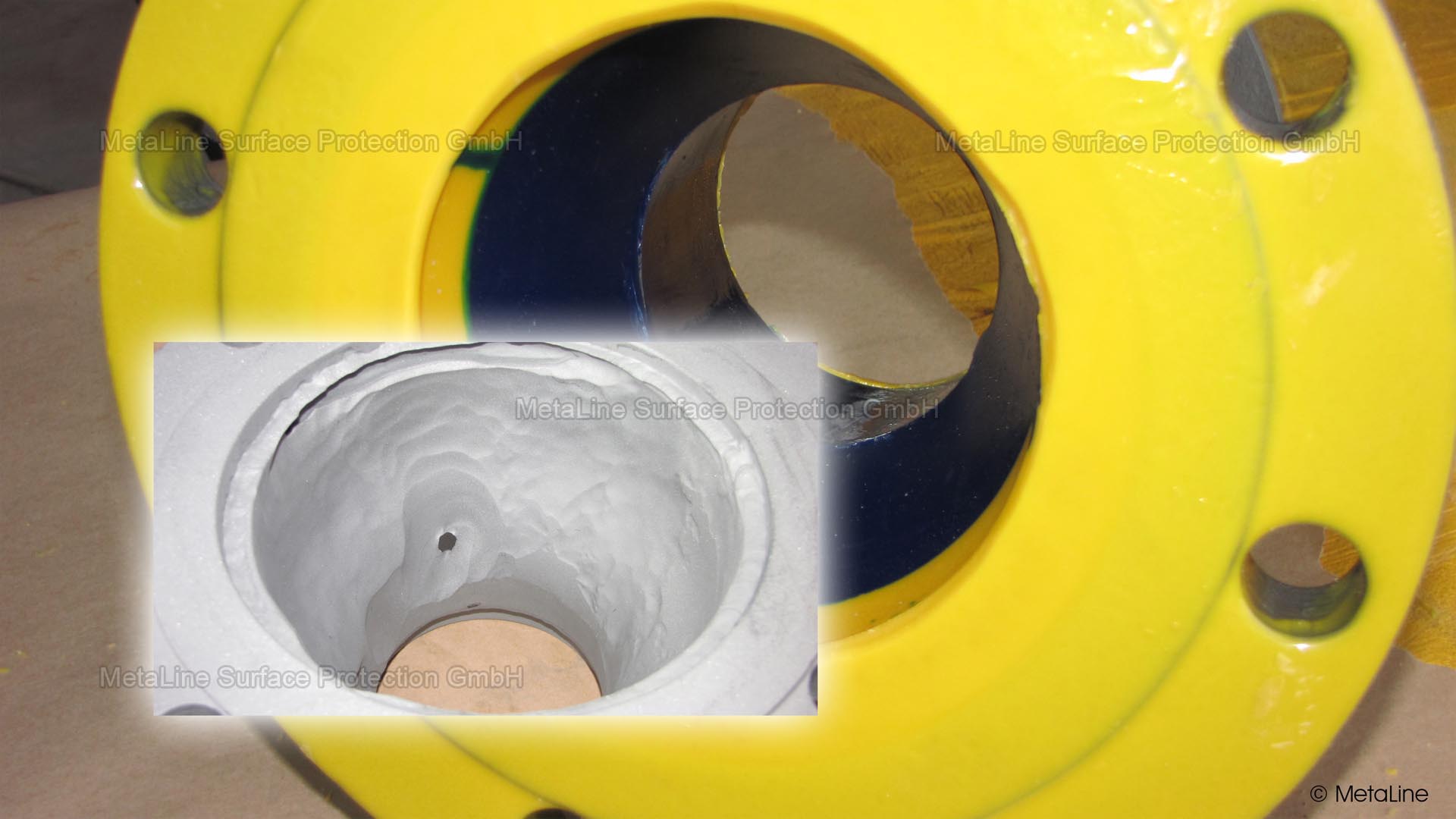

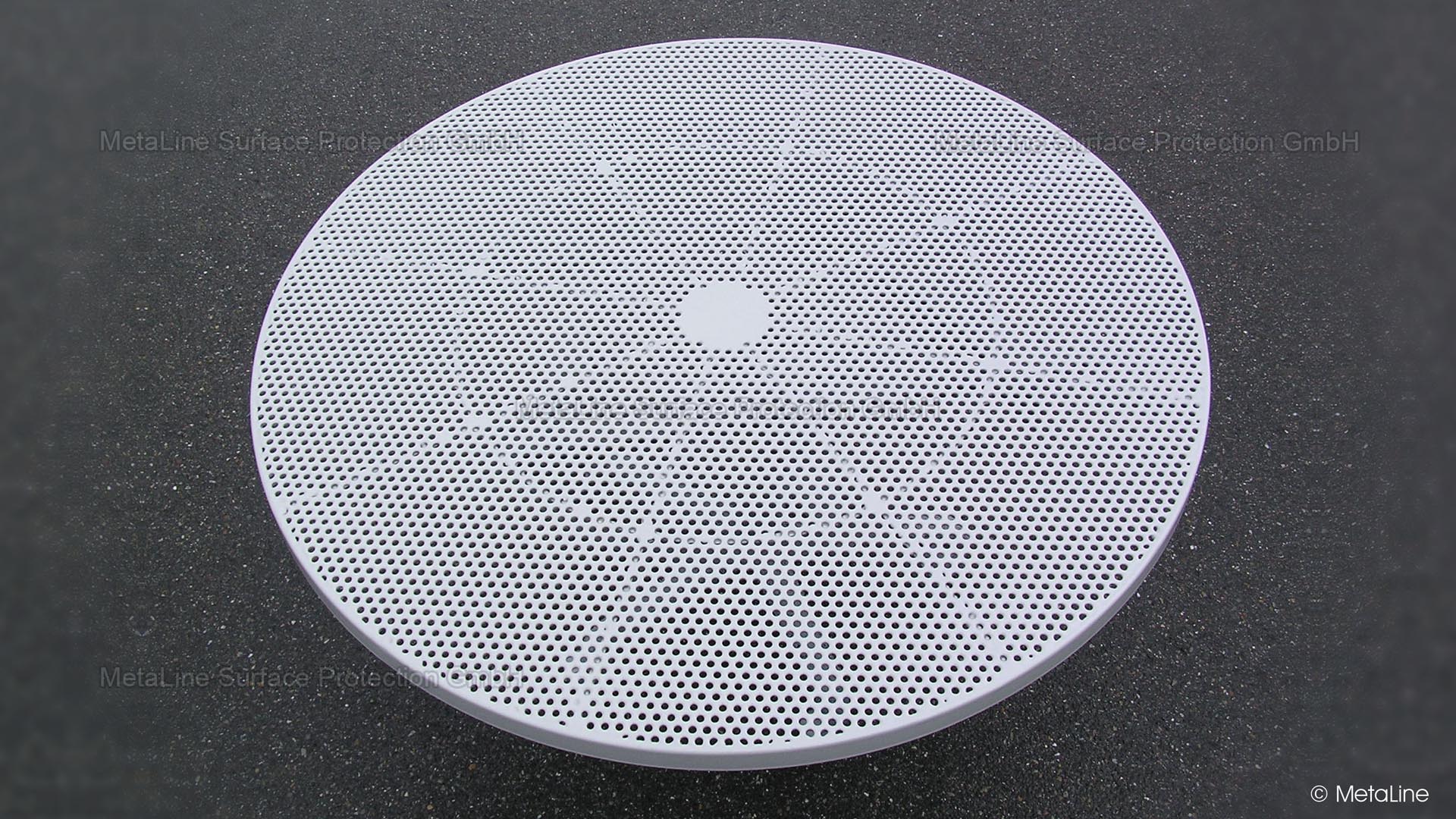

The continuous abrasive impact - regardless of the impact angle - leads to extreme wear and destruction. Workpiece carriers and blasting templates are permanently exposed to the attack without protection. Lifetimes of only a few weeks to a few months are the rule rather than the exception. In blasting cabinets, the operator's view is greatly reduced by the use of dark protective mats - bright, seamless elastomer coatings instead are a solution with a "view through".

Ask us about: blasting cabinets (dry / wet / medical), blasting baskets / hangers, cyclones / abrasive recovery, rotary table shot blasting machines, sandblasting stencils, part fixtures / work carts, dust collectors

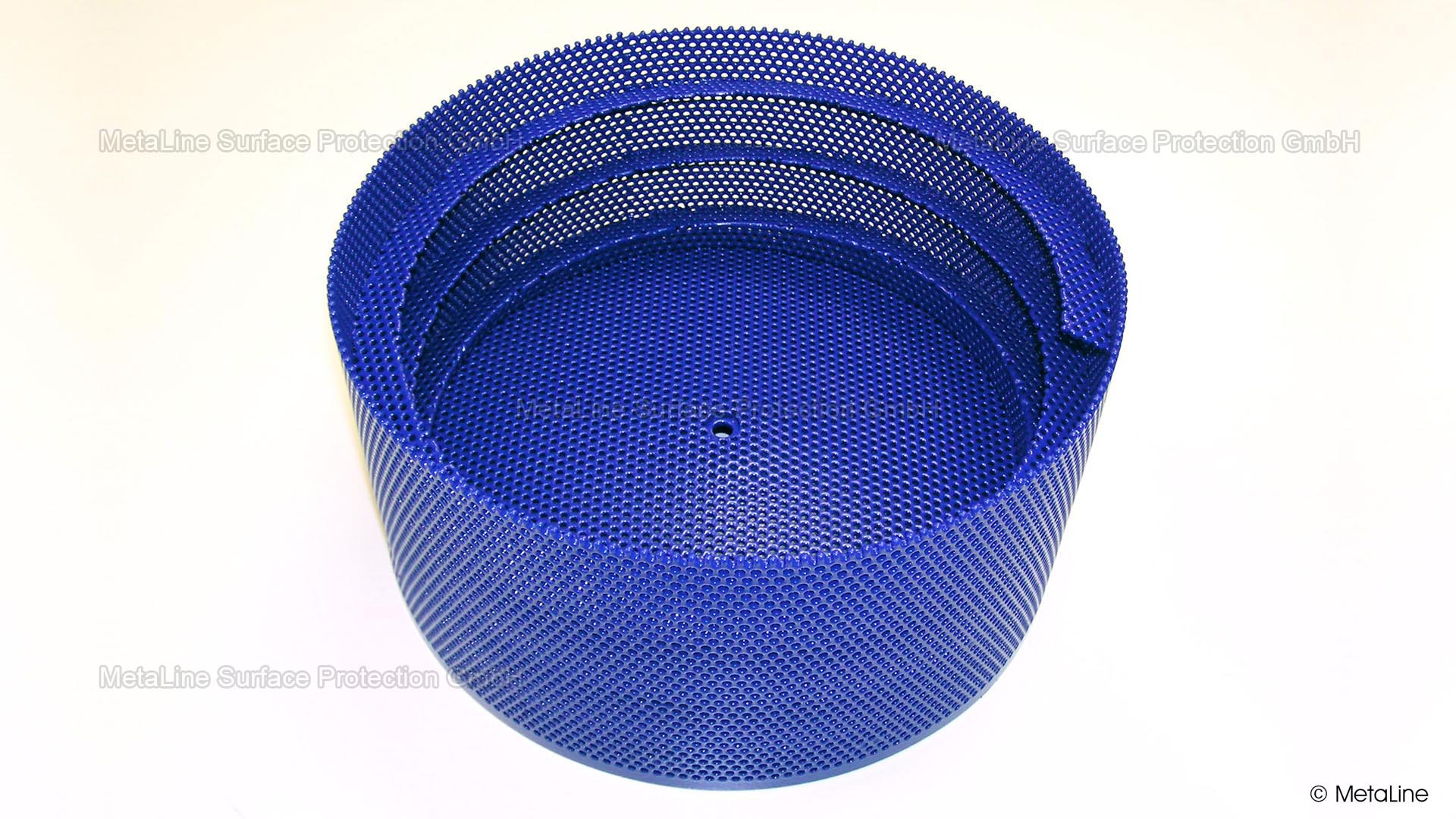

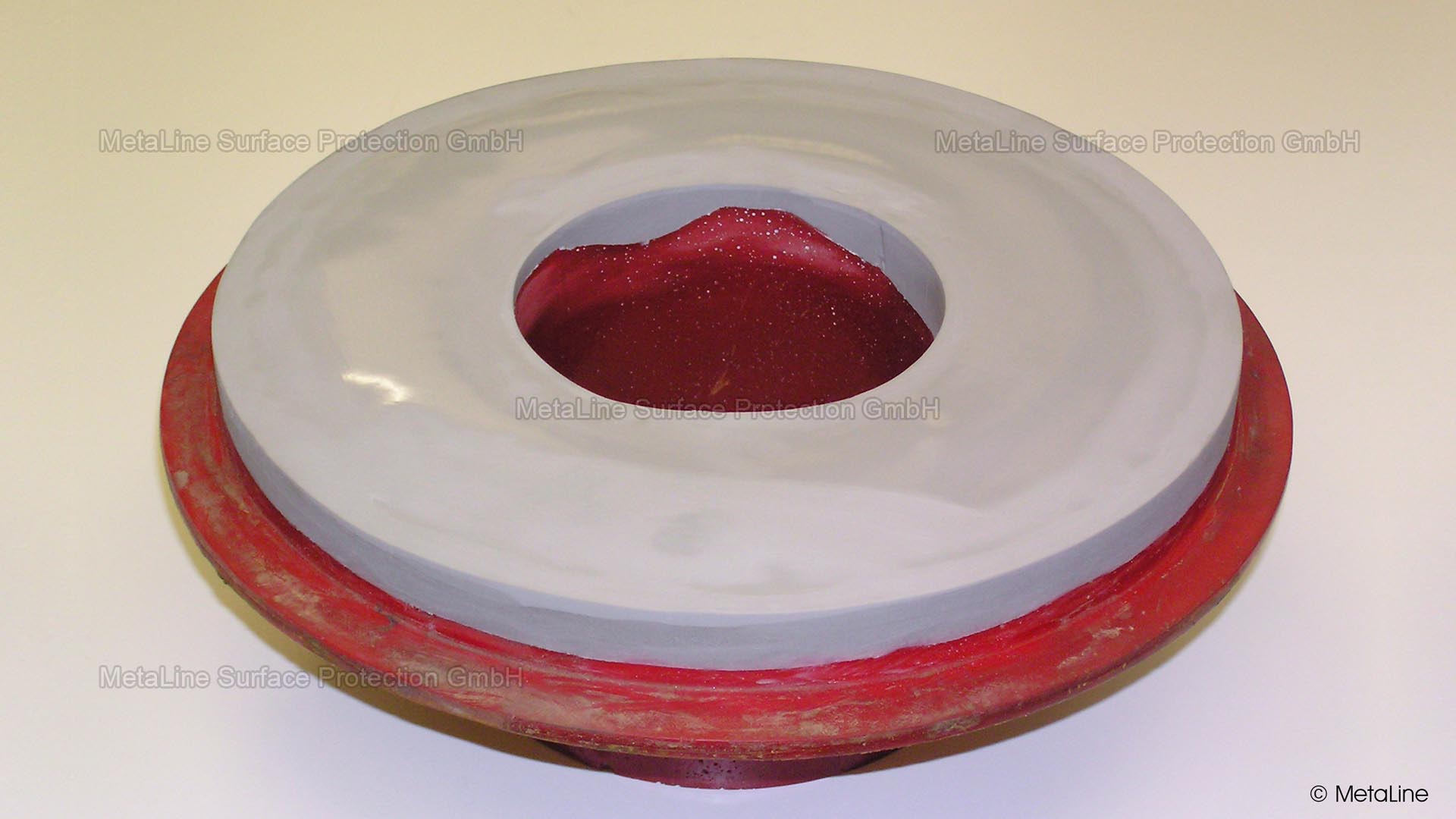

We have a solution for problems with wear in sand-blasting technology! Scope of application: Blasting cabins (dry / wet / medicine) Blasting baskets Cyclones / abrasive recovery Rotary tables Blasting templates Workpiece holders / frames Dust collectors MetaLine - Technical solutions in detail METALINE SERIES 700 MetaLine Series 700 coatings offer tried and tested solutions for injection or pressure blasting plants. Irrespective whether in dry or wet applications, their elastomeric properties enable enormous lifetime extension and noticeable noise reduction. In medical blasting plants the protective layer enables all-round insulation to assure metal and ferrite freedom in the blasting system. FDA approval is available. Bright colors improve lighting conditions and visibility. This process is not suitable, however, for whirl gate plants owing to the energy-consuming effects.

MetaLine Series 700 – MetaLine Series 700 coatings are proven problem solutions for injector or pressure blasting systems. Regardless of whether in dry or wet areas, the elastomer properties represent a considerable increase in service life and a remarkable reduction in noise. On medical blasting equipment, the protective skin provides complete insulation to ensure freedom from metal and ferrite in the blasting system. FDA approval is available. Bright colours improve light conditions and visibility in enclosed cabinets. The MetaLine process is unsuitable for wheel blast systems due to its energy-absorbing effect - thus reducing the efficiency of such installations.