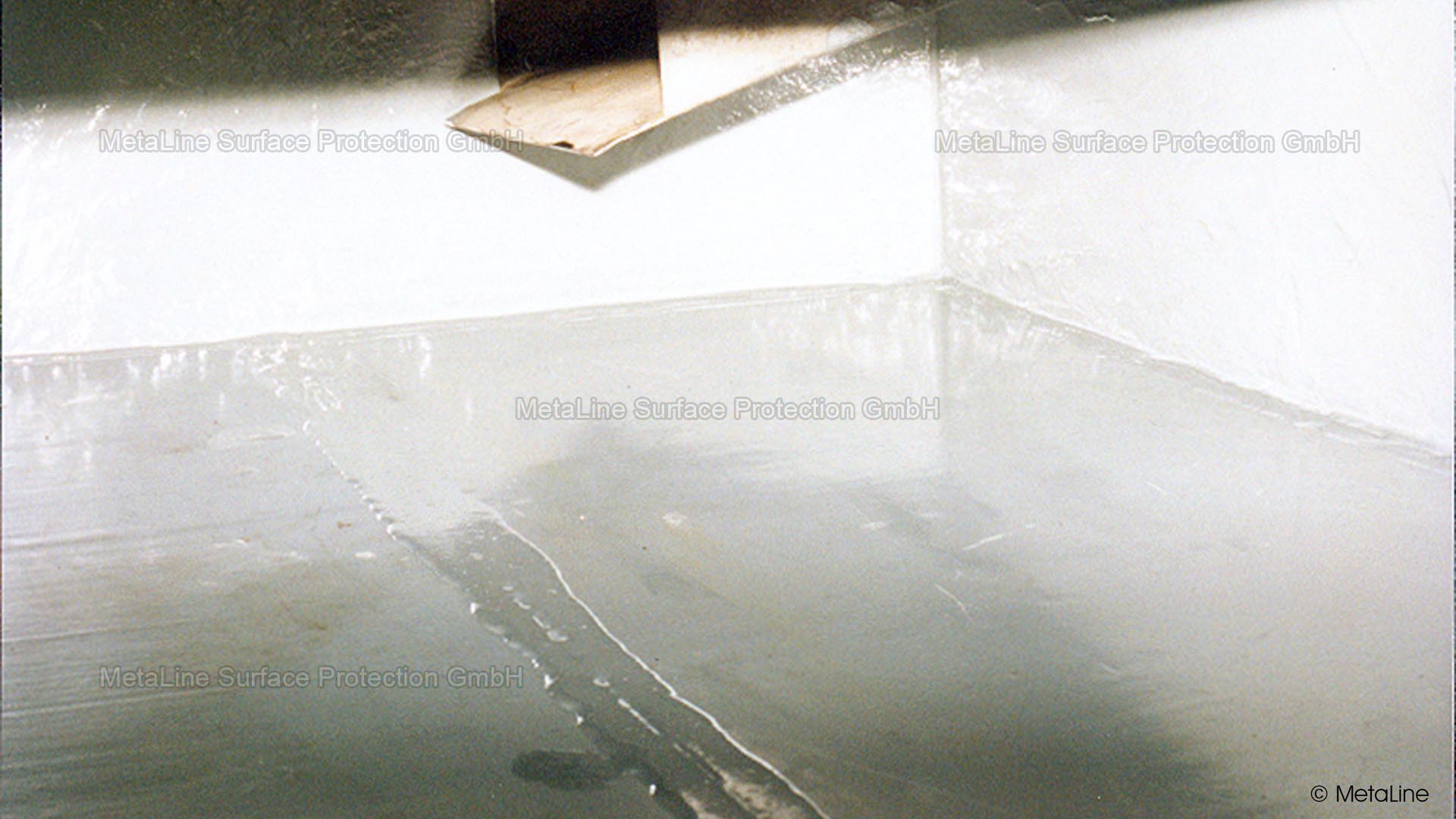

Leaking hot washing plant (Pero) for aqueous series cleaning of metal components

The water basin was sealed and stabilized with several layers of MetaLine 100 XTM and new steel plates

Ready – owing to the metal/synthetic sandwich structure the expected life-time is higher compared to untreated new systems

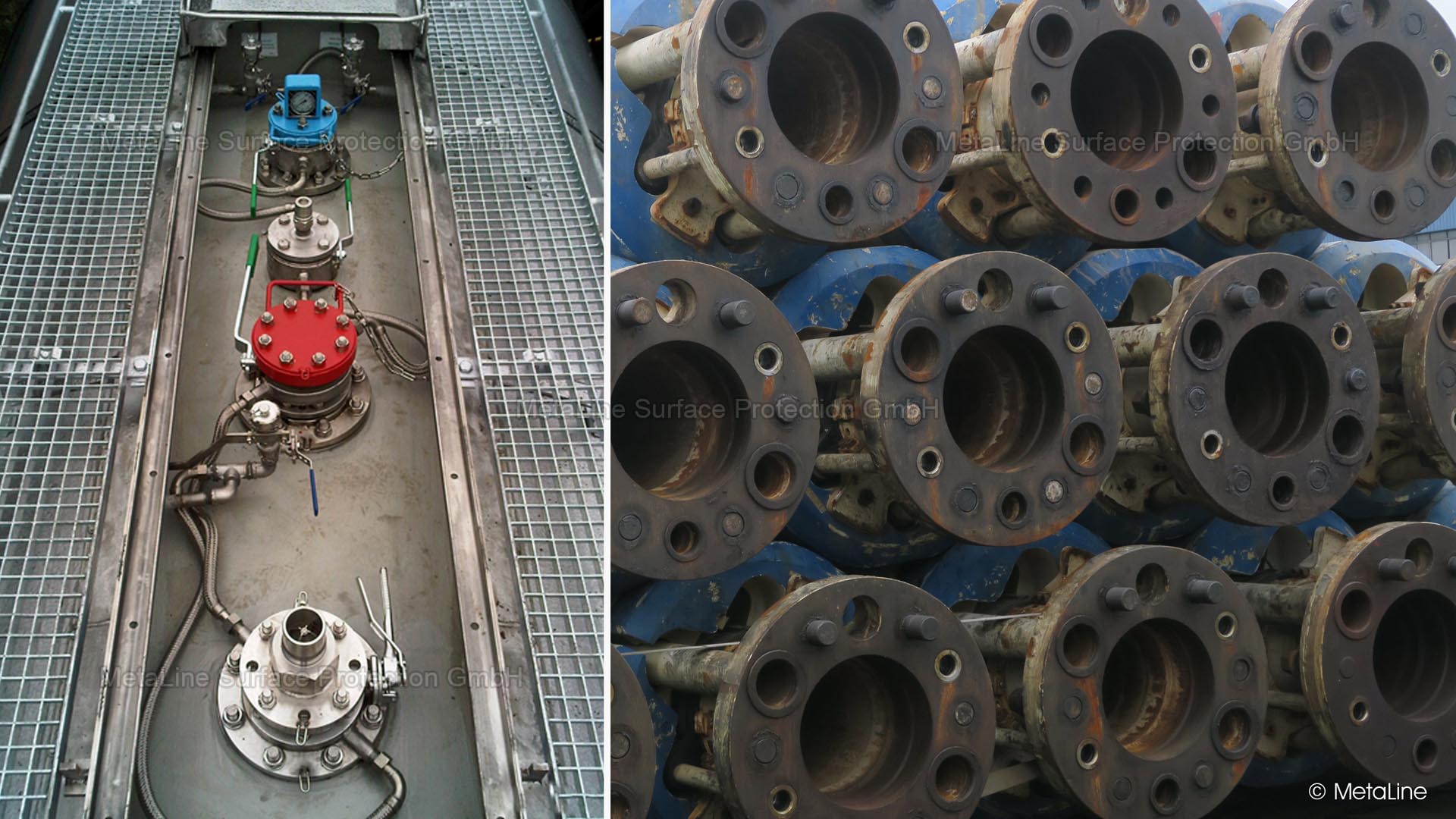

A common problem – leaking tank base

Ceramic sealing of rivet surfaces with MetaLine Ceramic Repair Compound SXL

A good repair concept does not only remove consequences but also tackles the inherent causes – in this case coating of a moisture-sensitive concrete base with MetaLine Series 700

Repair preparation – in this case metal moisture removal by use of propan-flame treatment

Preparations for sealing measures with MetaLine Ceramic Repair Compound SXL applicable by trowel

All-round highly chemical-resistant coating with liquid MetaLine Ceramic Repair Compound KXL

Railroad car coating – a seamless coating with MetaLine 100 XTM protects the topside of this railroad tanker against chemical aggression by spill and splash

This solution won't win an award for beauty, that's for sure, it offers, nevertheless an effective, rapid and permanent corrosion protection measure

Joint sealing – quite often a permanent source of trouble. Welding seams or joints simply move during tanking operations and cause smaller leakages. Not a huge issue, but still something which needs to be fixed by use of MetaLine Series 700 elastomeric coating technology

Lid cover coatings – MetaLine offers concepts against aggressive chemicals, wear & tear protection, electro-chemical insulation, FDA-approved linings. Simply ask us!

MetaLine Series 700 cartridge spray system – a milestone when it comes to processing elastomeric coating materials. There is no simpler and faster way of repair