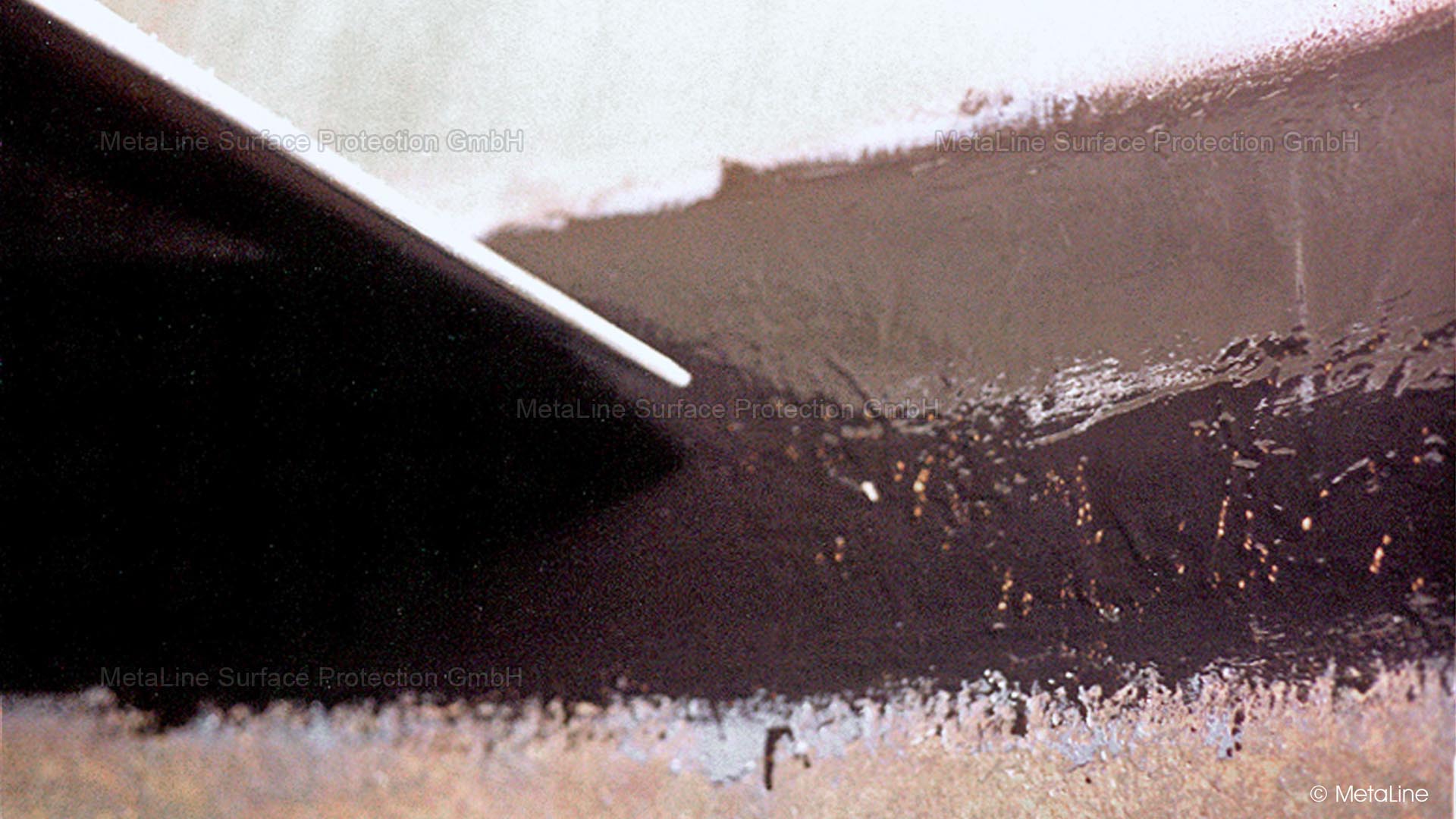

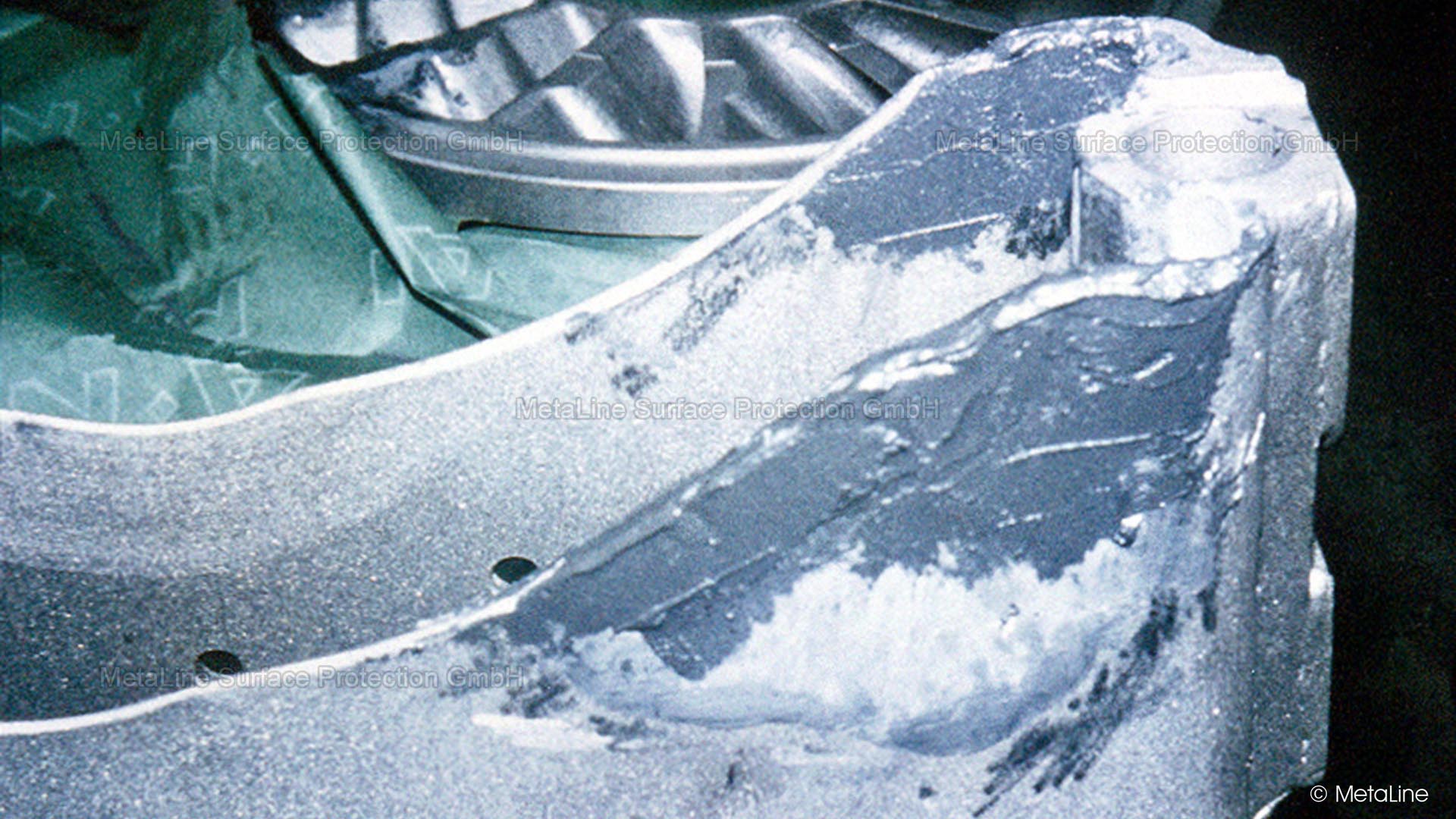

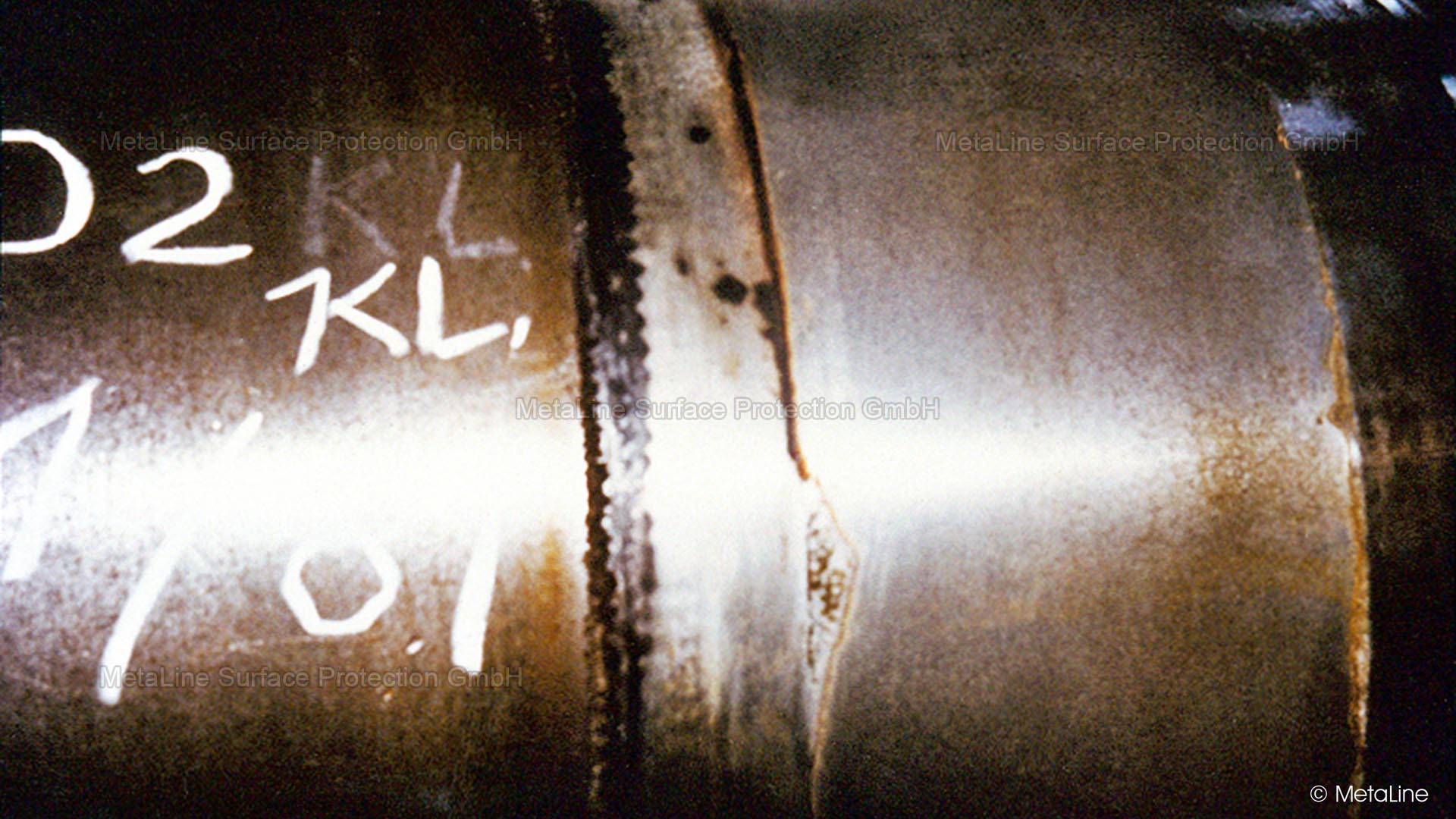

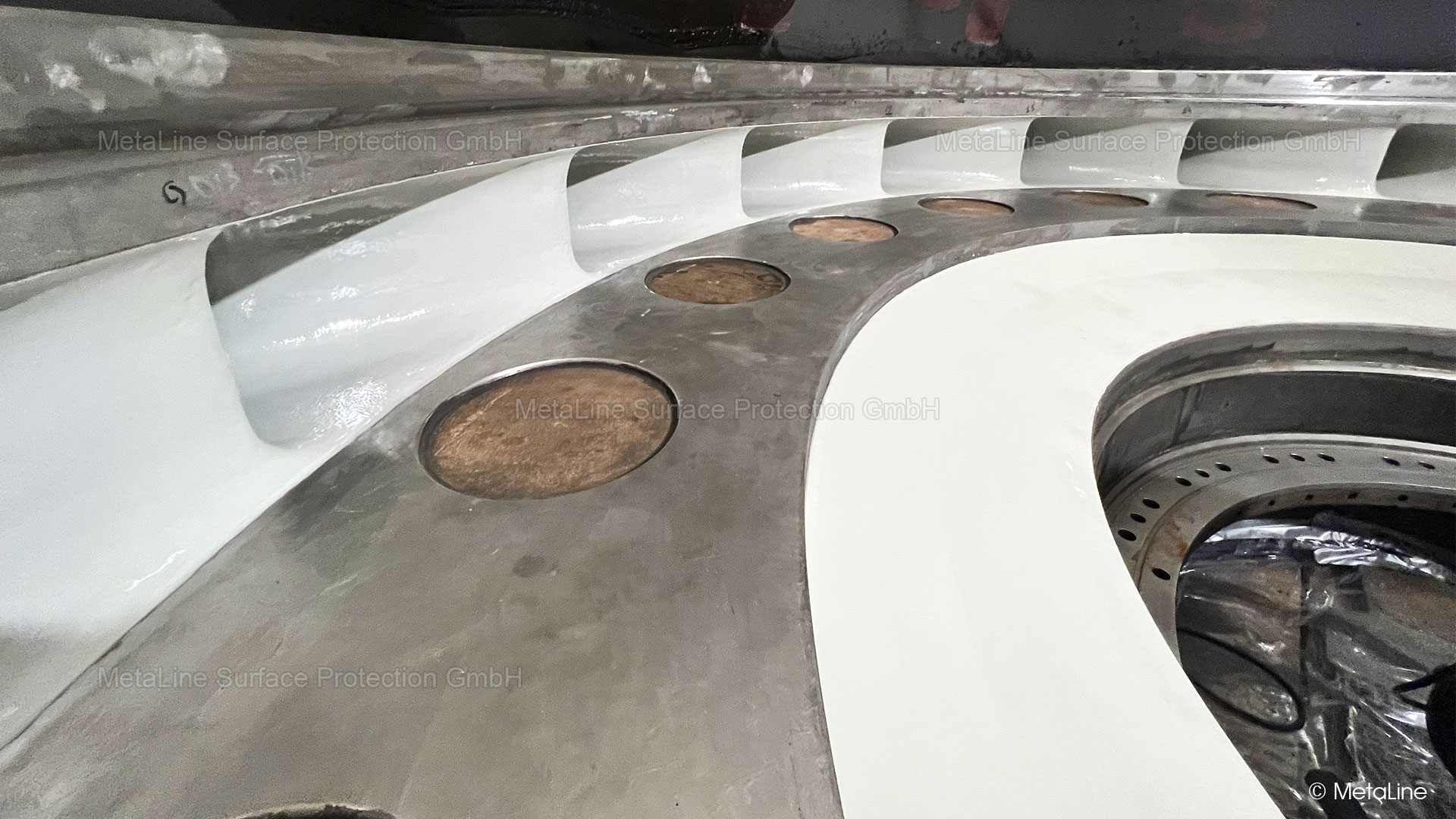

The guide vanes and housings of hydropower turbines are exposed to permanent loads due to the ongoing impact of floating debris. Very deep erosion and cavitation occur in the clearance area towards the impeller. Overhauling by welding overlay to repair this damage is not always an adequate and optimum solution for these often-older cast structures, not to mention the enormous time involved.

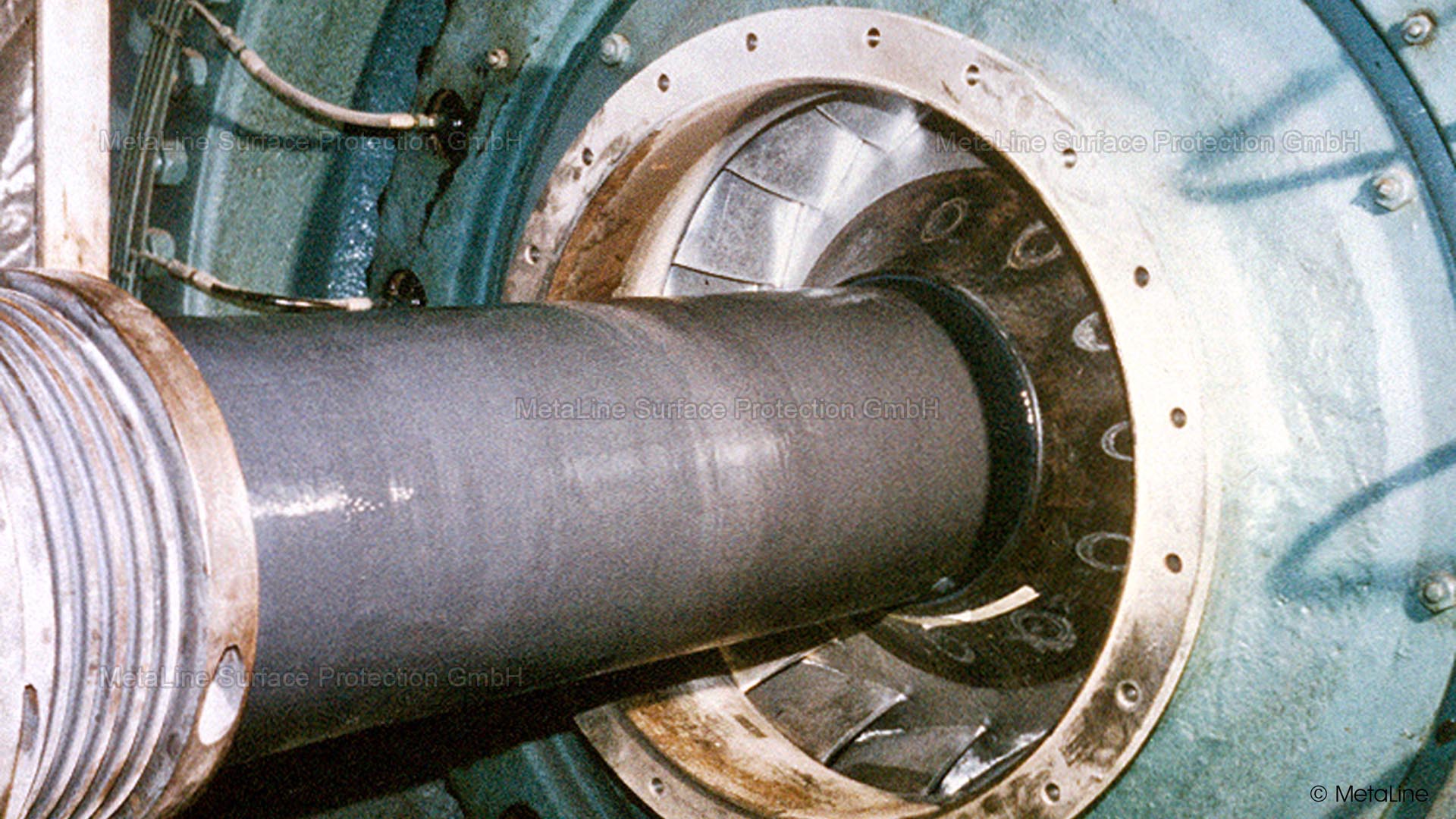

Ask us about: turbine casings, wicket gates, control devices, water brakes, suction pipes, drive shafts, guide vanes

MetaLine Series 700 – Sprayable / OEM Manufacturer quality MetaLine Series 700 coatings have much smoother surface structures in comparison with brush or trowel applied conventional repair methods. Hydro-dynamic flow conditions are positively influenced. Via its elastomeric features, this coating technology can eat up the destructive kinetic energy of impacting trash. Furthermore the continous vibrations in the system are dampened and will not lead anymore to disbonding or chipping of the protective skin. The continual variances in tension and pressure influences in the cavitation area are almost counterbalanced - simply as rubber would do it! MetaLine Series XL – Trowel- or brushable / Repair quality MetaLine XL series are special synthetic ceramic materials for the non-metallic replacement of lost cast metal structures. They are insensitive to high humidity during processing and do not require special handling skills. The application can also be made in higher layer thicknesses in a single operation. Major advantage is the fast installation even without dismantling the impeller from the spiral casing. After solidification, they provide protection against corrosive and erosive stresses for a certain period.