MetaLine 100 XTM offers an extremely good leak-tightness and is particularly resistant against corrosive or acid media

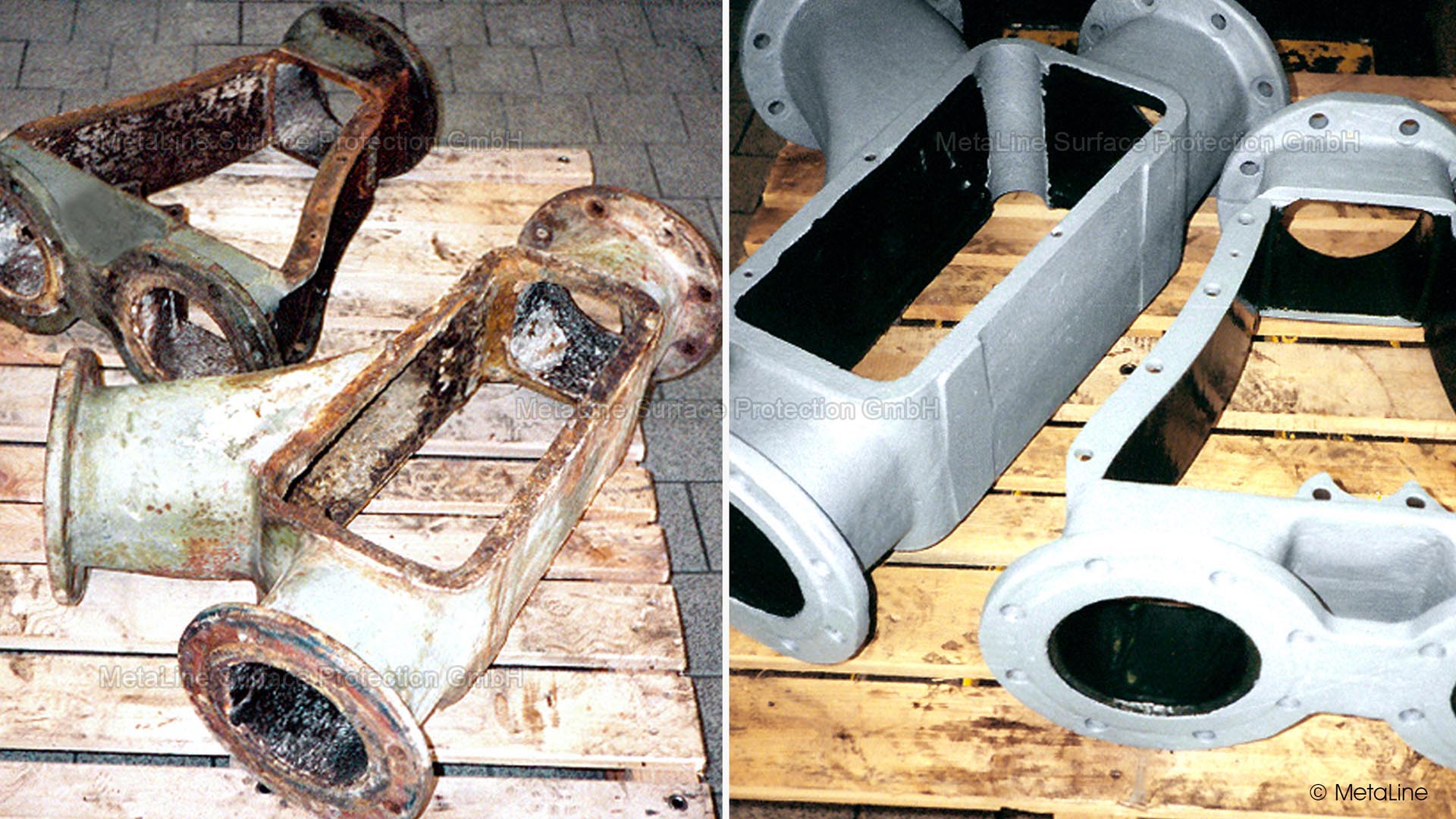

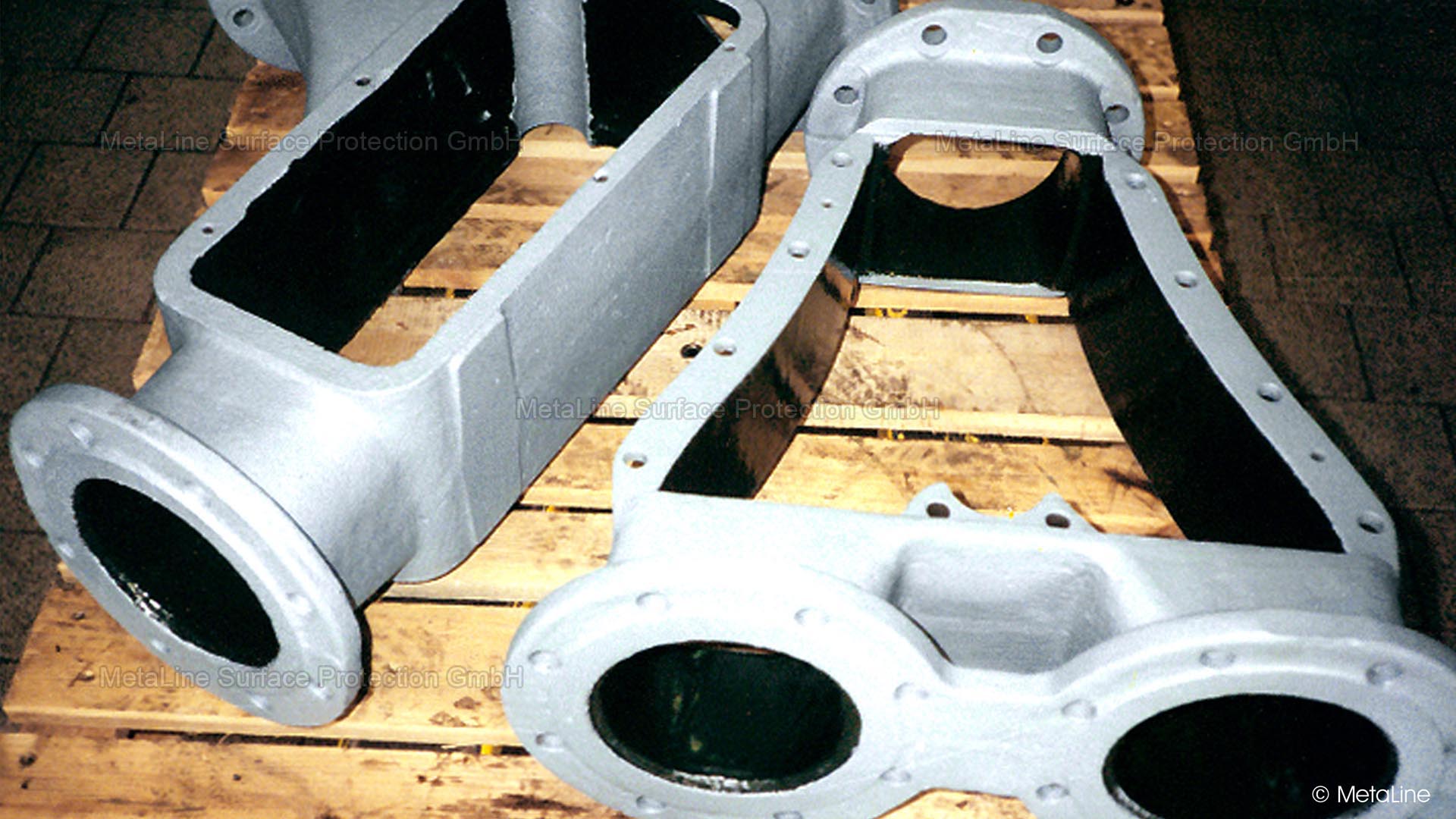

Cooling water distributor removed from a power plant to be transported to a MetaLine Partnershipmember for a complete overhaul service

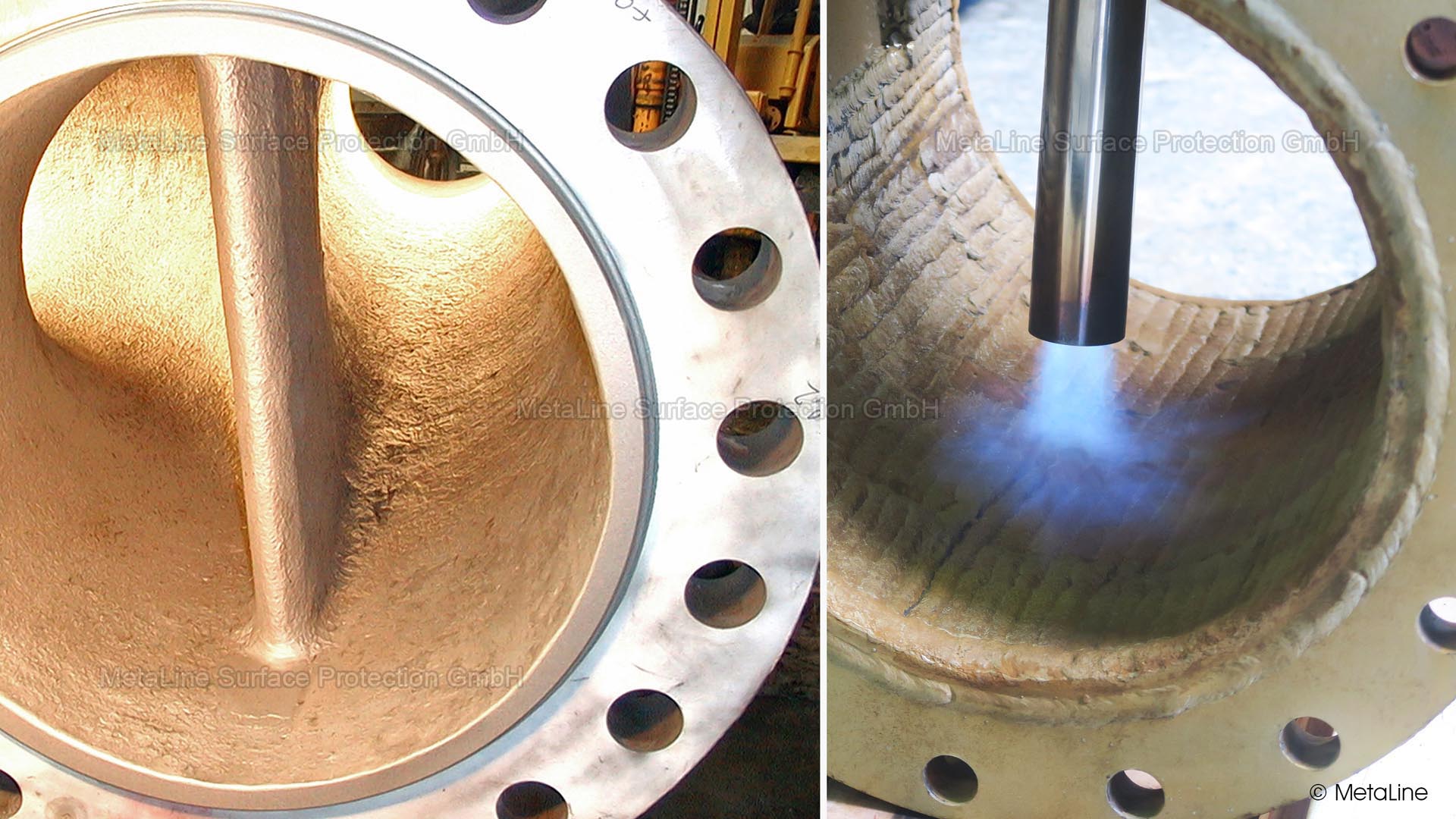

Cooling water distributing pipe in a power plant after sandblasting – ready for coating. MetaLine offers more than 50 years of experience in surface preparation of contaminated substrates

During coating with MetaLine 100 XTM

Oily water separator coating – Saltwater, oil and elevated temperatures create a hostile and corrosive environment for steel substrates. MetaLine 100 XTM helps to get rid of these headaches...

Corroded fabric distributing guides used in paper industry

After ceramic repair of worn areas

Chemical-resistant and wear-resistant coating

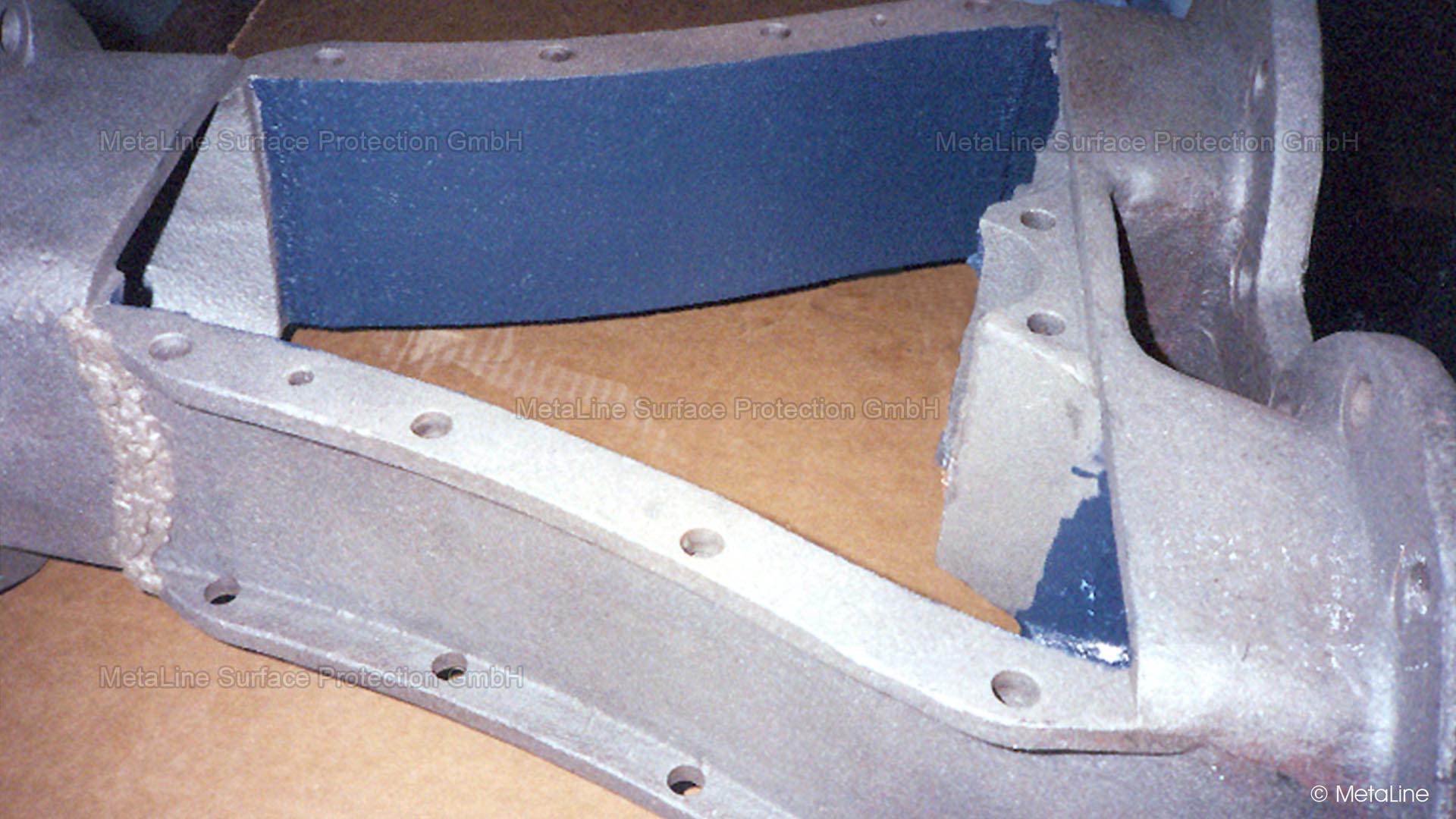

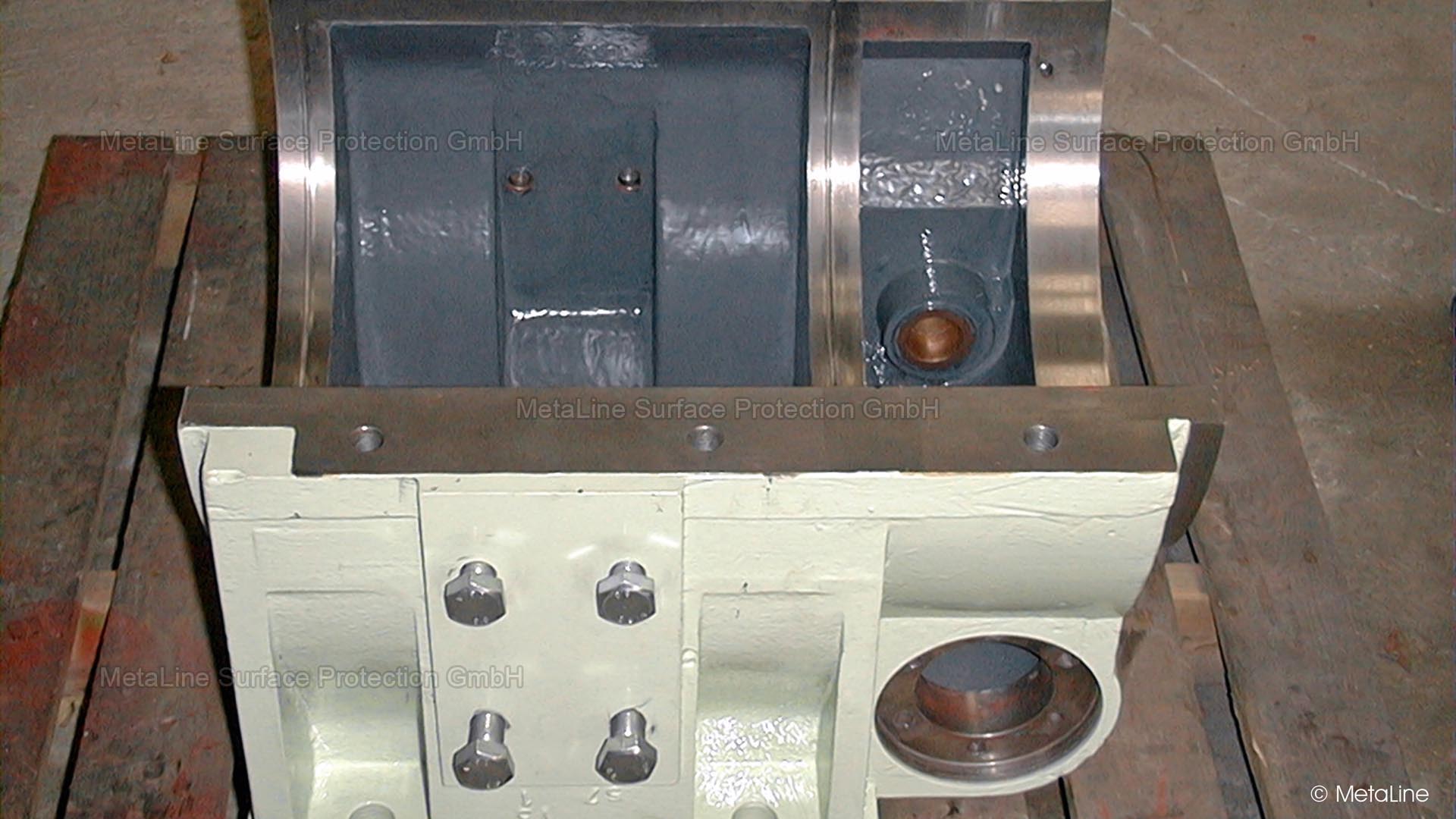

Compressor components coated with MetaLine 100 XTM

Compressor components coated with MetaLine 100 XTM

Compressor components coated with MetaLine 100 XTM

Corroded vacuum pump rotor

Vacuum pump rotor coated with MetaLine 100 XTM

Chemical attacks and destruction

Coated, protected and preserved – one problem less

Manufacturing plant in a French paper factory confronted with moisture, chemicals and mechanical abrasion. Shown here after sandblasting immediately before application of MetaLine protective coating

Corrosion resistant coating – 2 coats of MetaLine 100 XTM provide a long term protection to this moisture impacted steel surface