Severe erosion and corrosion on vacuum pump rotors—effectively repaired with MetaLine machinable synthetic materials.

Vacuum pump rotor repair - restoration of worn end faces with MetaLine repair ceramic SXL. The greatest advantage of ceramic repair materials is their complete resistance to corrosion because they do not contain any metal

Vacuum runner coating - firstly treated with the trowelable MetaLine repair ceramic SXL and then completely coated with the brushable MetaLine repair ceramic KXL. The overcoating is crucial to delay corrosion

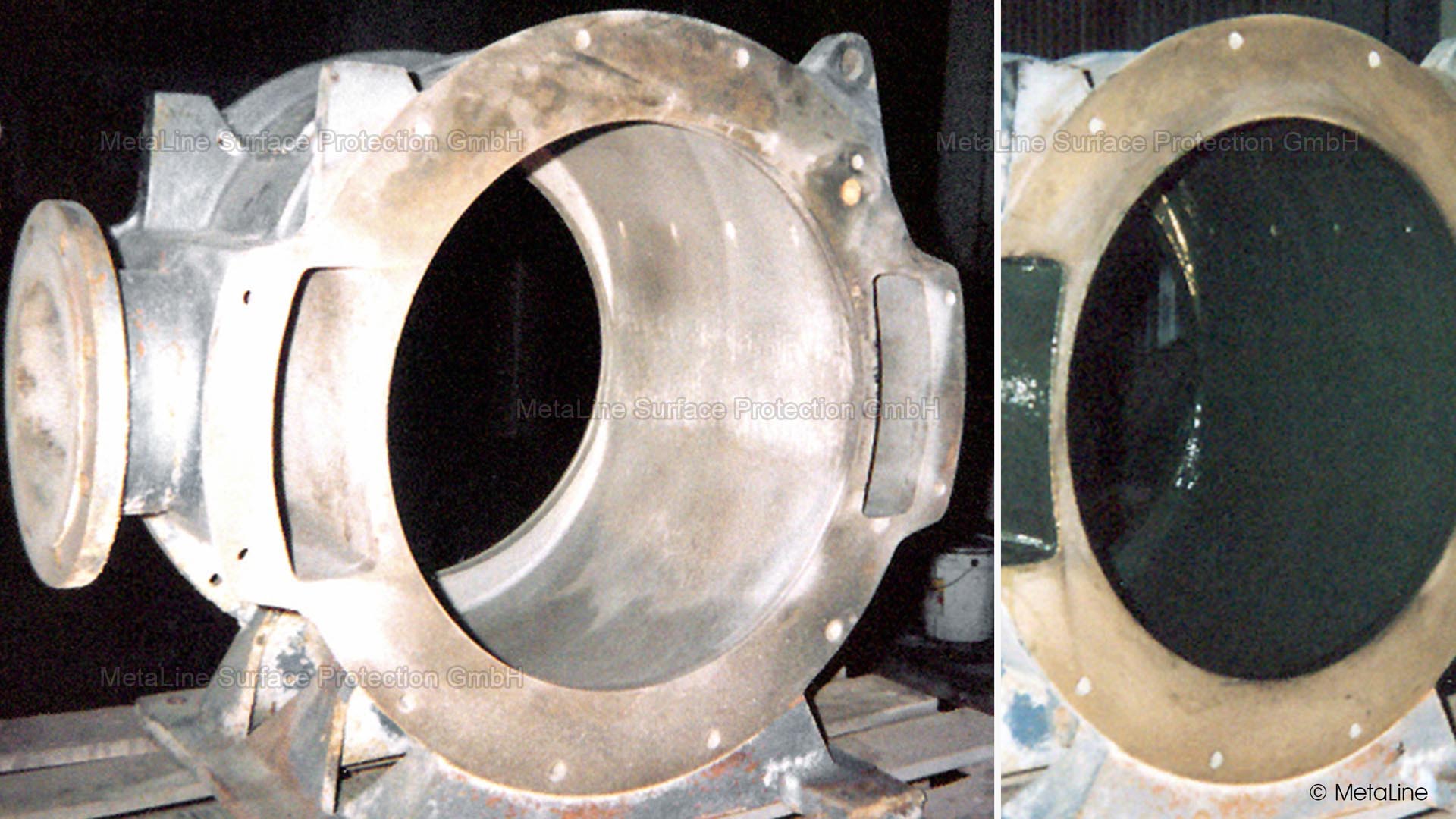

Vacuum pump protection - MetaLine repair ceramic KXL as a protective coating on the housing cover - brushed. Sufficient adhesion of the repair material to the substrate is of decisive importance. Professional and intensive preparation is therefore essential. Otherwise, the application will fail

Vacuum pump coatings - are not simple technical processes, but also require experience at one point or another! That's why we advise you on whether in-house processing makes sense for your application - also so that it is carried out a little better than in this example. According to the saying "you eat with your eyes"

Vacuum pump repair - how much does a new vacuum pump cost? 100,000 euros or more? And now you are looking for an online shop coating? Better look for a partner who has real experience with pump coatings and not just clever internet marketing!

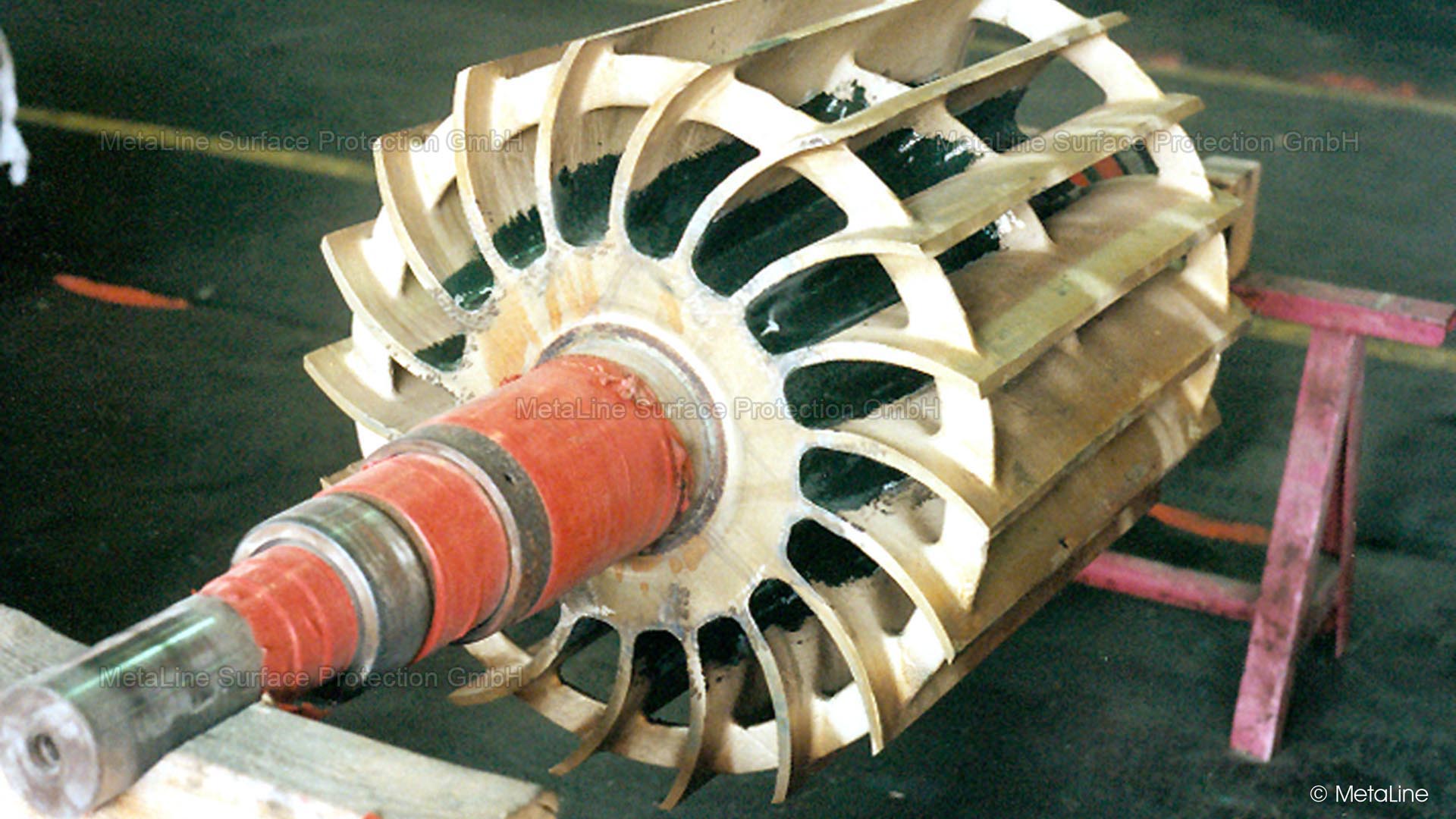

Vacuum pump rotor repair - wear and washout mean loss of performance - which costs real money in a vacuum pump! MetaLine is a very experienced partner when it comes to avoiding such losses. Since 1960 and therefore longer than anyone else in Germany!

Rotor repair - preparatory work for reprofiling. The edges are ground, drilled and studded. But there are limits! The "dead" cannot be revived. If it no longer makes sense to repair a component, then we say no - and don't waste your money in vain!

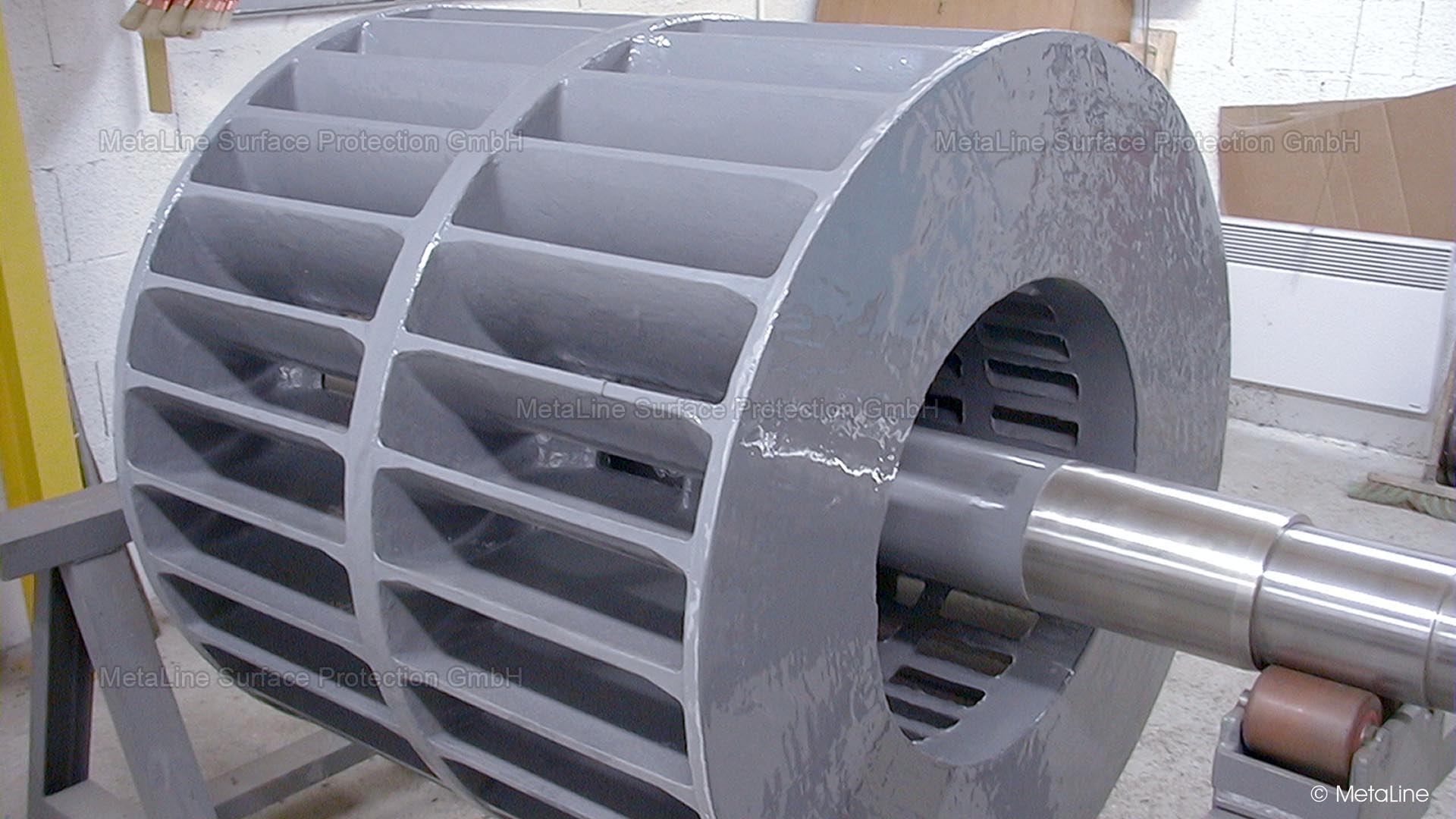

Rotor coating - better than new! Why? Because the entire surface was synthesized with the MetaLine repair ceramic KXL. This makes it completely metal- and corrosion-free - but unfortunately not wear-free - only wear-reduced. MetaLine can do a lot but not everything - only our American competition can promise that!

Vacuum runner coating – the ultimate coating solution after a ceramical reconstruction is our sprayable elastomeric lining MetaLine 785. A new dimension in erosion and cavitation resistance. The better is the enemy of the good!

Vacuum pump impeller coating – this runner of an uranium mine had been doubled in its lifetime by use of a 2 mm coating of MetaLine 785. The picture shows the runner after coating but prior final machining

Vacuum pump regeneration - unfortunately only a picture during processing - not quite finished yet. Elastomeric surfaces seal better than hard metallic or ceramic surfaces - which is why we also recommend lining vacuum pumps with our MetaLine 785 elastomer armor on a case-by-case basis

Vacuum pump repair – this extremely worn out pump casing has been successfully repaired in a combined molding and spraying application with MetaLine 785. The product costs have not been higher than 400,- EUR plus 6 working hours inclusive blasting

Vacuum pump overhaul – wear at the side part of a vacuum pump had been repaired by means of a casting application with MetaLine 785. An additional overcoating with a 2 mm (80 mils) thick coat finalized the repair

Vacuum pump lining - after coating the inside of the housing with MetaLine repair ceramic KXL. What distinguishes our repair materials from the others on the market is the fact that we also process these materials for you or at least provide you with practical support in their application. A good approach for a good solution!

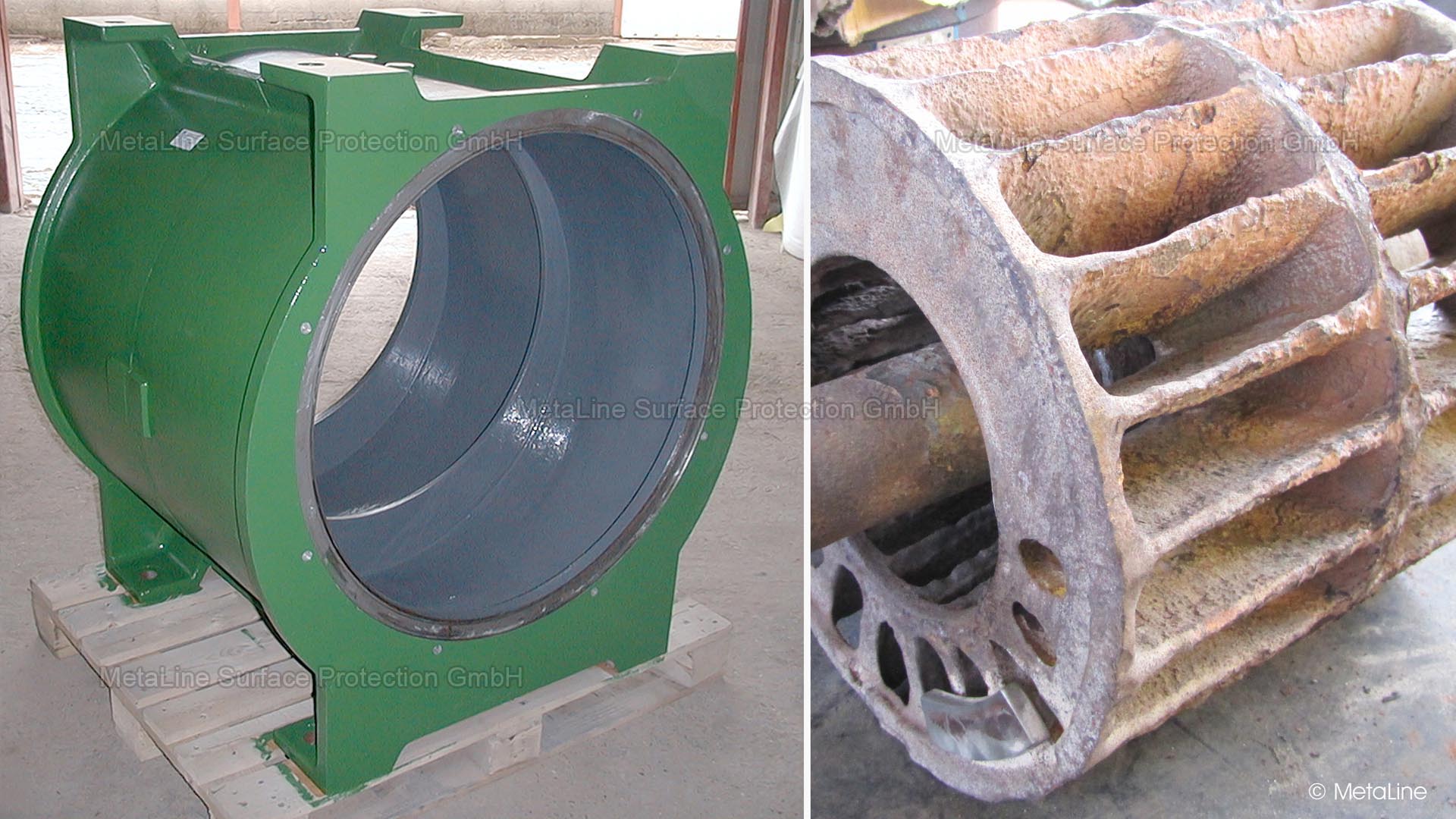

Vacuum pump refurbishment - inside & outside brought back to life! Does it make sense to coat a pump housing? Yes - because substance degradation is prevented and welding on concave housings is time-consuming. A coating maintains static stability and therefore functional reliability

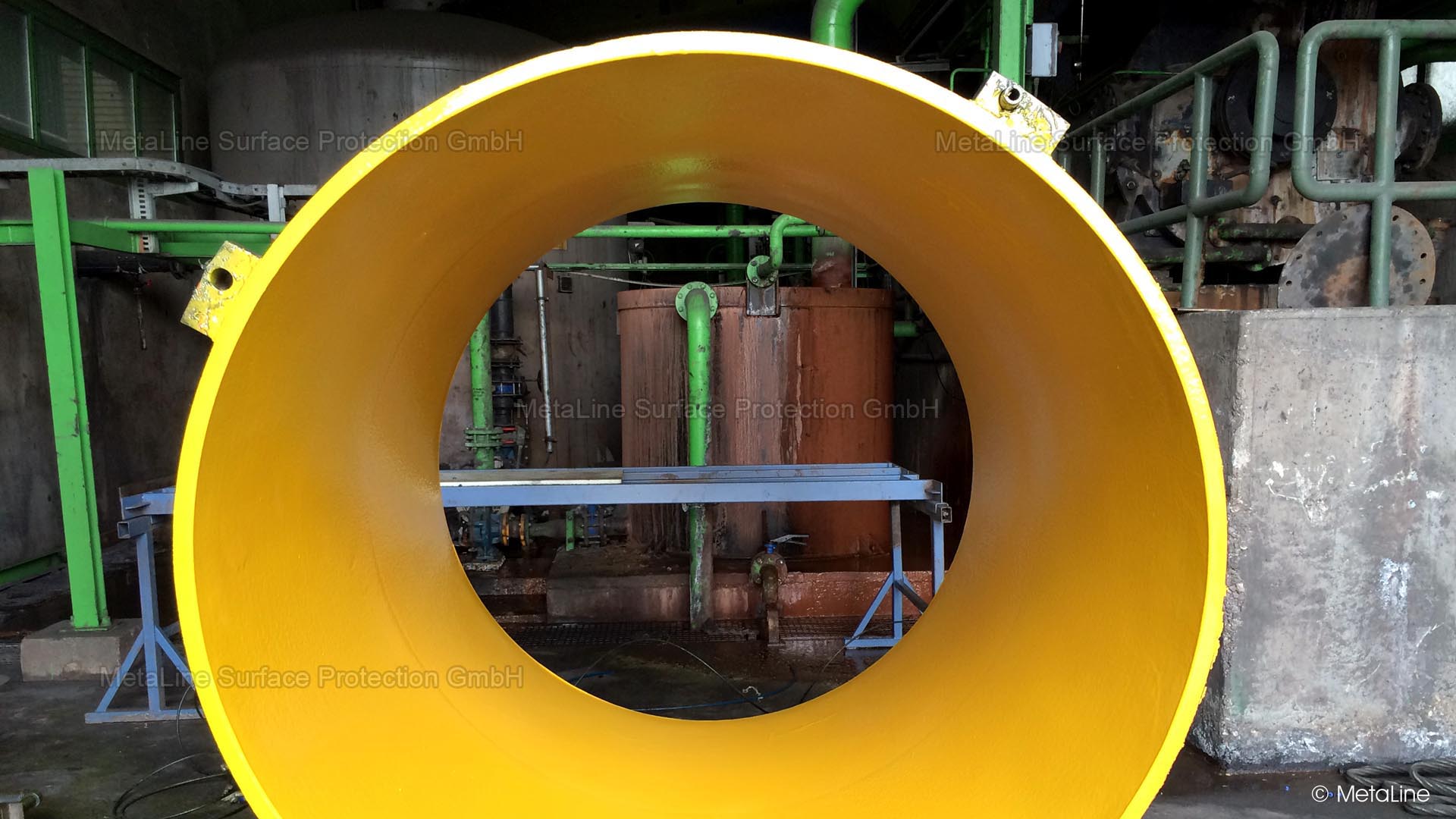

Vacuum pump housing coating - impressive dimensions for the housing volute of a vacuum pump. MetaLine 785 extends service life, improves efficiency and reduces operating costs