Conveyor belt repair - Longitudinal tears in conveyor belts can be professionally repaired with MetaLine 760. However, we cannot glue torn belts back together over a long length! Every technology has its limits

Conveyor belt repair - the MetaLine 760 stands for a polymer technology that enables permanent repair work without hot vulcanization on almost all types of conveyor belts - but not within a few minutes. Quality takes time!

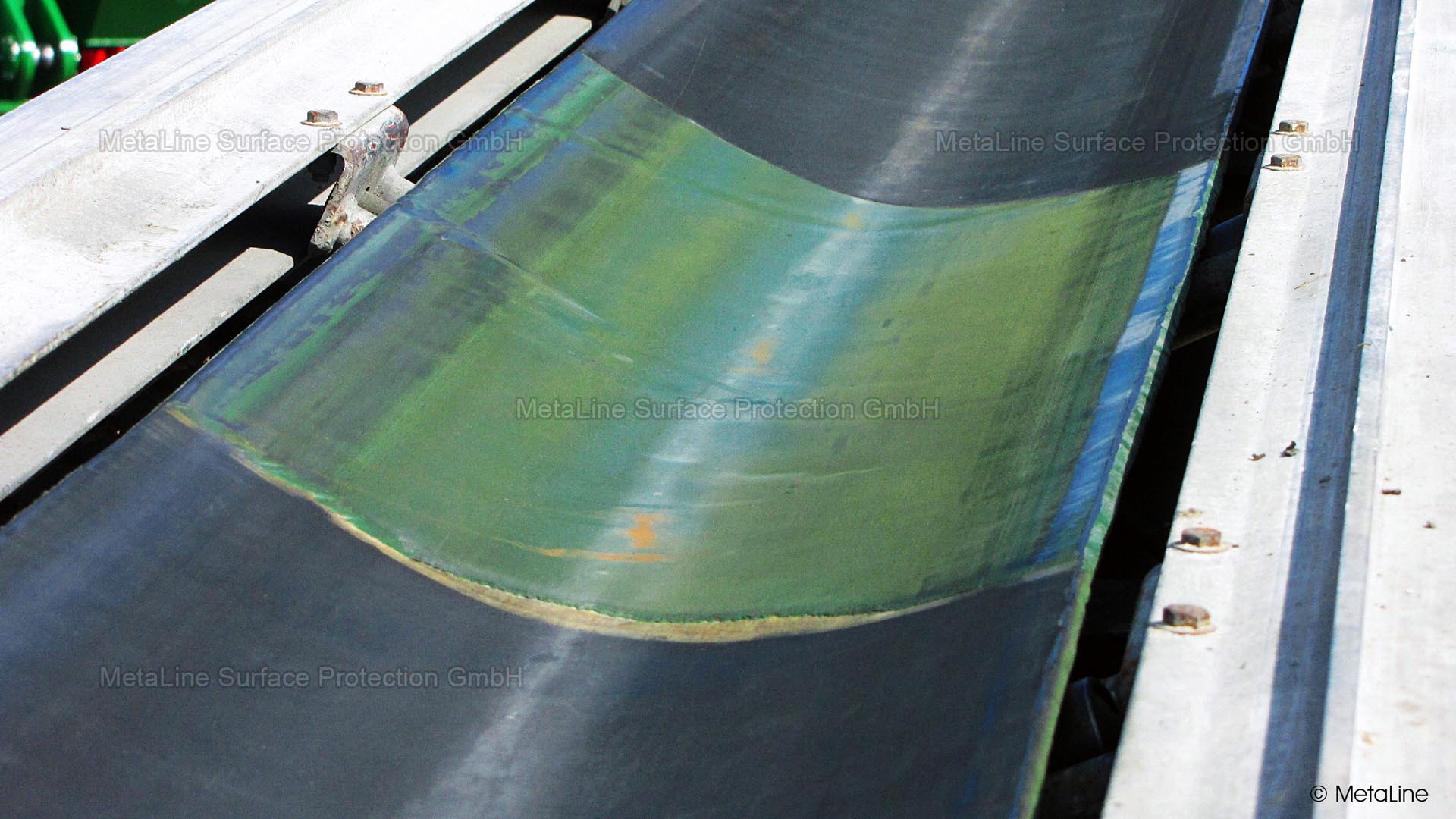

Conveyor belt repair - on-site coating of a bonded belt splice of a concrete conveyor belt with MetaLine 760. The coating was applied even with the belt surface so that the scraper cannot cause any damage. The belt splice is thus protected against mechanical and climatic influences

Conveyor belt repair - MetaLine 760 is applied step by step to the professionally prepared and primed conveyor belt. Once started, the application must be completed promptly to avoid soiling during the work

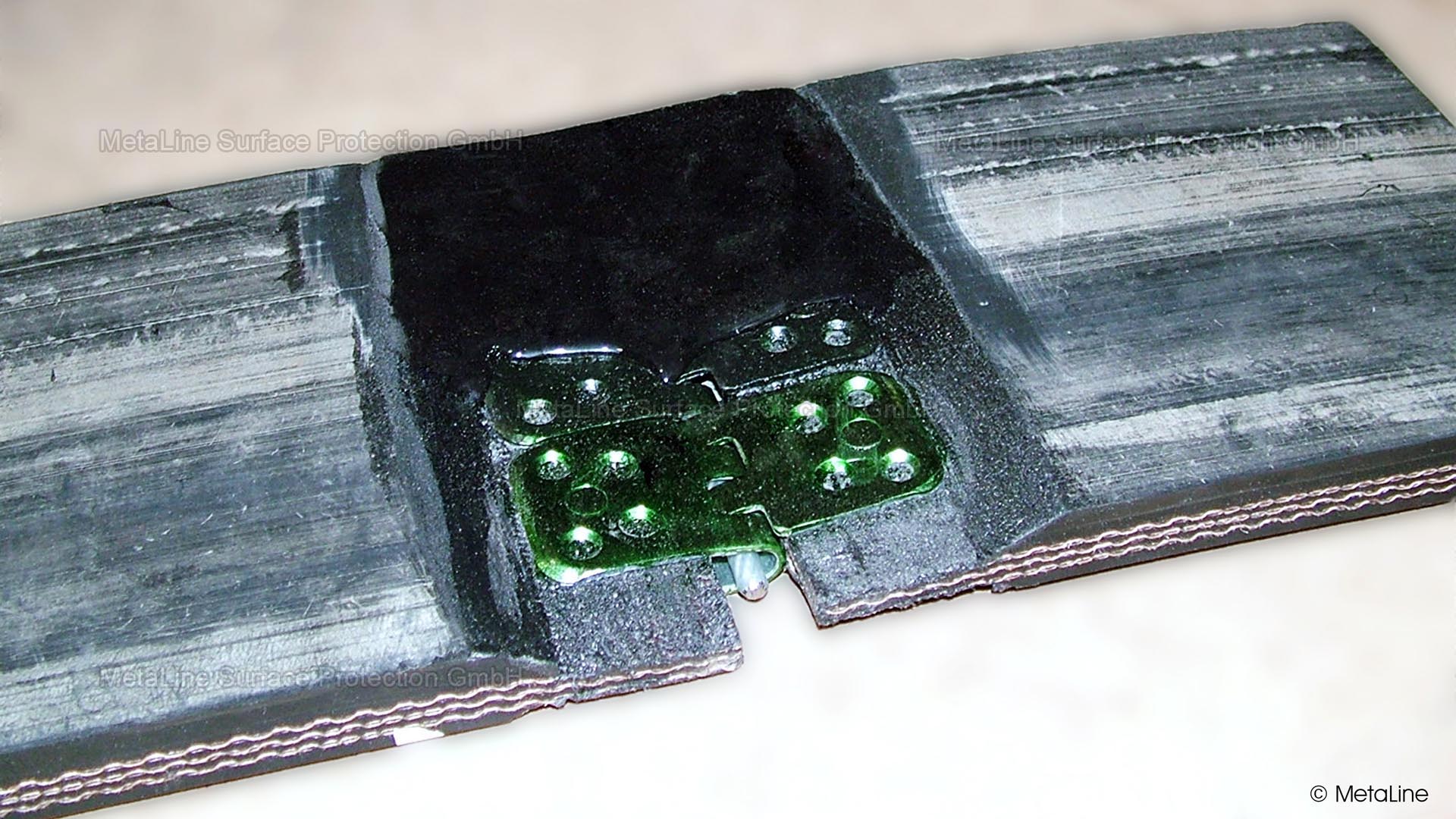

Conveyor belt splice - Coating a metal-clamped belt splice with MetaLine 760. This measure extends the service life of the metal fasteners. No great effort but a big difference in the service life of the conveyor belt. Optimize the existing with just a few simple steps - MetaLine!

Conveyor belt repair - the advantage of a conveyor belt repair with MetaLine 760 is that it is possible to work on several points at the same time. With classic hot vulcanization, the vulcanizing press has to be moved each time and each area has to be treated separately - or you can use several presses!

Conveyor belt repairs - the right tool in the right hands can work small technical miracles. Unfortunately, nothing that you can watch in a video and then simply carry out yourself. It takes a little more than that! What exactly? Just ask us!

Conveyor belt repair - two versions! One is good and one is bad! Note the correct edge boundary in the picture on the left. That's how it should be! On the right, you have saved yourself work and, above all, you have "saved" yourself a good result. What a pity!

Magnetic belt coating - MetaLine 785 increases the wear resistance of this magnetic conveyor belt. At the same time, the magnetic field strength is only marginally affected.

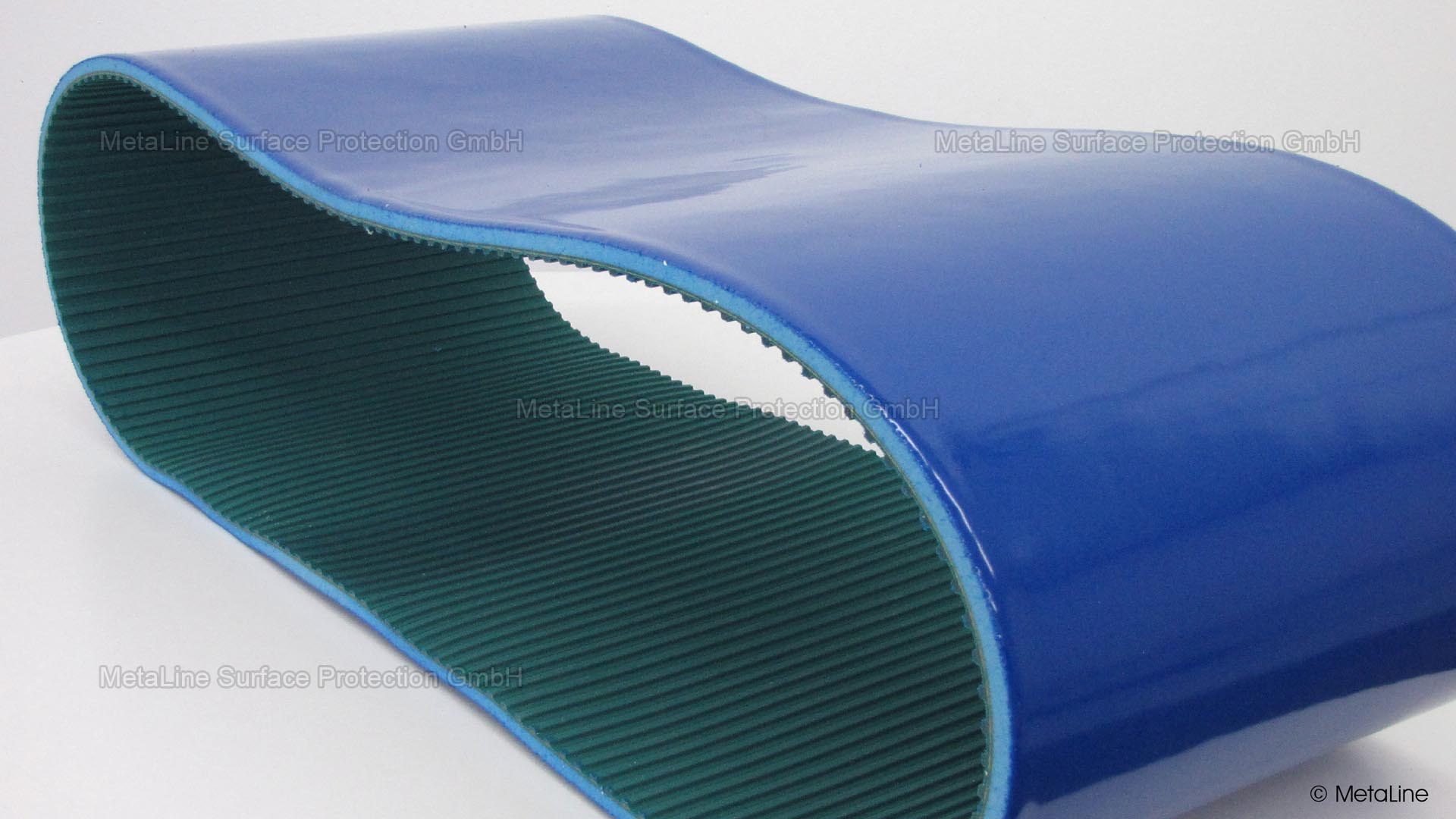

Conveyor belt coating - complete overcoating of a short PVC conveyor belt with MetaLine 760. The static friction had to be increased. FDA approval was also required!

Belt coating – MetaLine 785 gives a much higher surface grip to this special belts offering an increased operation performance

Conveyor belt coating - MetaLine 785 is sprayed flat onto a prepared belt. The belt is only installed and spliced after it has solidified. It is not possible to apply a complete coating while the belt is installed - especially not under slow rotation!

Rubber coating - the roughness required for professional rubber coating is clearly visible on the right-hand edge! We supply the necessary tools for pre-treatment - so that everything works properly!

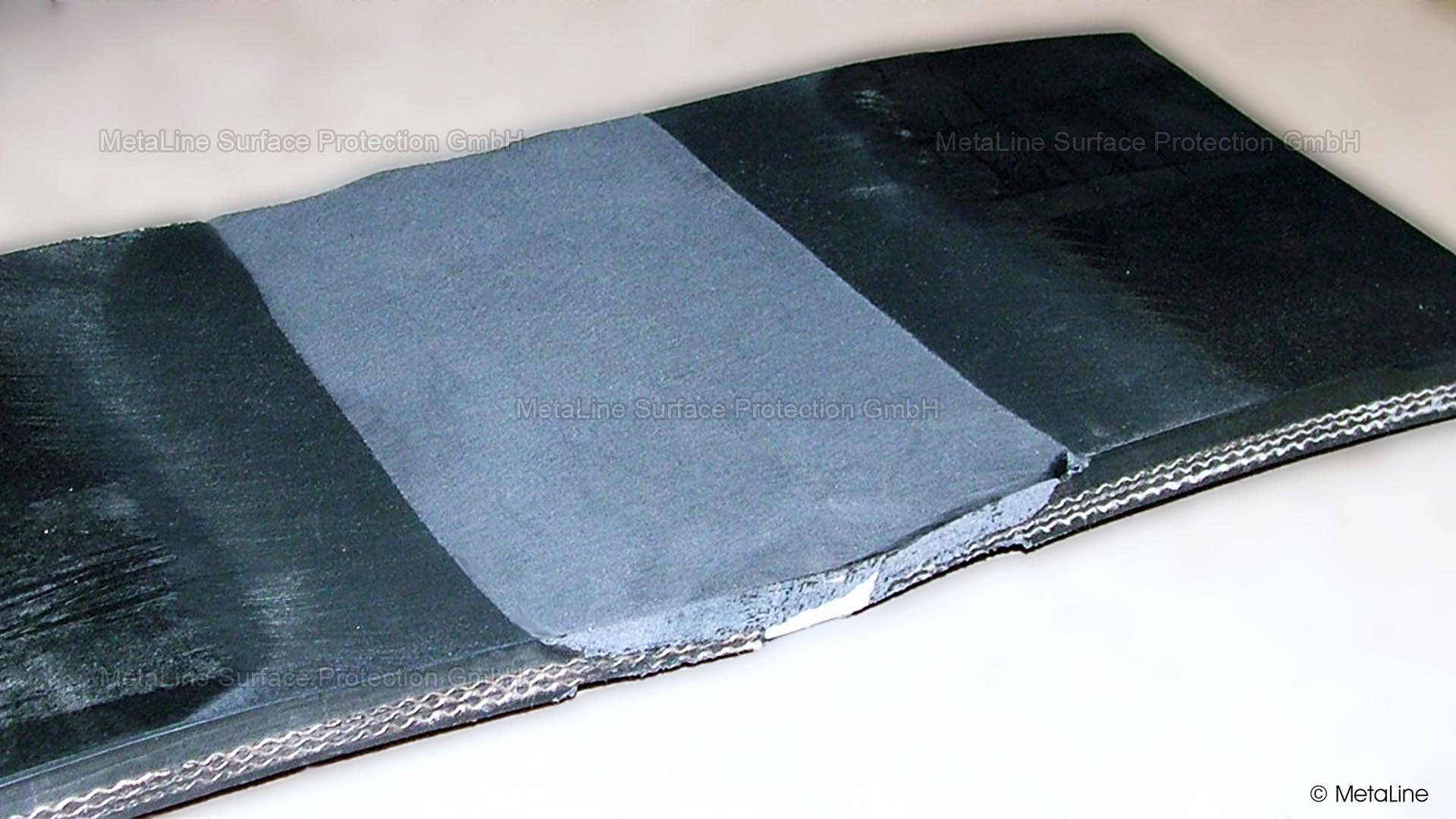

Fastener repair - diagram of the overcoating of a conveyor belt fastener (splicing) - here the preparation with the required primer and already half filled with MetaLine 760

Fastener coating - diagram of the overcoating of a belt fastener (splicing) - here the MetaLine 760 coating after complete application

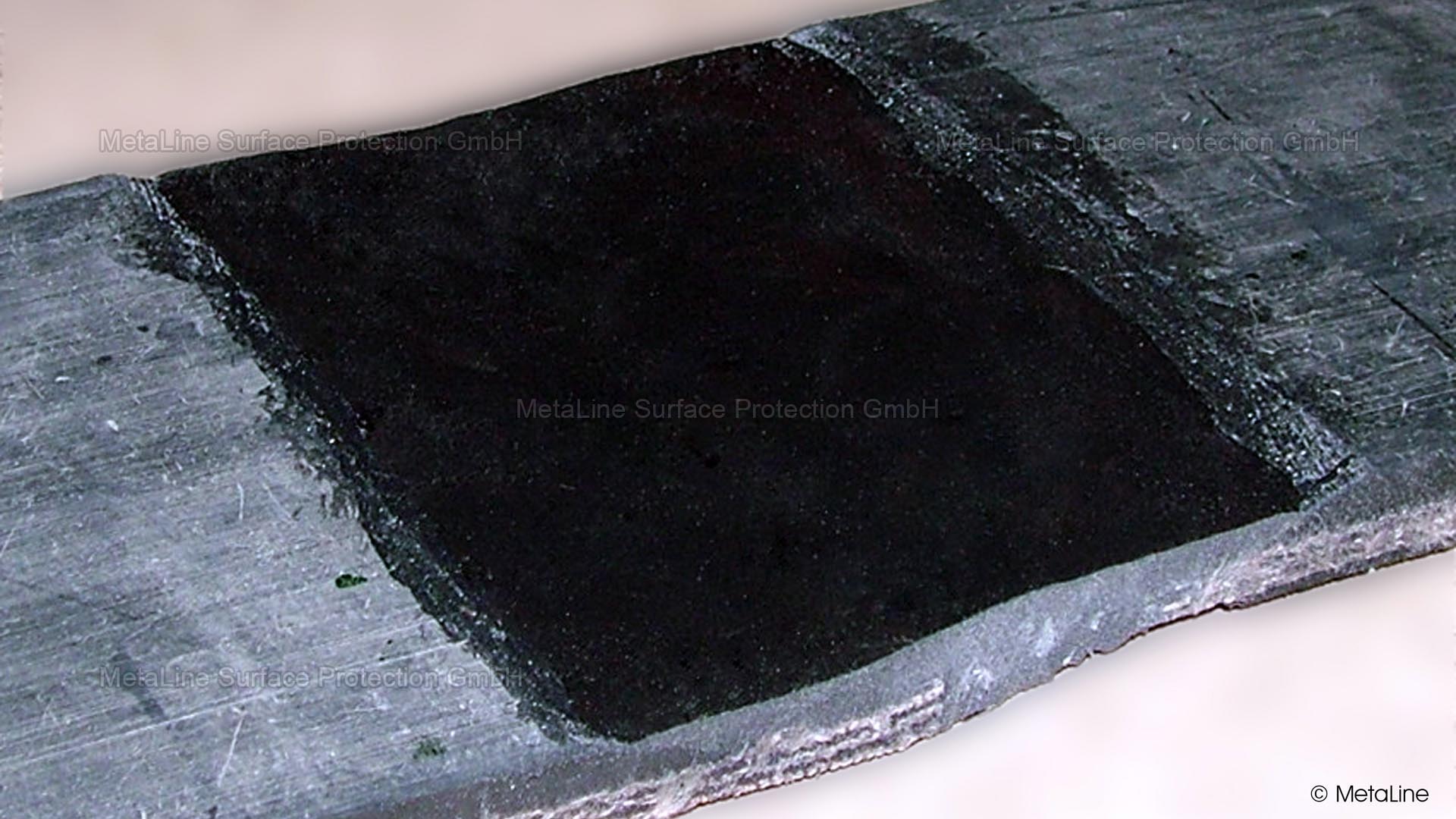

Rubber belt repair - diagram of overcoating a belt fastener (splicing) - here after grinding the MetaLine 760 to final dimensions

Conveyor belt coatings - are an interesting way of specifically changing the surface properties of conveyor belts. However, this requires experience in the selection and application of coatings. Take advantage of our more than 60 years of experience - you will not regret talking to us - PROMISED!

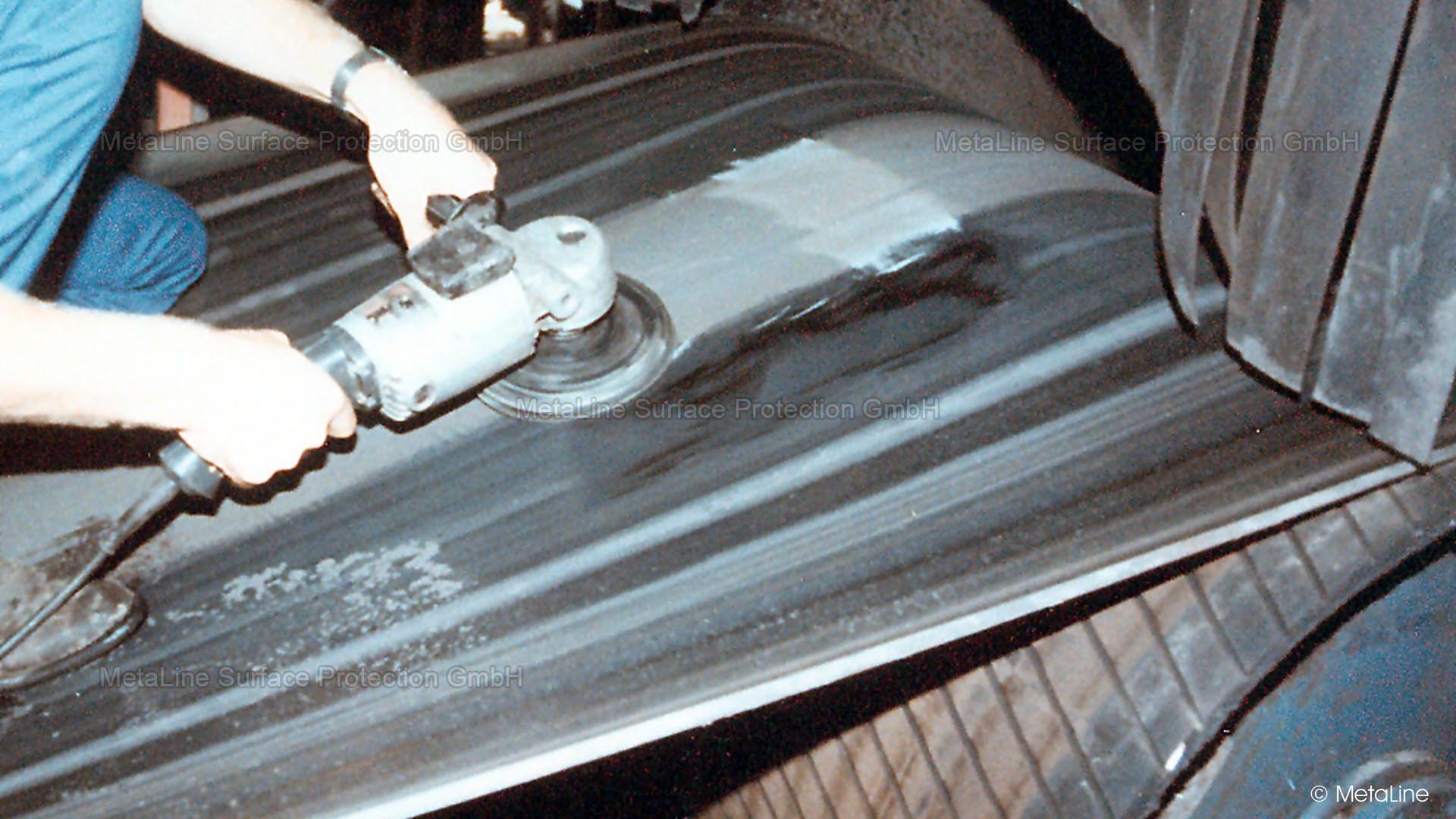

Conveyor belt repair - machining (grinding) a longitudinal cut in a conveyor belt repaired with MetaLine 760. A proven way to repair localized damage at low cost - but not a quick one. Re-commissioning is possible after 12 hours at the earliest

Conveyor belt coating - full-surface overcoating of a larger conveyor belt repair area with MetaLine. Please excuse the poor quality of the photo. It is not a studio photo but a real picture of a construction site

Conveyor belt lining - here the non-stick coating on a segment belt that conveys fly ash. The coating thickness is 1.5 mm MetaLine 795. Good non-stick properties depend on many factors, such as moisture content, particle size, temperature and others!

Conveyor belt repair – longitudal crack repair with MetaLine 760 on a conveyor belt in a Greek gravel works near Olympia. The precise design of the edge and the preparation of the substrate beyond this can be seen particularly clearly. You can't do better than that . . .

Drive pulley coating - insufficient friction caused the conveyor belt to spin in this Chilean copper mine. The drive pulley was prepared in its installed state and coated with 3 mm MetaLine 785. This allowed the static friction to be increased to a my(0) of 0.6. The customer was delighted with the function!

Pulley coating - an unusual repair when the roller is installed. Technically not the first choice, but if time does not permit otherwise, MetaLine 785 has the proverbial flexibility for the most unusual solutions . . .

Elevator bucket - the drive pulley of this conveyor belt of an elevator bucket system was coated with 3 mm (120 mils) MetaLine 785. The static friction had to be increased to prevent the belt from slipping