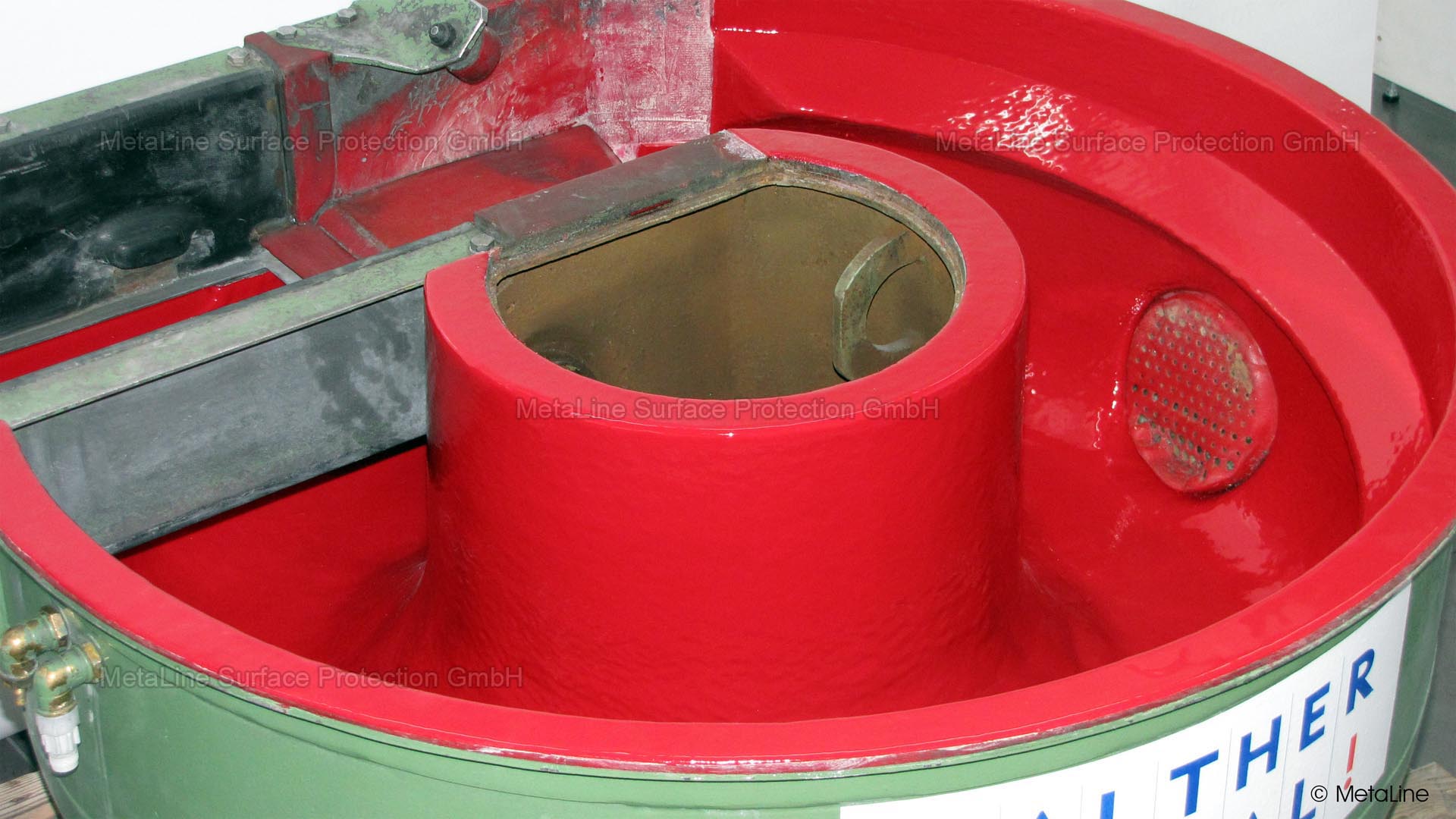

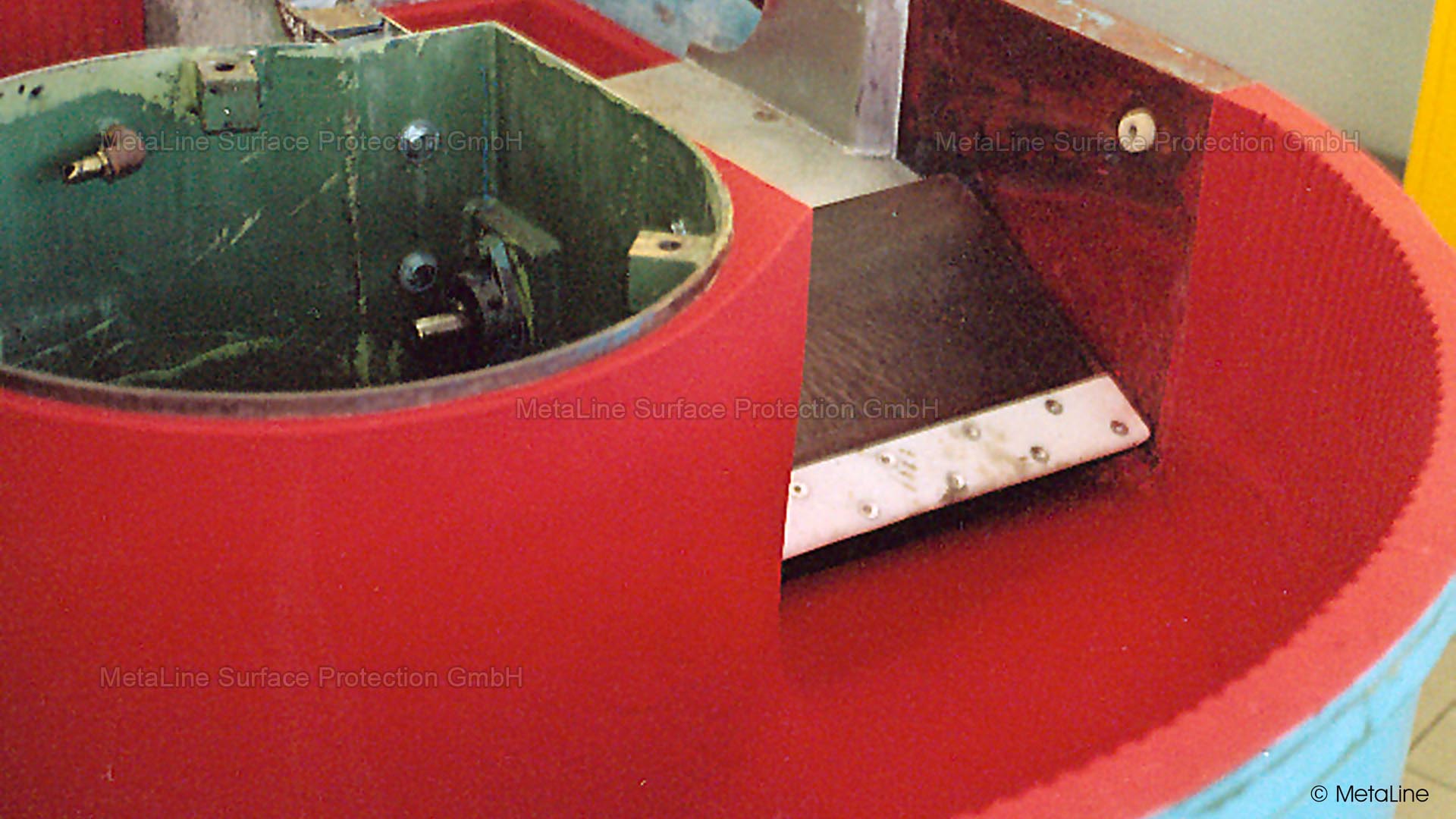

Partial repair of a rotary vibrator with MetaLine 785. The repair method by overcoating the existing linings (without removal) was developed by MetaLine

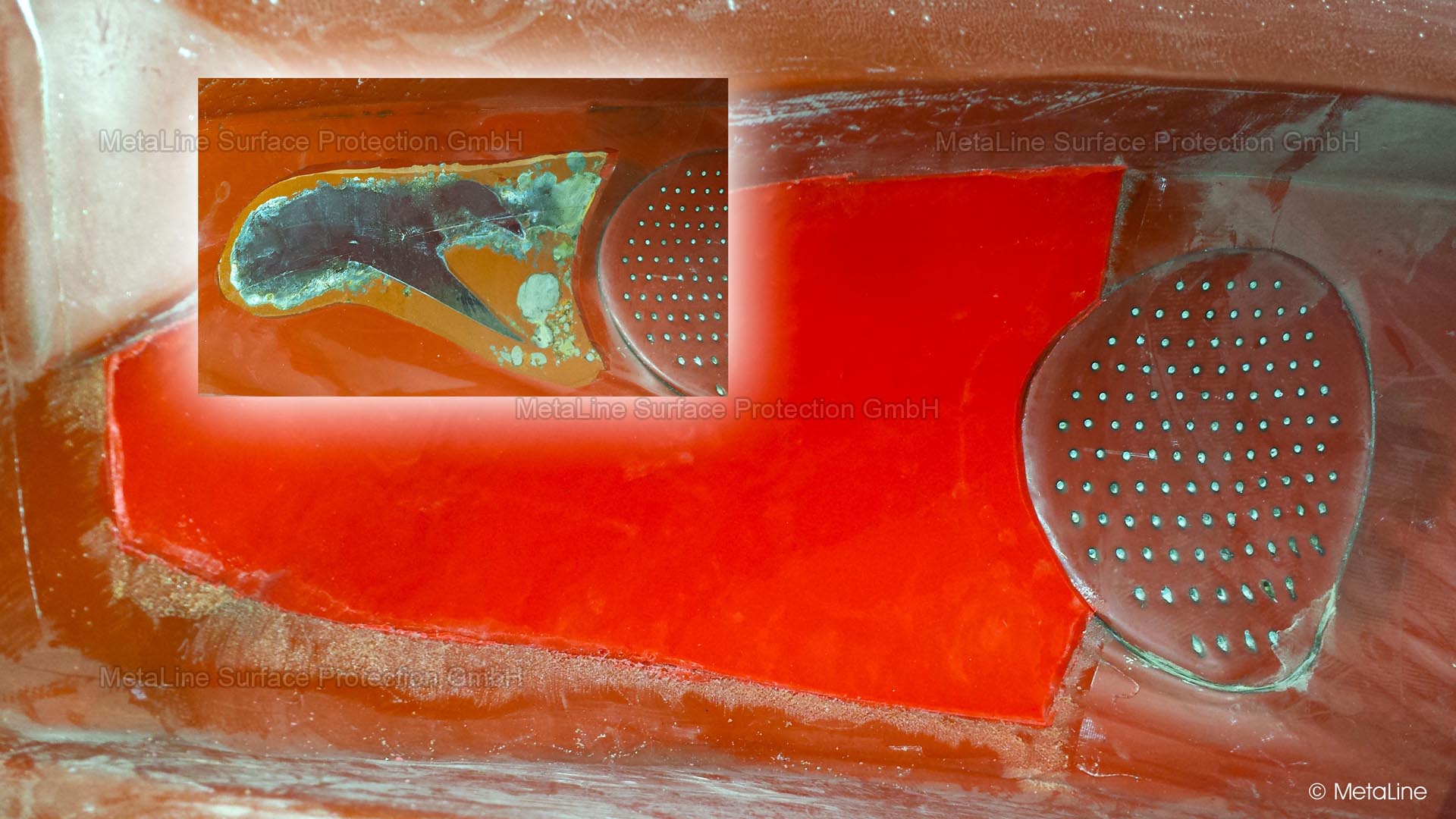

Coatings for tribofinishing equipment – MetaLine coatings stand for environmental safe ideas. Instead of burning out the existing lining, MetaLine cuts of the topcoat, reactivates it (see picture) and overcoats it. Technically safe, longlasting and costsaving . . .

Tribofinishing coating – Repaired, overcoated and exactly as good as new equipment. However cheaper, more environmentaly safe and faster as the equipment manufacturer can offer repairservice to you

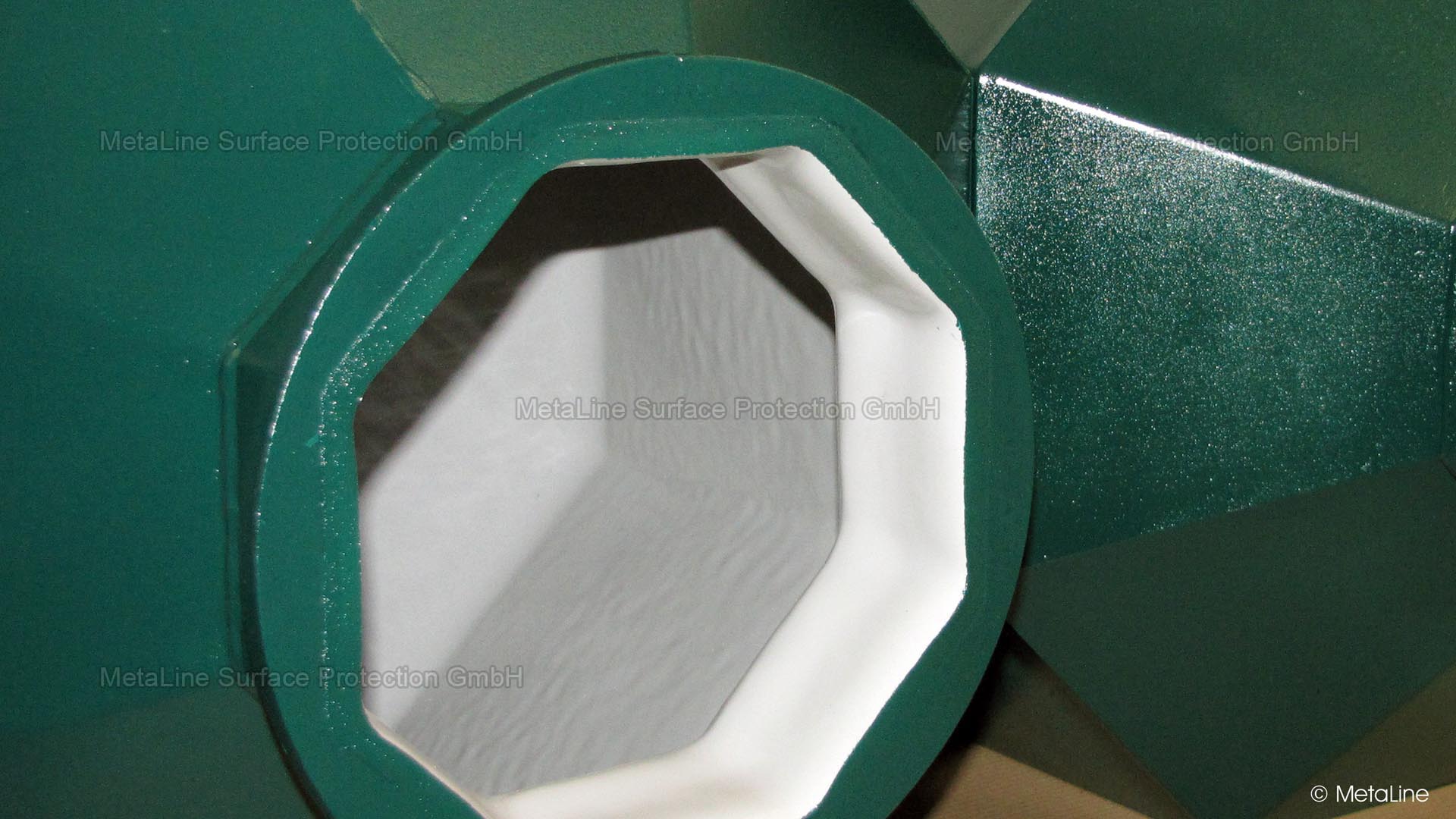

Tribofinishing repair coating – MetaLine 785 can be applied very accurately and precise which is of particular importance in the areas of exit doors

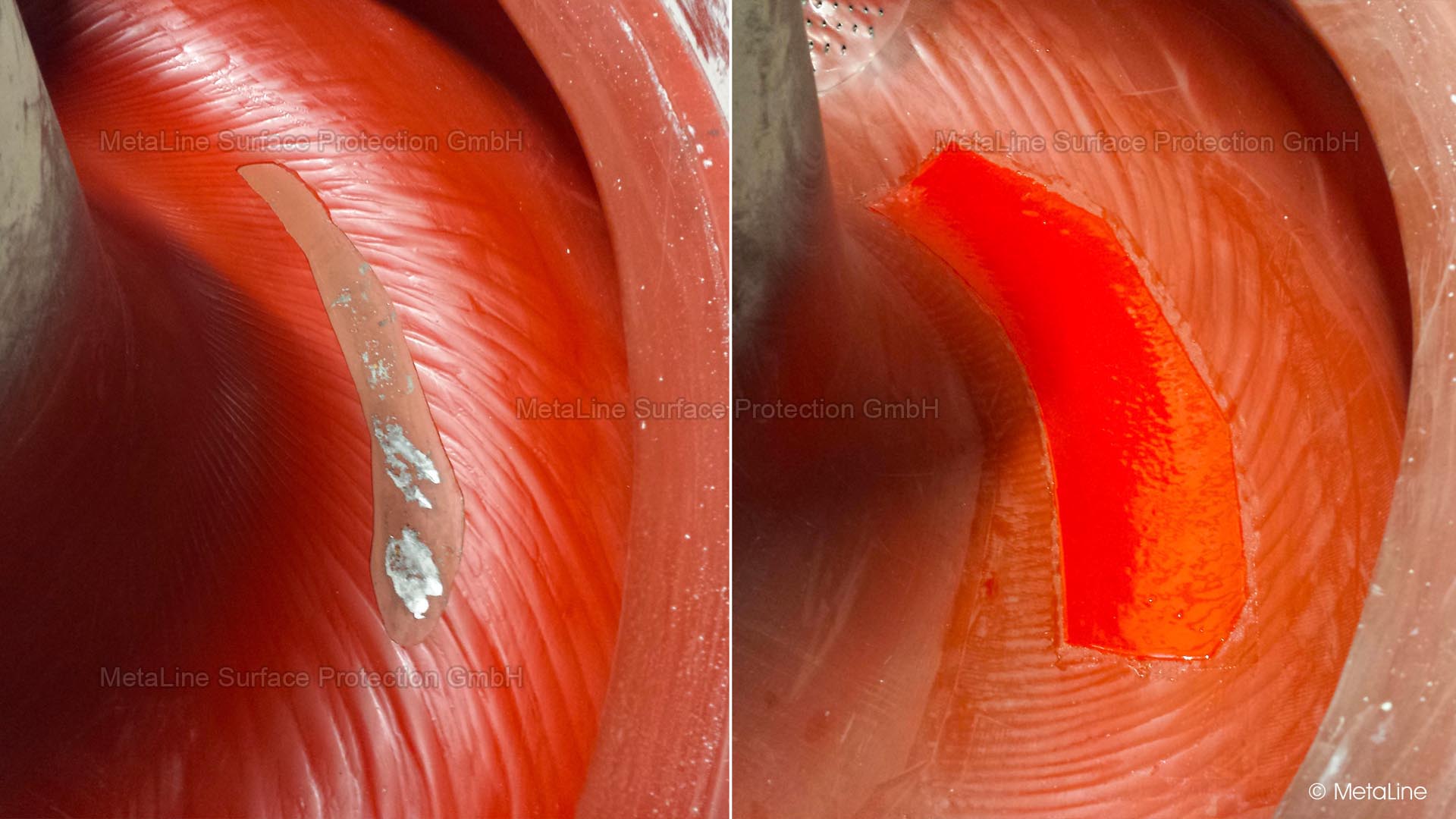

Tribofinishing coating – MetaLine 785 allows quick and professional repairs on site. The damaged stress zone of this machine had been repaired within a single working day

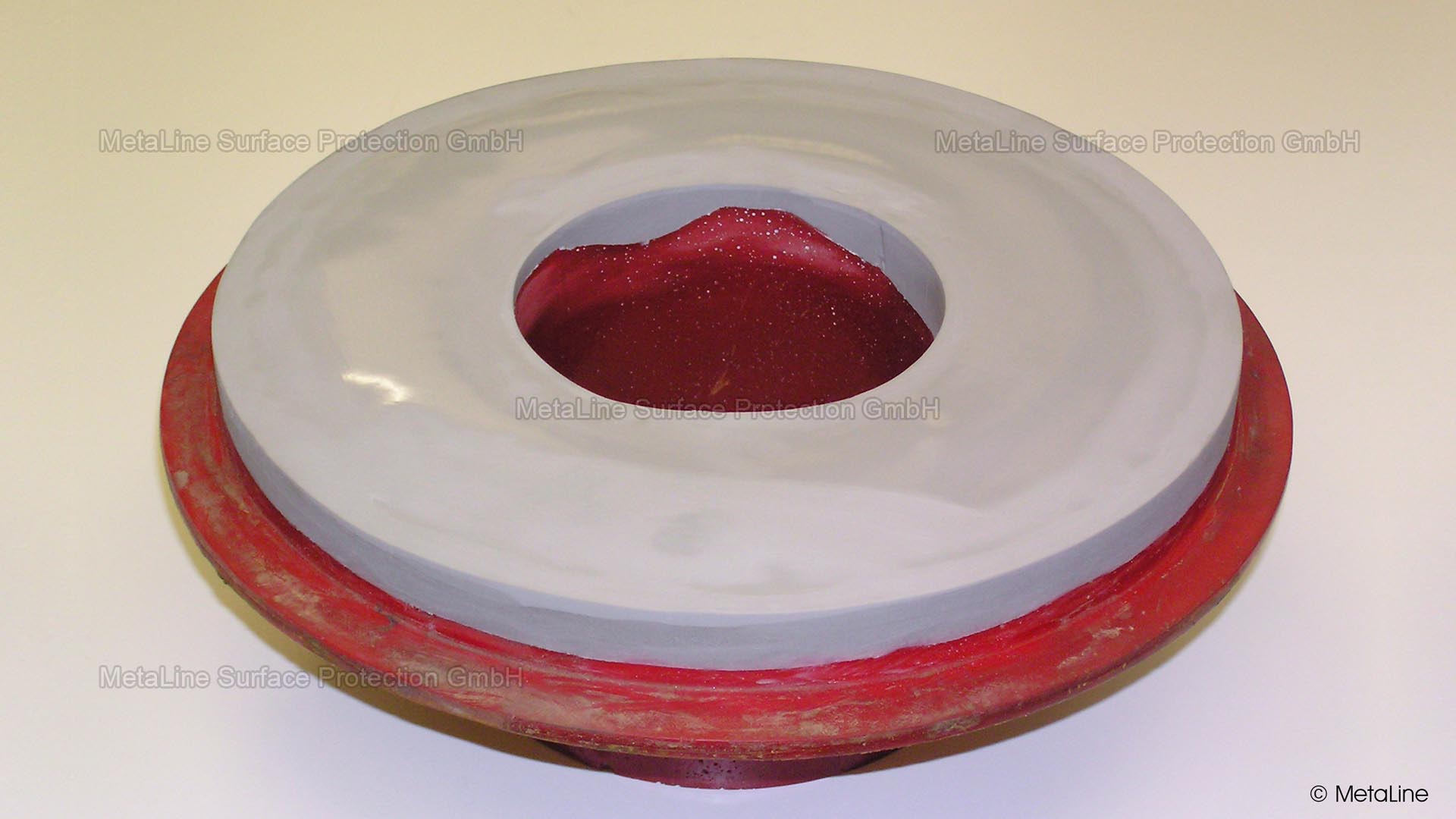

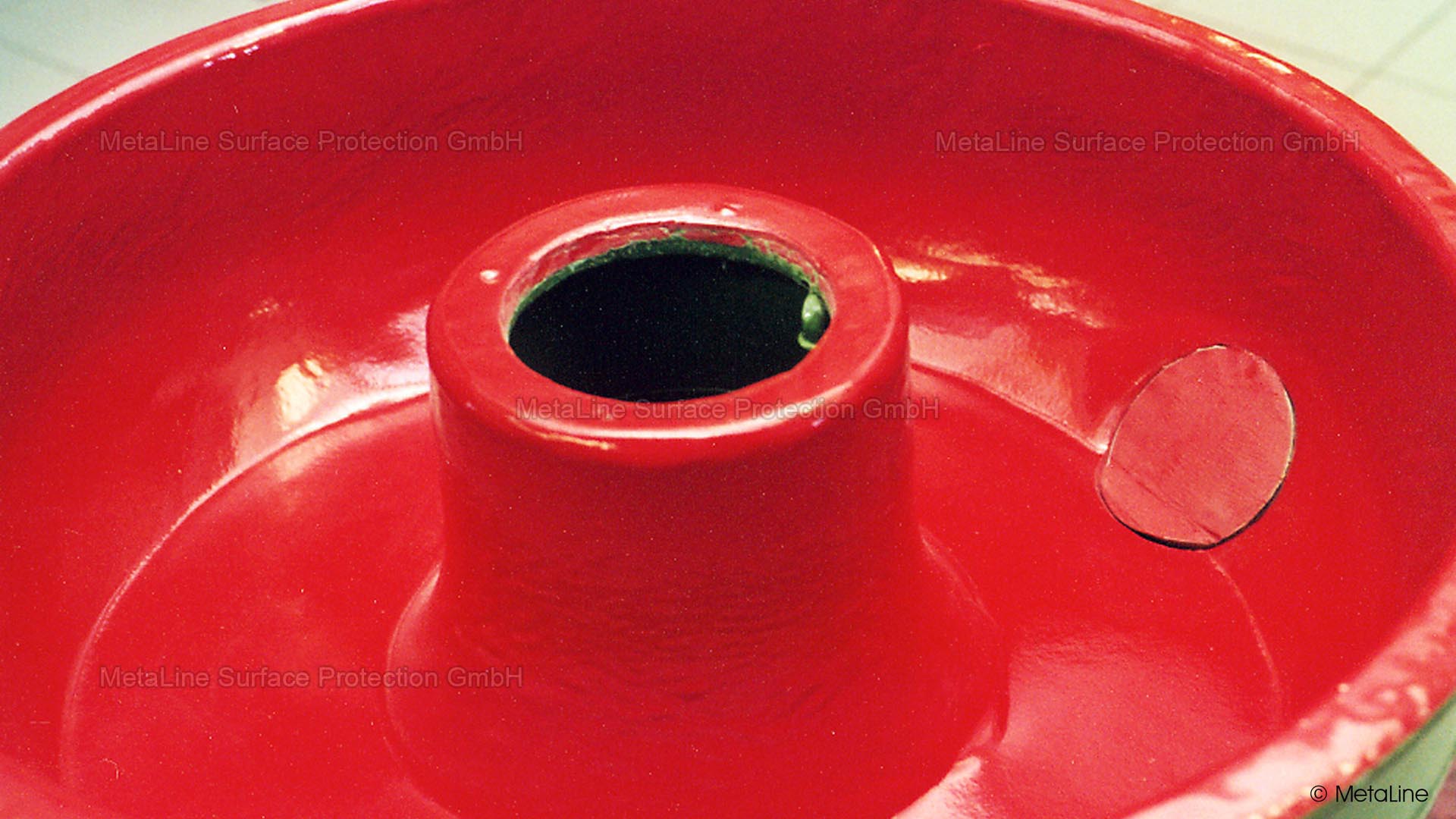

Repair of spare parts for centrifugal vibrators with MetaLine 785 by means of casting. This results in dramatic cost savings compared to traditional spare part purchase

Partial repair of a rotary vibrator with MetaLine 785 with a layer thickness amounting to 20 mm

Tumbling coating – you search for an economical solution to repair your worn vibratory grinding bowl? Without removing the complete existing lining? Without having to pay half the price of a new machine? Contact MetaLine and be surprised . . .

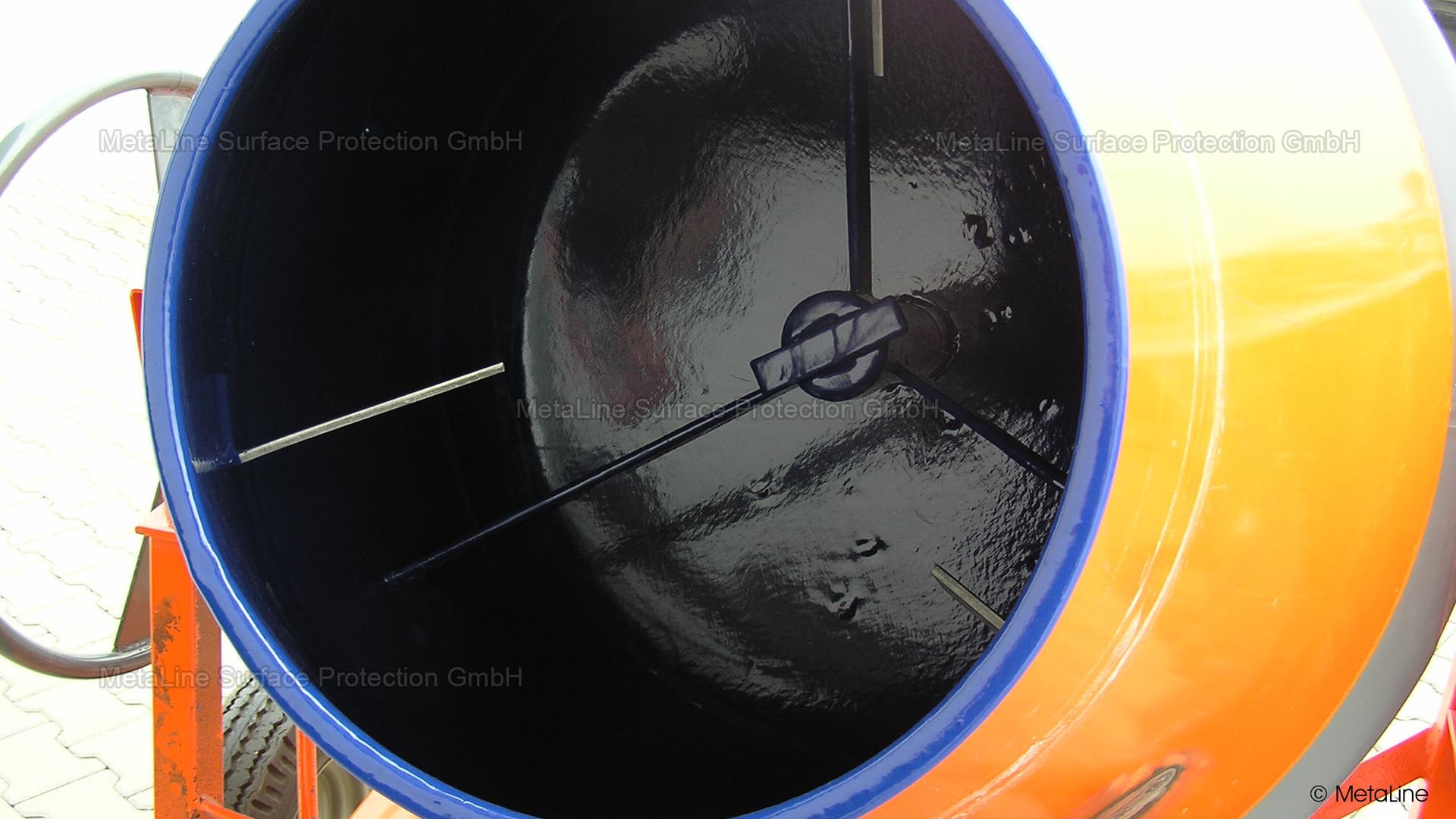

Quite unusual but nevertheless true – concrete mixer transferred into a rotary vibrator with 6 mm MetaLine 785

MetaLine has become OEM coater for small plastic rotary vibrators. It needs know-how to bond coatings on synthetic substrates

MetaLine is OEM coater for various manufacturers of rim polishing machines. That is a young market. MetaLine has given birth to it . . .

RIM polishing machine coating – to obtain a long service life even in low thickness is the remarkable product character of MetaLine. Not the price of a protective coating is of importance, but its longterm value only . . .

Galvanising drum coated on the inside with 10 mm MetaLine 785.Seamless, extremely resistant and fits like a second skin

Serial coater with MetaLine 785 for cutlery polishing machines. MetaLine supplies most manufacturers with our coatings for self-application

Seamlessly sprayed on repair lining of a rotary vibrator (type Spalek). The existing coat was prepared accordingly to MetaLine specifications and simply oversprayed

New lining of a rotary vibrator with MetaLine 785 after complete removal of the old layer

Coating of a used rotary vibrator with MetaLine 785 – without removal of the old layer! There is no process more environment-friendly

Initial lining of a vibrating trough with 10 mm MetaLine 785. MetaLine's Series 700 cartridge spray process is the perfect tool for applications of this size

Tribofinishing coating – MetaLine 785 in a thickness of up to 20 mm for the partial repair and overcoating of a damaged lining in a tribofinishing system

Repair and partial re-coating of a rotary vibrator on site in Poland. Minimum break down just over the weekend. There is no better sales argument in car manufacturing . . .

Repair and coating of a rotary vibrator by use of MetaLine 785 without removal of the old coating. Tremendous time and cost savings are the result