Pump repair - the first step in a repair is to restore the original contour. Here is a typical example of a badly worn diffuser. Only in the second step is the entire housing usually given an additional protective coating. The recontouring can be carried out using the classic welding process or with synthetic polymers - this decision is entirely up to YOU

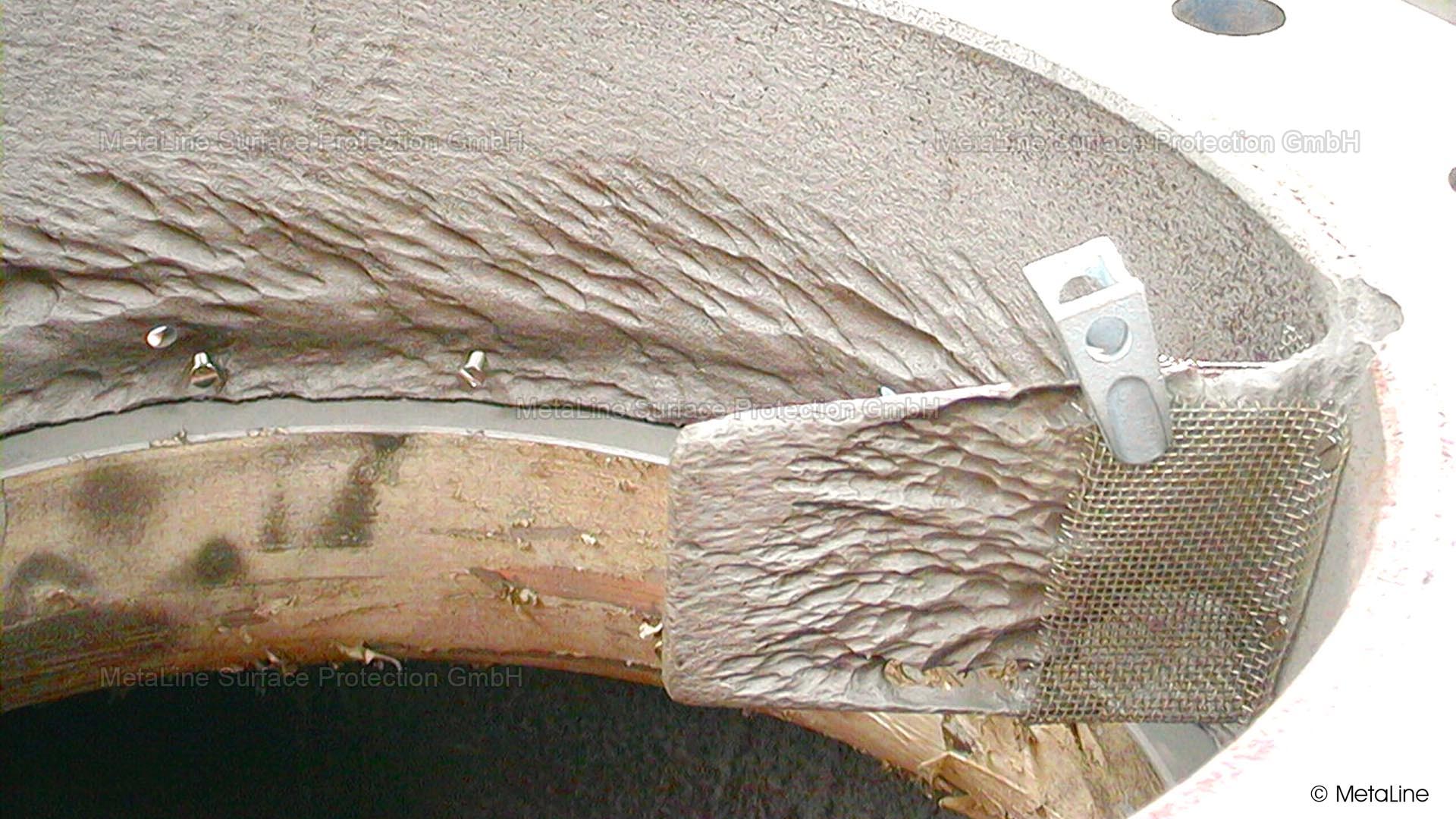

Pump repair - if you restore the contour synthetically, a metallic (NFe) mesh reinforcement must be used to bridge the defects. Many suppliers use fiberglass mats here. We strongly advise against this. When wear occurs, fibers are exposed again and a capillary suction effect occurs, which can trigger corrosion under the coating

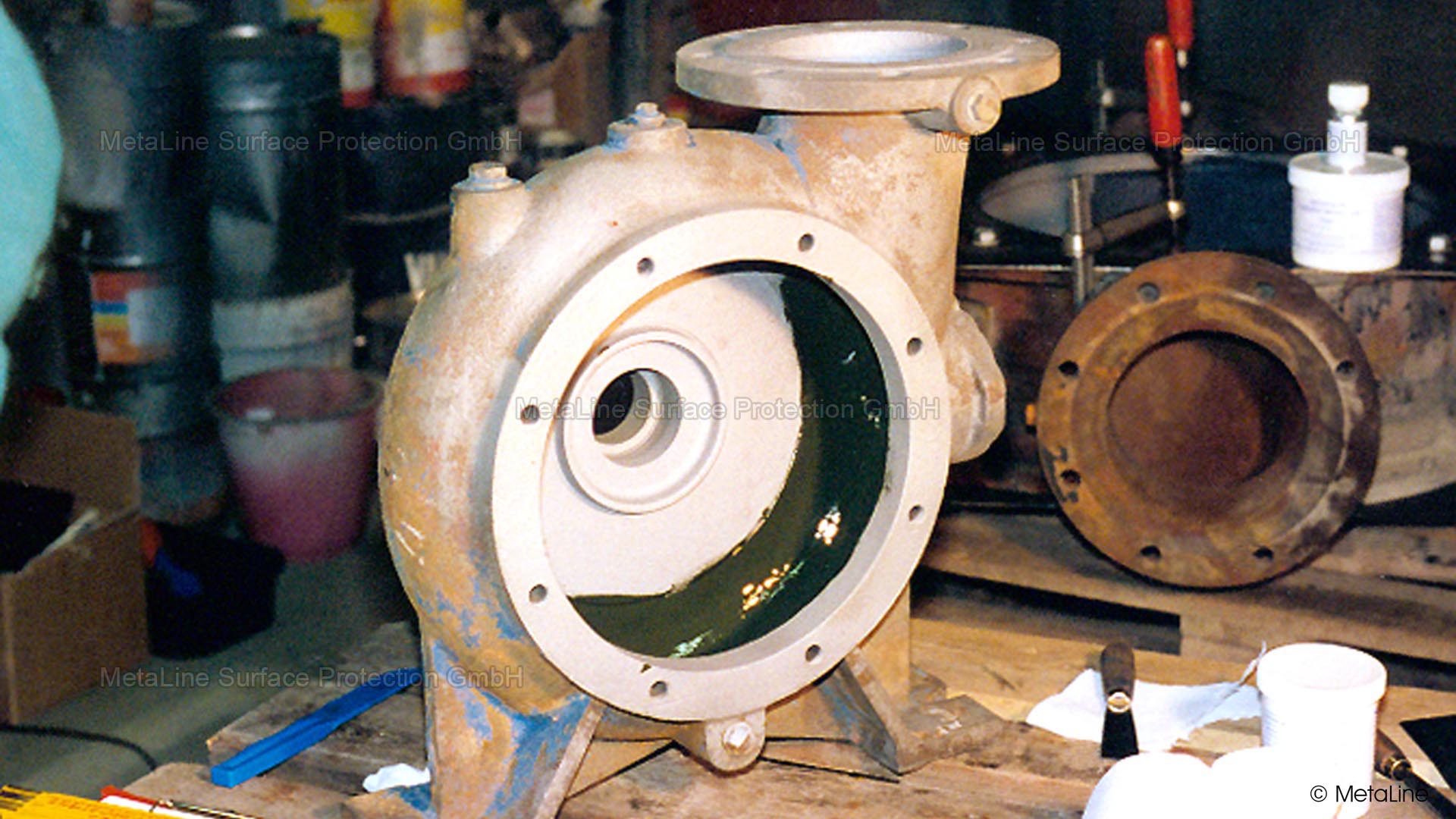

Pump service - the MetaLine repair ceramic SXL has restored the contour and, with its corrosion-free, electrically non-conductive properties, represents a high barrier to corrosion and galvanic corrosion in particular. What is still missing? The final full-surface protective coating - because without this, the work is not only incomplete, but even defective!

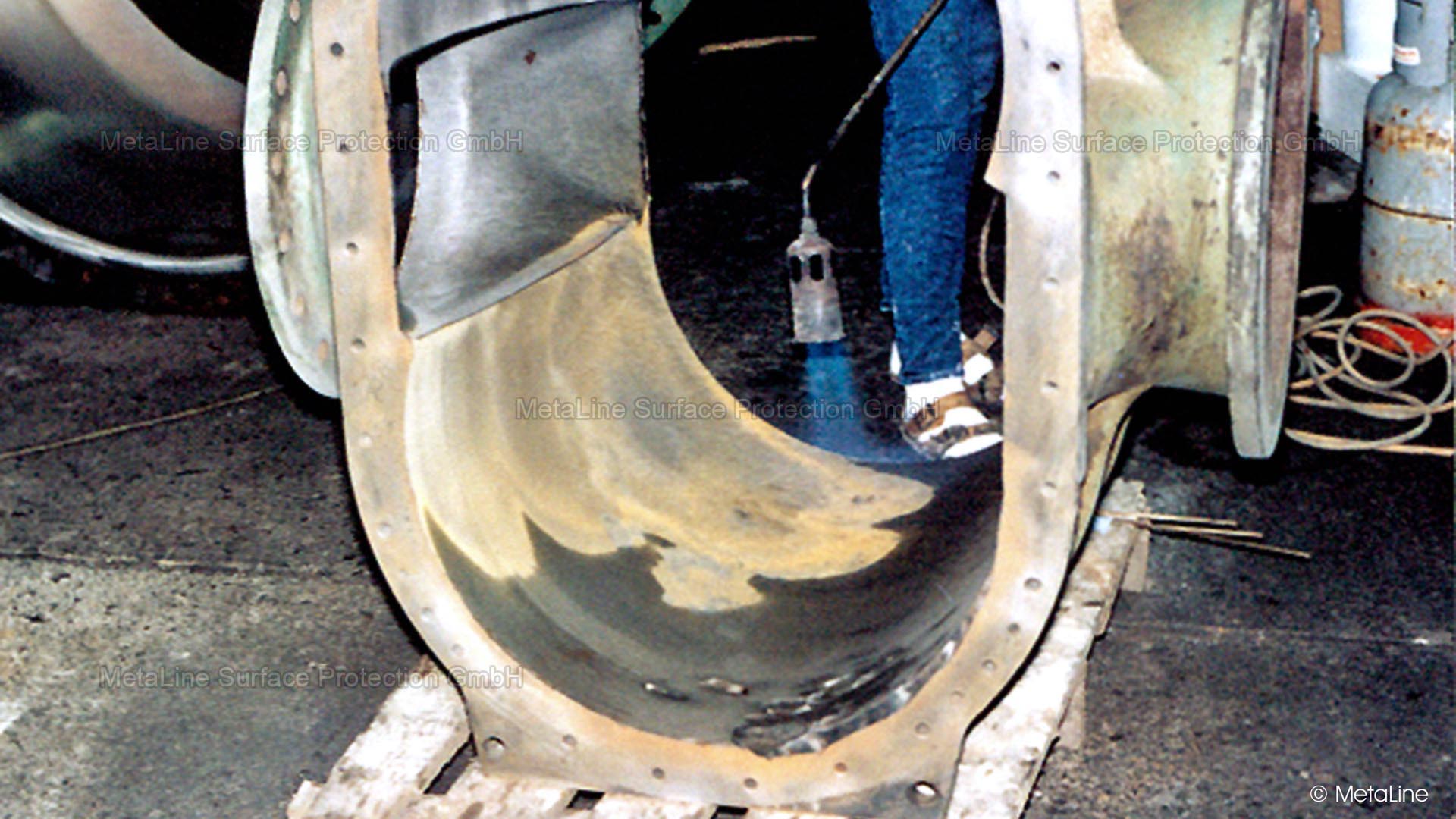

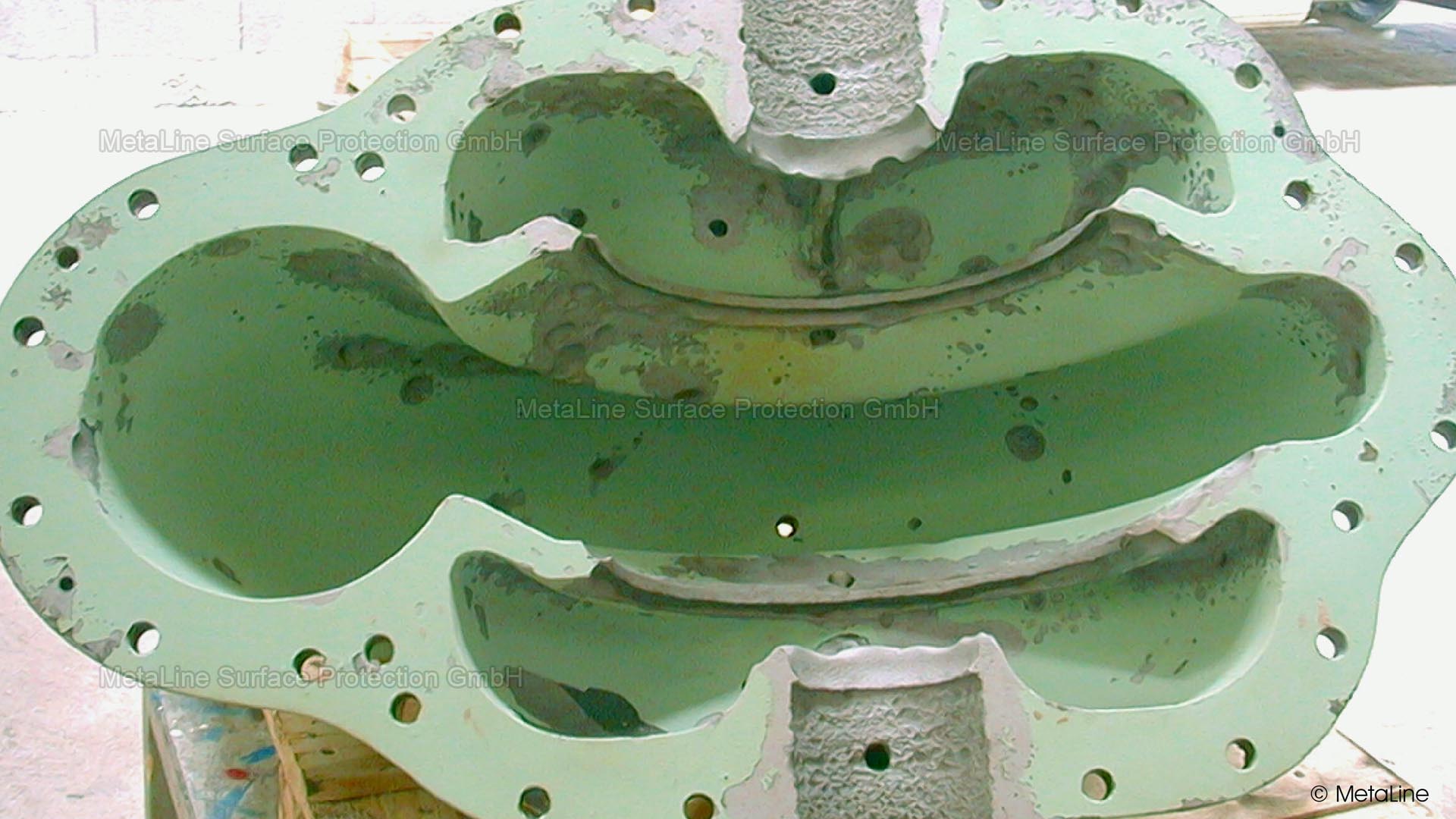

Pump maintenance - a heavily washed-out, eroded pump housing - there can be no clearer evidence of overloading of the steel used. Replacing the housing would only mean tackling the consequences but not the causes. In the case of erosion caused by fine particles such as sand, elastomeric coatings are an optimal way to improve and not just replace

Pump housing repair - in the previous picture we had recommended an elastomeric coating with MetaLine 785 for this housing. Here you can see that the lining was actually made with MetaLine repair ceramic SXL. Why? Because the customer wanted to do it himself. MetaLine supports you competently in both cases!

Pump sealing - with a synthetic MetaLine surface that always behaves differently to the cast iron previously used. It is corrosion-free - our best argument against simply replacing spare parts

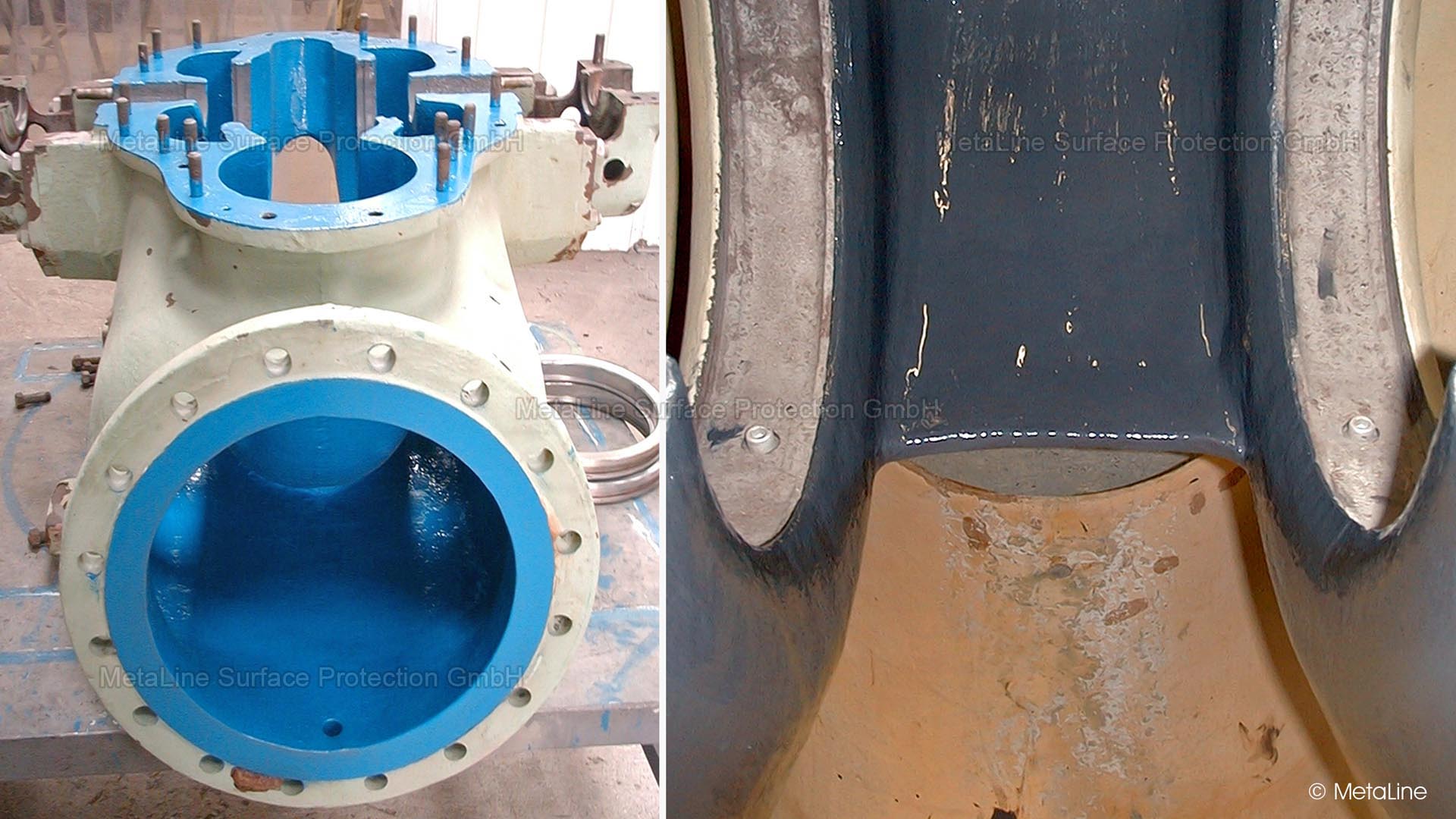

Pump overhaul - corroded and damaged pump housing. You can still see the remains of a coating that unfortunately did not fulfill its function. The work begins now - in several stages. But without professional sandblasting and capillary drying of the cast housing, the next coating will also fail again . . .

Pump optimization - during partial repair with MetaLine repair ceramic KXL. Would you prefer spray processing? Take a look at the MetaLine Series 700 cartridge spray process as an alternative. Honestly? A brush is the wrong tool for a hydrodynamically optimized surface!

Pump housing - coatings usually require a technical dialog - this is not always easy or quick! But it is effective! Please do not shy away from this dialog - the more we know about the specific problem, the more precise our proposal can be!

Pump linings - there are those who fundamentally doubt the effectiveness of protective coatings in pumps? We don't want to go that far - but we are also of the opinion that the majority of brushable do-it-yourself materials are not a permanent technical solution. As is so often the case, it depends on the specialization of the supplier of these materials!

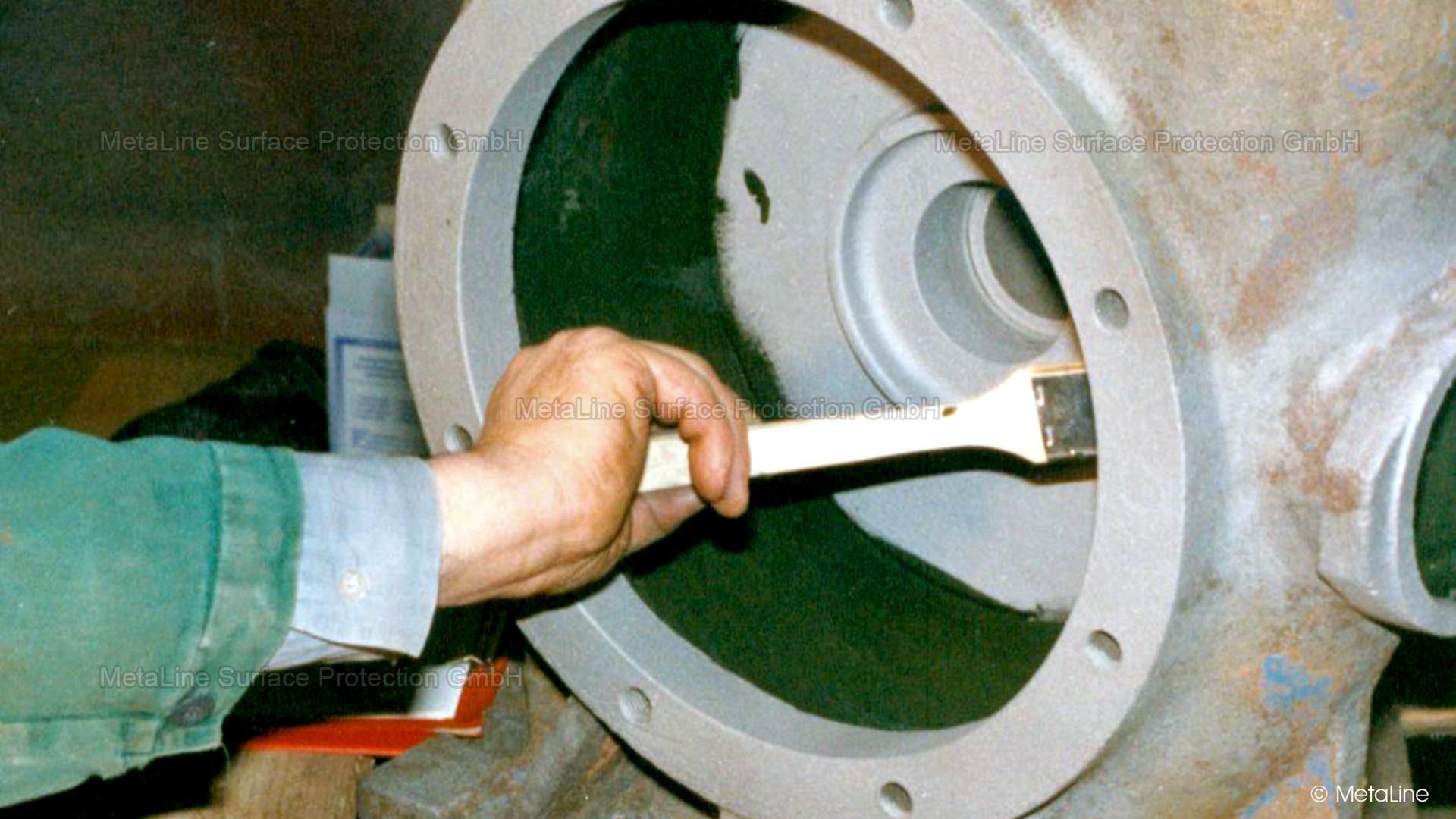

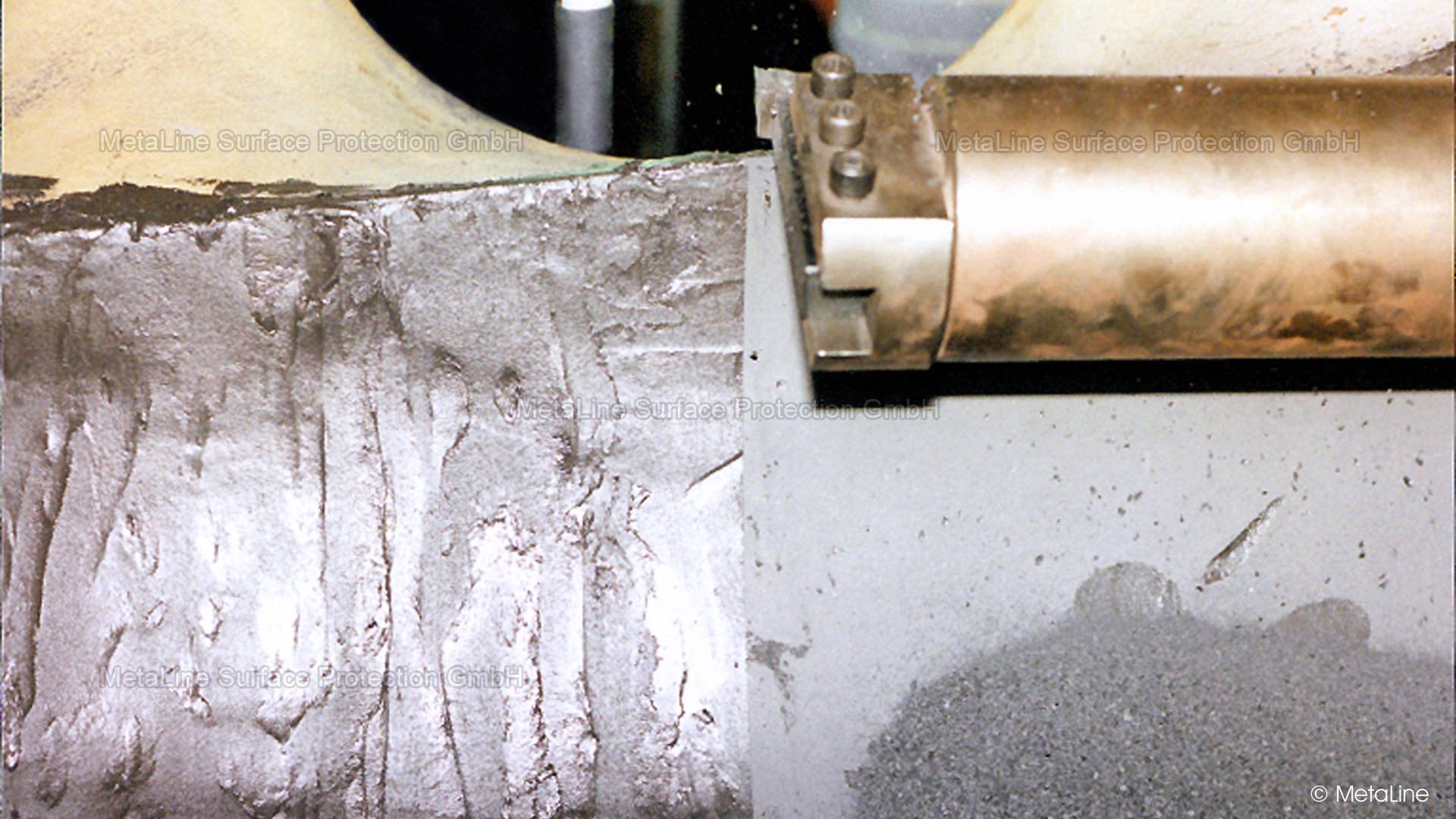

Pump repair - worn rotary plunger pump housing at a paper manufacturer in central Germany. The component is being dried with a flame to remove the moisture from the capillaries. Why the employee is wearing sandals and not safety shoes remains a mystery? It's not just about the safety of your plant, but also the safety of your employees

Pump housing repair - Machining the MetaLine repair ceramic SXL - however, oxide ceramic or diamond tools must be used. What is supposed to be wear-resistant unfortunately also has a wearing effect on the tools used

Pump coating - final coating with the brushable MetaLine repair ceramic KXL. Not particularly pretty - but the reality when you brush or fill such thixotropic materials. MetaLine is characterized by the fact that we also show these pictures openly on our website - it couldn't be more honest!

Pump wear - a split casing pump volute during the repair inspection. Not an easy case, because there are many small defects in completely different places. Success is the result of targeted and consistent analysis - which is exactly what we have been doing for the last 60 years

Pump housing coating - even if our times have become hectic and superficial - technical solutions are based on physical principles and not on video half-truths from the Internet. Our teacher was physics and we listen to it . . .

Pump optimization - a rubber hardness of 85 Shore A (MetaLine 785) is roughly equivalent to the hardness of a car tire - and we can install exactly this "mileage" in your pumps . . . Just ask us! We have unusual solutions